Have you ever wondered how metal parts are made? The secret often lies in lathe workholding. This technique helps secure the metal while a lathe shapes it. It’s like having a strong hand holding a piece of clay while you mold it.

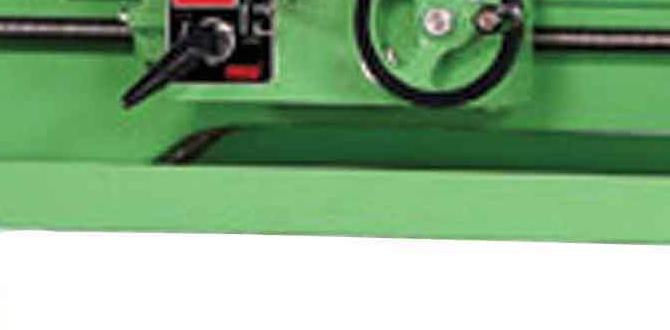

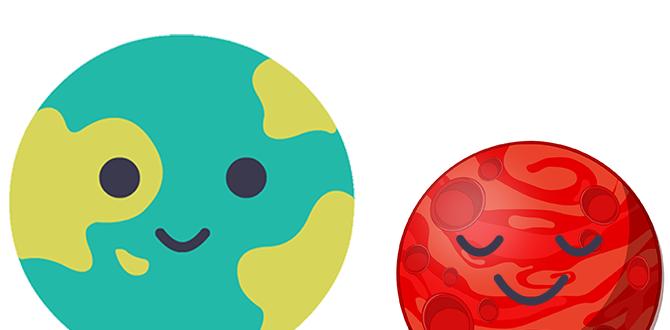

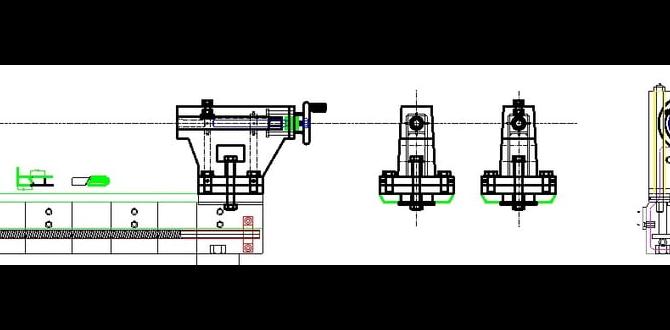

Imagine a craftsman in a workshop, surrounded by machines. He carefully places a metal piece on the lathe. The machine comes to life, spinning the metal. With each turn, it transforms into a precise shape. This is where CAD design shines, allowing users to create detailed plans for their projects.

Did you know that CAD design can save time and improve accuracy? Using computer software, anyone can design complex shapes easily. Lathe workholding ensures that these designs come to life, making strong and reliable parts.

Whether you’re an aspiring engineer or just love to tinker, understanding lathe workholding is key. It opens up a world of possibilities in metalworking. Are you ready to explore this fascinating topic?

Efficient Lathe Workholding For Metal Lathe Cad Design

Lathe Workholding & Metal Lathe CAD Design

Lathe workholding is key to precise machining. It keeps metal pieces steady during cutting. Did you know that the right setup can make or break your project? Using CAD design enhances this process. It allows users to visualize and plan their work more effectively. This results in better accuracy and efficiency. Imagine crafting a perfect piece by simply setting it up correctly! Understanding these techniques can elevate your metalworking skills significantly.Understanding Lathe Workholding

Definition and importance of workholding in lathe operations. Types of workholding methods used in metal lathes.Workholding is like giving your metal a cozy hug while it spins on a lathe. It keeps everything in place, which is super important for making smooth cuts and shapes. Without proper workholding, your project might turn into a wobbly mess, like jelly on a rollercoaster!

