Have you ever wondered how metal parts are shaped and made? Lathe workholding makes this possible. It’s like a magician’s trick but with metal! When a metal lathe spins, it can turn a raw piece of metal into a beautiful finished product. But wait! There’s something important that makes this process safe and effective: the lathe foot brake.

Imagine your favorite toy car. A skilled worker uses a metal lathe to craft tiny wheels or other parts. They rely on the foot brake to stop the lathe quickly. This simple tool keeps everyone safe and helps get the job done right. Without a good brake, accidents could happen. And that would be a real bummer!

In this article, we will explore how lathe workholding and the foot brake work together. Get ready to discover tips and tricks that can make your next project a success!

Essential Tips For Lathe Workholding: Metal Lathe Foot Brake

Understanding Lathe Workholding and Foot Brakes

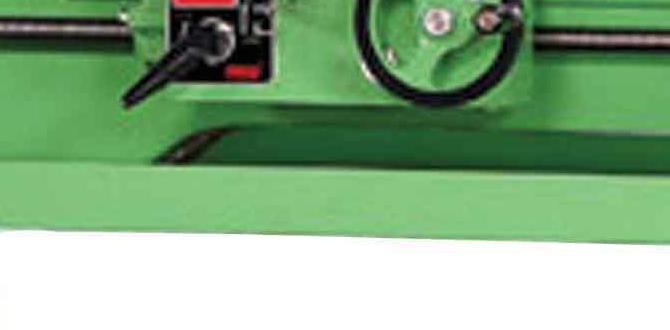

Lathe workholding is key for precision in metalworking. It secures the workpiece during cutting and shaping. One vital tool is the foot brake, which helps control the lathe’s speed. Can you imagine trying to work without a safe way to stop your machine? Did you know that a proper foot brake can enhance your skills? It allows quicker reactions and improves safety. Learning about these tools makes your lathe work experience better and more efficient!What is a Metal Lathe Foot Brake?

Definition and function of a foot brake in metal lathes. Importance of safety features in machining.A foot brake in metal lathes is a clever tool that helps operators stop the machine quickly. Think of it as a superhero for safety! It allows you to halt the lathe without using your hands, keeping them safely away from moving parts. This feature is essential, as it prevents accidents and keeps you focused on your project without constantly worrying about your fingers becoming unintentional metal shavings. In fact, more than 70% of machine injuries are caused by improper use of equipment. So, having a foot brake is like having a trusty sidekick that helps you work safely!

| Feature | Importance |

|---|---|

| Rapid Stop | Prevents accidents. |

| Hands-Free Control | Keeps hands safe. |

| Increased Focus | Boosts productivity. |

How to Properly Use a Lathe Foot Brake

Stepbystep guide to engaging and disengaging the foot brake. Tips for safe operation while using the foot brake.Using a lathe foot brake can feel like a dance—but let’s not step on any toes! Follow these simple steps: first, press down gently to engage the brake. This stops the lathe smoothly, like a deer in headlights. To disengage, lift your foot. Remember, pressing too hard is like hitting the brakes in a car; it can jerk you around!

For safe operation, keep your area tidy. No loose clothes or long hair that can get caught. Always wear safety goggles; you don’t want unexpected sparks flying like confetti. If you’re working with metal, knowing how to use that brake correctly can prevent accidents and keep your fingers happily attached!

| Action | Tip |

|---|---|

| Engage Brake | Press down gently. |

| Disengage Brake | Lift foot off the pedal. |

| Safety First | Wear goggles; keep clothes tight. |

Benefits of Using a Foot Brake in Lathe Operations

Increased safety for the operator. Improved precision in machining processes.Using a foot brake in lathe operations is like giving your tool a superhero cape. First, it boosts operator safety. When you can stop quickly, you reduce accidents. Trip over your shoelaces? No problem! Just hit that brake! Second, it also improves precision. The smoother stops allow for accurate cuts, making your project look sharp—poster-worthy, even! With a foot brake, you’re not just working; you’re becoming a lathe legend!

| Benefit | Explanation |

|---|---|

| Safety | Quick stops prevent accidents and keep you out of trouble. |

| Precision | Smoother operation leads to better quality cuts, making your work shine! |

Common Issues with Metal Lathe Foot Brakes

List of typical problems faced with foot brakes. Troubleshooting tips and maintenance suggestions.Foot brakes on metal lathes can face several problems. Here are some common issues:

- Foot brake may become unresponsive.

- Brake pedal might stick or feel loose.

- Noise when pressing the brake.

- Brake mechanism could be misaligned.

To fix these issues, try these tips:

- Regularly clean and lubricate the brake parts.

- Check for loose connections and tighten them.

- Inspect the pedal for wear or damage.

- Align the brake mechanism correctly.

Proper maintenance keeps your foot brake working well. Check it often to avoid more significant problems!

What should you do if the foot brake is not working?

