Essential Lathe Workholding Techniques For Metal Lathe Dro

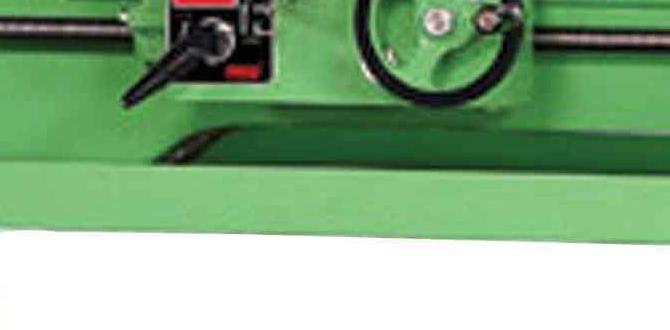

Lathe Workholding for Metal Lathes

Lathe workholding is crucial for precision in metalworking. A solid grip ensures you can craft exact pieces. Have you ever tried to cut metal that keeps slipping? That’s where great workholding comes in! It stops your material from moving and helps create accurate shapes. A Digital Readout (DRO) system boosts accuracy by showing exact measurements. With the right techniques, even beginners can achieve professional-level results. Discover the power of proper lathe workholding and watch your projects transform!Understanding Workholding in Lathe Operations

Definition and importance of workholding in lathe operations. Types of workholding devices and their applications.Workholding is all about keeping your material secure while it spins on a lathe. It’s super important because a loose piece can fly off like a frisbee on a windy day! There are various devices for this task. For example, chucks hold round items, while collets can grip smaller parts. Each type fits different needs and materials, helping shape your metal masterpiece. Here’s a quick look at some common workholding devices:

| Workholding Device | Application |

|---|---|

| Chucks | Great for round objects like pipes |

| Collets | Perfect for smaller, precise items |

| Faceplates | Used for irregular shapes |

Using the right device not only makes the job easier but also safer. Remember, your lathe is not a carnival ride; let’s keep the spinning to a minimum!

Choosing the Right Workholding Method

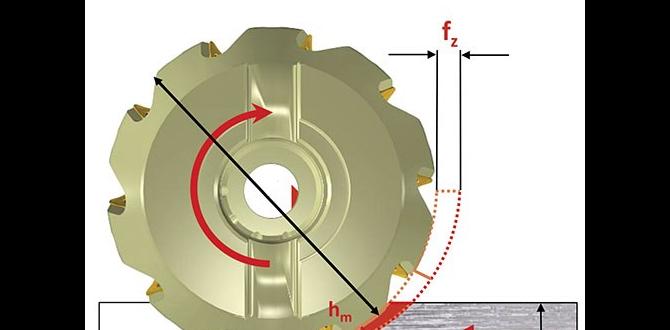

Comparison of different workholding techniques (chucks, collets, fixtures). Factors to consider when selecting a workholding method.Choosing the right method for holding your workpiece is crucial. Different techniques, like chucks, collets, and fixtures, each have their pros and cons. For example, chucks are versatile and easy to use, while collets offer better precision. Fixtures are great for complex shapes. Here are some important factors to think about:

- Type of material

- Workpiece size

- Accuracy needed

- Production speed

Consider these points carefully to find what works best for your project.

What are the advantages of each workholding method?

Chucks are easy to set up, collets provide a snug fit, and fixtures allow for high accuracy.

Setting Up Your Metal Lathe for Optimal Performance

Stepbystep instructions for setting up workholding devices. Common mistakes to avoid during the setup process.Ready to set up your metal lathe? Follow these steps for smooth workholding. Start by securing your workpiece tightly. Adjust the jaws carefully to hold it in place. Check for any wobbling. Remember, tight is crucial! Avoid common mistakes like forgetting to align the workholding device properly. This can cause poor cuts. Ensure your tools are sharp and clean for best results.

What tips can help with metal lathe setup?

Here are some quick tips:

- Always double-check your setup before starting.

- Keep your workspace organized. It helps prevent mistakes.

- Practice on scrap material to get comfortable.

