Have you ever wondered how metal parts are shaped perfectly? It all starts with lathe workholding. This clever technique helps secure materials while they are being worked on. Think of it like a strong grip when you hold a pencil. Without a good hold, the results could be messy.

Metal lathes are amazing machines that spin materials at high speeds. But what makes them really special is their drive system. This system powers the lathe and gives it control. Imagine trying to carve a statue from clay, but the clay keeps slipping away. Frustrating, right? That’s why the right drive system is so important.

In this article, we will explore how lathe workholding and the drive system work together. You’ll learn why they are vital for safe and accurate metalworking. Get ready to dive into a world where precision meets creativity!

Lathe Workholding: Metal Lathe Drive System Explained

Lathe Workholding Metal Lathe Drive System

Lathe workholding is vital for precision in metalworking. Proper workholding secures the workpiece firmly, ensuring accuracy and safety during operation. A metal lathe drive system powers the lathe, enabling smooth rotation of materials. Did you know that improper setup could lead to damaged parts or even accidents? Understanding these systems helps you achieve better results in your projects. With the right techniques, you can transform raw metal into amazing creations!What is Lathe Workholding?

Definition and importance of workholding in lathe operations. Types of workholding systems and their applications.Workholding keeps the material stable while the lathe turns it. This is important for safety and precision. Different systems help secure various shapes and sizes of materials used in lathe work. Some common types of workholding include:

- Chucks: For holding round objects.

- Collets: For small, precise parts.

- Vices: For flat and irregular shapes.

- Faceplates: For larger pieces.

Each type has its own uses, making lathe operations efficient and accurate.

Why is workholding important in lathe operations?

Workholding is crucial for safety, accuracy, and achieving the best results in machining.

Types of Workholding Solutions for Metal Lathes

Comparison of different workholding solutions such as chucks, collets, and fixtures. Advantages and disadvantages of each type in various machining scenarios.When working with metal lathes, choosing the right workholding solution is key. Here are three popular options: chucks, collets, and fixtures. Each type has its ups and downs, making them fit for different jobs.

- Chucks: Great for holding large pieces. They are easy to use but not very precise.

- Collets: Perfect for smaller parts with high accuracy. However, they can be costly.

- Fixtures: Offer the best stability. They are custom-made but may require more time to set up.

Choosing the right option can affect your project outcome. Think about your piece size and precision needs. Each solution has its place in metalworking.

What is the best workholding solution for beginners?

The best starting point for beginners is a chuck. It is simple to use and provides solid support for various workpieces.

Factors Influencing Workholding Selection

Key considerations in choosing a workholding system: material, shape, and size of the workpiece. The impact of production volume and complexity on workholding choices.Selecting the right workholding system can feel like a puzzle, but it’s easier than it sounds! First, consider the material; metals, for example, behave differently. Next, think about the shape and size of your workpiece—square or round? They need different grips. Lastly, your production volume matters: high volume means simpler setups, while complex projects may need special tools. More questions? Don’t worry, choosing the right fit just takes a little practice!

| Factor | Consideration |

|---|---|

| Material | Different metals require different holding methods |

| Shape | Round and square shapes need specific grips |

| Size | Size affects the type of clamps or fixtures used |

| Volume | High volume favors simple setups |

| Complexity | Complex projects may need custom solutions |

Best Practices for Effective Workholding in Metal Lathes

Techniques for securely clamping workpieces to minimize errors and improve safety. Regular maintenance and inspection tips for workholding devices.Clamping workpieces securely in metal lathes is vital for safe, precise machining. Use the right clamps or vises to hold pieces firmly. This reduces mistakes and keeps everyone safe. Regularly check your workholding devices. Ensure they are free of dirt and wear. Here are some tips:

- Inspect clamps for tightness regularly.

- Clean debris from surfaces often.

- Replace worn parts quickly.

Proper maintenance helps avoid accidents and prolongs your tools’ life. Remember, safety first!

What makes workholding safe in metal lathes?

