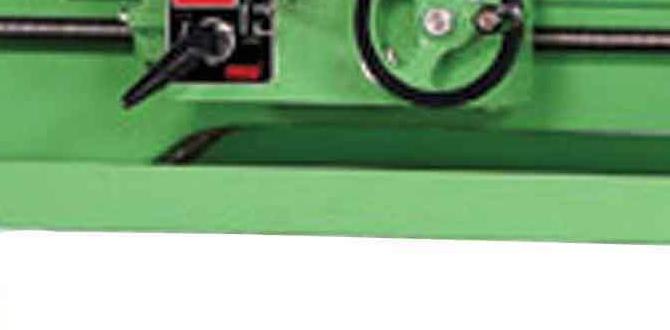

Have you ever wondered how metal parts are made? A lathe is a powerful tool that brings metal to life. Using lathe workholding is crucial in this process. It keeps the metal steady while it spins. Imagine a carousel of metal, perfectly shaped by the lathe as it turns.

Many folks don’t know that a metal lathe can do more than just cut. It can also shape and polish. This is where the power feed comes in. It makes the work easier and faster. With power feed, you can sit back and watch as the lathe works its magic.

Picture this: you have a metal piece in one hand and a lathe in the other. You want to create something great, but how do you hold it? That’s the beauty of workholding. It helps you focus on creativity, not struggle. Whether you are a beginner or a pro, understanding how to use a lathe well can change everything.

Did you know that with just a few adjustments, you can transform your lathe into a super tool? It’s true! Let’s dive deeper into how lathe workholding and power feed can help you make amazing metal projects.

Effective Lathe Workholding Techniques For Metal Lathe Power Feed

Lathe Workholding: Metal Lathe and Power Feed Essentials

Lathe workholding keeps metal pieces steady for precise cutting. It is important for any lathe user, whether beginner or expert. Have you ever tried to cut metal without it slipping? It’s nearly impossible! Metal lathes often use jaws or clamps to grip the workpiece. Power feed adds speed and ease, allowing you to focus on the cut. Learning how to use these tools correctly makes metalworking safer and more enjoyable. Plus, a well-secured piece can lead to better results and less waste.Understanding Lathe Workholding

Definition and importance of workholding in lathe operations. Types of workholding devices commonly used in metal lathes.Workholding is crucial in lathe operations. It keeps the metal piece steady while cutting happens. Without proper workholding, work can turn out messy. There are different devices to hold the workpieces in place. Here are some common types:

- Chucks: These grip round pieces securely.

- Collets: These hold smaller, cylindrical pieces well.

- Vises: These are great for flat or odd-shaped items.

Choosing the right workholding device makes a big difference. It ensures safety and accuracy in every project.

What are the different workholding devices in lathe operations?

Workholding devices include chucks, collets, and vises. Each has a specific role in keeping materials secure during machining.

The Role of Power Feed in Metal Lathes

Explanation of power feed and its advantages over manual feed. Key components of a power feed system.Power feed makes metal lathes run smoother and faster. Instead of turning the handles yourself, the machine does it for you. This saves time and effort, like having a robot butler for your lathe! The main parts of a power feed system include the motor, gears, and control switches. With power feed, you’ll get consistent results without turning into a workout warrior. Plus, it helps prevent mistakes. Less work, better results—it’s a win-win!

| Key Components | Function |

|---|---|

| Motor | Drives the movement |

| Gears | Transfer power smoothly |

| Control Switches | Manage speed and direction |

Choosing the Right Workholding Device

Factors to consider when selecting workholding solutions. Comparison of popular workholding devices for metal lathes.Choosing the right workholding device is key to successful lathe work. First, think about the size and shape of your metal piece. It needs to fit snugly without wiggling. That’s like finding the right seat on a roller coaster! Consider how often you’ll use it too. Some gadgets are good for one-time projects, while others work all day, every day. Lastly, look at popular choices:

| Device | Pros | Cons |

|---|---|---|

| Chucks | Versatile Easy to adjust |

Can be expensive Not ideal for all shapes |

| Collets | Great for precision | Limited size range May require more setup time |

| Vices | Stable hold Good for larger pieces |

Heavy Can take space |

Remember, you want a secure fit! If it feels loose, it’s like trying to hold onto a greased pig! Choose wisely, and your lathe work will be a breeze.

