Have you ever wondered what it takes to set up the best metal lathe in a workshop? Imagine crafting precise parts and tools with ease. A lathe can turn raw metal into something amazing. But where do you start with your lathe workshop setup?

It’s not just about choosing any lathe. The best metal lathe makes a real difference. You want one that fits your needs and space. Picture yourself shaping beautiful metal pieces. It all starts with the right setup.

Setting up a lathe workshop might seem daunting. But it can be fun and rewarding! Did you know that a well-organized space can make your projects smoother? With the right tools and layout, you can achieve great results.

In this article, we’ll explore how to create the perfect lathe workshop setup. Whether you’re a beginner or an expert, you’ll find helpful tips and tricks. Let’s dive in and discover what you need to get started!

Lathe Workshop Setup: Best Metal Lathe For Precision Work

Lathe Workshop Setup: Best Metal Lathe

Setting up a lathe workshop can be exciting. A good metal lathe is key for precise work. It helps in shaping metal parts efficiently. Think about your space and tools. Do you have enough room for your lathe? Consider adding essential accessories like chucks and tool rests. Did you know that properly lighting your workspace can improve your accuracy? Investing in the right equipment makes all the difference. Happy turning, and get ready to create amazing projects!Choosing the Right Metal Lathe

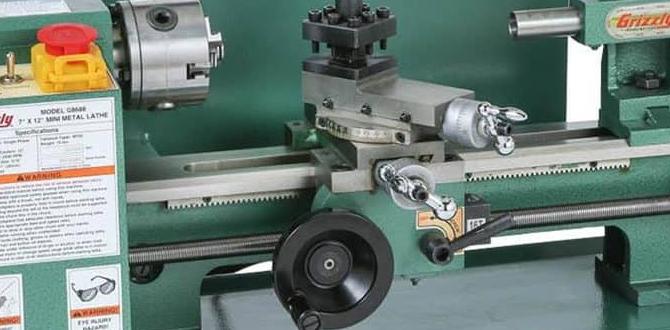

Factors to consider: size, power, and precision. Comparison of different types: bench lathes vs. floor lathes.Picking the right metal lathe is like choosing a pet; you want the one that fits your space and lifestyle. First, think about size. A small bench lathe is great for tight spaces, while a floor lathe offers more power. Next, consider power. More power means better performance, especially for tough jobs. Don’t forget precision. A precise lathe makes your projects shine! Here’s a quick comparison:

| Type | Size | Power | Best Use |

|---|---|---|---|

| Bench Lathe | Compact | Lower | Hobby Projects |

| Floor Lathe | Large | Higher | Professional Work |

Choose wisely, and your metal lathe will bring your ideas to life—without any furballs!

Essential Tools and Accessories for Your Lathe Workshop

Musthave tools: cutting tools, chucks, and tool holders. Accessory options: tailstocks, bed extensions, and digital readouts.Setting up your lathe workshop requires essential tools for smooth operation. First, you need cutting tools for shaping and finishing metal. Chucks hold your workpieces tightly. Tool holders keep your cutting tools in place. Accessories like tailstocks help you support long pieces. Bed extensions give you more room to work. Lastly, digital readouts show precise measurements. Here’s a quick list:

- Cutting tools

- Chucks

- Tool holders

- Tailstocks

- Bed extensions

- Digital readouts

What are the essential tools for a lathe workshop?

The essential tools include cutting tools, chucks, and tool holders. Accessories like tailstocks, bed extensions, and digital readouts enhance your workshop experience.

Optimal Workshop Layout for Lathe Operations

Space requirements and ideal configurations. Safety considerations and ergonomics in workshop design.Creating the right space for your lathe operations is essential. You need enough room to work comfortably and safely. Here are some key points to consider:

- Leave at least 3 feet of space around the lathe.

- Place tools and materials within arm’s reach to prevent stretching.

- Ensure good lighting to see your work clearly.

- Use proper flooring for stability.

Safety is also important. Make sure your workshop has:

- Protective gear, like goggles and gloves.

- Fire extinguishers within easy reach.

- A first aid kit to manage any injuries.

These steps will make your workshop safe and efficient.

What is the best layout for a lathe workshop?

The best layout uses space wisely. Place the lathe centrally. Keep tools nearby. This setup helps you work better and safer.

Key Factors:

- Enough walking space.

- Easy access to tools.

- Good ventilation.

Setting Up Your Metal Lathe: Step-by-Step Process

Assembly instructions and calibration tips. Common setup mistakes and how to avoid them.Start by carefully following the assembly instructions in the manual. Each piece matters! Make sure the machine is level and stable. Use a spirit level for this. Remember to check the alignment of the lathe’s components. Small mistakes can lead to big issues later.

Here are common setup mistakes:

- Not securing the lathe properly.

- Forgetting to adjust the tailstock.

- Ignoring the manufacturer’s setup guide.

Calibrating your metal lathe is both vital and simple. Take your time and don’t rush. This careful setup will lead to smoother operations and better projects!

What are common mistakes when setting up a lathe?

Common mistakes include not leveling the lathe or neglecting to calibrate the parts properly. These oversights can cause errors in your work.

How to avoid setup mistakes:

- Always read the manual first.

- Check each part as you assemble.

- Test your adjustments before starting projects.

Lathe Maintenance for Longevity and Performance

Routine maintenance tasks: cleaning and lubrication. Troubleshooting common issues and repairs.Taking care of your lathe is key for smooth work and long life. Start with simple routine tasks. Cleaning the machine keeps it free of dust and debris. Regular lubrication keeps parts moving well. Watch for common problems too. Here are quick tips:

- Check belts for wear.

- Look for loose bolts.

- Listen for strange noises.

Fix issues early to prevent bigger problems. A well-maintained lathe lasts longer and works better!

