Have you ever wondered how metal parts are shaped? It all starts with lathe workholding. This process helps hold materials securely while workers shape them into finished products.

Imagine turning a block of metal into a perfect cylinder. That’s what a metal lathe does! Its lead screw plays a vital role in this journey. But why is this important?

Consider this: without proper workholding techniques, your project might turn out wobbly or uneven. That’s no fun, right? The lead screw helps move the tool smoothly, ensuring precision. This means better quality parts and happier builders!

So, what makes lathe workholding so special? Let’s dive deeper into the world of lathes and discover the magic behind this essential tool!

Essential Techniques For Lathe Workholding: Metal Lathe Lead Screw

Lathe Workholding: Metal Lathe Lead Screw

Understanding lathe workholding is crucial for precision in metalworking. The lead screw plays a vital role in controlling movement. It helps the tool stay steady while cutting. Imagine trying to carve a sculpture without a strong base—it would be tricky! A reliable lead screw ensures accuracy, leading to a better final product. Did you know that different designs can affect performance? Learning about them can make your projects even more successful. Explore this essential component to enhance your skills!Key Components of a Metal Lathe

Description of essential parts including the bed, headstock, and tailstock. Supporting structures: carriage, cross slide, and apron.Every metal lathe has key parts that work together. The bed is the base, keeping everything stable. The headstock holds the motor and helps spin the metal. The tailstock supports tools and adds extra length. Other important components include:

- Carriage: Moves the tool back and forth.

- Cross Slide: Adjusts the tool side to side.

- Apron: Connects the carriage to the lathe’s control parts.

These components are vital for smooth and precise lathe work.

What are the main parts of a metal lathe?

The main parts of a metal lathe are the bed, headstock, and tailstock. Together, they make sure cutting metal runs smoothly and correctly.

Understanding the Lead Screw in Metal Lathes

Definition and function of the lead screw in metal lathes. Importance of lead screws for precision and accuracy in machining.A lead screw is a special part of a metal lathe that helps move the cutter along the material. Think of it as a train track for your machine; it guides everything precisely where it needs to go. This precision is super important because even a tiny error can mess up the whole project. In fact, with a good lead screw, you can achieve accuracy within thousands of an inch! So, next time you use a lathe, remember the lead screw is like a trusty sidekick, ensuring your work shines!

| Function | Importance |

|---|---|

| Moves the cutter | Ensures precision |

| Guides the workpiece | Enhances accuracy |

Types of Lead Screws Used in Metal Lathes

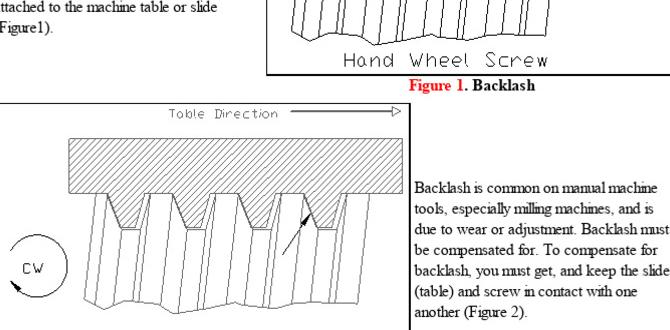

Differentiating between standard and antibacklash lead screws. Material choices and their implications on performance.Lead screws are important parts in metal lathes. They help control the movement of tools. There are two main types: standard and antibacklash lead screws. Standard screws can have some play, which makes them less precise. Antibacklash screws reduce this play and give better control. Different materials are used, too. Steel is common for strength, while brass offers smoother movement. Each material affects how well the lathe performs.

What are the different types of lead screws?

There are two types of lead screws:

- Standard lead screws

- Antibacklash lead screws

How does material affect lead screw performance?

Materials like steel and brass influence the strength and smoothness of movement.

- Steel is strong and durable.

- Brass is smoother and lighter.

