Have you ever wondered how to get the perfect cut on a metal lathe? Many hobbyists and professionals face challenges when working with different machines. One common issue is tailstock alignment. This step is crucial for accurate lathe workholding. If it is off, you could end up ruining your project.

Imagine spending hours on a piece, only to discover that it isn’t straight. Frustrating, right? Ensuring your metal lathe tailstock is aligned will help you avoid these problems. Aligning the tailstock properly can make all the difference.

Did you know that a small misalignment can throw off your entire workpiece? It’s true! Taking the time to learn about lathe workholding and tailstock alignment can really pay off. Let’s explore some easy tips and tricks to help you improve your metal lathe experience!

Lathe Workholding: Metal Lathe Tailstock Alignment Guide

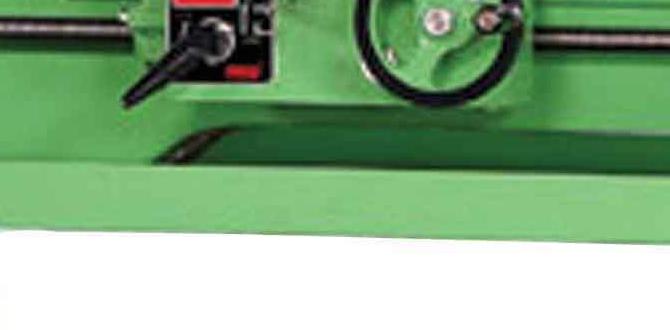

Understanding Lathe Workholding and Tailstock Alignment

Getting the perfect alignment on a metal lathe’s tailstock is crucial. Did you know that even a slight misalignment can ruin your project? Proper tailstock alignment helps in creating accurate and smooth cuts. It ensures that your work is securely held in place. Learning to adjust your lathe correctly can save time and materials. Imagine finishing a project without unnecessary errors! Mastering this skill will make you a better craftsman. Keep practicing, and watch your work improve!Importance of Tailstock Alignment

Impact of alignment on workpiece accuracy and surface finish.. Common issues arising from misalignment and their consequences..Tailstock alignment is super important in lathe work. If the tailstock is out of whack, it can ruin your workpiece. Picture this: a misaligned tailstock can lead to wobbly cuts and poor surface finish, like trying to ice a cake with a wobbly hand! This can cause big headaches, like increased wear on tools and inconsistent dimensions. The chart below shows some common misalignment issues and their effects:

| Misalignment Issue | Consequence |

|---|---|

| Too High or Low | Uneven cuts, poor finish |

| Side-to-Side Displacement | Wobbly workpiece, extra tool wear |

| Rotational Misalignment | Inaccurate diameters, difficult machining |

So, remember, a well-aligned tailstock is a happy tailstock! It helps keep your cuts smooth and your projects shining.

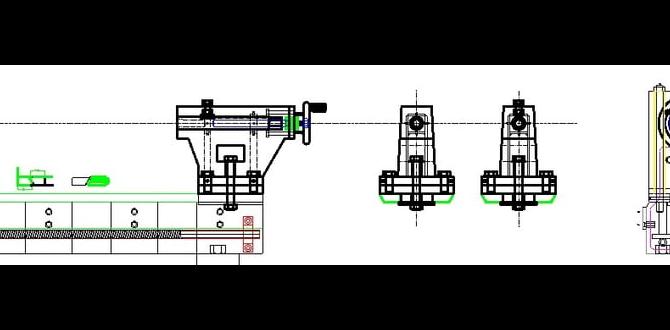

Methods for Tailstock Alignment

Stepbystep procedures for aligning the tailstock on a metal lathe.. Tools required for precise alignment..Aligning the tailstock of a metal lathe is like finding the sweet spot on a seesaw—balance is key! First, you need some tools: a dial indicator, a wrench, and a tape measure. To start, check if the tailstock is level by measuring from the spindle centerline to the tailstock. Adjust it using that trusty wrench. Next, use the dial indicator to ensure it lines up perfectly. Remember, a misaligned tailstock can lead to wobbly parts—no one wants a lumpy lug nut! So, double-check your work before you start spinning those metal masterpieces.

| Tool | Purpose |

|---|---|

| Dial Indicator | Measures alignment precision |

| Wrench | Adjusts the tailstock |

| Tape Measure | Checks distance for level |

Tips for Maintaining Tailstock Alignment

Regular maintenance checks and adjustments.. Best practices for ensuring consistent performance during operation..To keep your tailstock aligned, regular checks are important. Schedule these checks often. Look for wear or damage and adjust as needed. Good maintenance helps your machine work better. Here are some solid tips:

- Check the tailstock for tightness.

