Have you ever wondered how metal objects are shaped with such precision? It often starts with lathe workholding. This process is essential for anyone using a metal lathe. But what does it really involve?

Imagine you want to make a custom part for a model car. You grab a metal lathe, but there’s more to it than just spinning metal. You need to hold that metal piece firmly in place. That’s where effective lathe workholding comes into play.

Did you know that lathe thread cutting can create strong and lasting connections between parts? With the right tools and techniques, you can achieve perfect threads every time. This is crucial for projects that require durable and reliable components.

In this article, we will explore the world of lathe workholding and thread cutting. You will learn tips and tricks to become a master at it. Are you ready to dive into this fascinating journey of turning metal into useful creations?

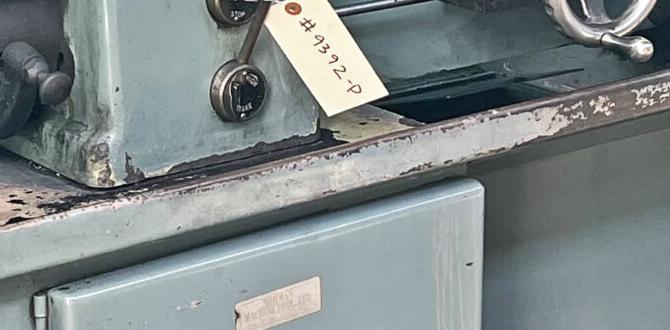

Effective Lathe Workholding Techniques For Metal Lathe Thread Cutting Lathe Workholding Is Paramount In Ensuring Precision And Accuracy During Metal Lathe Thread Cutting Operations. Whether You’Re A Seasoned Machinist Or A Hobbyist, Understanding The Importance Of Solid Workholding Setups Can Significantly Enhance The Quality Of Your Threaded Components. This Article Will Delve Into Essential Techniques And Tips For Effective Lathe Workholding That Will Optimize Your Thread Cutting Processes. Understanding Lathe Workholding Lathe Workholding Refers To The Methods Used To Secure The Workpiece On A Lathe Machine, Allowing For Safe And Precise Machining Operations. The Choice Of Workholding Device Can Affect Your Entire Threading Process, Influencing The Accuracy Of The Threads Being Cut. Types Of Workholding Devices 1. **Chucks**: The Most Common Workholding Tool Is The Chuck. It Securely Grips Various Shapes And Sizes Of Workpieces Using Adjustable Jaws. For Thread Cutting, A 3-Jaw Chuck Is Often Preferred Due To Its Balance And Ease Of Use. 2. **Collets**: Collet Systems Provide A Tighter Grip On Cylindrical Workpieces And Are Excellent For High-Precision Tasks. They Are Particularly Useful When Threading Smaller Diameters. 3. **Faceplates**: When Working With Larger Or Irregularly Shaped Workpieces, Faceplates Can Be Used. They Allow For More Flexibility In Holding The Workpiece In Place During The Thread Cutting Process. 4. **Mandrels**: These Are Essential For Internal Threading Or Holding A Workpiece That Is Hollow. They Provide Stability And Help Maintain The Alignment Of The Work During Machining. Best Practices For Workholding During Thread Cutting 1. **Secure Workpieces Properly**: Ensure That Your Workpiece Is Tightly Secured Without Being Deformed. Loose Workpieces Can Lead To Inaccuracies And Unsafe Conditions. 2. **Check Alignment**: Always Check The Alignment Of The Workpiece Before Starting The Thread Cutting Operation. Misalignment Can Result In Poor Thread Quality. 3. **Use Appropriate Speed**: Thread Cutting Speed Can Vary Depending On The Material Used And Diameter Of The Workpiece. Use The Correct Rpm Settings To Ensure A Clean Cut. 4. **Monitor Tool Wear**: Keep An Eye On Your Cutting Tools And Replace Them If They Show Signs Of Wear. Dull Tools Can Affect The Quality Of The Threads And Increase Production Time. 5. **Experiment With Cutting Fluids**: Using The Right Cutting Fluid Can Enhance Tool Life And Improve Thread Quality By Reducing Friction And Heat Generation. Conclusion Understanding Lathe Workholding Techniques And Utilizing The Right Devices Is Crucial For Successful Metal Lathe Thread Cutting. By Implementing Secure Workholding Methods And Following Best Practices, You Can Achieve High-Quality Threads And Improve Overall Machining Efficiency. Whether You’Re Working On Small Projects Or Larger Components, Remember That Effective Workholding Lays The Foundation For Great Results.

