Have you ever wondered how to hold metal pieces securely while working on a lathe? Lathe workholding is essential for any project. It keeps your materials in place, ensuring smooth cuts and precise shapes.

Many people think that using a regular lathe is enough. But what if you could upgrade to a CNC (Computer Numerical Control) system? A CNC retrofit can change everything. It makes lathe workholding easier and more accurate.

Picture this: you’re in your workshop, excited to start a new project. But your metal piece keeps slipping. Frustrating, right? With the right workholding techniques and modern upgrades, you can avoid this problem altogether.

Did you know that even small changes can enhance your lathe’s performance? Retrofits can give you advanced control over your tools. This means better results and less wasted time.

Join us as we explore lathe workholding methods and the benefits of CNC retrofits. Your metalworking journey might just take a surprising turn toward greater precision!

Effective Lathe Workholding For Metal Lathe Cnc Retrofit

Lathe Workholding: Metal Lathe CNC Retrofit

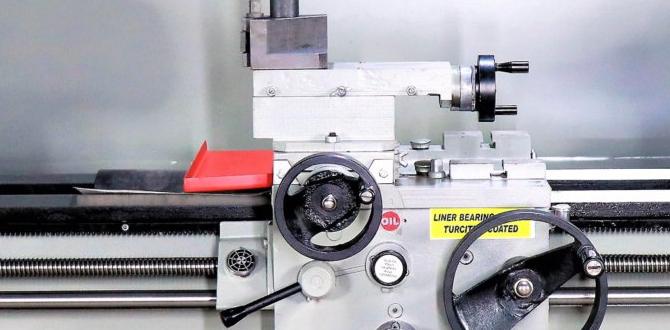

Do you know how important it is to hold metal parts securely on a lathe? Proper workholding techniques can improve your CNC retrofitting projects. You learn how to choose the right clamps, vices, and fixtures. These tools help keep your materials steady, leading to better cuts and finishes. Ever wondered how a tiny change can make a big difference in machine performance? Understanding lathe workholding can turn a good project into a great one!Types of Workholding Devices for Metal Lathes

Summary of various workholding devices: chucks, faceplates, and fixtures. Pros and cons of each device type.Metal lathes use various devices to hold materials steady. Let’s explore three common types: chucks, faceplates, and fixtures. Chucks grip circular parts tightly, making them perfect for round work; however, they can be tricky with odd shapes. Faceplates serve as a flat base for larger items but might wobble if not secured well. Lastly, fixtures are custom-made holders that keep things steady but can be pricey. Here’s a quick comparison:

| Device Type | Pros | Cons |

|---|---|---|

| Chucks | Tight grip on round parts | Not good for odd shapes |

| Faceplates | Great for large pieces | Can wobble if loose |

| Fixtures | Custom fit for any shape | Can be expensive |

Choosing the right device is like picking your favorite ice cream flavor. Everyone loves chocolate, but sometimes you crave vanilla!

Essential Features of Workholding Systems for CNC Retrofit

Critical characteristics to look for in workholding systems. The impact of flexibility and ease of use on CNC retrofitting success.Choosing a workholding system for your CNC retrofit can feel like picking toppings for pizza – so many choices! It’s vital to consider flexibility and ease of use. A system that adapts to different shapes and sizes makes life easier. Imagine juggling tools while trying to cut metal – not fun! Systems that let you quickly load and unload parts save time and frustration, turning your workshop into a smooth-running machine. Here’s a quick look at essential features:

| Feature | Importance |

|---|---|

| Flexibility | Handles various part shapes |

| Ease of Use | Reduces setup time |

| Durability | Lasts longer, withstands wear |

| Accessibility | Easier to load and unload |

With these features, you’ll be the pizza master of metalwork, cooking up precision pieces in no time!

Choosing the Right Workholding System for Your CNC Retrofit

Key considerations for selecting an appropriate system. How to assess compatibility with existing lathe setups.Picking the right workholding system is very important for a successful CNC retrofit. You need to think about three key points. First, consider how easy it is to use. Second, check if it fits well with your existing lathe setup. Lastly, see if it meets your project needs. A good fit can improve your work efficiency.

- Compatibility: Make sure the system works with your machine.

- User-Friendliness: Choose a system that is simple to operate.

- Project Requirements: Match the system to the jobs you’ll do.

What should I look for in a workholding system?

You need to think about easy operation, fit with your machine, and project goals. These points help you select the best workholding system.

Installation and Setup of CNC Workholding Devices

Steps for properly installing workholding systems on retrofitted CNC lathes. Common challenges and troubleshooting tips during setup.Installing CNC workholding devices on retrofitted lathes is crucial for smooth operation. Start by measuring the lathe’s specifications and ensuring all parts fit. Secure the workholding system with the right fasteners. Remember to calibrate your tools.

- Check for level alignment.

- Test the clamping pressure.

- Ensure there’s no vibration during operation.

If you face issues, check all connections and refer to the manual. Common challenges include misalignment and unstable setups. Adjust settings as needed for better performance.

What are common setup challenges for CNC lathes?

Common challenges include misalignment, incorrect tool settings, and vibrations. These can cause inaccuracies in machining. Proper checks and adjustments can solve many of these issues.

Maintenance and Care for Workholding Devices

Best practices for maintaining workholding devices for longevity and performance. Suggested inspection routines to ensure optimal functionality.Taking care of your workholding devices keeps them working well. Regular maintenance can help them last longer. Here are some best practices to follow:

- Keep everything clean. Dirt can cause problems.

- Check for wear and tear. Replace parts that look worn.

