Have you ever wondered how to make amazing things with a metal lathe? Lathe workholding is key to crafting cool projects. Imagine spinning metal to create shapes that are both useful and beautiful. It sounds fun, doesn’t it?

Many people use metal lathes in their workshops. They can turn simple pieces of metal into art or tools. Whether you’re a beginner or an expert, lathe workholding can help you achieve great results. Did you know that the right techniques can make your projects easier?

In this article, we will explore exciting metal lathe projects. You’ll learn about the tools and techniques needed for success. Get ready to dive into the world of lathe workholding and unleash your creativity!

Lathe Workholding: Essential Metal Lathe Projects To Try

Lathe Workholding and Metal Lathe Projects

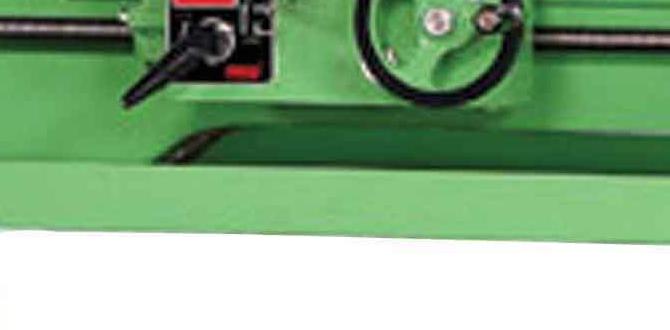

Lathe workholding is vital for metal lathe projects. Proper techniques keep materials stable, ensuring safety and precision. Did you know that improper workholding can lead to accidents? Using clamps and vises helps secure the workpiece correctly. Exciting projects include creating tools, parts, and even decorative items. Picture making your own metal toys or custom brackets! Learning these methods opens up endless possibilities for creativity and craftsmanship. Explore metal lathe projects today and unleash your inner maker!Understanding Lathe Workholding

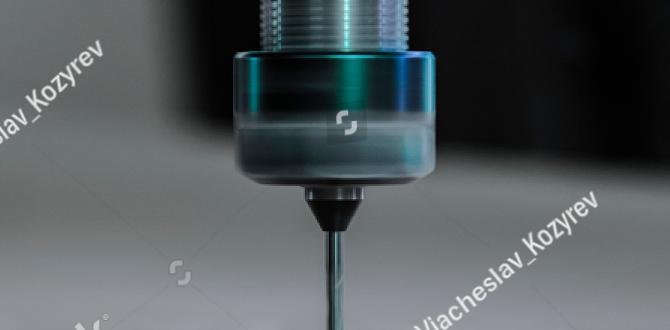

Definition and importance of workholding in metal lathe work. Common types of workholding devices and their applications.Workholding is like the superhero sidekick of metal lathe projects. It holds your workpiece steady while you shape and cut it. Think of it as having a good buddy to help you keep things together. There are many types of workholding devices, including chucks, vises, and collets. Each has its special job, making sure everything stays in place while you create. Without the right workholding, your masterpiece could turn into a wobbly disaster!

| Type of Device | Application |

|---|---|

| Chucks | Hold round pieces securely |

| Vises | Ideal for flat workpieces |

| Collets | Great for smaller items |

Choosing the right workholding device is important for precision and safety. Always remember: a good grip holds your work and your sanity! If not, you might end up with more than just chips flying around!

Creative Project Ideas for Skilled Metal Workers

Detailed descriptions of innovative and complex projects (e.g., custom components, artistic pieces). Tips for incorporating unique designs and functionalities.Metal workers can explore many fun and creative projects. Think about making unique custom parts or even artistic sculptures. By using lathe workholding techniques, artists can blend form and function. Here are some exciting ideas:

- Design custom knobs for furniture.

- Create decorative metal art pieces.

- Make personalized gifts like engraved keychains.

- Try building intricate mechanical toys.

Incorporating personal designs and special features can make these creations truly one-of-a-kind. Try mixing different materials for a unique touch!

What are some unique project ideas for metal lathe work?

Creative ideas include making custom tools, artistic sculptures, and personalized parts. These projects allow for unique designs and functionalities that showcase your skills.