Using the right clamps, regular inspections, and proper maintenance are key steps to safe workholding. Ensure everything is tight and clean to prevent errors.

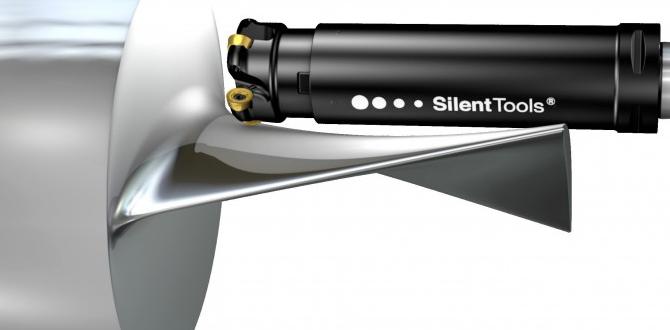

Innovations in Metal Lathe Drive Systems

Emerging technologies and designs that enhance drive system efficiency. The role of automation and smart technology in modern lathe workholding.New designs and technologies are changing how metal lathes work. These improvements help machines run better and faster. Automation plays an important role here. It lets machines work on their own, which saves time. Smart tech helps users control lathes easily. As a result, makers can focus on creating great products. Together, these changes make lathe workholding more efficient and reliable.

What are some advancements in lathe drive systems?

Emerging technologies include automation, smart controls, and better materials. These help machines work faster and save energy.

Key Features of Modern Lathe Drive Systems:

- Enhanced efficiency through automation

- Smart sensors for precision control

- Stronger materials for durability

Common Challenges in Lathe Workholding and Solutions

Identification of typical problems such as vibration and workpiece misalignment. Recommended solutions and troubleshooting tips for overcoming these challenges.Working with a lathe can feel like trying to juggle while riding a unicycle. Many face challenges like vibration or workpiece misalignment. Vibration can make your projects noisy and wobbly, like a dance party gone wrong! Misalignment leads to uneven cuts, not what you want on your masterpiece. A good fix is tightening your clamping method and using better supports. Always check your setup; sometimes a quick adjustment can fix it all. Below are simple tips to keep your lathe running smooth:

| Problem | Solution |

|---|---|

| Vibration | Tighten clamps and check for worn parts |

| Misalignment | Adjust the workpiece and check the bed level |

Future Trends in Lathe Workholding and Drive Systems

Predictions on the evolution of materials and designs in workholding mechanisms. The influence of Industry 4.0 on the future of metal lathe operations.Many experts believe that future lathe workholding will focus on lighter, stronger materials. This change could lead to faster production. Also, designs will improve, making them more user-friendly and efficient. As we enter the age of Industry 4.0, machines will connect and communicate better. This means more automation and smart systems in metal lathe operations. It will help operators work quicker and with fewer mistakes.

What is the impact of Industry 4.0 on lathe workholding?

Industry 4.0 will create smarter machines that share information. This will help workers improve speed and quality in lathe operations.

Key Predictions:

- New materials will enhance strength and reduce weight.

- Designs will focus on ease of use and automation.

- Improved connectivity will lead to better coordination in workflow.

Conclusion

In summary, understanding lathe workholding and metal lathe drive systems is essential for successful machining. Properly securing your metal workpiece ensures accuracy and safety. Exploring different drive systems can help you choose the best one for your projects. We encourage you to read more and practice these techniques to improve your skills and confidence with lathes.FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Drive Systems:Sure! A lathe is a machine that makes round things from metal or wood. We use workholding to keep the piece still while it spins. Drive systems help the lathe turn the piece really fast. This way, we can shape it into what we want. It’s important for making strong and smooth items!

Sure! Just ask your question, and I’ll provide a simple answer for you.

