Have you ever wondered how metal pieces are turned into beautiful shapes? A lathe does this magic! It spins a metal piece and helps create all kinds of things, from toy parts to car engines.

But what makes a lathe work smoothly? The answer lies in lathe workholding. This ensures that the metal stays in place while it’s being shaped. Imagine trying to ride a bike with a wobbly wheel! That’s what it’s like without proper workholding.

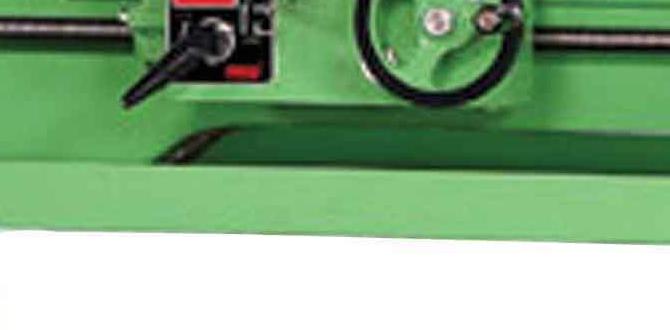

Another cool part of using a lathe is the control panel. This is where the fun begins! You can adjust speeds and settings to get the perfect cut. If you think of it like a video game, it’s a way to level up your crafting skills.

In this article, we will explore lathe workholding and the control panel. We’ll show you how these elements work together to create amazing things. Get ready to dive into the fascinating world of lathes!

Lathe Workholding: Mastering Metal Lathe Control Panel Techniques Introduction To Lathe Workholding Lathe Workholding Is Crucial For Achieving Precision And Accuracy In Metalworking Projects. Effective Workholding Ensures That The Workpiece Is Securely Fastened, Allowing The Metal Lathe To Perform Optimally. The Control Panel Of The Metal Lathe Plays A Significant Role In Overseeing Various Operational Aspects Such As Speed, Feed Rate, And Tool Position. Understanding How To Utilize These Components Effectively Is Essential For Anyone Looking To Excel In Machining Processes. Importance Of Workholding In Metal Lathes Workholding Refers To The Methods And Tools Used To Secure A Workpiece During Machining. For Metal Lathes, Proper Workholding Is Vital For Several Reasons: 1. **Precision**: Properly Secured Workpieces Minimize Movement, Which Is Crucial For Producing Accurate Dimensions. 2. **Safety**: Clamped Workpieces Reduce The Risk Of Accidents Due To Shifting During Operation. 3. **Efficiency**: Effective Workholding Techniques Enable Quicker Setups And Reduce Downtime. Types Of Workholding Devices Several Devices Are Utilized For Workholding On Metal Lathes, Including: – **Chucks**: These Are The Most Common Devices, Allowing For A Firm Grip On The Workpiece. Three-Jaw And Four-Jaw Chucks Are Widely Used, Each Suited For Different Types Of Workpieces. – **Collets**: They Provide High Precision For Cylindrical Parts And Are Adjustable To Accommodate Various Sizes. – **Faceplates**: Ideal For Holding Irregularly Shaped Workpieces, These Allow For Versatility In Clamping. – **Vices And Fixtures**: They Provide Additional Stability And Support For Specific Machining Tasks. Utilizing The Metal Lathe Control Panel The Metal Lathe’S Control Panel Is The Operator’S Interface, Featuring Various Controls That Govern The Machine’S Operation. Key Components Typically Found On The Control Panel Include: – **Speed Control**: Adjusts The Spindle Speed To Optimize Cutting Conditions Based On Material And Tooling. – **Feed Rate Adjustment**: Controls How Fast The Cutting Tool Moves Along The Workpiece, Influencing Surface Finish And Material Removal. – **Emergency Stops**: Essential For Ensuring Safety, These Allow For Quick Shutdowns In Emergency Situations. – **Programmable Settings**: Some Advanced Lathes Feature Cnc Controls Enabling Programmable Machining Cycles For Higher Efficiency. Best Practices For Metal Lathe Workholding 1. **Check Workpiece Compatibility**: Ensure The Chosen Workholding Device Fits The Workpiece Accurately. 2. **Regular Maintenance**: Keep The Lathe, Control Panel, And Workholding Devices In Good Condition To Prevent Machine Failures. 3. **Test Setup**: Before Full Production, Conduct Test Runs To Verify The Setup’S Integrity. 4. **Safety Protocols**: Always Adhere To Safety Procedures And Wear Appropriate Protective Gear During Lathe Operations. Conclusion Mastering Lathe Workholding And The Use Of A Metal Lathe Control Panel Is Essential For Any Metalsmith Or Machinist. By Understanding The Types Of Workholding Devices Available And Efficiently Utilizing The Control Panel, Operators Can Enhance Productivity And Ensure Precision In Their Machining Tasks. Investing Time In Learning These Techniques Will Lead To Higher-Quality Work And Safer Machining Practices.