- Lubricate moving parts. This reduces friction.

- Inspect for rust. Rust can damage your tools.

Doing these checks will keep your lathe tools functional and strong.

How often should you inspect workholding devices?

You should check your devices at least once a month. If you use them daily, inspect them weekly. Regular checks prevent big problems.

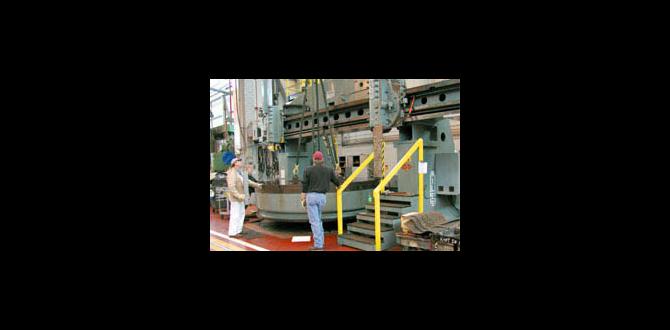

Advanced Workholding Techniques for Enhanced Precision

Techniques for improving precision and repeatability in CNC operations. Case studies showcasing successful implementation of advanced methods.Precision is key in CNC operations. Using advanced workholding techniques can greatly improve accuracy. Here are some top methods:

- Vacuum workholding: This method uses suction to hold parts securely.

- Magnetic clamps: These hold metal pieces firmly with magnetic force.

- Custom fixtures: These are tailored tools that fit specific parts for best results.

Successful implementations show big differences. A study revealed a 20% increase in production speed with vacuum systems. Another case found 10% reduction in rejects using custom fixtures. These methods not only improve precision but also save time and costs.

What are the benefits of advanced workholding techniques?

Advanced techniques like vacuum and magnetic clamps can boost productivity. They help with faster setups and less waste. This leads to higher profits and smoother operations.

Future Trends in Lathe Workholding Systems

Emerging technologies and innovations in workholding for CNC lathes. Predictions for the future landscape of lathe workholding solutions.New ideas are changing lathe workholding systems. Smart technology makes these systems faster and more accurate. Innovations like magnetic clamps and robotic arms will transform how we hold metal pieces. Manufacturers are excited about these changes. They expect better precision and speed. It is crucial for meeting high demands in production. Over the next few years, we will see exciting advancements in workholding tools. This will make jobs easier and improve the quality of work done on CNC lathes.

What innovations are expected in future lathe workholding systems?

The future of lathe workholding systems looks bright. Innovations will bring:

- Automation: Robots and automated systems will handle heavy lifting.

- Smart Sensors: These will help track the workpiece’s position.

- Adjustable Clamps: Many styles will fit different shapes and sizes.

Conclusion

In conclusion, lathe workholding is crucial for metal lathe projects, especially during CNC retrofits. Proper workholding secures your materials and improves accuracy. You can explore different workholding tools to find the best fit for your needs. Remember, a good setup leads to better results. We encourage you to dive deeper into this topic and experiment with your own projects!FAQs

Certainly! Here Are Five Questions Related To Lathe Workholding For Metal Lathes And Cnc Retrofits:Sure! When you work with a lathe, you need to hold the metal piece in place. This helps you shape it well. A good way to keep it steady is using special tools called chucks or clamps. These tools grip the metal tightly so it won’t move while you work on it. This makes your projects easier and helps you create better pieces.

Sure! Just ask me your question, and I’ll give you a short and clear answer.

What Are The Most Common Types Of Workholding Systems Used In Metal Lathes, And How Do They Differ In Terms Of Efficiency And Precision?In metal lathes, we often use three common workholding systems: chucks, collets, and faceplates. Chucks can hold lots of shapes, making them versatile. Collets hold round pieces tightly, which helps with precision. Faceplates allow you to attach bigger shapes but can be less precise. Each system can be more or less efficient based on your project needs.

Sure! Please ask your question, and I’ll be happy to help.

How Can A Cnc Retrofit Improve Workholding Capabilities In An Existing Manual Lathe Setup?A CNC retrofit changes your old lathe so it can hold parts better. You can use special tools that grip items tightly. This helps make sure your pieces don’t move while you work. With a CNC upgrade, you can also make more shapes easier and faster. Overall, it makes your work more precise and smooth!

Sure! Please provide the question you’d like me to answer.

What Factors Should Be Considered When Selecting Workholding Accessories, Such As Chucks Or Vises, For A Metal Lathe Project?When you choose workholding accessories for a metal lathe, think about the size of the piece you are working on. Make sure the accessory can hold it tight but not too tight. Consider the shape, too; some pieces are round, and others are square. Also, check how easy it is to use the accessory. You want something that helps you work safely and easily.

Sure! Please provide the question you’d like me to answer, and I’ll do my best to help you.

What Are Some Best Practices For Securing Irregularly Shaped Or Non-Conventional Workpieces During Lathe Operations?To secure odd-shaped pieces on a lathe, you should use a strong clamp or vise. Make sure the piece is tight so it doesn’t move. You can add extra supports, like wood blocks, to help hold it still. Always check everything before you start working. Safety first!

Sure! Please provide the question you’d like me to answer, and I’ll keep it simple and clear!

How Do Advancements In Cnc Technology Influence The Development Of New Workholding Solutions For Metal Lathes?Advancements in CNC (Computer Numerical Control) technology help us create better tools for holding metal pieces. These new tools are smarter and more precise. They let us work faster and make fewer mistakes. When we have better workholding options, we can make more interesting shapes and designs. This makes our projects easier and more fun!