Workholding Methods in Lathe Operations

Common workholding devices: chucks, collets, and fixtures. Pros and cons of each workholding method.In lathe operations, holding the workpiece steady is crucial. Common devices include chucks, collets, and fixtures. Chucks are like a strong hug for your metal piece—they grip it tightly. Collets are the fancy friends that hold smaller parts, perfect for precision. Fixtures, however, are the team players that secure customized shapes.

| Device | Pros | Cons |

|---|---|---|

| Chucks | Easy to use, versatile | Can be bulky for small parts |

| Collets | High precision | Limited in size range |

| Fixtures | Customizable for tasks | Time-consuming to set up |

Each device has its strengths and weaknesses. So, whether you need a strong grip or a delicate touch, there’s a perfect fit for your lathe workholding needs!

Choosing the Right Workholding Device for Your Project

Factors to consider: material, shape, and size of the workpiece. How to match workholding devices to specific machining tasks.Choosing a workholding device can feel like picking the right ice cream flavor. You want something that fits perfectly! First, think about the material, shape, and size of your workpiece. A melting scoop can slip away if it’s not the right cone! Next, ensure your device matches the job’s needs. For example, you wouldn’t use a tiny cup for a giant sundae, right?

| Factor | Details |

|---|---|

| Material | Is it metal, wood, or something else? |

| Shape | Square, round, or something wacky? |

| Size | How big or small is it? |

Remember, a good fit means fewer crashes and a smoother ride, like a joyride on a sunny day! So, choose wise and clamp tight!

Best Practices for Lathe Workholding

Ensuring proper setup and alignment for optimal results. Safety measures to take when working with lathes.Proper setup and alignment are crucial for successful lathe workholding. Make sure the workpiece is centered and secure. Check all settings before starting. This helps prevent errors and accidents. Safety is also very important. Always wear safety goggles and keep hands clear of moving parts.

- Secure the workpiece tightly.

- Keep tools sharp and in good condition.

- Adjust speed according to the material.

- Stay focused and avoid distractions.

What are key safety tips for using a lathe?

Key safety tips include wearing protective gear, securing loose clothing, and using guards on the machine. Always check your work area for any hazards.

Following these best practices will ensure you get great results while staying safe. A well-prepared workspace is the first step to a successful project! Remember, safety first!

Troubleshooting Common Workholding Issues

Identifying issues such as slipping or vibrations during operation. Solutions to enhance stability and accuracy.When using a lathe, you might see problems like slipping or vibrations. These issues can make your work less accurate. One way to fix slipping is to check the workholding device. Make sure it fits snugly. For vibrations, look at the lathe’s balance. A steady workholding setup is key for good results. Here are some quick tips:

- Check clamps for tightness.

- Use proper support to stabilize the workpiece.

- Replace worn parts if necessary.

Taking these steps can improve both stability and accuracy during lathe work.

What causes vibrations in lathe operations?

Vibrations can happen due to an unbalanced workpiece or loose tools. Checking your setup can help. A bit of adjustment can make your work smoother and more precise.

How can I improve stability in my workholding?

Improving stability can be done by using the right clamps and supports. Always ensure the lathe is on a flat surface and that tools are secured tightly.

Future Trends in Lathe Workholding Technologies

Innovations in workholding devices and automation techniques. Impact of technology on efficiency and precision in lathe work.New workholding devices are changing lathe work. These innovations use advanced materials and clever designs. Automation is also making work easier and faster. With software and robots, tasks can be done with great speed. This makes lathe work more precise. Workers spend less time fixing mistakes. Efficiency is on the rise. Here are some key points:

- Smart clamps for quick setup.

- Automated systems reduce human error.

- High-tech sensors ensure accuracy.

These trends will shape the future of lathe workholding technologies.

How will automation affect lathe work?

Automation will increase speed and reduce mistakes in lathe work. With robots and sensors, workers can focus on creative tasks instead.

Conclusion

In summary, a lathe is essential for shaping metal. The workholding setup keeps your pieces secure while the lead screw controls precision movement. Understanding these components helps you make better projects. We encourage you to practice using a lathe or read more about these tools. With more knowledge, you’ll become a skilled machinist in no time!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Regarding The Metal Lathe Lead Screw:Sure! The lead screw on a metal lathe helps move the tool very slowly and control cutting. We use it to make things like round shapes or nice edges. It’s really important for making precise parts. By turning a handle, you can move the tool just the right amount. This way, we can create exactly what we need!