What Are The Different Types Of Workholding Devices Used In Metal Lathes, And How Do They Affect Machining Accuracy?Metal lathes use several types of workholding devices. One common type is a chuck, which holds the metal tightly. Another type is a collet, which hugs the metal and keeps it steady. A steady rest helps support long pieces of metal. These devices keep the metal in place, which helps make sure we cut it accurately. If the metal moves, it can mess up our work!

How Do Drive Systems In Metal Lathes Vary Between Manual And Cnc Lathes, And What Implications Do These Differences Have On Productivity?Manual lathes use simple controls that you operate by hand. You move the parts yourself to shape the metal. CNC lathes, or Computer Numerical Control lathes, have computers that automatically control the movements. This means CNC lathes can work faster and make more precise pieces without much help from you. Because of this, CNC lathes can increase productivity, letting you create more items in less time.

What Factors Should Be Considered When Selecting A Workholding Method For A Specific Machining Operation On A Lathe?When picking a workholding method for a lathe, you should think about the shape of the piece you’re working on. You also need to consider how heavy it is and how tight it needs to be held. The tools you have and how easy it is to set everything up are important too. Finally, think about how long the project will take and if you need to move the piece easily.

How Does The Choice Of Spindle Speed And Torque In A Metal Lathe Drive System Influence The Performance And Finish Of The Machined Part?Spindle speed is how fast the metal lathe spins. If you use a high speed, the part can get a smooth finish but might be hard to control. Torque is the force that helps cut the metal. Higher torque helps make deeper cuts but can slow down the spin. Good choices for speed and torque help you make better parts with nice surfaces.

What Are Some Common Challenges Associated With Workholding In Lathe Operations, And What Techniques Can Be Employed To Overcome Them?In lathe operations, we often face challenges like the workpiece slipping or not being held tight enough. This can lead to mistakes in our work. To overcome these problems, we can use better clamps or adjust our setup carefully. We can also check the tightness of our tools regularly to make sure everything stays in place.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Drive Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that makes round things from metal or wood. We use workholding to keep the piece still while it spins. Drive systems help the lathe turn the piece really fast. This way, we can shape it into what we want. It’s important for making strong and smooth items!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll provide a simple answer for you.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Workholding Devices Used In Metal Lathes, And How Do They Affect Machining Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes use several types of workholding devices. One common type is a chuck, which holds the metal tightly. Another type is a collet, which hugs the metal and keeps it steady. A steady rest helps support long pieces of metal. These devices keep the metal in place, which helps make sure we cut it accurately. If the metal moves, it can mess up our work!”}},{“@type”: “Question”,”name”: “How Do Drive Systems In Metal Lathes Vary Between Manual And Cnc Lathes, And What Implications Do These Differences Have On Productivity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manual lathes use simple controls that you operate by hand. You move the parts yourself to shape the metal. CNC lathes, or Computer Numerical Control lathes, have computers that automatically control the movements. This means CNC lathes can work faster and make more precise pieces without much help from you. Because of this, CNC lathes can increase productivity, letting you create more items in less time.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Workholding Method For A Specific Machining Operation On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a workholding method for a lathe, you should think about the shape of the piece you’re working on. You also need to consider how heavy it is and how tight it needs to be held. The tools you have and how easy it is to set everything up are important too. Finally, think about how long the project will take and if you need to move the piece easily.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Spindle Speed And Torque In A Metal Lathe Drive System Influence The Performance And Finish Of The Machined Part?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Spindle speed is how fast the metal lathe spins. If you use a high speed, the part can get a smooth finish but might be hard to control. Torque is the force that helps cut the metal. Higher torque helps make deeper cuts but can slow down the spin. Good choices for speed and torque help you make better parts with nice surfaces.”}},{“@type”: “Question”,”name”: “What Are Some Common Challenges Associated With Workholding In Lathe Operations, And What Techniques Can Be Employed To Overcome Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In lathe operations, we often face challenges like the workpiece slipping or not being held tight enough. This can lead to mistakes in our work. To overcome these problems, we can use better clamps or adjust our setup carefully. We can also check the tightness of our tools regularly to make sure everything stays in place.”}}]}