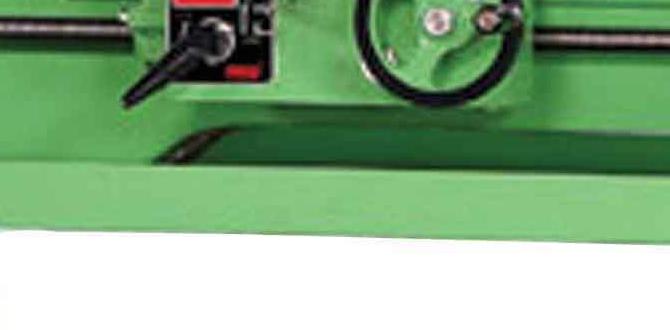

If you’ve ever watched a lathe in action, you might have been amazed. These machines spin metal with precision, creating amazing shapes and parts. But did you know that a crucial part of lathe work is something called workholding?

Workholding keeps your metal securely in place while you shape it. If it isn’t held tightly, the results can be messy. Have you ever tried to balance a wobbly object? It’s difficult, right? The same idea applies here.

There are many ways to hold metal on a lathe. Some people use clamps, while others prefer chucks. But there’s also something interesting called a lathe belt. This belt can help with the machine’s speed and power. It’s like a secret weapon to make your projects easier!

In this article, we’ll explore the world of lathe workholding and the importance of the metal lathe belt. You’ll learn tips that can help you improve your skills and create better projects. Ready to dive in?

Essential Guide To Lathe Workholding: Metal Lathe Belt Techniques

Lathe Workholding: Essential for Metal Lathe Success

Understanding lathe workholding is vital for anyone using a metal lathe. Proper workholding securely holds the material in place, ensuring safety and precision. Did you know that a loose workpiece can lead to mistakes and accidents? Choosing the right belt for your lathe also impacts performance. A good quality belt helps maintain speed and torque, maximizing efficiency. With the right techniques, even beginners can master lathe workholding to create amazing projects.Understanding Metal Lathe Workholding

Definition and importance of workholding in metal lathe operations. Common types of workholding devices used in metal lathes.Workholding is very important in metal lathe operations. It means holding the metal in place while cutting or shaping it. Good workholding keeps everything steady, making sure cuts are accurate. Without this, projects can go wrong. Common types of workholding devices include:

- Chucks – which hold round pieces.

- Collets – great for smaller objects.

- Faceplates – used for flat surfaces.

Using the right workholding tool helps make the job easier and safer. This leads to better results each time.

What is workholding in a metal lathe?

Workholding is the method used to secure material in place on a lathe. Good workholding is essential for precise cuts and safe operation.

Choosing the Right Workholding Device

Factors to consider: material, geometry, and production volume. Pros and cons of each workholding option for various applications.Selecting the right workholding device is key for effective lathe operations. Consider three main factors: material, geometry, and production volume. Each affects how well the part stays in place while you work. Here are some pros and cons:

- Material: Wood is easier to grip but metal offers strength.

- Geometry: Simple shapes are easier to hold; complex ones may need special devices.

- Production Volume: High volume needs quick setups; low volume can use simpler methods.

Your choice matters. It can boost productivity or cause mistakes. Always match your device with your task for the best results.

What factors help choose a workholding device?

It’s important to look at material, geometry, and production volume when picking your workholding solution. These aspects help ensure a smooth operation with fewer errors.

Selecting and Maintaining Lathe Belts

Key considerations when choosing a lathe belt: size, type, and durability. Maintenance tips for extending the lifespan of lathe belts.Choosing the right lathe belt is a bit like picking the perfect donut. You must consider size, type, and durability. First, make sure the belt fits your machine, just like a donut fits in your hand! Check the manufacturer’s guidelines for the right size. Next, choose the type of belt that suits your work. Some are better for heavy-duty jobs, while others prefer light tasks. To keep your belt lasting longer, clean it regularly and avoid keeping it too tight. Think of it like a happy donut: keep it just right, and it won’t get stale!

