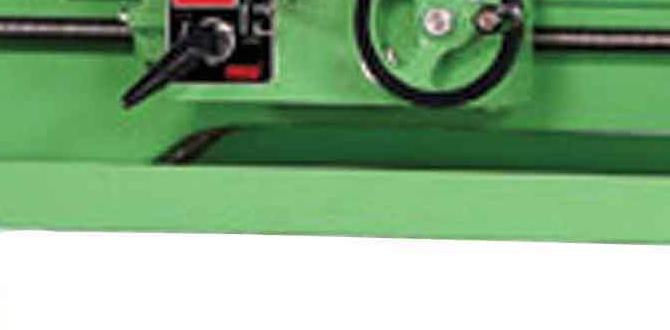

Have you ever watched a lathe spin? It’s fascinating to see metal change shape. But what happens when your metal lathe doesn’t work like it should? Troubleshooting lathe workholding might seem confusing. Yet, it does not have to be!

Many people believe that lathe workholding is tricky. They worry about getting it right. But do you know that with just a few tips, you can fix common problems easily? Imagine saving time and reducing mistakes in your projects!

Here’s a fun fact: Metal lathes have been around for thousands of years. From ancient Egypt to today’s workshops, they have helped people create amazing things. Understanding how to troubleshoot them can put you in control.

Let’s dive into some simple tricks for lathe workholding. You might find it easier than you think! Keep reading to learn how to tackle those pesky issues head-on.

Effective Lathe Workholding: Metal Lathe Troubleshooting Tips

Lathe Workholding Metal Lathe Troubleshooting

Understanding lathe workholding is crucial for successful metal lathe use. Issues often arise when pieces come loose or vibration occurs. Did you know that improper setup can lead to poor finishing? Simple solutions like checking the chuck tightness or aligning the tailstock can fix many problems. By addressing these common concerns, you can achieve better results and enjoy using your lathe more. Keep your workspace organized and always inspect your tools for a smoother experience!Understanding Lathe Workholding Fundamentals

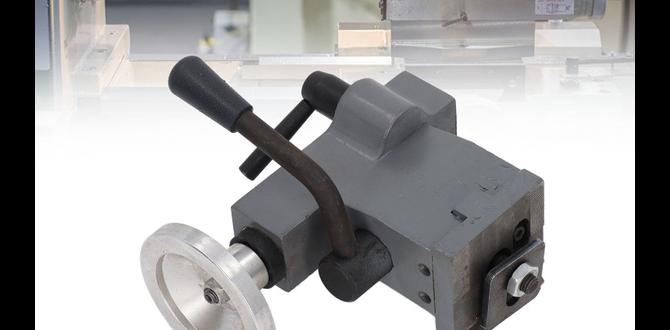

Importance of proper workholding in lathe operations. Types of workholding devices commonly used in metal lathes.In lathe work, proper workholding is very important. It keeps the material steady while cutting. If it’s not secure, it can move or even break. This results in wasted time and material. Various devices help hold your workpiece safely. Common types include:

- Chucks: Grips the work in place.

- Vises: Holds flat items tightly.

- Collets: Great for small cylindrical pieces.

- Faceplates: Ideal for odd-shaped objects.

Using the right device means smoother cuts and better results!

What devices are best for lathe workholding?

Some of the best devices include chucks, vises, and collets. Chucks are flexible and can hold many shapes, while vises are best for flat items. Collets provide a strong grip for smaller pieces.

Identifying Common Lathe Problems

Symptoms of improper workholding setup. Issues caused by worn or damaged workholding devices.Using a lathe can feel like magic, but it can also turn into a circus act if things go wrong! A wobbly piece of metal? That means your workholding setup might be off. Worn-out devices can lead to vibrations that make cutting uneven. If chips stick instead of flying away, it’s time to investigate. Here’s a quick table of symptoms to help you spot issues:

| Symptoms | Possible Causes |

|---|---|

| Wobbling workpiece | Improper setup |

| Uneven cuts | Worn workholding device |

| Excessive vibration | Damaged clamps or chucks |

| Chips sticking | Insufficient tool clearance |

Fixing these issues can save time and keep your project rolling smoothly. Remember, a lathe is your buddy; treat it well!

