Imagine you’re in a workshop, surrounded by buzzing machines. You’ve just turned on a metal lathe, ready to create something amazing. But wait! Is your lathe properly aligned? This simple question can make a big difference in your project.

Lathe workholding is a key part of using a metal lathe. It involves how you hold your material in place while working. If your workholding isn’t right, your metal pieces can end up crooked or uneven. That’s frustrating, right? It can waste time and material.

Did you know that even small misalignments can affect the end result? One tiny mistake might lead to a lopsided finish. But don’t worry! By learning about lathe alignment, you can avoid these problems.

This article will guide you through the importance of lathe workholding and alignment. You’ll discover tips that help you achieve perfect results every time. So, let’s dive into the world of metal lathe alignment and unlock your creativity!

Lathe Workholding: Essential Metal Lathe Alignment Tips

Lathe Workholding and Metal Lathe Alignment

Proper lathe workholding is crucial for successful machining. It ensures that your metal pieces stay stable during cutting. Imagine trying to carve a sculpture from ice while it’s sliding around—frustrating, right? Aligning your lathe correctly improves accuracy and reduces errors. A well-aligned lathe makes every cut cleaner and safer. Did you know that even slight misalignments can lead to uneven surfaces? Taking time to set up properly pays off in the end. Master these skills, and you’ll become a real lathe pro!Understanding Lathe Workholding Techniques

Definition and importance of workholding in lathe operations. Different types of workholding devices: chucks, vises, and fixtures.Workholding is like giving your metal piece a cozy hug while the lathe spins it round and round. Good workholding keeps everything steady, which is important for perfect cuts. Using devices like chucks, vises, and fixtures helps hold the piece in place. Chucks are great for round shapes, while vises grip flat surfaces. Fixtures hold unique shapes. Oh, and remember, a happy lathe makes for happy metal!

| Workholding Device | Best For |

|---|---|

| Chucks | Round objects |

| Vises | Flat surfaces |

| Fixtures | Unique shapes |

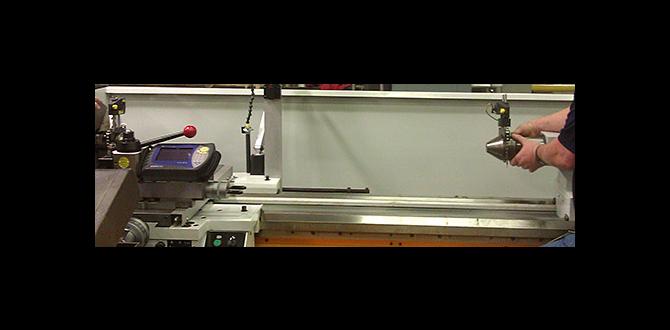

Essential Components of Lathe Alignment

Key components affecting lathe alignment: tailstock, headstock, and ways. Importance of proper alignment for precision machining.Every metal lathe relies on key parts to stay aligned. The headstock holds the spindle and controls rotation. The tailstock helps support the workpiece, while the ways keep everything straight and steady. Proper alignment is like a well-rehearsed dance; one misstep can lead to chaos! Without it, you’ll end up with wobbly cuts and uneven surfaces. Remember, a happy lathe makes happy parts!

| Component | Role |

|---|---|

| Headstock | Controls rotation |

| Tailstock | Supports the workpiece |

| Ways | Ensures straight alignment |

In metalwork, precision matters. A tiny mistake can become a huge issue. Aligning your lathe correctly leads to accurate cuts and better quality products. So, keep those components in check!

Methods for Achieving Proper Lathe Alignment

Stepbystep guide to aligning a lathe manually. Tools and measurements needed for accurate alignment.Aligning a lathe properly is like tuning a guitar—get it right, and it sings! Start with a level surface; if it’s not level, your lathe may start dancing around and not in a good way! Tools required for this job include a dial indicator, a straightedge, and a feeler gauge. Measure the distance from the tailstock to the spindle. Adjust until it’s correct. Use the following guide:

| Tool | Purpose |

|---|---|

| Dial Indicator | Checks direct alignment |

| Straightedge | Ensures flatness |

| Feeler Gauge | Measures tiny gaps |

Keep your lathe straight, or it might just turn out a bit wobbly—literally!