Lathe Workholding Metal Lathe Control Panel

Lathe workholding is key for precise metal turning. A well-designed control panel enhances user control, making it easier to adjust settings. Have you ever wondered how a simple twist can produce complex shapes? Understanding the features of a lathe control panel can help beginner and experienced machinists alike. Consider how each button serves a purpose, ensuring smooth operation while creating parts that fit together perfectly. Mastering these tools opens doors to endless possibilities in metalworking!Importance of Workholding in Lathe Operations

Explanation of workholding and its significance. Common workholding methods and fixtures used in metal lathes.Workholding is how we hold a piece of metal in place on a lathe. It is very important because it keeps the metal steady while we shape it. If the metal moves, the result won’t be right. Common workholding methods include:

- Chucks: These grip the metal tightly.

- Collets: These hold smaller pieces well.

- Jigs: These help position the metal perfectly.

Using the right workholding system helps produce accurate and high-quality work.

Why is workholding important for lathe operations?

Workholding keeps the metal secure, leading to better cuts and safer operations.

Key Components of a Metal Lathe Control Panel

Description of essential control panel elements (buttons, knobs, displays). Functions of each component in lathe operations.The control panel of a metal lathe is like the cockpit of an airplane—full of crucial buttons, knobs, and displays that keep everything running smoothly. Each component has its own job. The power button turns the lathe on, while speed knobs adjust how fast it spins. Displays show important information like speed and feed rate, ensuring you don’t make your project go *kaput*! Here’s a quick look at these key parts:

| Component | Function |

|---|---|

| Power Button | Turns the lathe on/off. |

| Speed Knob | Changes the rotation speed. |

| Feed Rate Control | Sets how fast the tool moves. |

| Emergency Stop | Shuts everything down in a hurry. |

| Display Screen | Shows speed and other readings. |

With these elements working together, the lathe can create everything from intricate parts to beautiful sculptures. Each twist, turn, and click counts—so don’t forget to enjoy the ride!

Setting Up Your Control Panel for Optimal Performance

Stepbystep guide to calibrating the control panel. Tips for ensuring safety and efficiency during setup.Getting your control panel ready is essential for smooth lathe work. First, check the connections. Plug everything in tightly. Next, power on the machine and make sure the lights shine like stars! Then, adjust the settings according to your task. Remember, safety first. Always wear goggles—you don’t want metal shavings in your eye! Below is a simple checklist to help you:

| Step | Action | Tip |

|---|---|---|

| 1 | Check connections | Ensure everything is snug |

| 2 | Power on | Watch for indicator lights |

| 3 | Calibrate settings | Double-check numbers! |

Follow these steps to keep your lathe buzzing smoothly. Happy turning!

Common Challenges with Lathe Control Panels

Identification of potential issues users may face. Solutions and troubleshooting techniques.Using a lathe control panel can be tricky. Users often face issues like incorrect settings, unresponsive buttons, or error messages. These problems can slow down work or lead to mistakes. Here are some simple solutions:

- Check connections and make sure everything is plugged in.

- Reset the control panel if buttons don’t respond.

- Consult the manual for error codes.

Frequent maintenance helps avoid these challenges. Keeping everything clean and updated is smart. With a little care, you can keep your lathe running smoothly!

What are some common problems with lathe control panels?

Common problems include unresponsive buttons, error messages, and incorrect settings. Many users face these issues when operating their lathes.

How can users troubleshoot these issues?

Users can troubleshoot by checking connections, resetting the panel, and reviewing the manual for error codes.