How often should I clean my lathe?

You should clean your lathe after every use to keep it in top shape.

What type of lubrication should I use?

Use machine oil for regular lubrication of your lathe. Choose oil suitable for metal work.

Resources for Further Learning and Community Engagement

Recommended books, websites, and online forums. Local and virtual workshops for skills enhancement.Learning more about metal lathes can be fun and exciting! Here are some great resources:

- Books: Check out “Metalworking 101” or “Lathe Basics” for easy guides.

- Websites: Visit forums like “Practical Machinist” or “Home Shop Machinist” to connect with friends.

- Workshops: Look for local classes or virtual sessions to improve your skills.

Engaging with others can help you learn faster and enjoy the process!

What are the best books for learning about metal lathes?

The best books include “Metalworking 101” and “Lathe Basics.” They are simple to read and full of helpful tips!

What online forums can help me connect with other metal lathe users?

You can find help in forums like “Practical Machinist” and “Home Shop Machinist.” These places have amazing people eager to share.

Are there any workshops for learning lathe skills?

Yes! Look for local classes or virtual workshops online. They can make learning fun and interactive!

Conclusion

In summary, choosing the best metal lathe for your workshop is crucial for success. Look for key features like size, power, and ease of use. Setting up your lathe correctly helps you work safely and efficiently. To get started, explore tutorials and guides that can enhance your skills. Let’s dive into the exciting world of metalworking together!FAQs

Sure! Here Are Five Related Questions About Setting Up A Lathe Workshop And Choosing The Best Metal Lathe:Sure! When setting up a lathe workshop, choose a clean and safe space. You need good lighting and ventilation. Picking the best metal lathe means looking for one that fits your projects. Check the size and power to make sure it matches what you want to make. Finally, remember to keep your tools organized and easily reachable!

Sure! Please provide the question you’d like me to answer, and I’ll do my best to help.

What Factors Should Be Considered When Selecting The Best Metal Lathe For A Workshop?When choosing a metal lathe, think about its size and weight. You want one that fits in your workshop. Check how much power it has to see if it can do tough jobs. Look at the controls to ensure they are easy to use. Finally, consider your budget to find a lathe you can afford.

How Much Space Is Typically Required To Set Up A Fully Functional Lathe Workshop?To set up a fully functional lathe workshop, you need about 200 to 500 square feet of space. This area gives you room for the lathe and tools. You also need space to move around safely. Make sure you have good lighting and ventilation too. That way, you can work comfortably!

What Essential Tools And Accessories Are Recommended To Have Alongside A Metal Lathe For Optimal Workshop Productivity?To use a metal lathe well, you’ll need some important tools and accessories. A good set of cutting tools helps shape the metal. You also need measuring tools, like calipers, to check sizes accurately. Safety gear, like goggles and gloves, keeps you safe. Finally, a good workbench makes everything easier to manage.

What Safety Measures Should Be Implemented In A Lathe Workshop To Ensure A Safe Working Environment?To keep a lathe workshop safe, we should wear safety glasses to protect our eyes. You need to wear gloves to prevent cuts. Always tie back long hair and avoid loose clothes to avoid getting caught in the machine. We must keep the workshop clean and organized to prevent trips. Plus, it’s important to know how to use the lathe correctly before starting.

How Can Beginners Effectively Learn To Operate A Metal Lathe And Maximize Their Workshop Setup?To learn to use a metal lathe, you can start by watching videos or reading simple books about it. Practice is really important, so try using the lathe on small projects first. Always follow safety rules, like wearing goggles. To set up your workshop, keep your tools organized and close by. This way, you can work well and have fun!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Setting Up A Lathe Workshop And Choosing The Best Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When setting up a lathe workshop, choose a clean and safe space. You need good lighting and ventilation. Picking the best metal lathe means looking for one that fits your projects. Check the size and power to make sure it matches what you want to make. Finally, remember to keep your tools organized and easily reachable!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll do my best to help.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting The Best Metal Lathe For A Workshop? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe, think about its size and weight. You want one that fits in your workshop. Check how much power it has to see if it can do tough jobs. Look at the controls to ensure they are easy to use. Finally, consider your budget to find a lathe you can afford.”}},{“@type”: “Question”,”name”: “How Much Space Is Typically Required To Set Up A Fully Functional Lathe Workshop? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a fully functional lathe workshop, you need about 200 to 500 square feet of space. This area gives you room for the lathe and tools. You also need space to move around safely. Make sure you have good lighting and ventilation too. That way, you can work comfortably!”}},{“@type”: “Question”,”name”: “What Essential Tools And Accessories Are Recommended To Have Alongside A Metal Lathe For Optimal Workshop Productivity? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use a metal lathe well, you’ll need some important tools and accessories. A good set of cutting tools helps shape the metal. You also need measuring tools, like calipers, to check sizes accurately. Safety gear, like goggles and gloves, keeps you safe. Finally, a good workbench makes everything easier to manage.”}},{“@type”: “Question”,”name”: “What Safety Measures Should Be Implemented In A Lathe Workshop To Ensure A Safe Working Environment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a lathe workshop safe, we should wear safety glasses to protect our eyes. You need to wear gloves to prevent cuts. Always tie back long hair and avoid loose clothes to avoid getting caught in the machine. We must keep the workshop clean and organized to prevent trips. Plus, it’s important to know how to use the lathe correctly before starting.”}},{“@type”: “Question”,”name”: “How Can Beginners Effectively Learn To Operate A Metal Lathe And Maximize Their Workshop Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To learn to use a metal lathe, you can start by watching videos or reading simple books about it. Practice is really important, so try using the lathe on small projects first. Always follow safety rules, like wearing goggles. To set up your workshop, keep your tools organized and close by. This way, you can work well and have fun!”}}]}