Have you ever wondered how metal pieces are shaped and held in place? Lathe workholding might be the answer. A metal lathe bench is a crucial tool for anyone interested in machining. It’s amazing how these machines work precision magic with every turn.

Imagine you’re creating a piece of art from a simple block of metal. A lathe helps you transform it into something smooth and polished. But how do you keep that metal secure while you shape it? That’s where workholding comes into play.

Workholding devices help grip your material tightly during the process. Without them, things would slip and slide. Did you know that even a little wobble can ruin a perfect piece? It’s true! That’s why understanding how to use your lathe bench and workholding tools is important.

In this article, we will explore the world of lathe workholding. We will look at different techniques and tips for getting the best results. Get ready to dive into a world where precision meets creativity.

Effective Lathe Workholding Techniques For Metal Lathe Bench

Understanding Lathe Workholding on a Metal Lathe Bench

Lathe workholding is vital for metal lathes. Properly securing your materials leads to better results. Have you ever struggled to keep a piece steady while working? A well-designed metal lathe bench can solve that problem. It supports your work and improves accuracy. Many tools are available, from chucks to vices. Each tool helps you grip different shapes and sizes. Selecting the right workholding method can transform your project. It’ll keep your hands free and your eyes focused!Understanding Workholding in Lathe Operations

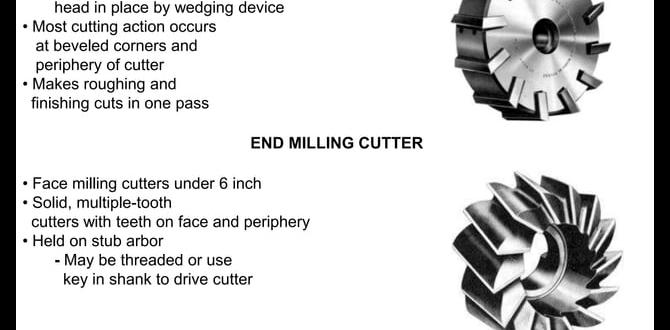

Definition and importance of workholding in metal lathes. Types of workholding methods commonly used.Workholding is crucial in lathe operations. It secures the metal piece while it spins. This ensures safety and precision. Without proper workholding, parts can wobble or break. Common methods include:

- Chucks: They grip the workpiece tightly.

- Collets: Great for cylindrical shapes.

- Vices: Hold flat materials securely.

Choosing the right workholding method is essential for quality results. It affects the speed and accuracy of the work.

What is workholding in lathe operations?

Workholding is the way we hold a piece of metal in place on a lathe. It helps in making accurate cuts and shapes.

Selecting the Right Workholding Device

Factors to consider when choosing a workholding device. How material type affects the selection process.Choosing the right workholding device is important for successful lathe work. First, think about your material type. Metals, wood, and plastics can all need different hold systems. Next, consider the size and shape of your workpiece. A secure grip helps avoid mistakes. Other factors include ease of use and safety. You always want to feel confident as you work.

What should I consider when selecting a workholding device?

Look at material type, size, shape, and ease of use.Factors to Consider:

- Material Type: Choose based on whether it’s metal, wood, or plastic.

- Size and Shape: Make sure your device fits your workpiece well.

- Ease of Use: A simple device helps you work faster.

- Safety: Ensure the device is safe to use.

Setting Up Your Metal Lathe Bench

Key dimensions for a properly configured lathe bench. Essential tools and equipment needed for setup.Creating the perfect spot for your metal lathe is like building a throne for a king. First, make sure your lathe bench is at the right height. Too low, and you’ll feel like a hunchback; too high, and you might need a trampoline! Aim for a comfortable height that keeps your back happy.

Next, gather your essential tools: a level, a wrench, clamping devices, and safety gear. Safety first, folks! Don’t skimp on that! You want to be the proud owner of your lathe, not a face-palm meme.

| Item | Purpose |

|---|---|

| Level | Ensures your bench is even. |

| Wrench | Tightens necessary parts. |

| Clamps | Holds materials steady. |

| Safety Gear | Protects you while working. |

With these dimensions and tools, you’ll set up a wonderful workspace for your lathe. And remember, every great project starts with a sturdy foundation—like building a house made of chocolate (but less tasty)!

Techniques for Secure Workholding

Best practices for clamping and securing materials. Tips for adjusting tension and ensuring stability.To keep materials secure during lathe work, use proper clamping methods. Choose the right clamps for your project. Strong grips hold materials tightly to prevent slipping. Always check tension before starting. Tighten clamps enough to secure but not too much to cause damage. Ensure stability by using flat surfaces and supporting long pieces with extra tools.

- Use appropriate clamps for different materials.

- Check tension regularly before operating.

- Support longer pieces with extra supports.

What are essential tips for securely holding materials on a lathe?

Use strong clamps, check the tension, and support long pieces for safety and stability.

Common Challenges in Lathe Workholding

Issues faced with workholding and their solutions. Maintaining precision and accuracy during lathe operations.Lathe workholding can be tricky at times. Issues with holding the material often arise. These problems can affect precision and accuracy. To tackle this, users can follow a few simple steps:

- Choose the right workholding device.

- Regularly check for wear and tear.

- Always align the material properly.

- Utilize proper force when tightening.

These solutions help keep your lathe work precise and reliable.

What are common issues in lathe workholding?

Common problems include slipping parts and misalignments. These can lead to errors and wasted material. Using the right tools and checking your setup often can greatly improve results.

Maintenance of Workholding Equipment

Routine checks and upkeep for workholding devices. Signs that indicate the need for repair or replacement.Maintaining equipment is key to keeping your lathe running smoothly. Regular checks on workholding devices help catch problems early. Look for these signs that it’s time to repair or replace parts:

- Unusual noises when in use.