There are different ways to hold metal in lathes. Here’s a quick look:

| Method | Description |

|---|---|

| Chucks | These grab the material tightly, like a bear hug. |

| Collets | These fit snugly around the material, perfect for small projects! |

| Vises | Think of this as a metal sandwich, holding everything together! |

Choosing the right method makes all the difference. It ensures safety and accuracy, leading to a happy lathe and a happy machinist! Now, let’s get spinning!

Benefits of Effective Workholding

Impact on precision and surface finish. Effects on productivity and machining efficiency.Using effective workholding can truly make your lathe work shine! It impacts both precision and surface finish, ensuring every cut is clean and smooth. Imagine trying to slice a cake while holding it with slippery hands—messy, right? That’s what poor workholding feels like. Plus, better workholding boosts productivity and machining efficiency, making you the speedster of your shop. Who doesn’t want to be a machining superhero?

| Benefits | Impact |

|---|---|

| Precision | Enhances accuracy of cuts |

| Surface Finish | Smooth, flawless results |

| Productivity | Increases output speed |

| Efficiency | Reduces wasted material |

Best Practices for Workholding Design in CAD

Considerations for material selection and durability. Designing for ease of setup and alignment.Choosing the right materials for your workholding is like picking the best buddy for a fun day at the park. They need to be strong and durable! This ensures your designs stay put, no matter how much they wiggle. And who likes a wobbly setup? To make your life easier, design it for quick setup and alignment. Think of it like building a Lego tower: the faster you can get the pieces together, the sooner you can show off your masterpiece!

| Material | Durability Rating |

|---|---|

| Aluminum | Medium |

| Steel | High |

| Plastic | Low |

Common Challenges and Solutions in Lathe Workholding

Identifying common issues in workholding setups. Effective troubleshooting techniques for improved performance.Workholding can feel like juggling flaming torches. Sometimes, things can go wrong in ways you never expected! Common problems include parts slipping or not being held firmly. Improper alignment can also lead to errors. To tackle these issues, start by checking your setup carefully. Make sure everything is tight and aligned correctly. If things still aren’t right, try using additional clamps or switching to a different chuck type. Remember, even the best lathe operators face challenges—like that time I mistook a donut for a washer!

| Common Issues | Solutions |

|---|---|

| Part Slipping | Tighten clamps and check alignment. |

| Improper Alignment | Use a level and adjust your setup. |

| Vibration | Balance the components and adjust speed. |

Case Studies on Successful Workholding Solutions

Examples of industries benefiting from optimal workholding designs. Analysis of specific projects showcasing innovative workholding approaches.Many industries see great wins from smart workholding designs. For example, the automotive sector has improved production speed with adjustable clamps. The aerospace industry benefits from custom fixtures to hold parts accurately. Here are some standout projects:

- Innovative designs in a car factory increased safety and reduced errors.

- Aerospace projects used advanced materials to grip delicate components without damage.

- Medical device manufacturing adopted flexible setups for various product sizes.

By focusing on clever solutions, companies improve quality and lower costs.

How do workholding solutions improve metal lathe operations?

Workholding solutions enhance metal lathe operations by ensuring parts are secure and precisely positioned. This leads to faster production and better quality, reducing waste and errors.

Conclusion

In summary, lathe workholding is essential for precision in metal lathe projects. Using CAD design helps you visualize your work and improve accuracy. By mastering these tools, you will create better projects. Now, explore more about lathe techniques and CAD software to enhance your skills. Dive into online resources or local workshops to keep learning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Metal Lathe, And Cad Design:Sure! We use a lathe to shape metal into different forms. It spins the metal while tools cut away bits to create shapes. Workholding is how we keep the metal nice and steady while we work on it. Computer-Aided Design (CAD) helps us plan our designs on a computer before we start working. This way, we can see what we want to make and fix any mistakes before starting!

Sure! Please provide the specific question you’d like me to answer, and I’ll be happy to help!