Common Challenges in Lathe Workholding and Alignment

Typical issues faced during workholding and alignment processes. Solutions and troubleshooting tips for common problems.Lathe workholding and alignment can be tricky. Some common issues include clamps slipping, misalignments, and vibrations. These problems can lead to poor cuts and wasted materials. Solutions involve checking all settings and tightening fixtures. Always inspect for wear and damage. If your workpiece moves, restart the setup. Frequent calibration helps. Stay patient and practice. Each mistake is an opportunity to learn!

What are typical challenges in lathe workholding?

Typical challenges include slipping clamps, misalignments, and vibrations.What solutions exist for alignment issues?

- Ensure fixtures are tightly secured.

- Check tool settings before use.

- Calibrate regularly to avoid issues.

Best Practices for Maintenance of Workholding Devices

Routine maintenance tips for longevity and performance. Importance of regular checks and calibrations.Regular maintenance keeps your workholding devices in tip-top shape. This helps them last longer and work better. Here are a few tips:

- Check for wear and tear often.

- Clean devices after each use.

- Lubricate moving parts regularly.

- Ensure all parts are aligned properly.

Regular checks help spot problems early. Calibrations keep everything precise. Did you know that well-maintained tools can improve performance by up to 30%? Keeping your devices in good shape is key to efficient lathe work!

Why is maintenance important for workholding devices?

Regular checks and calibrations ensure accuracy. They can prevent larger issues, saving time and money.

Advancements in Technology and Their Impact on Lathe Workholding

Innovations in CNC workholding solutions. The role of automation in improving lathe alignment and efficiency.New technology has changed lathe workholding a lot. CNC workholding solutions are now smarter. They help machines grip metal better and more safely. Automation also plays a big part. Machines can now align themselves without help. This makes working with lathes faster and more efficient. Here are some benefits:

- Improved accuracy and consistency.

- Less time wasted on setup.

- Higher productivity overall.

These advancements make work easier and create higher quality products. In the future, we can expect even more changes!

What are CNC workholding solutions?

CNC workholding solutions are tools that help machines hold parts securely while they work. This lets them cut and shape metal with great precision.

How does automation help with lathe alignment?

- Automation allows machines to self-correct during operation.

- It saves time and reduces errors.

Case Studies: Successful Lathe Workholding Solutions

Realworld examples of effective workholding implementations. Analysis of outcomes and lessons learned.In the world of lathe workholding, success stories are all around. One shop used a unique clamping system, which kept parts stable during tough cuts. They saved 30% on production time. Another team aligned their lathe accurately, leading to higher precision with every turn. They learned that small adjustments lead to big wins. Each case shows that effective workholding can transform results. Remember, a well-held part is like a well-sung note—picture perfect!

| Case Study | Implementation | Outcome | Lesson Learned |

|---|---|---|---|

| Shop A | Clamping system | 30% faster production | Stability is key! |

| Team B | Lathe Alignment | Best precision | Small tweaks make big differences! |

Resources for Further Learning on Lathe Workholding and Alignment

Recommended books, online courses, and workshops. Industry organizations and forums for networking and knowledge sharing.Learning more about lathe workholding and alignment can really help you improve your skills. Here are some great resources:

- Books: Look for books that focus on lathe work and techniques.

- Online Courses: Platforms like Coursera and Udemy offer courses on metalworking and lathe operations.

- Workshops: Local community colleges often provide hands-on workshops.

- Industry Organizations: Join groups like the National Tooling and Machining Association for networking.

- Forums: Online forums allow you to ask questions and share knowledge with others.

These resources can guide you and help you connect with other people who love working with lathes.

What are some good books for learning about lathes?

Great books include “The Complete Manual of Woodworking” and “Machinery’s Handbook.” These provide insights into techniques and best practices.

Are there online courses available?

Yes! Online platforms like Skillshare and LinkedIn Learning offer various courses on lathe operation.

How can workshops help me?

Workshops provide hands-on experience. You can learn from experts and gain practical skills.

What organizations can help me network?

Joining organizations like the American Society of Mechanical Engineers connects you with professionals in the field.

Where can I find forums for sharing knowledge?

Look at websites like Reddit or Stack Exchange for forums related to metalworking and machining.

