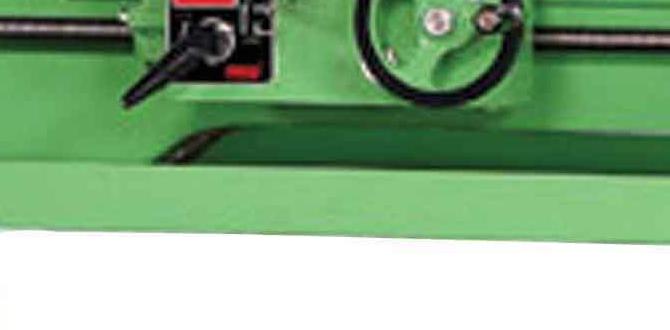

Have you ever wondered how metal parts are shaped and fitted together? Working with a lathe can be truly fascinating. A lathe is a powerful machine that spins materials so you can create precise shapes. One important part of lathe work is something called workholding. This is how you securely hold the metal pieces while you shape them.

Another interesting feature in lathe work is the threading dial. This tool helps you create threads that can screw together parts. Imagine building something where all the pieces fit perfectly. The threading dial makes that possible.

In this article, we will explore how workholding techniques improve your lathe projects. You’ll learn tips and tricks to make your metal lathe work even better. Get ready to dive into the world of lathe workholding and see how it can enhance your crafting skills!

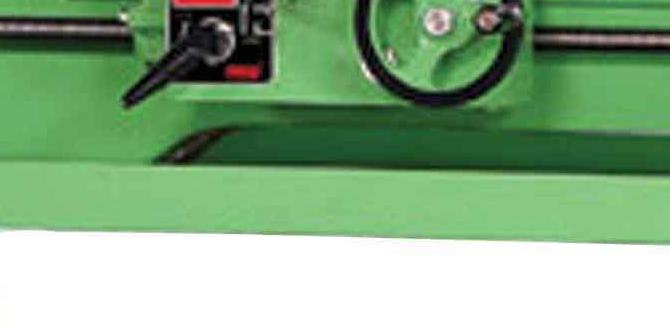

Lathe Workholding: Mastering Metal Lathe Threading Dial Techniques

Lathe Workholding: Mastering Metal Lathe Threading Dial

Lathe workholding is essential for metal lathes. It helps secure your project for precise cuts. A threading dial simplifies the threading process, making it easier for beginners and experts alike. Have you ever struggled to keep a steady hand while working on metal? This tool can change that! Learning to use a threading dial can lead to smooth, even threads. Unlock a new level of accuracy in your projects and impress others with your skills!Key Components of a Metal Lathe

Description of essential metal lathe parts and their functions. Importance of a reliable threading dial in threaded machining.A metal lathe has several important parts that help it work smoothly. Key components include the bed, where everything sits; the carriage, which moves the tool; and the tailstock, that supports the workpiece. One vital part is the threading dial. It helps you measure exact distances for threading. Think of it as a map that guides your journey to perfect threads. Without it, you could end up threading your way to disaster. It’s like trying to bake cookies without a recipe—chaos!

| Component | Function |

|---|---|

| Bed | Holds the whole lathe together |

| Carriage | Moves the cutting tool |

| Tailstock | Supports the workpiece |

| Threading Dial | Keeps track of thread measurements |

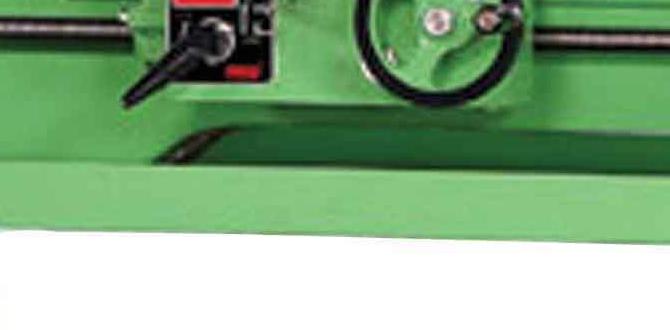

The Role of Threading Dials in Metal Lathes

Explanation of what a threading dial is and how it works. Benefits of using a threading dial for precision threading operations.A threading dial is a handy tool on a metal lathe. It helps users make precise threads on their workpieces. Working with the threading dial is simple. You align it with the cutting tool and turn the handle. The dial shows the exact measurement needed for threading. This allows for accurate cuts every time.

