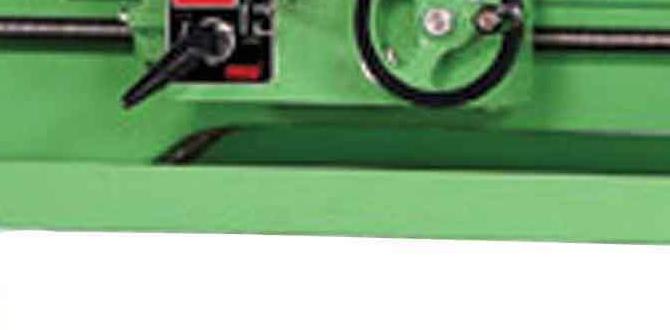

Have you ever wondered how a lathe turns metal into complex shapes? It’s magical! At the heart of this magic lies a key element: workholding. Workholding keeps the metal piece steady while the lathe spins.

One important part of workholding is the metal lathe pulley. This simple piece helps control movement and speed. Without it, your work would be messy and unpredictable.

Imagine trying to carve a perfect wooden toy, but the block slips away. Frustrating, right? That’s why understanding the lathe workholding process is so important. You need the right tools to achieve your craft goals.

In this article, we will dive into how metal lathe pulleys work. You’ll learn why they are essential for precision and control in your projects. Get ready to discover the secrets that keep metal turning smoothly!

Effective Lathe Workholding: Metal Lathe Pulley Techniques

Understanding Lathe Workholding with Metal Lathe Pulleys

Lathe workholding is essential for precision in metalworking. Metal lathe pulleys play a crucial role in this process. They help secure the workpiece while the lathe spins it. Have you ever tried holding something still while it spins? It’s not easy! Pulleys make this much simpler. They optimize the lathe’s power and ensure smooth operation. By learning how to use pulleys effectively, craftsmen can create better and more accurate metal parts.Understanding Lathe Workholding

Definition and importance of workholding in lathe operations. Common types of workholding devices used in metal lathes.Workholding is how you hold and secure materials on a lathe for cutting. It’s like giving your workpiece a big hug, so it doesn’t wiggle away! Proper workholding makes sure your cuts are smooth and exact. Common devices for holding metal include chucks, vises, and faceplates. Each device has its own secret superpower! Chucks grip round pieces like a bear hug, while vises hold flat ones like a best friend holding your hand!

| Type of Workholding Device | Best For |

|---|---|

| Chucks | Round parts |

| Vises | Flat pieces |

| Faceplates | Large workpieces |

In a nutshell, good workholding keeps everything tidy, making sure your lathe work is top-notch! Who knew holding stuff could be so important?

Choosing the Right Workholding Setup

Factors to consider when selecting workholding devices for specific projects. Pros and cons of various workholding methods.Picking the best workholding setup can feel like choosing the right toppings on pizza. There are many factors to think about. First, the size and shape of your project matter. Some tools work better for round parts, while others shine with flat pieces. Each method has its perks and quirks. For example, a chuck is great for easy gripping, but it can be tricky to set up. Here’s a quick look:

| Method | Pros | Cons |

|---|---|---|

| Chucks | Easy to use | Time-consuming setup |

| Vices | Holds tight | Limited to specific shapes |

| Collets | Great for precision | High cost |

Consider these options carefully. The right choice can make your lathe work smoother than butter on warm toast! Always remember that even a small change in setup can lead to big victories in your projects!

Setup and Alignment Techniques for Pulleys

Importance of proper alignment in precision machining. Stepbystep guide for aligning pulleys on a metal lathe.Getting your pulleys in line is super important for a smooth ride on the metal lathe. Proper alignment means your machine works like a charm and saves you from wobbly pieces that can make you scratch your head. Here’s a fun way to do it:

| Step | Action |

|---|---|

| 1 | Check the level of your lathe—no one likes a tilted party! |

| 2 | Loosen the pulley bolts with a wink—don’t go too hard! |

| 3 | Use a straightedge to line them up, like ducks in a row. |

| 4 | Tighten the bolts gently—no one wants a breakdance battle! |

Follow these steps, and you’ll have your pulleys aligned in no time. It makes everything run smoother. Remember, “A good setup can save a whole lot of headaches!”