Conclusion

In summary, lathe workholding and metal lathe alignment are crucial for successful machining. Proper alignment ensures accurate cuts and smooth operation. You should check your setup often to avoid mistakes. Understanding these concepts helps you improve your skills. Now, consider practicing your alignment techniques or reading more about lathe workholding for better results. Keep exploring and experimenting!FAQs

What Are The Best Methods For Aligning A Workpiece In A Metal Lathe To Ensure Accurate Machining?To align a workpiece in a metal lathe, first, make sure it’s tight in the chuck. You can use a dial indicator to check that it’s straight. This tool shows if the workpiece wobbles. Adjust it until it’s perfectly still. Finally, double-check your settings before starting to machine.

How Can You Check For Runout On The Lathe Spindle And What Impact Does It Have On Workholding?To check for runout on the lathe spindle, you can use a dial gauge. Place it on the spindle and spin it. If the needle moves up and down, there is a problem. Runout can cause your workpieces to wobble, making it harder to hold and shape them correctly. This can lead to mistakes and make your work less precise.

What Types Of Workholding Devices Are Most Effective For Securing Irregularly Shaped Metal Parts In A Lathe?To hold irregularly shaped metal parts in a lathe, you can use a few good tools. One option is a four-jaw chuck, which has four gripping parts that can hold odd shapes tightly. Another choice is a vise, which can clamp the metal part in place. You can also use clamps or straps to keep things steady. These tools help you work safely and make sure the part doesn’t move while you shape it.

How Do You Adjust The Tailstock Of A Metal Lathe To Maintain Alignment With The Headstock During Machining Operations?To adjust the tailstock of a metal lathe, first, check if it lines up with the headstock. You can do this by using a ruler or a special tool. If it’s not aligned, loosen the screws that hold the tailstock. Move it until it is straight, then tighten the screws again. This keeps the tailstock and headstock working together properly.

What Is The Importance Of Leveling The Lathe Bed In Relation To Workholding And Overall Machining Precision?When we level the lathe bed, it helps everything stay in the right place. If the lathe is not level, our workpieces may move or wobble. This can make our cuts uneven and messy. Leveling keeps our tools straight, which helps us make better, smoother parts. It is important for making things that fit together nicely.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Methods For Aligning A Workpiece In A Metal Lathe To Ensure Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a workpiece in a metal lathe, first, make sure it’s tight in the chuck. You can use a dial indicator to check that it’s straight. This tool shows if the workpiece wobbles. Adjust it until it’s perfectly still. Finally, double-check your settings before starting to machine.”}},{“@type”: “Question”,”name”: “How Can You Check For Runout On The Lathe Spindle And What Impact Does It Have On Workholding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check for runout on the lathe spindle, you can use a dial gauge. Place it on the spindle and spin it. If the needle moves up and down, there is a problem. Runout can cause your workpieces to wobble, making it harder to hold and shape them correctly. This can lead to mistakes and make your work less precise.”}},{“@type”: “Question”,”name”: “What Types Of Workholding Devices Are Most Effective For Securing Irregularly Shaped Metal Parts In A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To hold irregularly shaped metal parts in a lathe, you can use a few good tools. One option is a four-jaw chuck, which has four gripping parts that can hold odd shapes tightly. Another choice is a vise, which can clamp the metal part in place. You can also use clamps or straps to keep things steady. These tools help you work safely and make sure the part doesn’t move while you shape it.”}},{“@type”: “Question”,”name”: “How Do You Adjust The Tailstock Of A Metal Lathe To Maintain Alignment With The Headstock During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the tailstock of a metal lathe, first, check if it lines up with the headstock. You can do this by using a ruler or a special tool. If it’s not aligned, loosen the screws that hold the tailstock. Move it until it is straight, then tighten the screws again. This keeps the tailstock and headstock working together properly.”}},{“@type”: “Question”,”name”: “What Is The Importance Of Leveling The Lathe Bed In Relation To Workholding And Overall Machining Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we level the lathe bed, it helps everything stay in the right place. If the lathe is not level, our workpieces may move or wobble. This can make our cuts uneven and messy. Leveling keeps our tools straight, which helps us make better, smoother parts. It is important for making things that fit together nicely.”}}]}