| Consideration | Tip |

|---|---|

| Size | Follow manufacturer’s guidelines |

| Type | Match belt type to your task |

| Durability | Regular cleaning for longer life |

Safety Practices in Metal Lathe Workholding

Monitoring workholding security during operations. Personal protective equipment (PPE) and safe handling procedures.Keeping your metal lathe area safe is crucial. Always check if your workholding is secure. Loose parts can lead to chaos, or even worse, a flying piece of metal! Monitoring workholding security is key. Remember to wear proper gear like goggles and gloves. They protect you from flying chips and the occasional “whoops” moment. Follow the safe handling rules, and keep your workspace tidy, so you’re not climbing over parts like it’s an obstacle course!

| Personal Protective Equipment (PPE) | Purpose |

|---|---|

| Goggles | Protect your eyes from flying debris! |

| Gloves | Keep your hands safe from sharp edges! |

| Earplugs | Save your ears from loud machinery! |

Advanced Workholding Techniques

Innovative workholding solutions for complex machining tasks. Automation and its impact on workholding efficiency.For tricky machining tasks, innovative workholding techniques can make a big difference. Using specialized clamps or fixtures keeps pieces steady, like a toddler in a high chair! Automation plays a key role. It speeds up processes and boosts efficiency. Think of it as a robot arm giving you a hand, or maybe a few extra hands! When machines help hold the work, there’s less clutter and more time for creativity. Here’s a quick look:

| Technique | Benefits |

|---|---|

| Magnetic Workholding | Quick setup and reduced vibration |

| Vacuum Systems | Easy handling of thin materials |

| Hydraulic Clamping | Strong grip on heavy parts |

With these clever techniques, complex tasks become simpler. Remember, in the world of lathe workholding, it’s all about keeping things in place and making life easier. Who wouldn’t want a little help, especially from machines?

Case Studies: Successful Implementation of Workholding Systems

Realworld examples of effective workholding setups in industry. Lessons learned and best practices from experienced machinists.Many companies have found success with clever workholding systems. One famous example is a car manufacturer. They streamlined their process and improved safety by using clamps that hold parts securely. This saved time and reduced mistakes. Here are some insights from their experience:

- Clarity is key: Label tools and parts clearly.

- Test Solutions: Always test setups before full production.

- Feedback matters: Listen to machinists’ ideas for better designs.

These lessons show how right choices in workholding can lead to better results.

What are effective workholding setups?

Effective workholding setups hold the workpiece snugly while allowing easy access for cutting tools. A well-designed setup boosts productivity and quality.

Conclusion

In summary, lathe workholding is vital for metal lathe projects. It keeps your materials secure while you cut and shape them. Remember to choose the right belt to ensure smooth operation. Try experimenting with different setups for better results. For more tips, check out additional resources or guides on lathe work. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically For Metal Lathes Using Belts:Sure! Here are five questions about holding metal pieces on a lathe that uses belts. 1. What is a lathe? A lathe is a machine that spins metal pieces. You can shape or cut these pieces while they spin. 2. Why do we need workholding? We use workholding to keep the metal piece in place while it spins. This helps us work on it safely and easily. 3. How do belts help in lathes? Belts make the lathe spin fast. They connect the motor to the spinning parts, helping us shape the metal. 4. What can we shape on a lathe? You can shape things like rods, tubes, or even parts for toys. It’s like making a wooden stick but with metal. 5. Is using a lathe easy? With practice, using a lathe becomes easier. You just need to be careful and follow the steps!

Sure! Please share the question you’d like me to answer.

What Are The Best Practices For Securing Workpieces On A Metal Lathe To Ensure Stability And Precision During Machining?To keep workpieces steady on a metal lathe, always use a strong chuck or a vise. Make sure the workpiece is tight and secure before starting. Check it again after a few minutes of machining. Use wooden blocks or pads to protect the metal if needed. Always wear safety gear like goggles to protect your eyes!

How Does The Use Of A Belt-Driven System In A Metal Lathe Affect The Overall Performance And Accuracy Of Workholding?A belt-driven system in a metal lathe helps it run smoothly. This smoothness means you can hold the metal securely while cutting. When the machine runs well, it helps make better and more accurate shapes. So, using belts can improve the quality of your work.