Maintenance Tips for Longevity of Workholding and Control Panels

Routine maintenance practices for lathe workholding systems. Best practices for ensuring the control panel functions effectively.To keep your lathe workholding systems and control panels happy, follow some simple maintenance tips. Regularly check for wear and tear; it’s like giving your lathe a health check-up. Clean any dust or chips with a soft brush. You wouldn’t want them to throw a tantrum! Always keep the control panel dry and free from grime. Remember, a clean panel is a happy panel! Here’s a quick table for best practices:

| Maintenance Task | Frequency |

|---|---|

| Inspect for wear | Weekly |

| Clean surfaces | Daily |

| Check connections | Monthly |

By following these tips, you ensure your tool stays in great shape. Remember, happy tools make for happy projects!

Case Studies: Success Stories in Lathe Workholding

Examples of industries that successfully implemented workholding solutions. Analysis of outcomes and improvements in production efficiency.Many industries have found success using smart workholding solutions. Here are a few examples:

- Automobile Industry: Workholding helped speed up car part production, reducing time by 30%.

- Aerospace: Companies improved safety and precision, leading to fewer errors.

- Manufacturing: Efficient setups allowed for higher output, boosting profits.

These changes show how better workholding can make production faster and safer. Adopting these methods leads to success and growth.

What are some benefits of workholding solutions?

Efficient production time and improved safety are two major benefits. These solutions help companies to make more products quickly and with fewer mistakes.

The Future of Metal Lathe Technology

Trends shaping the evolution of workholding and control panels. Predictions for advancements in metal lathe technology.New trends are changing how we use metal lathes. Smart technology is one big change. This includes better workholding systems and advanced control panels. These tools help workers be more accurate and save time. Experts predict more automation and user-friendly interfaces in the future. This will make metal lathes easier to use. They may even become more connected, allowing for remote operation.

- Greater precision through advanced sensors.

- User-friendly designs for faster learning.

- Integration with other machines for better workflow.

What advancements can we expect in metal lathe technology?

In the coming years, metal lathe technology will focus on more automation and smart controls. These updates will boost efficiency and accuracy in manufacturing.

Conclusion

In conclusion, understanding lathe workholding and the metal lathe control panel is essential for safe and efficient machining. You can securely hold your workpiece using various methods. Familiarizing yourself with the control panel helps you operate the lathe confidently. To improve your skills, practice with your lathe and read more about different techniques. Let’s get crafting!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding For Metal Lathe Control Panels:I can help with that! Here’s my answer: When working on a metal lathe, we need to hold the metal pieces safely. This is called workholding. There are different tools for workholding, like chucks and clamps. These tools keep the metal steady as we cut or shape it. It helps us make better and safer projects!

Sure! I can help with that. Please provide the question you want me to answer.

What Are The Primary Types Of Workholding Devices Used On Metal Lathes, And How Do They Affect Machining Accuracy?The main types of workholding devices on metal lathes are chucks and collets. A chuck holds the metal piece tightly using jaws. Collets are like clamps that grip the piece more evenly. These devices help keep the metal steady while we work on it, making the cuts more accurate. When the metal is secure, we can create better shapes and sizes.

How Do Digital Control Panels Improve The Efficiency And Precision Of Lathe Workholding Setups?Digital control panels help us use lathes better. They show clear information about the tools and settings. With these panels, we can make quick changes and set up the lathe faster. This means our work is more precise, and we waste less time. Overall, digital controls make our work easier and more accurate!

What Safety Features Should Be Integrated Into A Control Panel For Metal Lathes To Ensure Safe Workholding Practices?To keep you safe when using a metal lathe, the control panel should have some important safety features. First, it should have an emergency stop button you can reach easily. This stops the machine quickly if something goes wrong. Next, there should be clear labels and lights that show when the machine is running. Lastly, you should have a safety guard to protect your hands while working. These features help everyone stay safe while using the lathe.

How Can The Design Of The Control Panel Impact The Ease Of Adjusting Workholding Setups During Machining Operations?The design of the control panel makes it easier for you to change workholding setups. If the buttons are clear and simple, you can adjust things quickly. A good layout lets you see what you need without confusion. When you can work fast, you save time and avoid mistakes. This way, you can focus on making great parts!

What Considerations Should Be Taken When Selecting Workholding Fixtures For Different Materials And Lathe Operations On A Control Panel?When choosing workholding fixtures for a control panel, you should think about the material you’re using. Some materials are soft, while others are hard. You want to make sure the fixture holds the material tightly but won’t damage it. Also, consider the shape of the part. It should fit well in the fixture so it stays in place while the lathe works. Lastly, think about how heavy the part is; you want a strong fixture that won’t tip over.