Enhancing Precision with Lathe DRO Systems

How DRO systems improve accuracy and efficiency. Tips for calibrating and maintaining your DRO system.Using DRO (Digital Readout) systems can work magic on your metal lathe. They increase accuracy and efficiency by showing exact measurements on clear displays. This means less guesswork and more *precision*. Calibrating your DRO is vital, though. Check your manual and keep it clean. Regular maintenance will keep it happy and humming. A well-calibrated DRO can boost your productivity by up to 30%! Who knew machines could be so *smart*?

| Tips for Calibrating Your DRO |

|---|

| Check manuals for setup steps |

| Inspect it regularly for dust |

| Use a precision gauge to check accuracy |

Popular Workholding Devices for Metal Lathes

Detailed review of chucks, collets, and vises. Pros and cons of each device type for various applications.Different workholding devices can make lathe work easier and more precise. Chucks hold pieces securely, making them great for round shapes. Collets grip smaller items tightly, ideal for fine work. Vises, meanwhile, provide strong support for larger parts. Here’s a quick look at each option:

- Chucks: Good for various shapes. Easy to use. Can be bulky.

- Collets: Excellent grip. Perfect for small parts. Limited size range.

- Vises: Strong support. Best for big pieces. Can be heavy and unwieldy.

Safety Best Practices in Lathe Workholding

Importance of safety in lathe operations. Essential safety measures to take when using workholding devices.Working with lathes can be thrilling, but safety must come first. A moment of carelessness can lead to serious injuries. Always remember to secure your workpiece firmly. Loose items can fly off and cause harm. Wear proper gear like goggles and gloves to protect yourself. It’s wise to keep your workspace clean to prevent accidents.

- Always check the lathe before starting.

- Keep hands away from moving parts.

- Have a first aid kit nearby.

- Do not rush; take your time.

Why is safety important in lathe work?

Safety helps prevent injuries and ensures smooth operations. Following safety measures keeps everyone safe in the workshop.

Essential safety measures:

- Secure the workpiece well.

- Wear protective equipment.

- Keep tools organized and clean.

Troubleshooting Common Workholding Issues

Identification of common issues encountered with lathe workholding. Solutions and preventative measures for effective problemsolving.Lathe workholding can be tricky, and issues pop up now and then. Common problems include slipping workpieces, improper alignment, and excessive vibrations. To tackle these, first check if your workpiece is securely clamped. If it’s still wobbly, try adjusting the chuck tighter. Use a level to ensure everything is lined up just right—like a game of Jenga, but without the falling! It’s also smart to inspect your tools regularly to keep those pesky problems away.

| Issue | Solution |

|---|---|

| Slipping workpiece | Clamp it tighter. |

| Improper alignment | Check with a level. |

| Excessive vibrations | Inspect and replace worn tools. |

Conclusion

In summary, lathe workholding is crucial for safe and accurate metal lathe operation. A Digital Readout (DRO) helps you measure precisely. Understanding these tools improves your skills and efficiency. Begin practicing with these techniques and check out more resources online for deeper learning. You’ll become a confident machinist in no time!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Digital Readouts (Dro):Sure! Here are five questions on lathe workholding and digital readouts. 1. What is lathe workholding? Lathe workholding is how we hold a piece of metal in place on a lathe. It makes sure the metal doesn’t move while we shape it. 2. Why do we use a Digital Readout (DRO)? A Digital Readout, or DRO, helps us see exactly where the cutting tool is. It makes our work more precise and easier. 3. How do you set up a lathe for work? You start by choosing the right tool and holding device. Then, you secure the metal piece tightly. Finally, you check the DRO for accuracy. 4. What are some common workholding devices? Common workholding devices include chucks and clamps. They help keep the metal steady while we work on it. 5. Why is safety important when using a lathe? Safety is important because lathes can be dangerous. We must wear safety gear and pay attention to our hands. This helps keep everyone safe while working.

Sure! Please tell me the question you’d like me to answer.

What Are The Most Common Types Of Workholding Devices Used In Metal Lathes, And How Do They Differ In Application?The most common workholding devices for metal lathes are chucks, collets, and faceplates. Chucks hold round pieces tightly and are great for many shapes. Collets fit smaller pieces snugly and are perfect for tools. Faceplates hold big, flat pieces but need extra care to set up. Each device works best for different kinds of jobs.