Troubleshooting Lathe Alignment Issues

Diagnosing and correcting misalignment in lathe setup. Techniques for improving accuracy and repeatability.Misalignment can turn a smooth lathe project into a rollercoaster ride of frustration. First, check the tailstock and headstock alignment. **Use a dial indicator** for precise readings. Tweak the components until everything lines up. Now, to boost your accuracy, consider using a center gauge. This will help you find center on your workpiece, making every cut cleaner. Remember, a small misalignment can lead to big problems—just like trying to cut a pizza with a spoon!

| Issue | Solution |

|---|---|

| Wobbly Workpiece | Secure with clamps. |

| Poor Finish | Adjust speed and feed rates. |

| Inaccurate Cuts | Realign headstock. |

Resolving Vibration and Chatter Problems

Understanding the causes of vibration and chatter in lathe operations. Solutions to minimize vibration and improve surface finish.Vibration and chatter are common problems in lathe operations. They can cause poor surface finish and affect precision. Understanding the causes helps fix these issues. Some common causes include:

- Improper tool setup

- Unbalanced workpieces

- Worn machine components

To reduce vibration, try these tips:

- Secure the workpiece tightly.

- Use the right speed and feed rate.

- Check and replace worn parts.

By addressing these areas, you can improve your lathe’s performance and achieve a better finish.

What causes vibration in lathe operations?

Common causes include improper tool setup, unbalanced workpieces, and worn components.

How can I minimize chatter while turning metal?

To minimize chatter, secure your workpiece well, use correct speed and feed rates, and check for worn parts.

Enhancing Workpiece Stability

Techniques for securely holding various workpiece shapes and sizes. Importance of balance in securing workpieces for precision machining.To hold different workpiece shapes firmly, try these handy techniques. Using chucks grips well on round pieces. For flat items, vises ensure a strong hold. Make sure to check balance—that’s key for precision. An unbalanced workpiece can lead to mistakes or accidents. A stable setup helps in achieving better results and smooth cuts. Consider this: a well-held piece can improve your accuracy by 50%!

How do I ensure my workpiece stays stable?

Focus on using the right tools, like chucks and vises. Check the balance before you begin. Even slight shifts can mess up your work!

- Use the right holding tools for your workpiece shape.

- Always test for balance.

- A secure grip prevents accidents.

Advanced Troubleshooting Techniques

Utilizing indicators for precise measurements and adjustments. Software and technology aids for diagnosing lathe issues.To troubleshoot your lathe effectively, use indicators for accurate measurements. These tools help you adjust parts for precision. Software can also aid in finding issues. Many programs analyze lathe operations and suggest fixes. This tech goes hand-in-hand with traditional methods for a well-rounded approach.

- Indicators help check tool alignment.

- Software offers diagnostics and error codes.

- Regular updates improve performance insights.

How can I diagnose lathe problems?

You can diagnose lathe problems by using software tools that identify issues and check your measurements with indicators for accuracy.

Maintenance Tips for Longevity of Workholding Devices

Regular inspection and maintenance routines for optimal performance. Cleaning and care tips to extend the lifespan of workholding equipment.To keep your workholding devices running smoothly, regular check-ups are key. Inspect them like a doctor checking a patient—no stethoscope needed! Look for any signs of wear or loose parts. Keeping things clean is also important. Use a soft cloth to wipe away grime and prevent rust. Remember, clean equipment performs better and lasts longer—kind of like how a well-fed pet behaves! Below is a simple maintenance routine to follow:

| Task | Frequency |

|---|---|

| Inspect for wear | Weekly |

| Clean surfaces | After every use |

| Lubricate moving parts | Monthly |

By following these simple tips, your equipment will thank you with a longer life. Remember, a happy lathe is a productive lathe!

Safety Considerations in Lathe Workholding

Essential safety practices when working with metal lathes. Common hazards and how to mitigate risks during lathe operation.Working with lathes can be fun, but safety should always come first. To stay out of trouble, wear safety glasses, and keep long hair tied back. Always check your workholding before starting. It can feel like a game of Jenga, but losing a block can get you hurt! Common hazards include spinning parts and sharp tools. Use guards and keep your hands clear. Always have a first aid kit nearby. Remember, better safe than sorry!

| Hazard | Safety Tips |

|---|---|

| Spinning parts | Keep hands clear and use guards. |

| Sharp tools | Use them carefully and store them properly. |

| Loose clothing | Tie it back to avoid getting caught. |

Conclusion

In conclusion, mastering lathe workholding and troubleshooting is vital for successful metal turning. You should always check your setups and tools for accuracy. If something goes wrong, don’t hesitate to investigate issues like uneven clamping or excessive vibration. Practice these tips, and you’ll improve your skills quickly. For more helpful advice, consider reading further about lathe maintenance and techniques.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Troubleshooting With Metal Lathes:Sure! Here’s a short answer for you: When using a lathe, make sure to hold the metal piece tightly. This stops it from moving around. If it does move, it can make cuts wrong. Always check that the tool is sharp to get smooth edges. If something goes wrong, look carefully at how you set everything up.