Tips for Enhancing Workholding Stability

Techniques to reduce vibration and improve cutting accuracy. Materials and tools that enhance workholding stability.To enhance workholding stability, here are some tips that can be beneficial. Start by using solid materials like steel or aluminum. These materials resist bending and help keep everything steady. Reduce vibration by tightening all screws and adjusting your setup. Using proper clamps also helps. Try using a heavier base, which can stabilize the workpiece. Remember, good cutting accuracy means smoother operations.

How can I reduce vibration when using a lathe?

To reduce vibration, tighten the workpiece properly and use high-quality tools. Choosing the right speed for your machine also minimizes shaking. Consider using rubber pads under your lathe for extra support.

- Use strong materials like steel or aluminum.

- Tighten all screws and clamps.

- Choose the right speed for your lathe.

Common Challenges in Lathe Workholding

Identification of common issues faced by machinists. Solutions to overcome these challenges in workholding setups.Machinists often face some challenges with their workholding setups. Common issues include parts slipping during machining and poor alignment. These problems can lead to waste of time and materials. It is crucial to find the right solution to avoid these challenges.

- Ensure proper clamping: Use clamps that fit well and hold the part securely.

- Check alignment: Make sure the part is aligned correctly before starting.

- Use the right tools: Select tools designed for the specific task.

Taking these steps can help improve accuracy and efficiency in lathe workholding.

What are common issues in lathe workholding?

Common issues include part slippage, poor alignment, and tool chatter.

How can these challenges be solved?

Solutions involve using proper clamps, aligning parts correctly, and selecting the right tools.

Safety Considerations in Lathe Workholding

Recommended safety practices while using metal lathe pulleys. Common hazards and how to mitigate risks during lathe operations.Working with metal lathes can be fun, but safety is very important. Always wear safety glasses to protect your eyes. Keep your hair tied back and wear gloves without loose fingers to avoid getting caught. Check tools and pulleys before use. Look for signs of wear. Here are some safety tips:

- Avoid wearing jewelry.

- Don’t operate the lathe alone.

- Keep the area clean and organized.

By following these steps, you can reduce accidents and enjoy your lathe work!

What are the common hazards with lathe workholding?

Common hazards include entanglement and flying debris. Proper safety gear and precautions can help prevent injuries.

How can risks be reduced during lathe operations?

- Use guards to cover moving parts.

- Maintain a safe distance while operating.

- Be aware of your surroundings.

Future Trends in Workholding Technology

Innovations in workholding techniques and materials. The role of automation and smart technology in lathe workholding.Workholding technology is changing fast! Innovators are exploring new materials that are strong and lightweight, like carbon fiber. This helps in making lathe workholding easier and more efficient. Plus, automation is making its mark too. Picture a robot helping you hold that stubborn metal piece while you cut it. It’s like having a tiny assistant who doesn’t ask for coffee breaks!

| Innovation | Benefit |

|---|---|

| New materials | Stronger, lighter equipment |

| Automation | More efficient work |

These changes show how the future is bright for workholding. So, keep your eyes peeled! The machines of tomorrow might be a little smarter than you!

Resources for Further Learning

Recommended books, websites, and online courses for indepth knowledge. Industry organizations and forums for lathe machinists and enthusiasts.Want to dive deeper into lathe work? Here are some great resources! Check out books like “Machining Fundamentals” for solid basics. Visit websites like MachinistTools and PracticalMachinist for tips. Online courses are available on sites like Udemy and Coursera. Join forums and groups, such as the National Tooling and Machining Association, for networking and learning from experts.

What are good online resources for lathe work?

Online platforms like Udemy and Coursera provide excellent courses for beginners and experts. Websites such as PracticalMachinist offer a wealth of information and community support.

Conclusion

In summary, lathe workholding is essential for accurate metal lathe jobs. A pulley helps secure your materials, making your work smoother. Always choose the right workholding tools to improve safety and precision. Explore different techniques to enhance your skills. By practicing, you can master lathe work and create amazing projects. Dive deeper into lathe workholding for more tips and ideas!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding For Metal Lathe Pulleys:Sure! Here are some questions about workholding for lathe pulleys. 1. What is a lathe? A lathe is a machine that shapes metal by spinning it and cutting it into the right shape. 2. Why do we need workholding? We need workholding to keep the metal parts steady while we cut them. This way, we make sure everything fits properly. 3. What is a pulley? A pulley is a wheel that helps move things, usually by using a rope or belt. 4. How do we hold pulleys on the lathe? We can use clamps or jaws to grab the pulley tightly. This keeps it safe while we work. 5. What happens if the pulley moves while we cut it? If the pulley moves, we might make mistakes. It can also be dangerous for us.