Setting Up Your Metal Lathe for Optimal Workholding

Stepbystep guide to properly securing workpieces. Tips for adjusting workholding setups based on material types.Getting your metal lathe ready is like prepping for a big dance party! First, make sure your workpiece is snug in the chuck—tight enough so it won’t wiggle, but not so tight that it feels like it’s in a bear hug. Next, if you’re working with softer metals, loosen the grip a bit to avoid dents. For harder materials, give a firm hold. Remember, adjusting based on the material type is key. Here’s a simple guide:

| Material Type | Workholding Tip |

|---|---|

| Wood | Looser fit to prevent cracks |

| Aluminum | Moderate grip to avoid marring |

| Steel | Firm grip for stability |

With these easy steps, your workpiece will feel secure and ready to spin! Just remember, safety comes first—no one wants to dance with a runaway drill!

Common Issues with Workholding and Power Feed

Identification of typical problems encountered during lathe operations. Troubleshooting techniques for workholding and power feed complications.Lathe work can feel like a circus sometimes! Sometimes, workholding can loosen, making your part wobble around like it’s dancing. Other issues include power feed stopping unexpectedly, which can ruin your masterpiece. To fix these hiccups, first, check the clamping system; maybe it just needs a tad more tightening. If your power feed fails, inspect the wiring—sometimes it’s as simple as a loose connection. Remember, patience pays off! Now let’s look at some common challenges:

| Issue | Solution |

|---|---|

| Loose Workholding | Tighten clamps and check for damage. |

| Power Feed Shutdown | Inspect wiring and connections. |

| Inconsistent Cutting | Adjust speed and feed rates. |

Every lathe has its quirks, but with a little troubleshooting, you can create wonderful things!

Advanced Techniques for Enhanced Efficiency

Innovative methods to improve workholding setups. Utilizing accessories to optimize power feed performance.To make your metal lathe work even smoother, try these fun tricks! First, improve your workholding setups with cool accessories like vise grips or clamps. They keep your material steady and stop it from dancing around. Next, optimize your power feed performance using gear drives that help in achieving consistent speed. This way, you won’t feel like a snail while working. So, let’s crank it up and enjoy the ride!

| Technique | Benefit |

|---|---|

| Vise Grips | Steady material, no dancing! |

| Gear Drives | Consistent speed, smooth work! |

Maintenance and Safety Tips for Lathe Workholding

Regular maintenance practices for workholding components. Safety measures to ensure secure operation during lathe work.Taking care of your lathe workholding is very important. Regular checks ensure it works safely. Here are some common practices:

- Clean the workholding parts after use to remove debris.

- Check for any wear or damage before starting.

- Lubricate moving parts for smooth operation.

- Store tools in a dry place to avoid rust.

Safety is key during lathe operation. Always wear protective gear, such as gloves and goggles. Make sure the workpiece is secure. Follow the machine’s guidelines for safe handling. This ensures a safe working environment for everyone.

Why is regular maintenance important for lathe workholding?

Regular maintenance prevents accidents and prolongs the lifespan of workholding parts. Proper care keeps everything running smoothly.

Key safety measures to remember:

- Always turn off the machine before cleaning.

- Keep the area clear of clutter.

Future Trends in Lathe Workholding and Power Feed

Emerging technologies and their potential impact on lathe operations. Predictions for the evolution of workholding techniques in the metalworking industry.New tools and smart machines are changing how we do lathe work. These technologies can help make workholding easier and faster. Robotics and automation will likely play big roles in the future. For example, machines may adjust grips by themselves. This will reduce errors and save time.

- Advanced sensors can improve precision.

- Smart software can manage power feeds automatically.

- 3D printing may lead to custom workholding parts.

These trends show that lathe workholding will keep evolving. As machines get smarter, they can handle more complex tasks. The future looks bright for the metalworking industry!

What are the future trends in lathe workholding?

Future trends include automation, advanced sensors, and smart software for better precision and efficiency. These technologies will change how workers approach metalworking tasks.

Conclusion

In conclusion, understanding lathe workholding and power feeds is important for metalworking. Using the right tools helps you create precise parts. Remember to secure your workpieces firmly for safety and accuracy. If you want to learn more, explore different workholding methods and power feed systems. Practice what you learn, and you’ll improve your skills over time!FAQs

Here Are Five Related Questions On The Topic Of Lathe Workholding, Metal Lathes, And Power Feed:Lathes are special machines that help shape metal. They hold metal pieces tightly so they don’t move while we work on them. A metal lathe spins the metal, making it easier to cut and shape it. Power feed helps move the cutting tool automatically, saving you time and effort. Working with a lathe can be fun and helps create many useful objects!