Lathe Workholding and Metal Lathe Thread Cutting

Lathe workholding is essential for creating precise metal parts. Did you know that a simple clamp can make a huge difference in accuracy? Properly securing your workpiece prevents movement during thread cutting. This technique allows you to shape and create strong threads for screws and bolts. Knowing how to use tools like chucks and collets can enhance your projects. By mastering these skills, you’ll improve both safety and quality in your metalworking adventures!Understanding Lathe Workholding Basics

Definition and importance of workholding in lathe operations. Different types of workholding systems (chucks, vises, fixtures).Workholding is like giving a lathe a warm hug. It keeps metal pieces steady so they don’t wiggle while we cut and shape them. This step is super important! Imagine trying to paint a moving canvas. Frustrating, right?

Different tools help us hold things in place. Here’s a quick look:

| Workholding System | Usage |

|---|---|

| Chucks | Best for round parts |

| Vises | Great for flat pieces |

| Fixtures | Custom solutions for unique shapes |

Choosing the right system is key. Think of it like picking the right shoes for a dance party—comfort is everything! Without good workholding, your lathe work could turn into a clumsy tango.

Choosing the Right Workholding System for Thread Cutting

Factors to consider for optimal thread cutting results. Comparison of various workholding options (3jaw chucks, collet chucks).Picking the right workholding system is key for smooth thread cutting. Think about how tight it grips your workpiece, as a loose fit can spoil your masterpiece. You can choose between 3-jaw chucks and collet chucks. 3-jaw chucks are versatile but might not hold smaller pieces as well. On the other hand, collet chucks provide a snug hug for tiny jobs. It’s like choosing between a warm hug from a bear or a snug blanket! Check out the comparison below:

| Type | Grip Strength | Best For |

|---|---|---|

| 3-Jaw Chuck | Good | General use |

| Collet Chuck | Very Strong | Small, precise jobs |

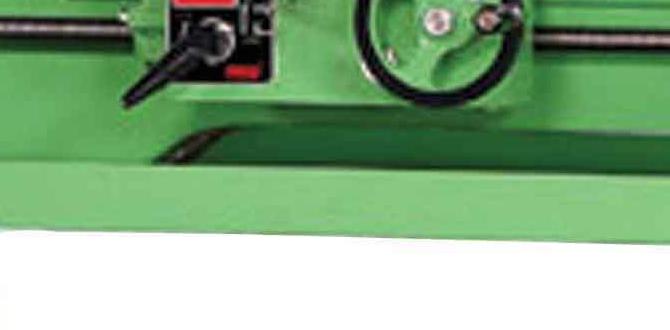

Setting Up the Metal Lathe for Thread Cutting

Stepbystep guide to preparing the lathe and workpiece. Importance of precision in setup for accurate thread cutting.Getting your metal lathe ready for thread cutting is like prepping for a big party—you need everything in place. First, check the machine’s settings. Make sure they match the thread pitch you want. A wrong setting could lead to wonky threads—like a cake with a tilted birthday candle! Next, secure your workpiece tightly. Use clamps to keep it steady. If it wobbles, your threads will, too. Remember, precision is key. A tiny mistake can ruin your work. Follow the steps carefully, and your threads will be sharp enough for a compliment!