What Are The Most Common Types Of Workholding Devices Used In Metal Lathes, And How Do They Differ In Application?The most common workholding devices on metal lathes are chucks and tailstocks. A chuck holds a piece of metal tightly in place. You can use it for different shapes, like cylinders or squares. A tailstock supports the other end of the metal piece, helping to make it stable. Each device has a special job to keep the metal safe while you work.

How Can Cad Software Be Utilized To Design Custom Workholding Solutions For Specific Lathe Operations?You can use CAD software, which stands for Computer-Aided Design, to create custom tools for holding pieces on a lathe. First, you draw a picture of the tool you need using the software. Then, you can change the size and shape to fit your specific job. This helps the lathe hold your work tightly and safely while it spins. Finally, you can even see how it will look before you make it!

What Factors Should Be Considered When Selecting A Workholding Method For Complex Or Irregularly Shaped Metal Parts?When choosing a way to hold metal parts, think about the shape and size of the part. Make sure the method keeps it steady while you work. You should also consider how easy it is to set up and change. Finally, check if the method protects the part from getting hurt or scratched.

How Does The Design Of A Workholding Fixture Influence The Accuracy And Repeatability Of Machining Operations On A Metal Lathe?The design of a workholding fixture helps keep the metal piece steady while we machine it. If the fixture holds the piece tightly, it won’t move around. This means we can cut the metal more accurately. Good fixtures also help us set up the same way each time, making it easier to repeat the work. This helps us create the same results every time we use the lathe.

What Are The Best Practices For Integrating Cnc Programming With Cad-Designed Workholding Setups To Optimize Machining Efficiency?To make CNC programming and CAD (Computer-Aided Design) work together well, you should plan carefully. First, you can use clear drawings to show how parts fit in the machine. Next, set up your workholding, which keeps the parts still, exactly how the design wants. Then, program the CNC machine to match what the CAD design says. Finally, test everything to make sure it works perfectly together.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Metal Lathe, And Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! We use a lathe to shape metal into different forms. It spins the metal while tools cut away bits to create shapes. Workholding is how we keep the metal nice and steady while we work on it. Computer-Aided Design (CAD) helps us plan our designs on a computer before we start working. This way, we can see what we want to make and fix any mistakes before starting!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the specific question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Most Common Types Of Workholding Devices Used In Metal Lathes, And How Do They Differ In Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The most common workholding devices on metal lathes are chucks and tailstocks. A chuck holds a piece of metal tightly in place. You can use it for different shapes, like cylinders or squares. A tailstock supports the other end of the metal piece, helping to make it stable. Each device has a special job to keep the metal safe while you work.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Design Custom Workholding Solutions For Specific Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software, which stands for Computer-Aided Design, to create custom tools for holding pieces on a lathe. First, you draw a picture of the tool you need using the software. Then, you can change the size and shape to fit your specific job. This helps the lathe hold your work tightly and safely while it spins. Finally, you can even see how it will look before you make it!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Workholding Method For Complex Or Irregularly Shaped Metal Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a way to hold metal parts, think about the shape and size of the part. Make sure the method keeps it steady while you work. You should also consider how easy it is to set up and change. Finally, check if the method protects the part from getting hurt or scratched.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Workholding Fixture Influence The Accuracy And Repeatability Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of a workholding fixture helps keep the metal piece steady while we machine it. If the fixture holds the piece tightly, it won’t move around. This means we can cut the metal more accurately. Good fixtures also help us set up the same way each time, making it easier to repeat the work. This helps us create the same results every time we use the lathe.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Integrating Cnc Programming With Cad-Designed Workholding Setups To Optimize Machining Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make CNC programming and CAD (Computer-Aided Design) work together well, you should plan carefully. First, you can use clear drawings to show how parts fit in the machine. Next, set up your workholding, which keeps the parts still, exactly how the design wants. Then, program the CNC machine to match what the CAD design says. Finally, test everything to make sure it works perfectly together.”}}]}