Have you ever wondered how metal objects are shaped and built? It all starts with lathe workholding. If you’re a beginner, learning about a metal lathe can be exciting and a bit daunting. But don’t worry! With the right knowledge, you’ll feel like a pro in no time.

Imagine transforming a simple piece of metal into a sleek tool or a unique art piece. That’s the magic of using a lathe! The key to this magic lies in how you hold the metal lathe correctly. If you don’t secure your workpiece well, even the best lathe can’t help you.

Did you know that lathes have been around for thousands of years? Ancient craftsmen used them to create beautiful objects. Today, they are still essential in workshops, enabling both hobbyists and professionals to make incredible things.

In this article, we’ll explore the basics of lathe workholding for beginners. We’ll share tips, tricks, and important things to remember. By the end, you’ll be ready to tackle projects on your own!

Lathe Workholding: Essential Metal Lathe For Beginners

Lathe Workholding: Metal Lathe for Beginners

Lathe workholding is essential for beginners in metal lathe projects. A sturdy setup keeps your material steady while you shape it. Have you ever tried to cut a piece of wood that kept slipping? Frustrating, right? Using appropriate workholding tools can prevent that. You’ll learn about chucks, vices, and fixtures tailored for beginners. Discover how each one helps you achieve precision and a smoother finish. Getting this right makes your metalworking journey much more enjoyable!Understanding the Basics of Metal Lathes

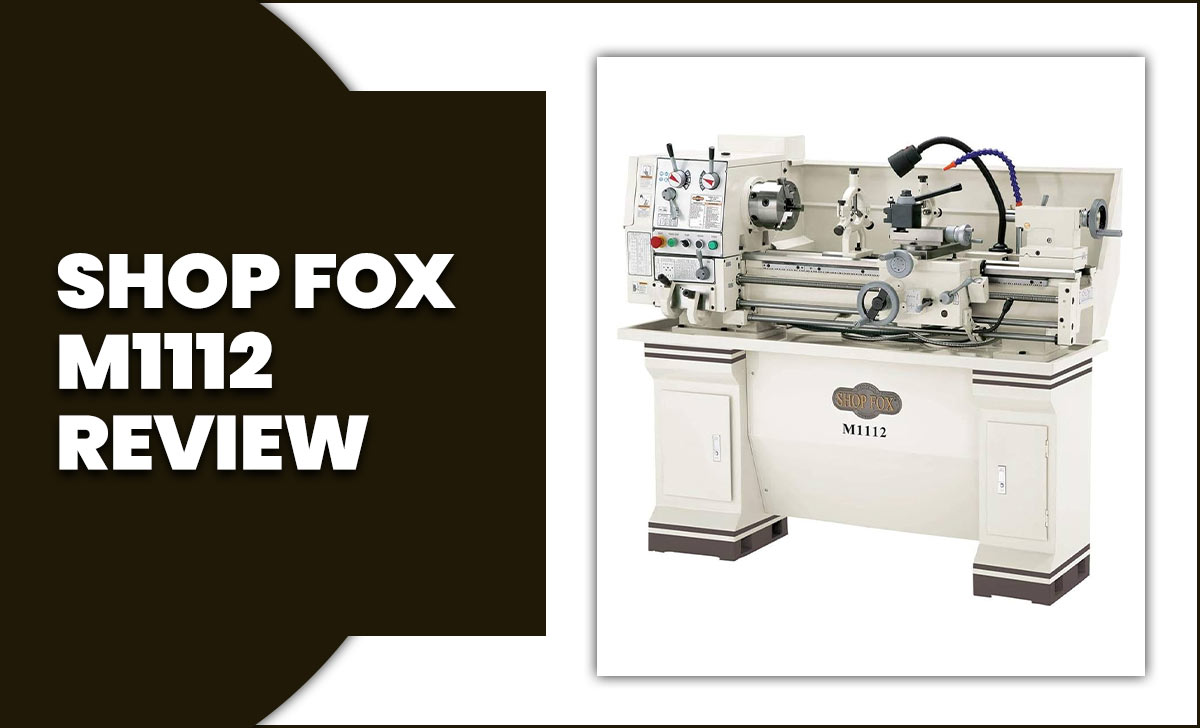

Definition and function of a metal lathe. Key components of a metal lathe.A metal lathe is like a magical spinning plate for metal. It helps shape metal pieces into cool things, from simple knobs to fancy sculptures. At its heart are key parts: the headstock, tailstock, and carriage. Think of them as the metal lathe’s best buddies. They work together to hold, move, and shape the metal while it spins. Without these, you’d end up with a very confused piece of metal!