- Inspect alignment with a dial indicator.

- Lubricate moving parts regularly.

- Clean the area to avoid debris buildup.

These steps ensure smooth operations and long life for your lathe.

How often should I check tailstock alignment?

It’s best to check tailstock alignment every week or after heavy use. This simple practice can save you time and money in repairs.

Real-World Applications and Use Cases

Examples of projects where accurate tailstock alignment made a difference.. Case studies highlighting the importance of precision in machining processes..Many projects show the importance of correct tailstock alignment. Accurate alignment helps in making precise parts. Here are some examples:

- Furniture Making: Aligning the tailstock ensures the legs are even and sturdy.

- Automotive Parts: Precision made in engines improves car performance.

- Prototyping: Good alignment helps create models that fit together perfectly.

One case study showed that a small error in alignment led to the loss of 30% of materials in machining. This shows how important lathe workholding metal lathe tailstock alignment is for success.

Why is tailstock alignment important?

Tailstock alignment is crucial because it ensures parts fit well and work correctly. It prevents waste and saves time in machining.

Conclusion

In summary, properly aligning your lathe tailstock is vital for accurate metalworking. This ensures your workpiece stays secure and true while cutting. You can improve your skills by practicing alignment techniques. Remember to regularly check your equipment for the best results. For more tips and detailed guides, keep exploring resources on lathe workholding and metalworking. Happy shaping!FAQs

Sure! Here Are Five Questions Related To Lathe Workholding And Tailstock Alignment:Sure! When using a lathe, holding the piece tightly is important. This keeps it from moving while you work. The tailstock helps support the other end. You need to check it is lined up correctly to make good shapes. If everything is aligned, your work will be smoother and nicer!

Sure! Please provide the question you would like me to answer.

What Are The Critical Steps To Ensure Accurate Alignment Of The Tailstock On A Metal Lathe?To align the tailstock on a metal lathe, first, make sure the lathe is on a flat surface. Next, check that the tailstock is pushed all the way against the bed of the lathe. Then, use a test bar to see if the tailstock is straight with the spindle. If it isn’t, adjust the tailstock until it matches the spindle perfectly. Finally, lock it in place so it stays straight while you work.

How Can Misalignment Of The Tailstock Affect The Precision Of Workpieces During Machining Operations?If the tailstock is not lined up right, it can wobble your workpiece when you cut it. This makes it hard to get straight, even cuts. You might end up with parts that don’t fit together correctly. So, keeping the tailstock straight helps your projects turn out better.

What Tools Or Techniques Can Be Used To Measure Tailstock Alignment In A Metal Lathe?You can measure tailstock alignment using a few simple tools. One common tool is a dial indicator. You attach it to the tailstock and check the alignment with the main part of the lathe. Another tool is a test bar. You place it in the lathe and see if it is straight. Both methods help you make sure everything is lined up correctly.

How Often Should Tailstock Alignment Be Checked And Adjusted For Optimal Lathe Performance?You should check and adjust the tailstock alignment often. If you use the lathe a lot, do this every week. If you use it less, check it every month. Always check it when you notice problems with your work. This helps your lathe work better!

What Common Issues Can Arise From Improper Tailstock Alignment, And How Can They Be Rectified?Improper tailstock alignment can cause several problems. Your workpiece might wobble, which makes it hard to cut correctly. It can also lead to uneven shapes or even damage your tools. To fix this, check the tailstock position and adjust it until it is aligned properly with the machine. You can also use a ruler or a special tool to help with the adjustment.