- Cracks or dents on surfaces.

- Part feels loose or unstable.

Taking care of your bench makes work easier and safer. Don’t ignore small issues; they can lead to bigger problems down the road!

How often should you check workholding equipment?

It’s best to perform checks monthly. This helps spot issues before they get serious. Regular checks keep your tools in good shape!

Expert Tips for Effective Lathe Workholding

Innovative techniques from experienced machinists. Safety considerations while working with lathes.Working with lathes is fun but needs care! Experienced machinists share key tips. First, use jigs to hold your workpiece securely. This helps keep everything in place. Second, always wear protective gear. Safety glasses and gloves are essential. Be alert and keep your hands clear while the lathe is running. Lastly, practice proper cleaning after each use. It helps keep your workspace organized. Remember, a safe workspace is a happy workspace!

What are some innovative workholding techniques?

Innovative techniques include using custom jigs and clamps to secure materials effectively. These tools can improve precision and safety during lathe operations.

Why is safety important while working with lathes?

- Wearing safety gear protects your eyes and hands.

- Staying alert helps prevent accidents.

- Cleaning the workspace can reduce hazards.

Future Trends in Lathe Workholding Technology

Emerging technologies and innovations in workholding solutions. The impact of automation on lathe workholding methods.New technologies are changing how we hold workpieces on lathes. These innovations are making workholding faster and more precise. Some exciting developments include:

- Smart clamps that adjust automatically for better grip.

- Magnetic systems that speed up setup time.

- Robotic arms that improve accuracy with less effort.

Automation is making lathe workholding easier. Machines do more work, which saves time and increases safety. It’s clear that the future is bright for lathe workholding technology!

What are the emerging technologies in lathe workholding solutions?

Emerging technologies include smart clamps, magnetic systems, and robotic arms. They improve speed and precision in lathe workholding.

How is automation impacting lathe workholding methods?

Automation enhances efficiency and safety in lathe workholding. Machines take on more tasks, simplifying the process.

Conclusion

In summary, lathe workholding is crucial for accurate metal lathe projects. A sturdy bench helps keep everything steady. Remember to choose the right clamps and tools for your needs. We encourage you to practice regularly and explore more resources. With time, you’ll improve your skills and create amazing projects. Keep learning and enjoy your lathe work!FAQs

What Are The Different Types Of Workholding Devices Commonly Used In Metal Lathe Operations?In metal lathe operations, we use different workholding devices to hold the metal while we shape it. One common device is a chuck. It grips the metal securely and can be turned easily. Another type is a faceplate, which holds larger or odd-shaped pieces. We can also use clamps to keep metal steady while we work. These devices help us make clean and accurate cuts.

How Do You Properly Set Up A Workpiece On A Metal Lathe For Precision Machining?To set up a workpiece on a metal lathe, first, make sure the lathe is turned off. Then, choose the right size and shape of the metal piece you want to shape. Next, place it in the lathe’s clamps or chuck so it fits tightly. After that, adjust the tool to just touch the metal. Finally, turn on the lathe and start machining carefully!

What Are The Advantages And Disadvantages Of Using A Four-Jaw Chuck Versus A Three-Jaw Chuck For Workholding?A four-jaw chuck holds things very well and can grip different shapes safely. You can adjust each jaw, so it works with odd or tricky objects. However, it takes longer to set up because you have to move each jaw separately. A three-jaw chuck is faster to use because it can hold round things quickly and easily. But it’s not as flexible for holding weird shapes.

How Can Collet Chucks Enhance The Accuracy Of Workholding In A Metal Lathe?Collet chucks hold the metal piece tightly and evenly. This makes sure it doesn’t move while we work on it. When the piece stays still, we can cut or shape it more accurately. This means our projects will look better and fit together nicely. Using collet chucks helps us do our best work!

What Safety Precautions Should Be Taken While Working With A Lathe And Its Workholding Systems?When using a lathe, we should always wear safety goggles to protect our eyes. Make sure long hair is tied back and loose clothing is tucked in. Always keep our hands away from moving parts. Check that the workpiece is secured tightly before we start. Lastly, never distract someone using the lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Different Types Of Workholding Devices Commonly Used In Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathe operations, we use different workholding devices to hold the metal while we shape it. One common device is a chuck. It grips the metal securely and can be turned easily. Another type is a faceplate, which holds larger or odd-shaped pieces. We can also use clamps to keep metal steady while we work. These devices help us make clean and accurate cuts.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Workpiece On A Metal Lathe For Precision Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a workpiece on a metal lathe, first, make sure the lathe is turned off. Then, choose the right size and shape of the metal piece you want to shape. Next, place it in the lathe’s clamps or chuck so it fits tightly. After that, adjust the tool to just touch the metal. Finally, turn on the lathe and start machining carefully!”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Four-Jaw Chuck Versus A Three-Jaw Chuck For Workholding? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A four-jaw chuck holds things very well and can grip different shapes safely. You can adjust each jaw, so it works with odd or tricky objects. However, it takes longer to set up because you have to move each jaw separately. A three-jaw chuck is faster to use because it can hold round things quickly and easily. But it’s not as flexible for holding weird shapes.”}},{“@type”: “Question”,”name”: “How Can Collet Chucks Enhance The Accuracy Of Workholding In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Collet chucks hold the metal piece tightly and evenly. This makes sure it doesn’t move while we work on it. When the piece stays still, we can cut or shape it more accurately. This means our projects will look better and fit together nicely. Using collet chucks helps us do our best work!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken While Working With A Lathe And Its Workholding Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe, we should always wear safety goggles to protect our eyes. Make sure long hair is tied back and loose clothing is tucked in. Always keep our hands away from moving parts. Check that the workpiece is secured tightly before we start. Lastly, never distract someone using the lathe.”}}]}