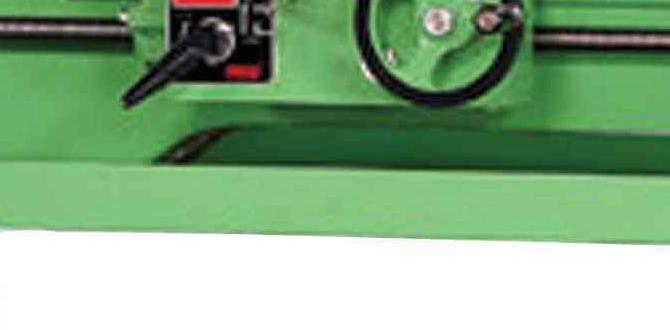

Have you ever watched a metal lathe in action? It’s mesmerizing! The way the machine spins and shapes metal can seem almost magical. But there’s more to it than just spinning metal. One key part that makes this magic possible is the compound rest.

The compound rest helps hold the workpiece firmly while the lathe does its job. This means you can create precise shapes and cuts easily. Imagine making a perfect handle for your favorite tool. That’s the power of great workholding!

Many new machinists overlook the importance of the lathe workholding setup. Yet, it can make or break your project. Using the right tools and methods can save time and effort. It also ensures safety while you work.

Let’s dive into the world of lathe workholding and discover how the compound rest can enhance your metalworking skills. Whether you are a beginner or a seasoned pro, you will find something valuable. Ready to transform your projects? Let’s get started!

Comprehensive Guide To Lathe Workholding: Metal Lathe Compound Rest

Lathe Workholding: Understanding Metal Lathe Compound Rest

Lathe workholding is vital for precision in metalworking. The compound rest helps position the tool for accurate cuts. Are you curious how this improves your project? With the compound rest, you can easily adjust angles and depths. This adds versatility to your machine. Did you know that mastering this skill can enhance your metalworking projects? Learning to use the compound rest can make your work easier and more rewarding, opening new possibilities in your crafting journey.Understanding the Basics of Lathe Workholding

Definition of workholding in lathe operations. Importance of precision and stability in metalworking.Workholding in lathe operations means keeping the metal piece in place while it spins. Think of it like holding a warm, wiggly pancake while trying to cut it. You need precision and stability to get a neat result! A shaky setup could turn your masterpiece into a scrambled mess. The right tools help ensure everything stays steady, making sure your project flows smoothly without hiccups.

| Feature | Importance |

|---|---|

| Precision | Helps achieve desired shapes without errors. |

| Stability | Keeps the workpiece secure, avoiding accidents. |

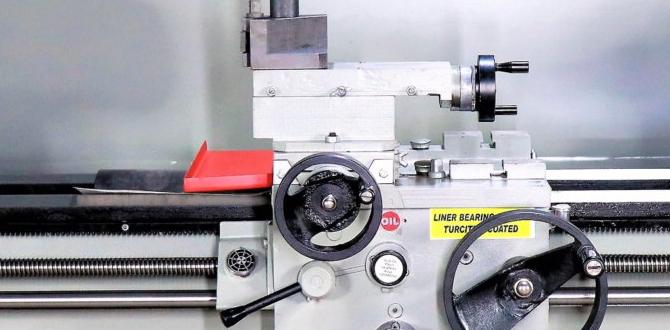

The Role of the Compound Rest in Metal Lathes

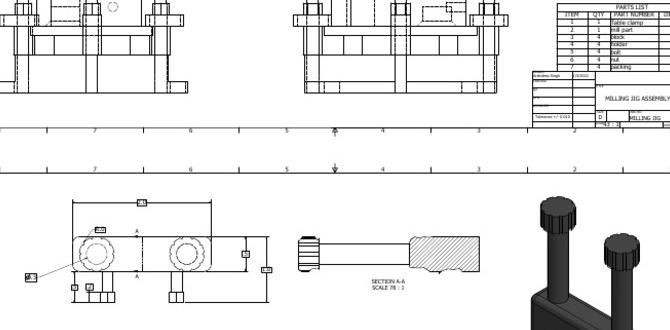

Explanation of the compound rest functionality. Key components and their purposes.The compound rest is an important part of a metal lathe. It helps position the cutting tool accurately. This makes sure the metal is shaped just right. Key components of the compound rest include:

- Swivel Base: Allows the rest to turn for different angles.

- Tool Post: Holds the cutting tool in place.

- Handwheel: Lets the user move the tool smoothly.

With these components, the compound rest helps create precise cuts. This leads to high-quality metal parts.

What is the purpose of the compound rest?