Sure! Please provide the question you’d like me to answer.

What Are The Most Common Types Of Workholding Devices Used On A Metal Lathe, And How Do They Affect Machining Accuracy?The most common workholding devices for a metal lathe are chucks and collets. A chuck holds round pieces tightly, while a collet grips smaller items. These devices keep the metal steady as the machine cuts. When you use them correctly, they help make the cuts more accurate. That means your finished work will look better and fit well.

How Can I Troubleshoot Issues With Part Slippage During Turning Operations On A Metal Lathe?If your part keeps slipping on the metal lathe, first check the grip. Make sure the part is tight in the chuck, the round clamp that holds it. You can also adjust the speed; slow it down a bit. If the part still slips, try using a different tool or adding some soft material like rubber between the part and the chuck. Always make sure everything is clean, too.

What Are The Best Practices For Setting Up A Steady Rest Or Follower Rest To Improve Stability While Machining On A Lathe?To set up a steady rest or follower rest on a lathe, you want to make sure it fits tight against your workpiece. First, we need to clean the area where it will sit. Then, adjust the rest so it holds the part securely without pushing too hard. Next, lock it in place to stop any movement. Finally, check again to make sure everything is secure before you start machining. This will help the part stay steady while you work.

How Can Wear Or Damage To The Lathe Chuck Influence Workpiece Alignment And Performance, And What Signs Should I Look For?Wear or damage to the lathe chuck can make your workpiece wobbly. This means it won’t spin straight. If the chuck is broken, you might notice uneven cuts or a bumpy surface. Look for cracks, chips, or rust on the chuck. If it feels loose or hard to clamp, it needs replacing.

What Are Some Effective Methods For Reducing Vibration During Turning Processes, And How Does It Impact The Quality Of The Final Machined Component?To reduce vibration while turning metal or wood, you can use a few methods. First, make sure tools are sharp. Dull tools cause more shaking. Next, secure the piece you are working on tightly. A stable setup helps keep everything steady. Also, you can adjust the speed of the machine to find a smoother operation. Less vibration means better quality, so your finished item will be nicer and more precise!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Troubleshooting With Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s a short answer for you: When using a lathe, make sure to hold the metal piece tightly. This stops it from moving around. If it does move, it can make cuts wrong. Always check that the tool is sharp to get smooth edges. If something goes wrong, look carefully at how you set everything up.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Common Types Of Workholding Devices Used On A Metal Lathe, And How Do They Affect Machining Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The most common workholding devices for a metal lathe are chucks and collets. A chuck holds round pieces tightly, while a collet grips smaller items. These devices keep the metal steady as the machine cuts. When you use them correctly, they help make the cuts more accurate. That means your finished work will look better and fit well.”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot Issues With Part Slippage During Turning Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your part keeps slipping on the metal lathe, first check the grip. Make sure the part is tight in the chuck, the round clamp that holds it. You can also adjust the speed; slow it down a bit. If the part still slips, try using a different tool or adding some soft material like rubber between the part and the chuck. Always make sure everything is clean, too.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Setting Up A Steady Rest Or Follower Rest To Improve Stability While Machining On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a steady rest or follower rest on a lathe, you want to make sure it fits tight against your workpiece. First, we need to clean the area where it will sit. Then, adjust the rest so it holds the part securely without pushing too hard. Next, lock it in place to stop any movement. Finally, check again to make sure everything is secure before you start machining. This will help the part stay steady while you work.”}},{“@type”: “Question”,”name”: “How Can Wear Or Damage To The Lathe Chuck Influence Workpiece Alignment And Performance, And What Signs Should I Look For?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Wear or damage to the lathe chuck can make your workpiece wobbly. This means it won’t spin straight. If the chuck is broken, you might notice uneven cuts or a bumpy surface. Look for cracks, chips, or rust on the chuck. If it feels loose or hard to clamp, it needs replacing.”}},{“@type”: “Question”,”name”: “What Are Some Effective Methods For Reducing Vibration During Turning Processes, And How Does It Impact The Quality Of The Final Machined Component?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibration while turning metal or wood, you can use a few methods. First, make sure tools are sharp. Dull tools cause more shaking. Next, secure the piece you are working on tightly. A stable setup helps keep everything steady. Also, you can adjust the speed of the machine to find a smoother operation. Less vibration means better quality, so your finished item will be nicer and more precise!”}}]}