| Component | Function |

|---|---|

| Headstock | Holds the spindle and drives the workpiece. |

| Tailstock | Supports tools or extends the length of the workpiece. |

| Carriage | Moves the cutting tool across the metal. |

Types of Workholding Devices for Metal Lathes

Chucks: Types and applications. Collets: Benefits and usage.Metal lathes have cool tools called workholding devices, which help hold the metal pieces steady. One type is a chuck. They come in three main styles: scroll chucks for quick gripping, collet chucks for precise fits, and faceplate chucks for larger items. Each style has a specific job, just like superheroes!

| Chuck Type | Application |

|---|---|

| Scroll Chuck | Quick gripping for regular tasks |

| Collet Chuck | Precise fits for small items |

| Faceplate Chuck | Holding larger workpieces |

Collets are another option. They fit snugly around your metal piece. This gives better accuracy and improved grip. Using collets can keep your work from wobbling—all bad things happen when metal wobbles! So remember, whether it’s a chuck or a collet, both are here to save the day in your lathe work!

Choosing the Right Workholding Device for Your Projects

Factors to consider in selection (material, size, etc.). Comparing different workholding solutions.Choosing the right workholding device can feel like picking a favorite ice cream flavor—tough but important! First, consider material. Metal or plastic? Each has its perks. Next up is size. Make sure it fits your project snugly—like a sweater on a teddy bear! Don’t forget to compare solutions. A vise might be great for small jobs, while a chuck is perfect for larger pieces. Check out this handy table:

| Device Type | Best For | Material |

|---|---|---|

| Vise | Small projects | Metal |

| Chuck | Large pieces | Plastic or Metal |

| Faceplate | Irregular shapes | Metal |

With these tips, you’ll be ready to hold your work and impress your friends. Just remember, locking things down shouldn’t be as tough as convincing a cat to take a bath!

Setting Up and Adjusting Workholding Devices

Stepbystep guide to installation. Tips for achieving optimal alignment and stability.To set up and adjust your workholding devices correctly, follow these simple steps:

- First, clean the lathe and the device. A clean surface helps with accuracy.

- Next, secure the device tightly. Use wrenches to make sure it won’t move.

- Align the device with the lathe’s center. This ensures even cuts.

- Finally, check stability. Test the setup before starting your project.

For optimal results, remember these tips:

- Use a dial indicator to check alignment.

- Double-check all screws and clamps.

- Keep tools within reach for quick adjustments.

How can I ensure my workholding device is stable?

To ensure stability, always check that your device is tightly secured and aligned at the center of the lathe. This guarantees balanced cuts, making your work easier and more accurate.

Essential Safety Practices When Using a Lathe

Personal protective equipment (PPE) requirements. Common hazards and how to mitigate them.Using a lathe can be fun, but safety comes first! Always wear protective glasses to shield your eyes from flying debris. A good pair of gloves can save your fingers from unexpected mishaps. Watch out for common hazards, like loose clothing getting caught in the machine. Tie back long hair and avoid baggy clothes. Remember, safety is key – unless you want to lose a hair or two!

| Personal Protective Equipment (PPE) | Common Hazards | How to Mitigate |

|---|---|---|

| Protective Glasses | Flying Chips | Keep Work Area Clean |

| Gloves | Crushed Fingers | Avoid Loose Clothing |

| Ear Protection | Loud Noise | Limit Noise Exposure |

Common Mistakes to Avoid in Lathe Workholding

Frequent errors beginners make. Understanding the consequences of improper workholding.Beginners often make simple mistakes in lathe workholding. One big error is not tightening the workpiece properly. It can slip and ruin your work or worse – send flying across the room! Ouch! Another common mix-up is using the wrong chuck for the job. This can lead to uneven cuts. Remember, proper workholding is key! It keeps your project safe and sound. Here’s a quick look at some of those blunders:

| Common Mistakes | Consequences |

|---|---|

| Not tightening the workpiece | Slips and accidents |

| Using the wrong chuck | Uneven cuts |

| Ineffective setup | Poor finish quality |

By avoiding these mistakes, you can make lathe magic happen! Remember, workholding isn’t a magic trick; it’s about being smart and safe.

Advanced Techniques for Experienced Users

Specialized workholding setups for complex projects. Custom fixtures: when and how to use them.As you get more skilled, you’ll dive into cool workholding setups for tricky projects. Specialized fixtures can make your life easier. Think of them as your trusty sidekick on the lathe journey. They hold your workpiece tight, so you can focus on making something amazing instead of chasing parts around like a puppy after a squirrel!

