Have you ever wondered how metal parts are made? If you think about a cool machine that spins, you might be thinking of a lathe. Lathes are special tools used to shape metal. But how do you hold that metal while it’s spinning?

That’s where lathe workholding comes in! It’s all about how you secure the metal on a lathe. If it’s not held right, things can go wrong. Imagine a spinning metal piece flying off. Yikes! Choosing the right workholding method can make all the difference.

Many people wonder which metal lathe brands are the best. Each brand has different features. Some are great for beginners, while others work best for experts. Did you know there are brands that have been around for over a hundred years? They have a lot of experience in helping metal workers succeed.

In this article, we will explore the world of lathe workholding and the best metal lathe brands. You might just find the perfect tool to bring your ideas to life!

Top Metal Lathe Brands For Effective Lathe Workholding

Lathe Workholding Metal Lathe Brands

Choosing the right lathe is vital for precise machining. Metal lathe brands like Haas and Jet stand out for reliability. They offer various models suited for different projects. Have you ever wondered why some lathes are more popular than others? It’s often due to their quality and user-friendly features. Fun fact: a good lathe can help turn metal into amazing shapes! Selecting the right workholding method is also essential for accuracy in your work.Understanding Workholding in Lathe Operations

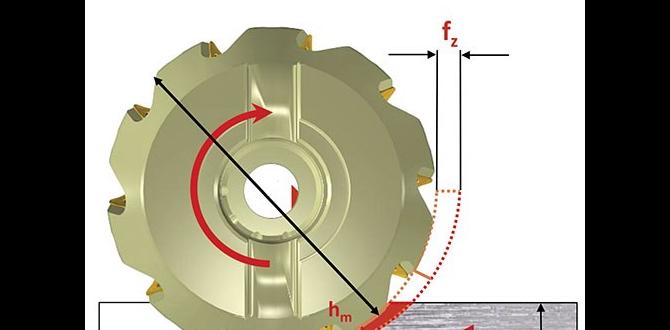

Definition and importance of workholding in metal lathe machining.. Factors influencing effective workholding practices..Workholding is the method of securely holding a piece of metal in place on a lathe during machining. This is important because proper workholding prevents movement, ensuring safe and accurate cuts. The effectiveness of workholding depends on several factors:

- Type of lathe and fixtures

- Material properties of the workpiece

- Cutting tool parameters

- Desired machining precision

Without good workholding, projects can become messy or unsafe. Think about it: Would you paint on a moving canvas? Proper holds make a big difference!

Why is workholding crucial in lathe operations?

Workholding ensures safety and accuracy in machining, allowing for quality outcomes.

Criteria for Selecting Metal Lathe Brands

Key features to consider when evaluating lathe brands.. Comparison of durability, precision, and versatility among brands..Choosing a metal lathe brand requires careful thought. You want one that won’t throw a tantrum after a few uses! Durability is key—look for machines that can withstand wear and tear. Then, consider precision. A lathe that produces precise cuts can be your best friend. Lastly, think about versatility. Brands that offer a range of tools will keep your projects exciting. Here’s a fun comparison guide:

| Brand | Durability | Precision | Versatility |

|---|---|---|---|

| Brand A | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Brand B | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

| Brand C | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

Finding the right lathe is like dating—you need to look for a brand that matches what you want!

Workholding Accessories for Metal Lathes

Essential workholding accessories such as chucks, vises, and clamps.. How to choose the right accessories based on specific tasks..To make metal lathe work easier and safer, using good workholding accessories is key. Essential items include:

- Chucks

- Vises

- Clamps

Choosing the right accessory depends on your task. For example, chucks hold round objects and are great for turning. Vises are best for holding flat pieces. Lightweight clamps offer quick adjustments. Each tool is a helper for the job!

How do I choose workholding accessories?

Think about your project. What shape do you need to hold? Round parts need chucks, while flat items work well with vises. The right tool makes a difference!

Maintenance and Care for Longevity

Best practices for maintaining workholding equipment.. Tips for extending the lifespan of metal lathe accessories..To keep your workholding equipment in top shape, follow these best practices. Regular cleaning is essential; dust and grime can harm your tools. Always check for wear and tear. Replace any damaged parts to avoid bigger issues down the line. Lubrication is key, too. Proper oil keeps everything running smoothly.

- Store equipment in a dry place.

- Avoid exposure to corrosive materials.

- Use protective covers when not in use.

Taking care of your metal lathe accessories extends their lifespan. This makes your projects easier and more enjoyable!

How can I maintain my lathe accessories?

Regularly clean and inspect your accessories. Make sure they are free from rust. Store them properly to prevent damage. Lubricate moving parts to keep everything functional.

Comparative Analysis of Workholding Solutions

Detailed comparison of different workholding options available.. Case studies showcasing successful lathe workholding implementations..Different workholding solutions help keep pieces steady during lathe work. Each has its own pros and cons. For example:

- Chucks: These are common and can hold many shapes.

- Vises: Great for flat materials, providing secure grip.

- Collets: Perfect for small, round items.

Case studies show that companies using the right workholding solutions see better results. One workshop improved efficiency by 30% after switching to a high-quality chuck. Understanding these options leads to success in metal lathe projects.

What are some successful lathe workholding examples?