Using a threading dial has some clear benefits:

- High precision: It ensures each thread is uniform.

- Easy operation: Even beginners can use it quickly.

- Time-saving: You can work faster without errors.

With a threading dial, metal lathe work becomes smoother and more efficient!

What is the benefit of using a threading dial?

A threading dial helps create perfect threads, saves time, and is easy to use. It allows for better accuracy in threading tasks, making work enjoyable and efficient.

Types of Threading Dials

Comparison of various threading dials available in the market. Pros and cons of each type based on user needs.Different threading dials can change how you work with metal lathes. Let’s look at a few types and their pros and cons:

- Mechanical Dials: Simple and reliable. Good for basic tasks. However, they may lack precision.

- Digital Dials: Accurate and easy to read. Great for detailed work. They can be costly and need power.

- Retrofit Dials: Upgradable for older machines. They offer new features. Yet, installation can be tricky.

Choosing the right dial depends on your needs. What works best for you?

What types of threading dials are best for beginners?

Mechanical dials are often best for beginners. They are easy to use and don’t require extra setup.Key Points:

- Simple operations

- Low cost

- Less chance of errors

Setting Up the Threading Dial for Optimal Performance

Stepbystep guide to calibrating the threading dial. Tips on ensuring accuracy during setup.To set up the threading dial, first, ensure the lathe is off. Then, follow these steps:

- Check the dial for any damage.

- Align the threading dial with the spindle.

- Turn the dial until it clicks into place.

- Set the zero point by rotating it clockwise.

To ensure accuracy, check these tips:

- Double-check your measurements.

- Use a caliper for precise readings.

- Adjust the speed of the lathe if needed.

This will help you achieve smooth, precise threads. Happy lathing!

How can I calibrate the threading dial accurately?

You can calibrate the threading dial by carefully setting the zero point, regularly checking measurements, and ensuring all parts are tightly secured.Helpful Tips:

- Use the right tools for measuring and adjustments.

- Clean the threading area before starting.

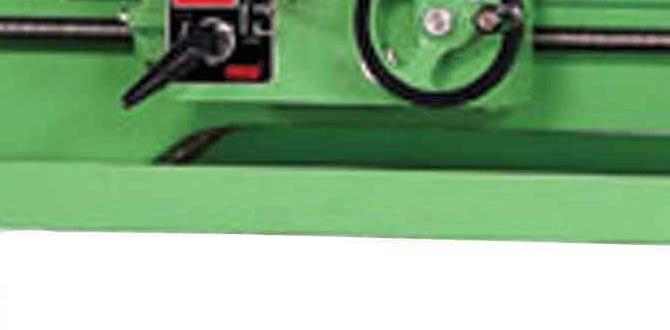

Common Challenges and How to Overcome Them

Identification of typical problems encountered during lathe workholding. Solutions and troubleshooting tips for effective operation.While using a lathe, you might face several challenges. Problems can occur in holding the metal workpieces tightly or in threading correctly. These issues can lead to poor results. To fix them, consider these tips:

- Check if the workpiece is secure in the chuck.

- Adjust the threading dial carefully.

- Use proper tool angles for cutting.

- Ensure the lathe is well-lubricated.

By following these steps, you can avoid many common mistakes and enjoy smoother operation.

What are some common lathe problems?

Common problems include slipping workpieces, uneven threading, and improper cuts.How can I improve lathe performance?

Regular checks on setup and using correct techniques can enhance performance.Maintenance and Care for Threading Equipment

Recommendations for maintaining threading dials and lathes. Importance of regular inspections and servicing.Taking care of your threading equipment is important. Regular maintenance keeps everything running smoothly. Here are some tips:

- Check the threading dials for dirt or wear.

- Clean the lathe after each use.

- Oil moving parts to prevent rust.

- Inspect regularly for loose screws.

Regular servicing can save you time and costs. It reduces the chance of breaking parts and improves accuracy. Always be proactive in looking after your equipment!

Why is regular inspection important?

Regular inspection prevents disasters and keeps machines working well. It can spot tiny issues before they become big problems. This saves money and maintains quality in your work.