Sure! Please provide the question you’d like me to answer.

What Is The Primary Function Of The Lead Screw In A Metal Lathe, And How Does It Affect Workholding Precision?The lead screw is a long, threaded stick in a metal lathe. It helps move the cutting tool back and forth. When the lead screw works well, it makes sure the tool cuts evenly and accurately. This means your workpiece holds its shape better. Thanks to the lead screw, we can create smooth and precise shapes in metal.

How Can Improper Alignment Of The Lead Screw Impact The Accuracy And Quality Of Machined Parts On A Metal Lathe?If the lead screw on a metal lathe isn’t lined up right, it can cause problems. You might end up with parts that are too big or too small. This happens because the tool moves in the wrong places. When parts are not accurate, they don’t fit together well. This can make the final product less useful or even broken.

What Types Of Workholding Devices Can Be Effectively Used With A Lathe’S Lead Screw To Ensure Stable And Secure Clamping Of Workpieces?You can use several devices to hold workpieces on a lathe. The three most common are chucks, collets, and faceplates. Chucks grab the workpiece tightly, while collets fit smaller pieces better. Faceplates are flat and hold big or odd-shaped items. Using these tools keeps your workpiece steady while you cut or shape it.

How Can A Lathe Operator Troubleshoot Issues Related To The Lead Screw When Faced With Inconsistent Feed Rates During Machining?If you notice the feed rates are not steady, check the lead screw first. Make sure it’s clean and not blocked. You can also look for any loose parts that might be causing the problem. Tighten anything that seems loose. If that doesn’t help, you may need to replace the lead screw.

What Maintenance Practices Should Be Followed For The Lead Screw And Its Associated Components To Ensure Optimal Performance In Lathe Workholding?To keep the lead screw and parts working well, you should regularly clean them. Use a soft cloth to wipe away dust and dirt. You should also add a little oil to the screw and threads to make them move smoothly. Check for any damage or wear often. If something seems broken, fix it right away.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Regarding The Metal Lathe Lead Screw:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! The lead screw on a metal lathe helps move the tool very slowly and control cutting. We use it to make things like round shapes or nice edges. It’s really important for making precise parts. By turning a handle, you can move the tool just the right amount. This way, we can create exactly what we need!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of The Lead Screw In A Metal Lathe, And How Does It Affect Workholding Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lead screw is a long, threaded stick in a metal lathe. It helps move the cutting tool back and forth. When the lead screw works well, it makes sure the tool cuts evenly and accurately. This means your workpiece holds its shape better. Thanks to the lead screw, we can create smooth and precise shapes in metal.”}},{“@type”: “Question”,”name”: “How Can Improper Alignment Of The Lead Screw Impact The Accuracy And Quality Of Machined Parts On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lead screw on a metal lathe isn’t lined up right, it can cause problems. You might end up with parts that are too big or too small. This happens because the tool moves in the wrong places. When parts are not accurate, they don’t fit together well. This can make the final product less useful or even broken.”}},{“@type”: “Question”,”name”: “What Types Of Workholding Devices Can Be Effectively Used With A Lathe’S Lead Screw To Ensure Stable And Secure Clamping Of Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use several devices to hold workpieces on a lathe. The three most common are chucks, collets, and faceplates. Chucks grab the workpiece tightly, while collets fit smaller pieces better. Faceplates are flat and hold big or odd-shaped items. Using these tools keeps your workpiece steady while you cut or shape it.”}},{“@type”: “Question”,”name”: “How Can A Lathe Operator Troubleshoot Issues Related To The Lead Screw When Faced With Inconsistent Feed Rates During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you notice the feed rates are not steady, check the lead screw first. Make sure it’s clean and not blocked. You can also look for any loose parts that might be causing the problem. Tighten anything that seems loose. If that doesn’t help, you may need to replace the lead screw.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed For The Lead Screw And Its Associated Components To Ensure Optimal Performance In Lathe Workholding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lead screw and parts working well, you should regularly clean them. Use a soft cloth to wipe away dust and dirt. You should also add a little oil to the screw and threads to make them move smoothly. Check for any damage or wear often. If something seems broken, fix it right away.”}}]}