How Can A Digital Readout (Dro) Improve The Accuracy And Efficiency Of Machining Operations On A Metal Lathe?A digital readout (DRO) shows exact measurements on a screen. This helps you see the size of the metal you are working on. You can make cuts more accurately because you read the numbers clearly. It saves time, too, since you won’t have to measure more than once. With a DRO, we can create better parts faster!

What Factors Should Be Considered When Choosing A Workholding Method For Different Materials And Part Geometries In Lathe Work?When choosing how to hold a part on a lathe, think about what the part is made of. Different materials, like metal or plastic, may need special grips. Also, look at the shape of the part. If it’s round or has unique edges, we need the right holder to keep it still. Finally, make sure the holder is safe and won’t let the part slip while we work on it.

How Do You Properly Set Up A Workpiece In A Metal Lathe To Ensure Optimal Stability And Precision During Machining?To set up a workpiece in a metal lathe, first, make sure it’s clean. Then, you should place the workpiece in the center of the lathe. Tighten it securely using the clamps. Check if it spins straight by turning it on briefly. Adjust if needed, so it runs smoothly. Always wear safety gear while working!

What Are Some Best Practices For Maintaining And Calibrating A Digital Readout System On A Metal Lathe?To keep a digital readout system on a metal lathe working well, you should clean it often. Wipe down the screen and buttons with a soft cloth. Next, check the connections to make sure everything is tight and secure. You also need to calibrate, or adjust, the system regularly so it shows the right measurements. Always follow the manufacturer’s instructions for the best results.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Digital Readouts (Dro):”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions on lathe workholding and digital readouts. 1. What is lathe workholding? Lathe workholding is how we hold a piece of metal in place on a lathe. It makes sure the metal doesn’t move while we shape it. 2. Why do we use a Digital Readout (DRO)? A Digital Readout, or DRO, helps us see exactly where the cutting tool is. It makes our work more precise and easier. 3. How do you set up a lathe for work? You start by choosing the right tool and holding device. Then, you secure the metal piece tightly. Finally, you check the DRO for accuracy. 4. What are some common workholding devices? Common workholding devices include chucks and clamps. They help keep the metal steady while we work on it. 5. Why is safety important when using a lathe? Safety is important because lathes can be dangerous. We must wear safety gear and pay attention to our hands. This helps keep everyone safe while working.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Common Types Of Workholding Devices Used In Metal Lathes, And How Do They Differ In Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The most common workholding devices for metal lathes are chucks, collets, and faceplates. Chucks hold round pieces tightly and are great for many shapes. Collets fit smaller pieces snugly and are perfect for tools. Faceplates hold big, flat pieces but need extra care to set up. Each device works best for different kinds of jobs.”}},{“@type”: “Question”,”name”: “How Can A Digital Readout (Dro) Improve The Accuracy And Efficiency Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital readout (DRO) shows exact measurements on a screen. This helps you see the size of the metal you are working on. You can make cuts more accurately because you read the numbers clearly. It saves time, too, since you won’t have to measure more than once. With a DRO, we can create better parts faster!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Choosing A Workholding Method For Different Materials And Part Geometries In Lathe Work?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing how to hold a part on a lathe, think about what the part is made of. Different materials, like metal or plastic, may need special grips. Also, look at the shape of the part. If it’s round or has unique edges, we need the right holder to keep it still. Finally, make sure the holder is safe and won’t let the part slip while we work on it.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Workpiece In A Metal Lathe To Ensure Optimal Stability And Precision During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a workpiece in a metal lathe, first, make sure it’s clean. Then, you should place the workpiece in the center of the lathe. Tighten it securely using the clamps. Check if it spins straight by turning it on briefly. Adjust if needed, so it runs smoothly. Always wear safety gear while working!”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Maintaining And Calibrating A Digital Readout System On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a digital readout system on a metal lathe working well, you should clean it often. Wipe down the screen and buttons with a soft cloth. Next, check the connections to make sure everything is tight and secure. You also need to calibrate, or adjust, the system regularly so it shows the right measurements. Always follow the manufacturer’s instructions for the best results.”}}]}