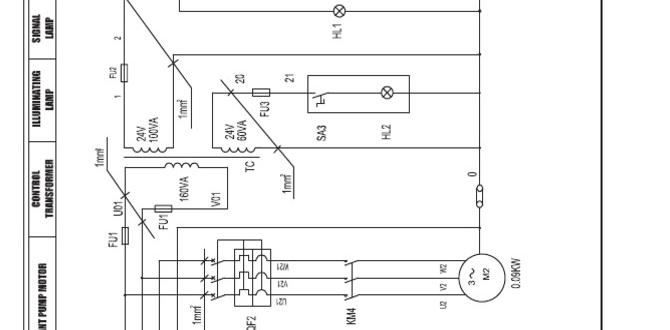

Setup Tips for Effective Workholding on a Lathe

Stepbystep guide to setting up workpieces securely on various workholding devices. Common mistakes to avoid during the setup process.Securing your workpiece on a lathe is crucial for a smooth project. Start by aligning your piece with the lathe’s center. Use a sturdy chuck or a vise. Make sure it’s tight, but not too tight—let’s not crush it! Remember, a good setup will help you avoid those “oops” moments.

| Common Mistakes | Tips to Avoid Them |

|---|---|

| Not checking for alignment | Always double-check your setup! |

| Over-tightening the chuck | Use just enough pressure to hold the piece. |

| Ignoring safety gear | Keep goggles on, or you might get a surprise! |

Following these steps will make your lathe workholding easier and more effective. Happy turning!

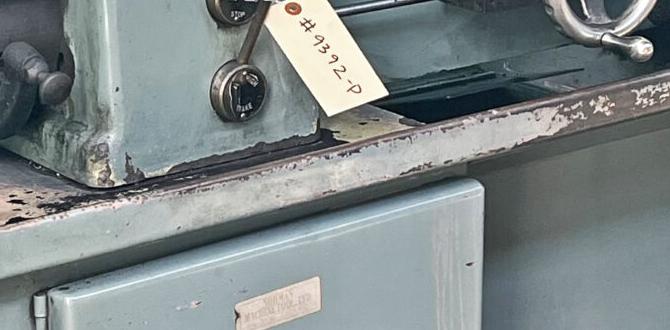

Maintenance and Care for Workholding Equipment

Best practices for maintaining and cleaning workholding tools to ensure longevity and accuracy. Signs that indicate the need for tool replacement or repair.To keep your workholding tools in great shape, regular maintenance is key. Start by cleaning them after each use. Wipe off oils and dirt. Use a soft cloth for this task. Lubricate moving parts to prevent wear and tear. Check your tools often. Look for signs of damage, like cracks or rust. If you notice these signs, it might be time for repair or even replacement.

- Keep it clean to avoid grime buildup.

- Lubricate parts regularly.

- Check for rust or cracks.

- Replace tools that no longer grip well.

What are signs that workholding equipment needs repair?

Signs include rust, cracks, and poor grip. If your tools shake during use or don’t hold materials tightly, they may need fixing or replacing.

Resources for Further Learning

Recommended books, websites, and courses on lathe workholding and metal projects. Community forums and groups for sharing experiences and getting advice.Learning about lathe projects can be exciting! Here are some great resources to explore:

- Books: Look for titles like “Lathe Work” and “Metalworking for Beginners.” They are easy to read and full of tips.

- Websites: Websites like Instructables and YouTube have tons of tutorials on projects and workholding techniques.

- Online Courses: Check platforms like Udemy and Coursera for courses specifically on lathe work.

- Forums and Groups: Join online communities like Reddit’s r/metalworking. Here, you can share experiences and get helpful advice.

Conclusion

In summary, lathe workholding is crucial for safe and accurate metal lathe projects. It helps you secure your workpiece firmly. Remember to choose the right clamps or chucks for better results. We encourage you to practice with various materials. Dive deeper into tutorials and guides to improve your skills. You’ll soon create impressive projects with confidence!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Projects:Lathe workholding is how we hold pieces in place while we cut or shape them with a lathe. A lathe is a machine that spins material, like metal or wood, so we can carve it. It’s helpful for making parts like toy wheels or small pieces for models. You can use tools like chucks or vices to keep the materials steady. These tools help us make sure everything is safe and accurate.

Sure! Please provide me with the specific question you would like me to answer.

What Are The Most Effective Types Of Workholding Methods For Securing Irregularly Shaped Metal Pieces During Lathe Machining?To keep oddly shaped metal pieces in place while using a lathe, you can use a few different methods. A good option is a custom fixture, which is a special holder made just for your piece. You can also use clamps, which squeeze the metal tightly. Another choice is a magnetic chuck, which uses magnets to hold the metal steady. These methods help you work safely and get a good finish on your piece.

