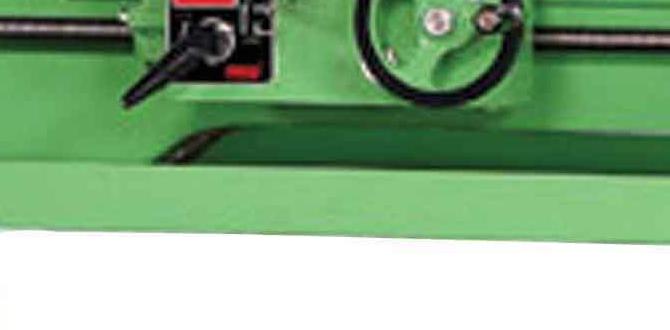

Have you ever watched a lathe in action? It can be quite mesmerizing. A metal lathe spins metal pieces, helping create shapes we see every day. But have you heard about the importance of workholding? It’s a key part of using a lathe. Without proper workholding, the metal can slip or move. This can lead to mistakes or even accidents.

Imagine trying to shape a piece of metal with it rolling around! That wouldn’t work well at all, right? One tool that makes lathe work easier is the handwheel. With a handwheel, you have more control. You can make precise cuts and shapes. It’s like having a secret weapon in your workshop.

In this article, we will explore the world of lathe workholding. You will discover why it matters and how the handwheel can improve your projects. Get ready to dive into the fascinating world of metalworking!

Effective Lathe Workholding: Metal Lathe Handwheel Techniques

Lathe Workholding Metal Lathe Handwheel

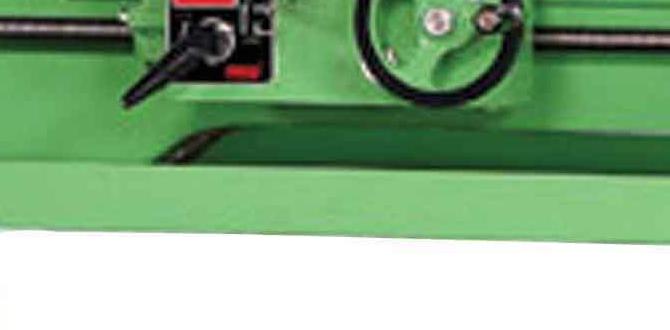

Lathe workholding is vital for precise machining. A metal lathe handwheel helps control movement effectively. Did you know that a well-designed handwheel can improve accuracy? It allows users to adjust the lathe easily while maintaining focus on the job. Safe and secure workholding keeps the metal piece stable. Proper techniques can enhance your skill level. Whether you’re a beginner or an expert, mastering the handwheel is crucial in the lathe process.Understanding Lathe Workholding Principles

Explanation of workholding in metal machining. Importance of stability and precision in lathe work.Workholding is key in metal machining. It keeps the material steady while cutting. This stability ensures precision, so your cuts are accurate and clean. A stable setup helps avoid mistakes. When using a lathe, focus on keeping everything tight and secure. This way, you get better results with every turn of the lathe workholding metal lathe handwheel. Think of it like holding a pencil steady when drawing—better control means a better picture!

Why is stability important in lathe work?

Stability is crucial for accurate cuts. It helps prevent issues that can ruin a project. Additionally, it keeps both the tool and the material safe from damage. Making adjustments can lead to better outcomes each time.

Key benefits of stability and precision:

- Better accuracy in shaping materials.

- Reduced chance of mistakes.

- Longer tool life.

- Safer working environment.

Selecting the Right Handwheel for Your Lathe

Factors to consider when choosing a handwheel. Compatibility with various lathe models.Choosing the right handwheel for your lathe is important. Here are some factors to think about:

- Size: Make sure the handwheel fits your lathe’s size.

- Material: Select durable materials that can handle tough work.

- Grip: Look for a handwheel with a good grip for better control.

- Compatibility: Ensure it works with your specific lathe model.

Checking compatibility is key to using your lathe safely and smoothly.

What should I consider for handwheel compatibility?

Choose a handwheel that matches your lathe model. Always check specifications to ensure perfect fit and function.

Selecting the right handwheel improves both safety and efficiency. A good handwheel makes operating your lathe easier and more enjoyable.

Techniques for Effective Lathe Workholding

Best practices for securing workpieces. Utilizing handwheels to enhance machining accuracy.Securing your workpieces is key in lathe work. It’s like hugging a teddy bear— a good grip keeps everything safe! Use clamps and chucks to hold your materials tight. Remember, a wobbly piece is a bad piece! Handwheels can enhance machining accuracy too. With these wheels, you can control movement smoothly. It’s like steering a spaceship, but with more metal and less space pirates!

| Technique | Description |

|---|---|

| Clamping | Use clamps to secure your workpiece firmly. |

| Chucks | These hold cylindrical pieces best. |

| Handwheels | They make precise adjustments a breeze! |

Common Problems and Solutions in Lathe Workholding

Frequent issues faced during machining. Tips for troubleshooting workholding challenges.Working with a lathe can be fun, but it has its challenges. Common problems include vibration, workpiece slipping, and uneven cuts. To fix these issues, follow these tips:

- Check the setup. Ensure everything is tight.

- Balance the workpiece properly.

- Use the right speed for your material.

- Inspect tools for wear and tear.

By addressing these areas, you can improve your lathe workholding and enjoy smoother projects!

What are some common problems in lathe workholding?

Common problems include vibrations, slipping workpieces, and uneven cuts. These can make your work frustrating. It’s important to identify the issue quickly to avoid mistakes.