Conclusion

In conclusion, using a threading dial for lathe workholding is essential for precise cuts. It helps you line up threads accurately. Understanding this tool makes your metal lathe work easier and more efficient. We encourage you to practice with your lathe and learn more about threading techniques. Explore tutorials and guides to improve your skills further!FAQs

Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Focusing On Metal Lathe Threading Dials:Sure! A lathe is a tool that helps us shape metal. The threading dial is like a helper that shows you how to make threaded lines on the metal. When you turn the dial, it helps you line up your cuts. This makes it easier to create screw threads, which are important for joining things together. Using the threading dial can save you time and make your work more precise!

Sure! Please provide the question you would like me to answer.

What Is The Function Of A Threading Dial On A Metal Lathe, And How Does It Improve Threading Accuracy?A threading dial on a metal lathe helps you cut threads accurately on metal pieces. When you turn the dial, it shows you when to move the tool for the next cut. This makes sure your threads match up perfectly. Without the dial, you might miss the right spot, and the threads could be uneven. So, it makes your work easier and more precise!

How Do You Properly Set Up A Threading Dial For A Specific Thread Pitch On A Metal Lathe?To set up a threading dial for a specific thread pitch, first, choose the thread you want. Then, look at the threading dial. You need to match the number on the dial to the thread pitch. Turn the dial until the number lines up correctly. Finally, you can start threading by turning the handle.

What Are The Advantages And Disadvantages Of Using A Threading Dial Compared To Other Threading Methods, Such As The Use Of A Beading Tool Or A Tailstock?Using a threading dial has some good points and some not-so-good points. One advantage is that it helps you make precise threads easily. This can be very helpful when you’re working on important projects. However, a disadvantage is that it can be tricky to use if you don’t have experience. Compared to tools like a beading tool or a tailstock, the threading dial might not be as simple for everyone.

How Can You Troubleshoot Common Issues With A Threading Dial, Such As Misalignment Or Backlash During Operation?To fix problems with a threading dial, first check if it’s straight and lined up. You can do this by looking closely at it while it’s working. If it feels loose or wobbly, you might need to tighten its screws. For backlash, try adjusting the dial settings to reduce any play. Always remember to turn it gently to avoid breaking anything.

What Maintenance Practices Should Be Followed To Ensure The Optimal Performance Of A Threading Dial On A Metal Lathe?To keep the threading dial on a metal lathe in good shape, you should do a few things. First, clean it regularly to remove dust and chips. Next, check for any loose parts and tighten them if needed. You should also oil the moving parts to help them work smoothly. Finally, always follow the manufacturer’s instructions for best care.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Focusing On Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a tool that helps us shape metal. The threading dial is like a helper that shows you how to make threaded lines on the metal. When you turn the dial, it helps you line up your cuts. This makes it easier to create screw threads, which are important for joining things together. Using the threading dial can save you time and make your work more precise!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Function Of A Threading Dial On A Metal Lathe, And How Does It Improve Threading Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial on a metal lathe helps you cut threads accurately on metal pieces. When you turn the dial, it shows you when to move the tool for the next cut. This makes sure your threads match up perfectly. Without the dial, you might miss the right spot, and the threads could be uneven. So, it makes your work easier and more precise!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Threading Dial For A Specific Thread Pitch On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a threading dial for a specific thread pitch, first, choose the thread you want. Then, look at the threading dial. You need to match the number on the dial to the thread pitch. Turn the dial until the number lines up correctly. Finally, you can start threading by turning the handle.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Threading Dial Compared To Other Threading Methods, Such As The Use Of A Beading Tool Or A Tailstock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a threading dial has some good points and some not-so-good points. One advantage is that it helps you make precise threads easily. This can be very helpful when you’re working on important projects. However, a disadvantage is that it can be tricky to use if you don’t have experience. Compared to tools like a beading tool or a tailstock, the threading dial might not be as simple for everyone.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues With A Threading Dial, Such As Misalignment Or Backlash During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with a threading dial, first check if it’s straight and lined up. You can do this by looking closely at it while it’s working. If it feels loose or wobbly, you might need to tighten its screws. For backlash, try adjusting the dial settings to reduce any play. Always remember to turn it gently to avoid breaking anything.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Optimal Performance Of A Threading Dial On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the threading dial on a metal lathe in good shape, you should do a few things. First, clean it regularly to remove dust and chips. Next, check for any loose parts and tighten them if needed. You should also oil the moving parts to help them work smoothly. Finally, always follow the manufacturer’s instructions for best care.”}}]}