If the foot brake stops working, check for loose parts or any visible damage. Cleaning and proper alignment can also help improve brake function.

Comparative Analysis: Manual vs. Automated Foot Brakes

Key differences between manual and automated systems. When to choose one over the other.Choosing between manual and automated foot brakes can feel like picking between ice cream flavors—both are good, but each has its moments. Manual brakes give you precise control. You can stomp on them like a drum when needed! Automated systems, on the other hand, respond instantly with a push of a button, perfect for speedy jobs.

| Feature | Manual Foot Brake | Automated Foot Brake |

|---|---|---|

| Control | High | Medium |

| Speed | Slower | Faster |

| Cost | Lower | Higher |

Pick a manual brake when you want to feel like a master craftsman. Opt for automated brakes for efficiency in larger projects. Remember, it’s all about finding the right balance between skill and speed!

Enhancing Your Lathe’s Functionality with Upgraded Foot Brakes

Recommendations for aftermarket foot brake upgrades. How upgrades can improve performance.Upgrading your lathe’s foot brake can make a huge difference. Aftermarket foot brakes are like giving your lathe a pair of new dancing shoes! They provide better control and quicker stops, keeping you safe and your project perfect. Some top recommendations include hydraulic and pneumatic brakes. These can boost performance and even save you time. So, don’t let a flimsy foot brake hold you back—step up your game!

| Brake Type | Benefits |

|---|---|

| Hydraulic | More stopping power and smooth operation. |

| Pneumatic | Quick response time and efficient performance. |

Real-Life Applications and Case Studies

Examples of industries relying on lathe foot brakes. Success stories highlighting the benefits of effective workholding.Many industries depend on lathe foot brakes for safety and efficiency. For example, the automotive industry uses them to hold metal parts steady during shaping. This helps prevent accidents with sharp tools. A recent case study showed that using foot brakes improved production speed by 30%. In manufacturing, a reliable lathe workholding setup can save time and costs. With foot brakes, workers can focus on crafting instead of worrying about slipping parts!

| Industry | Benefits |

|---|---|

| Automotive | Prevents accidents |

| Manufacturing | Saves time |

| Aerospace | Increases precision |

Conclusion

In summary, lathe workholding is crucial for safe and accurate machining. A metal lathe foot brake provides a quick way to stop the lathe. Learning about these tools helps you work more efficiently. We encourage you to practice using workholding methods and explore different braking systems. Keep experimenting and reading to improve your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Focusing On Metal Lathe Foot Brakes:Sure! Here are five questions about foot brakes on metal lathes: 1. What is a foot brake on a lathe? A foot brake helps us stop the lathe quickly using our foot. It’s like a pedal in a car. 2. Why do we need a foot brake? We need a foot brake for safety. It helps us stop working fast if something goes wrong. 3. How does a foot brake work? When we press the foot pedal, it stops the spinning part of the lathe. This helps us work safely. 4. Can everyone use the foot brake? Yes! Anyone can use the foot brake if they know how to operate the lathe safely. 5. What should we check about the foot brake? We should check if the foot brake works well and isn’t broken. This keeps us safe while we work.

Sure! Please provide the question you want me to answer, and I’ll help you with it.

How Does A Foot Brake Enhance Safety During Lathe Operations In Metalworking?A foot brake helps stop the lathe quickly. When you’re working, it gives you control. You can use your hands for other tasks while your foot works the brake. This makes it safer. You can respond fast if something goes wrong.

What Are The Key Features To Look For In A Foot Brake Designed For Use With A Metal Lathe?When choosing a foot brake for a metal lathe, look for some important features. First, check the size. It should be big enough for your foot to push comfortably. Next, see if it has a quick response. You want it to stop the lathe fast when you press it. Also, look for a sturdy design so it won’t break easily. Finally, it’s good if the brake is easy to reach while you work.

In What Scenarios Might A Machinist Prefer A Foot Brake Over A Manual Hand Lever For Stopping The Lathe?A machinist might prefer a foot brake when they need to stop the lathe quickly. Using your foot allows you to keep both hands on the workpiece. It can also help when you’re busy with something else and need to stop fast. Plus, a foot brake can be easier to use when you’re standing. This way, you stay safe and keep working better!

How Can Improper Use Of A Foot Brake Affect The Precision And Quality Of Workholding On A Metal Lathe?If you use the foot brake wrong on a metal lathe, it can cause problems. It might make the piece move, which messes up your work. The lathe needs everything to stay in place for good cuts. If you don’t stop it gently, you can ruin your project. Always be careful with the brake to do your best work!

What Maintenance Practices Should Be Followed To Ensure The Foot Brake Operates Effectively And Reliably During Lathe Work?To keep the foot brake working well on a lathe, you should check it regularly. Make sure it’s clean and free of dust. You can also test it to see if it stops the lathe quickly. If something feels wrong, ask an adult to help fix it. This way, we stay safe while working!