Sure! Just give me the question you’d like me to answer, and I’ll be happy to help!

What Are The Most Common Workholding Methods Used In Metal Lathes To Ensure Precise Machining Of Workpieces?On a metal lathe, we often use a few common ways to hold workpieces. One method is the chuck. It grabs the piece tightly, so it doesn’t move. We also use a faceplate, which holds bigger pieces flat. Finally, there are centers that help keep the ends steady while we work. These methods help us make accurate and smooth parts.

How Does The Power Feed System Work In A Metal Lathe, And What Advantages Does It Offer Over Manual Feeding?The power feed system in a metal lathe uses a motor to move the cutting tool automatically. This means you don’t have to push or turn the handles yourself. It helps you work faster and more accurately. Plus, it reduces tiredness because you don’t need to use your hands as much. This way, you can focus on getting a good result!

What Are The Key Factors To Consider When Selecting A Chuck For A Specific Lathe Operation?When picking a chuck for your lathe, you should think about its size first. Make sure the chuck fits your workpiece well. Next, consider the type of material you’ll be working with, like wood or metal. You also need to think about how you will hold your piece securely. Lastly, check the chuck’s grip strength to make sure it won’t slip while you work.

How Can Improper Workholding Impact The Overall Accuracy And Surface Finish Of Machined Parts In A Lathe?If you don’t hold a piece of metal properly in a lathe, it can move around. This can make your cuts uneven, which means the part won’t be accurate. Also, a loose piece can bounce, making the surface look rough. So, good holding keeps everything in place for better results!

What Types Of Power Feed Controls Are Available For Metal Lathes, And How Do They Differ In Functionality And Ease Of Use?Metal lathes have different types of power feed controls. Some let you set a speed and let the machine work by itself. Others need you to control the speed with your hands. Automatic feeds are easier because you can focus on other things. Hand feeds, though, give you more control but need more of your attention.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Workholding, Metal Lathes, And Power Feed:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathes are special machines that help shape metal. They hold metal pieces tightly so they don’t move while we work on them. A metal lathe spins the metal, making it easier to cut and shape it. Power feed helps move the cutting tool automatically, saving you time and effort. Working with a lathe can be fun and helps create many useful objects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Most Common Workholding Methods Used In Metal Lathes To Ensure Precise Machining Of Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “On a metal lathe, we often use a few common ways to hold workpieces. One method is the chuck. It grabs the piece tightly, so it doesn’t move. We also use a faceplate, which holds bigger pieces flat. Finally, there are centers that help keep the ends steady while we work. These methods help us make accurate and smooth parts.”}},{“@type”: “Question”,”name”: “How Does The Power Feed System Work In A Metal Lathe, And What Advantages Does It Offer Over Manual Feeding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The power feed system in a metal lathe uses a motor to move the cutting tool automatically. This means you don’t have to push or turn the handles yourself. It helps you work faster and more accurately. Plus, it reduces tiredness because you don’t need to use your hands as much. This way, you can focus on getting a good result!”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Chuck For A Specific Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a chuck for your lathe, you should think about its size first. Make sure the chuck fits your workpiece well. Next, consider the type of material you’ll be working with, like wood or metal. You also need to think about how you will hold your piece securely. Lastly, check the chuck’s grip strength to make sure it won’t slip while you work.”}},{“@type”: “Question”,”name”: “How Can Improper Workholding Impact The Overall Accuracy And Surface Finish Of Machined Parts In A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you don’t hold a piece of metal properly in a lathe, it can move around. This can make your cuts uneven, which means the part won’t be accurate. Also, a loose piece can bounce, making the surface look rough. So, good holding keeps everything in place for better results!”}},{“@type”: “Question”,”name”: “What Types Of Power Feed Controls Are Available For Metal Lathes, And How Do They Differ In Functionality And Ease Of Use?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes have different types of power feed controls. Some let you set a speed and let the machine work by itself. Others need you to control the speed with your hands. Automatic feeds are easier because you can focus on other things. Hand feeds, though, give you more control but need more of your attention.”}}]}