One example is a factory that improved its lathe accuracy by 25% using custom vises. This shows how important the right tools are for effective work.

Challenges in Workholding and How to Overcome Them

Common issues faced in workholding with metal lathes.. Solutions and innovations to mitigate workholding challenges..Workholding with metal lathes can be tricky. Common problems arise from improper clamping and misalignment. These issues can lead to mistakes and wasted material. However, there are solutions to these challenges. Innovations in technology and better designs help secure the workpiece. Options like quick-change chucks and soft jaws improve accuracy. Many operators find success using these tools. They ensure parts stay in place without slipping.

What are the common issues in workholding with metal lathes?

Operators face several challenges. These include:

- Poor clamping

- Misalignment

- Vibration

- Tool wear

How can innovations help workholding challenges?

New tools and designs improve grip and accuracy. Features like self-centering chucks and modular fixtures reduce errors and save time. Additionally, learning and adapting to new technology can enhance performance.

Conclusion

In conclusion, choosing the right lathe workholding system is crucial for metalwork. Brands like Grizzly and Jet offer reliable options. Remember to match the brand with your project needs. You can explore reviews or visit local shops for hands-on experience. Dive deeper into lathe workholding to enhance your skills and enjoy creating amazing projects. Happy working!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Brands:Sure! When working with a lathe, you need to hold the metal pieces tightly. Good brands for metal lathes include Jet, Grizzly, and Delta. Each brand has its own features and prices. You should pick one based on what you need. Always follow safety rules when using a lathe!

Sure! Please provide the question you’d like me to answer.

What Are The Most Popular Brands Of Metal Lathes That Offer Reliable Workholding Solutions?Some popular brands of metal lathes are Haas, Jet, and Grizzly. They all make strong tools that hold parts tightly. These brands are known for their good quality and easy-to-use design. You can trust them to help you work safely and efficiently.

How Do Different Types Of Workholding Devices, Such As Chucks And Collets, Vary Among Leading Metal Lathe Manufacturers?Different metal lathe companies use various workholding devices like chucks and collets. Chucks can hold larger pieces while collets are better for smaller ones. Each brand can have unique designs for these devices, making them special. We need to pick the right one for the project we are working on. It’s like choosing different tools for different jobs!

What Factors Should Be Considered When Choosing A Metal Lathe Brand For Specific Workholding Needs?When choosing a metal lathe brand, think about what you want to make. First, check the size and weight of the projects. Next, look at how easy it is to use and set up. Also, consider the cost and how much support the brand offers. Finally, read reviews to see what other people say about it.

How Do User Reviews And Expert Opinions Compare Various Metal Lathe Brands In Terms Of Workholding Effectiveness?User reviews and expert opinions often say that some metal lathe brands hold workpieces better than others. They look at how tight and secure a piece of metal is when using the lathe. Many users like brands that keep the metal steady while they work on it. Experts check how each brand’s clamps and users’ experiences make a difference. Overall, it’s important to choose a brand known for good workholding.

What Innovations In Workholding Technology Are Being Introduced By Top Metal Lathe Manufacturers In Recent Years?Recently, metal lathe makers are creating new ways to hold metal pieces securely. They use stronger materials, making clamps and tools last longer. Some companies now offer quick-change systems. This means we can switch parts fast and save time. These changes help us work better and make things more accurately.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Brands:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When working with a lathe, you need to hold the metal pieces tightly. Good brands for metal lathes include Jet, Grizzly, and Delta. Each brand has its own features and prices. You should pick one based on what you need. Always follow safety rules when using a lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Popular Brands Of Metal Lathes That Offer Reliable Workholding Solutions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some popular brands of metal lathes are Haas, Jet, and Grizzly. They all make strong tools that hold parts tightly. These brands are known for their good quality and easy-to-use design. You can trust them to help you work safely and efficiently.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Workholding Devices, Such As Chucks And Collets, Vary Among Leading Metal Lathe Manufacturers?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different metal lathe companies use various workholding devices like chucks and collets. Chucks can hold larger pieces while collets are better for smaller ones. Each brand can have unique designs for these devices, making them special. We need to pick the right one for the project we are working on. It’s like choosing different tools for different jobs!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Choosing A Metal Lathe Brand For Specific Workholding Needs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe brand, think about what you want to make. First, check the size and weight of the projects. Next, look at how easy it is to use and set up. Also, consider the cost and how much support the brand offers. Finally, read reviews to see what other people say about it.”}},{“@type”: “Question”,”name”: “How Do User Reviews And Expert Opinions Compare Various Metal Lathe Brands In Terms Of Workholding Effectiveness?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “User reviews and expert opinions often say that some metal lathe brands hold workpieces better than others. They look at how tight and secure a piece of metal is when using the lathe. Many users like brands that keep the metal steady while they work on it. Experts check how each brand’s clamps and users’ experiences make a difference. Overall, it’s important to choose a brand known for good workholding.”}},{“@type”: “Question”,”name”: “What Innovations In Workholding Technology Are Being Introduced By Top Metal Lathe Manufacturers In Recent Years?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Recently, metal lathe makers are creating new ways to hold metal pieces securely. They use stronger materials, making clamps and tools last longer. Some companies now offer quick-change systems. This means we can switch parts fast and save time. These changes help us work better and make things more accurately.”}}]}