Custom fixtures are lifesavers when you need unique shapes. These aren’t just for show; they help you keep everything straight. Use them when your parts are too awkward for standard setups. Get creative, measure twice, and build a fixture that matches your design. Safety first, fun second!

| Fixture Type | Best For |

|---|---|

| Vise Jaws | Flat parts |

| Magnetic Holders | Non-ferrous materials |

| Custom Clamps | Odd shapes |

Resources for Further Learning and Improvement

Recommended books and online courses. Community forums and local workshops for beginners.Learning lathe workholding can be exciting! A great way to dive deeper is through recommended books like “Metalworking for Beginners” or online courses that introduce all the essentials. Community forums are also gold mines for advice and tips—perfect for asking that “why does my lathe make weird noises?” question. Local workshops can be fun too—mixing practice with socializing, and who knows? You might find a fellow lathe-lover to share your machine mysteries!

| Resources | Description |

|---|---|

| Books | “Metalworking for Beginners” |

| Online Courses | Introductory lathe courses available on platforms like Udemy or Coursera |

| Community Forums | Websites like Reddit or specific metalworking forums |

| Local Workshops | Check out classes at community colleges or hobby shops |

Conclusion

In conclusion, lathe workholding is essential for beginners using a metal lathe. It helps you secure materials for precise cutting. Remember to choose the right clamps and tools for your projects. Practice makes perfect, so start with simple tasks. Explore more resources to expand your skills and confidence in lathe work. Happy machining!FAQs

What Are The Different Types Of Workholding Devices Used In Metal Lathes, And How Do They Function?Metal lathes use different tools to hold metal pieces securely while we work on them. A chuck is a common device that grips round metal. There are different types of chucks. For example, a three-jaw chuck holds the metal tightly and centers it for cutting. A faceplate helps hold flat pieces of metal. It has holes to screw the metal down. Finally, a collet is a special holder that fits snugly around small objects. These devices let us shape and cut metal safely.

How Can Beginners Ensure That Their Workpiece Is Securely Mounted On The Lathe To Prevent Movement During Machining?To keep your workpiece safe on the lathe, start by using the right chuck. A chuck is a tool that holds the workpiece tightly. Then, make sure to tighten all the screws well. You can also check the setup carefully before starting. This way, your workpiece won’t move while you work!

What Are The Common Mistakes Beginners Make When Setting Up Workholding For Lathe Operations, And How Can They Be Avoided?Beginners often make mistakes like not securing the part tightly. This can cause it to move around while the lathe runs. Another mistake is using the wrong tools to hold the piece. To avoid these problems, always check that the part is secure before starting. Use the right clamps or chucks that fit your material well.

What Safety Precautions Should Beginners Take When Using Workholding Setups On A Metal Lathe?When using a metal lathe, you should wear safety glasses to protect your eyes. Make sure your hair and clothes are tucked away to avoid getting caught. Always keep your hands away from the moving parts. Check that everything is tight and secure before you start. Finally, listen to your teacher or supervisor for any extra rules.

How Does The Choice Of Workholding Method Affect The Precision And Accuracy Of The Machining Process In Lathe Work?The way we hold the piece of metal on a lathe affects how well it cuts. If we choose a strong workholding method, the metal stays steady. This helps to make precise cuts and keeps everything accurate. If the piece wobbles, it can create mistakes. So, picking the right way to hold the piece is very important!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Different Types Of Workholding Devices Used In Metal Lathes, And How Do They Function?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes use different tools to hold metal pieces securely while we work on them. A chuck is a common device that grips round metal. There are different types of chucks. For example, a three-jaw chuck holds the metal tightly and centers it for cutting. A faceplate helps hold flat pieces of metal. It has holes to screw the metal down. Finally, a collet is a special holder that fits snugly around small objects. These devices let us shape and cut metal safely.”}},{“@type”: “Question”,”name”: “How Can Beginners Ensure That Their Workpiece Is Securely Mounted On The Lathe To Prevent Movement During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your workpiece safe on the lathe, start by using the right chuck. A chuck is a tool that holds the workpiece tightly. Then, make sure to tighten all the screws well. You can also check the setup carefully before starting. This way, your workpiece won’t move while you work!”}},{“@type”: “Question”,”name”: “What Are The Common Mistakes Beginners Make When Setting Up Workholding For Lathe Operations, And How Can They Be Avoided?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Beginners often make mistakes like not securing the part tightly. This can cause it to move around while the lathe runs. Another mistake is using the wrong tools to hold the piece. To avoid these problems, always check that the part is secure before starting. Use the right clamps or chucks that fit your material well.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Beginners Take When Using Workholding Setups On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should wear safety glasses to protect your eyes. Make sure your hair and clothes are tucked away to avoid getting caught. Always keep your hands away from the moving parts. Check that everything is tight and secure before you start. Finally, listen to your teacher or supervisor for any extra rules.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Workholding Method Affect The Precision And Accuracy Of The Machining Process In Lathe Work?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The way we hold the piece of metal on a lathe affects how well it cuts. If we choose a strong workholding method, the metal stays steady. This helps to make precise cuts and keeps everything accurate. If the piece wobbles, it can create mistakes. So, picking the right way to hold the piece is very important!”}}]}