Tips for troubleshooting lathe workholding problems:

- Ensure all components are secure.

- Use a suitable clamping method.

- Adjust cutting speed to the material.

Upgrading Your Handwheel: Enhancements and Modifications

Options for improving handwheel efficiency. Custom modifications for specific machining tasks.Upgrading your handwheel can make your lathe work much smoother. First, consider adding a larger wheel for better grip. This helps with precision. Next, you can install a gear system. This makes turning easier and quicker. Custom modifications can improve your tasks too. For example, you might add a locking feature. This keeps your settings firm while you work. Explore options that suit your needs best!

What upgrades can improve my handwheel?

Consider upgrades like a larger diameter wheel for better grip or a gear system for ease of use.

What custom modifications can I make?

- Adding a locking feature

- Installing rubber grips for comfort

- Adjusting the wheel size for task precision

Safety Considerations When Working with Metal Lathes

Key safety practices to follow. Importance of proper workholding for operator safety.Safety is very important when using a metal lathe. Here are some key practices to follow:

- Always wear safety glasses.

- Keep your hands away from moving parts.

- Check the machine for loose tools before starting.

Using proper workholding methods is crucial for operator safety. It keeps the material secure and prevents accidents. Remember, a secure piece is a safe piece! This means no slipping or unexpected movements while you work. Always double-check your setup.

Why is safety important when using a metal lathe?

Safety prevents accidents and injuries. A secure workspace helps workers feel confident and focused.

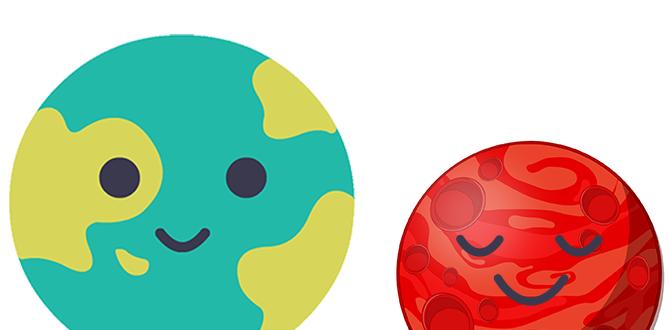

Future Trends in Lathe Workholding Technologies

Exploration of innovations in workholding solutions. Predictions for advancements in lathe handwheel design.Exciting changes are coming in workholding technologies for lathes! Imagine better clamps that hold your metal as tight as a hug from grandma. Future designs will be smarter and easier to use. The lathe handwheel may even get a makeover, becoming more ergonomic. Users can expect brighter colors—pink, anyone?—and smoother turns, making work feel like a breeze. Get ready for innovations that will make your work fly! It’s like upgrading from a bicycle to a spaceship!

| Innovation | Key Features |

|---|---|

| Smart Clamps | Adjust automatically for different sizes. |

| Ergonomic Handwheels | Designed for comfort and ease of use. |

| Color Customization | Choose your favorite shades! |

In the world of lathe workholding, change is the only constant. Future trends promise exciting breakthroughs. Who knew metal work could be so fun?

Conclusion

In summary, understanding lathe workholding is essential for effective metal lathe operation. The handwheel helps you adjust and control the piece you’re working on. By mastering these tools, you improve your skills and projects. Don’t stop here—explore more about lathe techniques and practice regularly. With time, you’ll become a confident craftsman!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Focusing On The Metal Lathe Handwheel:Sure! The metal lathe handwheel helps you move the tool closer to your workpiece. When you turn the handwheel, it makes cutting easier. You can control how fast or slow the tool moves. Always be careful and keep your hands safe while using it!

Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help.

What Are The Different Types Of Workholding Devices Commonly Used On A Metal Lathe, And How Does The Handwheel Facilitate Their Operation?On a metal lathe, you can use different workholding devices like chucks, collets, and faceplates. Chucks hold round pieces tight, while collets are great for smaller, precise parts. Faceplates help secure larger or odd-shaped items. The handwheel lets you move the lathe easily. You can adjust the position of the workpiece for better cutting.

How Can You Ensure Proper Alignment Of The Workpiece When Using A Handwheel On A Metal Lathe?To ensure proper alignment of the workpiece on a metal lathe, you first check that it’s straight. Use the handwheel to slowly move the tool towards the workpiece. Keep it even on both sides to avoid uneven cuts. You can also use a ruler or caliper to measure distances. Always make small adjustments and double-check to get it just right.

What Safety Precautions Should Be Taken When Operating The Handwheel Of A Metal Lathe During Workholding Setup?When using the handwheel of a metal lathe, always wear safety goggles. Make sure your hair and loose clothes are tucked away. Keep your hands clear of moving parts. Check that all tools are ready and safe to use. Lastly, never rush; take your time to do it right.

How Does The Size And Design Of The Handwheel Affect The Precision And Ease Of Adjustments During Metal Lathe Operations?The size and design of the handwheel matter a lot when we use a metal lathe. A larger handwheel lets you make bigger turns, which can be easier for your hands. A smaller handwheel helps you make tiny, precise adjustments. If the design feels comfy and easy to grip, you can adjust the lathe better. This helps you create better pieces when you work with metal!

What Maintenance Practices Are Recommended For The Handwheel And Its Components To Ensure Smooth Operation During Lathe Workholding?To keep the handwheel working well, you should clean it often. Wipe off dust and dirt with a soft cloth. Check for any loose parts and tighten them if needed. You can also put a little oil on moving parts to help them turn easily. Regular checks keep everything running smoothly!