What Are The Advantages And Disadvantages Of Various Workholding Devices, Such As Chucks, Collets, And Clamps, For Belt-Driven Metal Lathes?Chucks, collets, and clamps are all tools to hold metal pieces on lathes. Chucks are strong and great for rough shapes, but they can be heavy. Collets hold small, precise parts very tightly, making them great for detailed work, but they can be more expensive. Clamps are easy to use and cheap, but they can sometimes slip if not tight enough. So, each tool has its good and bad points, depending on what you need to do!

How Can Operators Troubleshoot Common Issues Related To Workholding On A Metal Lathe With A Belt Drive Mechanism?To troubleshoot workholding issues on a metal lathe, first, check the tightness of the belt. If it’s too loose, the lathe won’t spin correctly. Next, make sure the workpiece is secure in the chuck, which holds it in place. If it’s wobbly, tighten the chuck. Lastly, look for any dirt or debris. Clean them off so everything works smoothly.

What Types Of Belts Are Commonly Used In Metal Lathes, And How Do They Influence The Workholding Method And Machining Process?In metal lathes, we commonly use flat belts and V-belts. Flat belts are wide and help move the machine smoothly. V-belts are shaped like a V, which gives them a strong grip. These belts keep the lathe running well, making sure the metal stays steady while we work on it. This helps us make better pieces and finish our projects faster.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically For Metal Lathes Using Belts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about holding metal pieces on a lathe that uses belts. 1. What is a lathe? A lathe is a machine that spins metal pieces. You can shape or cut these pieces while they spin. 2. Why do we need workholding? We use workholding to keep the metal piece in place while it spins. This helps us work on it safely and easily. 3. How do belts help in lathes? Belts make the lathe spin fast. They connect the motor to the spinning parts, helping us shape the metal. 4. What can we shape on a lathe? You can shape things like rods, tubes, or even parts for toys. It’s like making a wooden stick but with metal. 5. Is using a lathe easy? With practice, using a lathe becomes easier. You just need to be careful and follow the steps!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Securing Workpieces On A Metal Lathe To Ensure Stability And Precision During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep workpieces steady on a metal lathe, always use a strong chuck or a vise. Make sure the workpiece is tight and secure before starting. Check it again after a few minutes of machining. Use wooden blocks or pads to protect the metal if needed. Always wear safety gear like goggles to protect your eyes!”}},{“@type”: “Question”,”name”: “How Does The Use Of A Belt-Driven System In A Metal Lathe Affect The Overall Performance And Accuracy Of Workholding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A belt-driven system in a metal lathe helps it run smoothly. This smoothness means you can hold the metal securely while cutting. When the machine runs well, it helps make better and more accurate shapes. So, using belts can improve the quality of your work.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Various Workholding Devices, Such As Chucks, Collets, And Clamps, For Belt-Driven Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Chucks, collets, and clamps are all tools to hold metal pieces on lathes. Chucks are strong and great for rough shapes, but they can be heavy. Collets hold small, precise parts very tightly, making them great for detailed work, but they can be more expensive. Clamps are easy to use and cheap, but they can sometimes slip if not tight enough. So, each tool has its good and bad points, depending on what you need to do!”}},{“@type”: “Question”,”name”: “How Can Operators Troubleshoot Common Issues Related To Workholding On A Metal Lathe With A Belt Drive Mechanism?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot workholding issues on a metal lathe, first, check the tightness of the belt. If it’s too loose, the lathe won’t spin correctly. Next, make sure the workpiece is secure in the chuck, which holds it in place. If it’s wobbly, tighten the chuck. Lastly, look for any dirt or debris. Clean them off so everything works smoothly.”}},{“@type”: “Question”,”name”: “What Types Of Belts Are Commonly Used In Metal Lathes, And How Do They Influence The Workholding Method And Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathes, we commonly use flat belts and V-belts. Flat belts are wide and help move the machine smoothly. V-belts are shaped like a V, which gives them a strong grip. These belts keep the lathe running well, making sure the metal stays steady while we work on it. This helps us make better pieces and finish our projects faster.”}}]}