The compound rest is crucial for precise cuts on a lathe. It allows for easy adjustments, helping create accurate metal shapes.

Setting Up the Compound Rest: Step-by-Step Guide

Detailed instructions on adjusting the compound rest. Tips for aligning workpieces accurately.Begin by ensuring your lathe is secure. Next, carefully loosen the compound rest lock. Adjust the rest to the desired angle, often 29 to 30 degrees for cutting. Tighten the lock gently. To align workpieces accurately:

- Use a center finder to locate the workpiece center.

- Check the alignment by spinning the workpiece; it should not wobble.

- Adjust as needed for perfect alignment.

Regular checks will improve your work quality. Practice makes perfect in lathe workholding.

Why is aligning workpieces important?

Aligning workpieces ensures smooth cuts and reduces errors. It saves time and improves the quality of your projects.

Common Challenges and Solutions in Lathe Workholding

Typical problems faced during lathe operations. Practical solutions to enhance workholding effectiveness.Many users face issues during lathe operations. Some common problems include

- workpiece slipping out of the chuck

- part vibration

- difficulty in setting the cut depth

To improve workholding, consider these solutions:

- Use a quality chuck.

- Ensure proper alignment.

- Adjust the compound rest carefully.

Following these tips can significantly enhance your lathe workholding experience. Remember, a well-set lathe means smoother cuts and better results!

What are common problems with lathe workholding?

Common problems include slipping workpieces, vibrations, and difficulty in adjusting cut depth.

How can I improve lathe workholding?

You can improve workholding by using quality chucks, ensuring proper alignment, and adjusting the compound rest carefully.

Best Practices for Maintaining Your Compound Rest

Routine maintenance tips for optimal performance. Signs that your compound rest may require servicing.Keeping your compound rest in tip-top shape can be a breeze with some care! Regularly cleaning it ensures no gunk builds up to spoil your fun. Lubricate moving parts to keep everything running smoother than a buttered slide. If your lathe starts to act weird, like producing strange noises or showing wobbles, it might be time for a check-up. Remember, a happy compound rest equals happy lathe work!

| Maintenance Tips | Signs of Service Needed |

|---|---|

| Clean regularly | Strange noises |

| Lubricate moving parts | Wobbly movements |

| Inspect for wear | Inconsistent cuts |

Advanced Techniques for Enhanced Workholding Efficiency

Innovative setups and modifications for complex projects. Autodesk Fusion 360 as a design tool for custom fixtures.Finding new ways to hold workpieces can improve your projects. Using custom fixtures allows you to create unique setups. Autodesk Fusion 360 is a great tool for designing these fixtures. It helps you visualize your projects before starting. Here are a few innovative options:

- Adjustable clamps that fit different shapes.

- Magnetic mounts for quick changes.

- Height adjustment features for precision.

These upgrades can make your lathe workholding more efficient and your work easier.

What are advanced setups in lathe workholding?

Advanced setups allow for greater precision and flexibility. They help tackle complex tasks with ease.

Real-world Applications and Case Studies

Examples of industries utilizing compound rests effectively. Success stories showcasing improved precision and efficiency.Many industries, from aerospace to automotive, use compound rests for their metal lathes. For example, aerospace companies need precise parts to keep planes flying smoothly. One case involved a car manufacturing plant that improved productivity by 30% after adopting new workholding techniques. That’s like going from a bicycle to a rocket! Check out the table below for more fun facts:

| Industry | Improvement |

|---|---|

| Aerospace | Increased Precision |

| Automotive | 30% Faster Production |

| Manufacturing | Enhanced Efficiency |

Success stories show how compound rests can make a big difference. With improved tools, even a hamster could make precise parts—if only we could teach them how!

Future Trends in Lathe Workholding Technology

Emerging technologies and materials in lathe workholding. Predictions for the future of metal lathe operations.Exciting changes are on the horizon for lathe workholding technology! Think about smart materials that adjust to grip differently. Machines of the future may even come with sensors. These sensors could make sure everything stays secure, like a dedicated clown holding your favorite balloon! Experts predict a rise in automated systems that enhance productivity and precision. Soon, metal lathe operations might feel like a science fiction movie, minus the aliens, of course!

| Emerging Technologies | Future Predictions |

|---|---|

| Smart Materials | Improved Accuracy |

| Sensors for Grip | Increased Automation |

| AI Integration | Faster Production Times |

Conclusion

In summary, the lathe compound rest helps you hold and shape metal securely. It’s important for precise cutting. By learning how to use it properly, you can improve your skills. Remember to practice regularly and explore more resources online. This way, you can become more confident in your lathe workholding techniques. Let’s start creating amazing projects together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Regarding The Compound Rest On A Metal Lathe:The compound rest on a metal lathe helps you hold and move your work piece. You can adjust it for different angles. This makes it easier to cut shapes like chamfers or grooves. Always check the setup before you start working. It keeps everything safe and neat!