How Does The Choice Of Chuck (Three-Jaw Vs. Four-Jaw) Impact Precision In Lathe Operations, And What Are Their Respective Advantages?Using the right chuck on a lathe can make a big difference in how precise your work is. A three-jaw chuck holds round things like pipes very well. It’s quick and easy to use. A four-jaw chuck can hold different shapes, like squares, more firmly. This helps you make very precise cuts, especially on uneven shapes. So, for quick jobs, use a three-jaw; for tricky shapes, a four-jaw is better.

What Are Some Best Practices For Setting Up A Metal Lathe Project To Ensure Optimal Safety And Accuracy Throughout The Machining Process?To stay safe and accurate with a metal lathe, first, wear safety gear like goggles and gloves. Check that the machine is clean and in good shape before starting. Always secure your metal piece tightly to prevent it from moving. Set the right speed and use the correct tools for your project. Keep your hands and loose clothing away from moving parts.

How Can You Adapt Standard Workholding Solutions To Accommodate Delicate Or Soft Materials When Machining On A Metal Lathe?To hold soft or delicate materials on a metal lathe, we can use special pads. These pads help grip the material without damaging it. You can also use a lighter touch when tightening the clamps. Another way is to make a custom holder that fits the shape of your material. This keeps it safe while we work on it.

What Are Some Innovative Custom Workholding Solutions That Experienced Machinists Use For Complex Lathe Projects?Experienced machinists use some cool tools to hold their workpieces on lathes. They might create special clamps to grip odd shapes. Sometimes, they design custom fixtures that fit the piece perfectly. Others use soft jaws on a chuck, which is a tool that holds round parts tightly. These clever solutions help us make accurate and detailed pieces.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Projects:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe workholding is how we hold pieces in place while we cut or shape them with a lathe. A lathe is a machine that spins material, like metal or wood, so we can carve it. It’s helpful for making parts like toy wheels or small pieces for models. You can use tools like chucks or vices to keep the materials steady. These tools help us make sure everything is safe and accurate.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the specific question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Effective Types Of Workholding Methods For Securing Irregularly Shaped Metal Pieces During Lathe Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep oddly shaped metal pieces in place while using a lathe, you can use a few different methods. A good option is a custom fixture, which is a special holder made just for your piece. You can also use clamps, which squeeze the metal tightly. Another choice is a magnetic chuck, which uses magnets to hold the metal steady. These methods help you work safely and get a good finish on your piece.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Chuck (Three-Jaw Vs. Four-Jaw) Impact Precision In Lathe Operations, And What Are Their Respective Advantages?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using the right chuck on a lathe can make a big difference in how precise your work is. A three-jaw chuck holds round things like pipes very well. It’s quick and easy to use. A four-jaw chuck can hold different shapes, like squares, more firmly. This helps you make very precise cuts, especially on uneven shapes. So, for quick jobs, use a three-jaw; for tricky shapes, a four-jaw is better.”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Setting Up A Metal Lathe Project To Ensure Optimal Safety And Accuracy Throughout The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To stay safe and accurate with a metal lathe, first, wear safety gear like goggles and gloves. Check that the machine is clean and in good shape before starting. Always secure your metal piece tightly to prevent it from moving. Set the right speed and use the correct tools for your project. Keep your hands and loose clothing away from moving parts.”}},{“@type”: “Question”,”name”: “How Can You Adapt Standard Workholding Solutions To Accommodate Delicate Or Soft Materials When Machining On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To hold soft or delicate materials on a metal lathe, we can use special pads. These pads help grip the material without damaging it. You can also use a lighter touch when tightening the clamps. Another way is to make a custom holder that fits the shape of your material. This keeps it safe while we work on it.”}},{“@type”: “Question”,”name”: “What Are Some Innovative Custom Workholding Solutions That Experienced Machinists Use For Complex Lathe Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Experienced machinists use some cool tools to hold their workpieces on lathes. They might create special clamps to grip odd shapes. Sometimes, they design custom fixtures that fit the piece perfectly. Others use soft jaws on a chuck, which is a tool that holds round parts tightly. These clever solutions help us make accurate and detailed pieces.”}}]}