| Steps | Details |

|---|---|

| Check Settings | Match lathe settings to thread pitch |

| Secure Workpiece | Use clamps for a stable setup |

| Ensure Precision | Avoid mistakes for perfect threads |

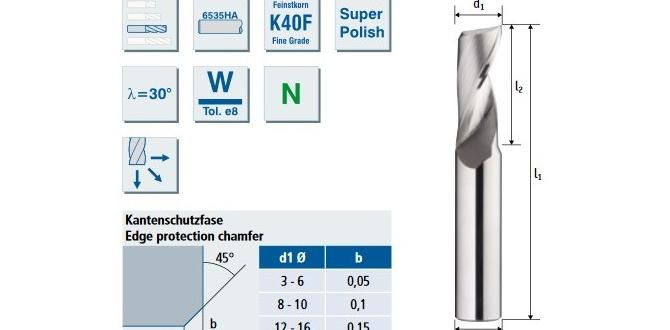

Techniques for Effective Thread Cutting on a Lathe

Detailed explanation of threading tools and their uses. Best practices for manual and automatic thread cutting.Thread cutting on a lathe requires proper tools and techniques. There are various types of threading tools, including single-point and multi-tooth cutters. Each tool has a unique purpose based on the type of thread being cut. For best results, always keep these practices in mind:

- Use a steady feed rate.

- Ensure precise depth adjustments.

- Clean and lubricate tools regularly.

- Utilize proper machine settings for automatic cutting.

Remember, practice helps improve your skills. Soon, you’ll cut threads like a pro!

What tools do I need for thread cutting on a lathe?

You will need threading tools like taps, dies, and single-point cutters for clean threads.

What are some tips for manual thread cutting?

- Keep your hands steady.

- Measure deeply with a caliper.

- Start slow to avoid mistakes.

Many people find that practice makes perfect. Don’t rush!

Common Challenges in Lathe Thread Cutting and Solutions

Identifying and troubleshooting common issues (chip removal, thread alignment). Tips for achieving better thread quality and consistency.Thread cutting on a metal lathe can be tricky. One common issue is chip removal. Chips can clog the cutting area, leading to a messy job. To fix this, you can use a coolant or a chip removal system. Another challenge is thread alignment. Misalignment can ruin your threads faster than a cat running away from a bath! Always double-check your setup and use an indicator for accuracy.

To achieve better thread quality, keep your tools sharp and your lathe clean. The smoother the surface, the happier your threads will be! Remember, practice makes perfect. Just like learning to ride a bike—fall a little, laugh a lot, and soon you’ll be flying!

| Issue | Solution |

|---|---|

| Chip Removal | Use coolant or a chip removal system |

| Thread Alignment | Double-check setup with an indicator |

Safety Precautions and Best Practices

Essential safety measures when working with metal lathes. Maintenance tips for workholding equipment to ensure longevity and performance.Using a metal lathe can be fun, but safety should always come first! Always wear safety glasses to protect your eyes from flying chips. Stay focused and keep your hair and loose clothing away from the machine. It’s like giving the lathe a big hug—just not too close! Regularly maintain your workholding equipment by cleaning and checking for wear. This keeps everything running smoothly and ensures your tools are happy. A happy lathe makes for a happy worker!

| Safety Measure | Tip |

|---|---|

| Wear Safety Goggles | Protects your eyes from debris |

| Stay Alert | Focus prevents accidents |

| Keep Area Clean | Reduces slip hazards |

| Regular Maintenance | Ensures your tools last longer |

Conclusion

In summary, lathe workholding is crucial for safe and precise metal lathe thread cutting. It helps keep your workpiece steady and accurate. Understanding different hold-down methods can improve your projects. We encourage you to practice these techniques and read more about lathe safety and operation. You’ll gain confidence and skill as you work with lathes!FAQs

Here Are Five Related Questions On The Topic Of Lathe Workholding In Metal Lathe Thread Cutting:When using a lathe to cut threads in metal, we need to hold the metal piece securely. We can use a tool called a chuck to grip the metal. This keeps it in place while we use the lathe. It’s important to set everything up right for safe and accurate work. Always check that the metal is tight before starting!

Sure! Just ask your question, and I’ll give you a simple and clear answer.

What Are The Key Considerations For Selecting The Appropriate Workholding Device For Thread Cutting On A Metal Lathe?When choosing a workholding device for thread cutting on a metal lathe, think about a few important things. First, make sure it holds your metal piece tightly so it doesn’t move. Second, check if it fits the size and shape of your workpiece. Third, consider how easy it is to set up and take off. Finally, think about how well it helps you see what you’re doing while you cut the thread.