Sure! Just ask me your question, and I’ll be happy to help.

What Are The Most Common Types Of Workholding Fixtures Used For Machining Pulleys On A Metal Lathe?When we machine pulleys on a metal lathe, we often use a few different workholding fixtures. A common one is the chuck, which holds the pulley tightly while we work on it. Another option is a faceplate, which can hold larger pulleys. You can also use clamps or vices to keep the pulley steady. These tools help us make sure everything stays in place while we cut or shape the pulley.

How Do You Ensure Proper Alignment And Stability Of A Pulley When Setting It Up In A Lathe?To set up a pulley on a lathe, you need to make sure it’s straight and steady. First, you check that the pulley is level. Then, you adjust it until it is in the right position. After that, you tighten the screws so it doesn’t move. Finally, you give it a little spin to see if it turns smoothly.

What Are The Advantages And Disadvantages Of Using A Chuck Versus Collets For Holding Pulleys In A Metal Lathe?Using a chuck holds pulleys well and is easy to set up. It can handle big and heavy pieces. But it might not hold smaller or odd-shaped parts firmly. Collets, on the other hand, grip small parts tightly and are great for tiny jobs. However, they can be harder to change and fit only specific sizes.

How Can You Use A Live Center Or Tailstock To Support A Pulley During Machining Operations?You can use a live center or tailstock to help hold a pulley while you work on it. The live center spins with the pulley, so it doesn’t slow you down. You can push the tailstock against the pulley to keep it steady. This support makes it easier to cut or shape the pulley without it moving around.

What Safety Precautions Should Be Taken When Working With Pulleys On A Metal Lathe To Prevent Accidents?When using pulleys on a metal lathe, always wear safety goggles to protect your eyes. Keep long hair tied back and avoid loose clothing. Make sure to turn off the machine before changing anything. Always keep your hands away from moving parts. Lastly, be aware of your surroundings and let others know when you are using the lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding For Metal Lathe Pulleys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about workholding for lathe pulleys. 1. What is a lathe? A lathe is a machine that shapes metal by spinning it and cutting it into the right shape. 2. Why do we need workholding? We need workholding to keep the metal parts steady while we cut them. This way, we make sure everything fits properly. 3. What is a pulley? A pulley is a wheel that helps move things, usually by using a rope or belt. 4. How do we hold pulleys on the lathe? We can use clamps or jaws to grab the pulley tightly. This keeps it safe while we work. 5. What happens if the pulley moves while we cut it? If the pulley moves, we might make mistakes. It can also be dangerous for us.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask me your question, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Most Common Types Of Workholding Fixtures Used For Machining Pulleys On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we machine pulleys on a metal lathe, we often use a few different workholding fixtures. A common one is the chuck, which holds the pulley tightly while we work on it. Another option is a faceplate, which can hold larger pulleys. You can also use clamps or vices to keep the pulley steady. These tools help us make sure everything stays in place while we cut or shape the pulley.”}},{“@type”: “Question”,”name”: “How Do You Ensure Proper Alignment And Stability Of A Pulley When Setting It Up In A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a pulley on a lathe, you need to make sure it’s straight and steady. First, you check that the pulley is level. Then, you adjust it until it is in the right position. After that, you tighten the screws so it doesn’t move. Finally, you give it a little spin to see if it turns smoothly.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Chuck Versus Collets For Holding Pulleys In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a chuck holds pulleys well and is easy to set up. It can handle big and heavy pieces. But it might not hold smaller or odd-shaped parts firmly. Collets, on the other hand, grip small parts tightly and are great for tiny jobs. However, they can be harder to change and fit only specific sizes.”}},{“@type”: “Question”,”name”: “How Can You Use A Live Center Or Tailstock To Support A Pulley During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a live center or tailstock to help hold a pulley while you work on it. The live center spins with the pulley, so it doesn’t slow you down. You can push the tailstock against the pulley to keep it steady. This support makes it easier to cut or shape the pulley without it moving around.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Working With Pulleys On A Metal Lathe To Prevent Accidents?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using pulleys on a metal lathe, always wear safety goggles to protect your eyes. Keep long hair tied back and avoid loose clothing. Make sure to turn off the machine before changing anything. Always keep your hands away from moving parts. Lastly, be aware of your surroundings and let others know when you are using the lathe.”}}]}