Sure! Just give me the question, and I’ll provide a short and simple answer for you.

What Is The Primary Function Of The Compound Rest In A Metal Lathe, And How Does It Affect Workholding During Machining Operations?The compound rest on a metal lathe helps you tilt and move the cutting tool easily. This makes it easier to carve different shapes in the metal. By adjusting the compound rest, you can hold the workpiece better while cutting. This keeps your work more accurate and neat during machining.

How Can The Positioning And Adjustment Of The Compound Rest Enhance The Accuracy And Precision Of Cut On A Metal Lathe?When you position and adjust the compound rest on a metal lathe, you can make better cuts. This part helps change the angle of the tool. Getting the angle right means you can cut more smoothly and evenly. With careful adjustments, you reduce mistakes and get a more perfect shape. This makes your finished pieces look nice and fit better!

What Are The Common Techniques For Securing Workpieces In The Compound Rest, And How Do They Differ Based On The Type Of Machining Operation?To hold workpieces on a compound rest, we can use clamps, vices, or chucks. Clamps squeeze the piece tight. Vices have jaws to grip it securely. Chucks are special tools that grab the workpiece from all sides. Each method suits different tasks; for example, chucks work best for round pieces, while vices are great for flat ones.

What Are The Best Practices For Setting Up The Compound Rest To Achieve Optimal Cutting Angles For Complicated Shapes Or Threading Tasks?To set up the compound rest, first, make sure your machine is steady. You need to adjust the angle of the tool carefully. Use a protractor to check your angles. Always double-check your settings before starting. This way, you can cut shapes and threads more easily and accurately.

How Do Different Types Of Tailstocks And Tool Holders Interact With The Compound Rest To Improve Workholding Stability In Lathe Operations?Different tailstocks and tool holders help hold parts firmly on a lathe. When you adjust the compound rest, they fit together better and keep pieces steady. For example, a fixed tailstock holds things tightly, while a movable one can support longer items. Good tool holders can keep your cutting tools in place, which makes your work more accurate and safer. This way, you can make better shapes and cuts!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Regarding The Compound Rest On A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest on a metal lathe helps you hold and move your work piece. You can adjust it for different angles. This makes it easier to cut shapes like chamfers or grooves. Always check the setup before you start working. It keeps everything safe and neat!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question, and I’ll provide a short and simple answer for you.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of The Compound Rest In A Metal Lathe, And How Does It Affect Workholding During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest on a metal lathe helps you tilt and move the cutting tool easily. This makes it easier to carve different shapes in the metal. By adjusting the compound rest, you can hold the workpiece better while cutting. This keeps your work more accurate and neat during machining.”}},{“@type”: “Question”,”name”: “How Can The Positioning And Adjustment Of The Compound Rest Enhance The Accuracy And Precision Of Cut On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you position and adjust the compound rest on a metal lathe, you can make better cuts. This part helps change the angle of the tool. Getting the angle right means you can cut more smoothly and evenly. With careful adjustments, you reduce mistakes and get a more perfect shape. This makes your finished pieces look nice and fit better!”}},{“@type”: “Question”,”name”: “What Are The Common Techniques For Securing Workpieces In The Compound Rest, And How Do They Differ Based On The Type Of Machining Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To hold workpieces on a compound rest, we can use clamps, vices, or chucks. Clamps squeeze the piece tight. Vices have jaws to grip it securely. Chucks are special tools that grab the workpiece from all sides. Each method suits different tasks; for example, chucks work best for round pieces, while vices are great for flat ones.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Setting Up The Compound Rest To Achieve Optimal Cutting Angles For Complicated Shapes Or Threading Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the compound rest, first, make sure your machine is steady. You need to adjust the angle of the tool carefully. Use a protractor to check your angles. Always double-check your settings before starting. This way, you can cut shapes and threads more easily and accurately.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Tailstocks And Tool Holders Interact With The Compound Rest To Improve Workholding Stability In Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different tailstocks and tool holders help hold parts firmly on a lathe. When you adjust the compound rest, they fit together better and keep pieces steady. For example, a fixed tailstock holds things tightly, while a movable one can support longer items. Good tool holders can keep your cutting tools in place, which makes your work more accurate and safer. This way, you can make better shapes and cuts!”}}]}