How Does The Choice Of Workholding Method (E.G., Chuck, Collet, Or Faceplate) Impact The Accuracy And Quality Of The Threads Produced?The way you hold the workpiece, like using a chuck, collet, or faceplate, really matters. A good grip keeps the piece steady while we shape the threads. If it moves around, the threads can come out uneven or messy. So, using the right method helps us make better and more accurate threads. This means our work stays neat and fits together well!

What Techniques Can Be Employed To Minimize Vibration And Improve Stability During Thread Cutting Operations On A Lathe?To minimize vibration and improve stability when cutting threads on a lathe, you can try a few things. First, make sure your lathe is well-supported and on a sturdy table. You can also use sharp tools, as they cut better and create less vibration. Adjust the speed of the lathe to find what works best. Finally, hold the workpiece tightly so it doesn’t move around.

How Can Workholding Setups Be Adjusted To Accommodate Different Sizes And Shapes Of Workpieces While Ensuring Precise Thread Cutting?To adjust workholding setups for different sizes and shapes, you can change the clamps or jaws. These parts hold the workpiece in place. You might also use soft materials to grip odd shapes better. Always check the position carefully to ensure precise thread cutting. This helps make sure everything fits and cuts correctly.

What Are The Common Errors Or Challenges Encountered In Workholding During Thread Cutting, And How Can They Be Mitigated?When you cut threads, things can go wrong. One problem is the tool moving or slipping. This can make the threads uneven. To stop this, hold the workpiece tightly and check it often. Another problem is not lining everything up right. You can fix this by measuring carefully before you start.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Workholding In Metal Lathe Thread Cutting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe to cut threads in metal, we need to hold the metal piece securely. We can use a tool called a chuck to grip the metal. This keeps it in place while we use the lathe. It’s important to set everything up right for safe and accurate work. Always check that the metal is tight before starting!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll give you a simple and clear answer.”}},{“@type”: “Question”,”name”: “What Are The Key Considerations For Selecting The Appropriate Workholding Device For Thread Cutting On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a workholding device for thread cutting on a metal lathe, think about a few important things. First, make sure it holds your metal piece tightly so it doesn’t move. Second, check if it fits the size and shape of your workpiece. Third, consider how easy it is to set up and take off. Finally, think about how well it helps you see what you’re doing while you cut the thread.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Workholding Method (E.G., Chuck, Collet, Or Faceplate) Impact The Accuracy And Quality Of The Threads Produced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The way you hold the workpiece, like using a chuck, collet, or faceplate, really matters. A good grip keeps the piece steady while we shape the threads. If it moves around, the threads can come out uneven or messy. So, using the right method helps us make better and more accurate threads. This means our work stays neat and fits together well!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Minimize Vibration And Improve Stability During Thread Cutting Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To minimize vibration and improve stability when cutting threads on a lathe, you can try a few things. First, make sure your lathe is well-supported and on a sturdy table. You can also use sharp tools, as they cut better and create less vibration. Adjust the speed of the lathe to find what works best. Finally, hold the workpiece tightly so it doesn’t move around.”}},{“@type”: “Question”,”name”: “How Can Workholding Setups Be Adjusted To Accommodate Different Sizes And Shapes Of Workpieces While Ensuring Precise Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust workholding setups for different sizes and shapes, you can change the clamps or jaws. These parts hold the workpiece in place. You might also use soft materials to grip odd shapes better. Always check the position carefully to ensure precise thread cutting. This helps make sure everything fits and cuts correctly.”}},{“@type”: “Question”,”name”: “What Are The Common Errors Or Challenges Encountered In Workholding During Thread Cutting, And How Can They Be Mitigated?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you cut threads, things can go wrong. One problem is the tool moving or slipping. This can make the threads uneven. To stop this, hold the workpiece tightly and check it often. Another problem is not lining everything up right. You can fix this by measuring carefully before you start.”}}]}