Have you ever wondered how things are made from metal? Imagine stepping into a workshop full of buzzing machines. A metal lathe is one of those magical tools that can turn solid metal into amazing shapes.

In a lathe workshop setup, everything has its place. Proper organization helps in managing time and getting better results. But what if you could make this process even easier? Automation can do just that! It transforms a regular workshop into a high-tech space.

Picture this: you press a button, and your metal lathe starts working all by itself. This isn’t just a dream; it’s reality for many workshops today. Automation saves time, and helps prevent mistakes. Plus, it opens up new creative possibilities.

In this article, we will explore the basics of setting up a lathe workshop. We will also look at how you can add automation to your metal lathe. Ready to dive into the fascinating world of metalworking? Let’s get started!

Efficient Lathe Workshop Setup: Metal Lathe Automation Guide

Lathe Workshop Setup: Metal Lathe Automation

Setting up a lathe workshop can be exciting and rewarding. Have you ever thought about how automation can make your tasks easier? Metal lathe automation improves precision and speed, helping you create high-quality parts effortlessly. Imagine programming your lathe to perform repetitive tasks while you focus on creative projects. You’ll learn how to organize your workspace for efficiency, select the right tools, and maintain safety. With smart setup, your workshop becomes a hub of innovation.Understanding the Basics of Metal Lathe Automation

Definition of metal lathe automation. Benefits of automating a metal lathe.Metal lathe automation makes machining simpler by using machines and tools to control processes automatically. This means you can make more parts with less work. Imagine a robot that never needs coffee breaks! The benefits of this automation are huge. It saves time, improves accuracy, and helps prevent mistakes. Plus, it frees up your hands for more important tasks, like planning your next big project or perfecting your coffee-making skills!

| Benefits | Description |

|---|---|

| Time-saving | Automation speeds up production. |

| Precision | Machines make fewer mistakes than humans. |

| Less effort | You can do more tasks while machines work for you! |

Choosing the Right Metal Lathe for Your Workshop

Key features to consider when selecting a lathe. Comparison between manual and automated lathes.Picking a metal lathe is important for your workshop. First, look for key features like size, speed, and sturdiness. A good lathe should handle both small and large jobs. Next, decide between manual and automated lathes. Manual lathes require more hands-on work, while automated lathes save time and effort. Think about how you will use the lathe. Do you want to control everything or prefer some help? Choosing the right one can improve your work!

What features should I consider for a metal lathe?

Key features include:

- Size: Fits your workspace.

- Speed: Adjustable for different tasks.

- Sturdiness: Can handle heavy materials.

Should I choose a manual or automated lathe?

Manual lathes let you control every step. They are great for learning. Automated lathes save time. They handle tasks quickly and reduce human error. Choose based on your skill level and project needs!

Essential Tools and Accessories for Lathe Setup

List of musthave tools for metal lathe operation. Recommended accessories for enhanced performance.Setting up a metal lathe? You’ll need the right tools! First, grab a solid set of cutting tools. They are the magic wands of the lathe world. Next, don’t forget a dial indicator for precise measurements and a good set of calipers—because nobody wants a “wonky” project!

For enhanced performance, think about adding a quick-change tool post. It’s like upgrading from a bicycle to a motorcycle; it saves you time and works like a charm! A nice steady rest also helps keep things in line.

| Essential Tools | Recommended Accessories |

|---|---|

| Cutting tools | Quick-change tool post |

| Dial indicator | Steady rest |

| Calipers | Tool holders |

These tools and accessories will set you on the right path. Soon, your lathe will be spinning masterpieces instead of spaghetti!

Designing Your Lathe Workshop Layout

Importance of workshop layout for efficiency. Tips for optimal placement of machinery and tools.Planning your workshop is like building a treehouse—do it right, and everyone wants to play! A smart layout boosts production and keeps you safe. Place machines where you can reach them easily. This avoids the “dance of the awkward shuffle” as you move from station to station. A simple way to organize is shown below:

| Tool | Ideal Placement |

|---|---|

| Lathe | Near the center for easy access |

| Workbench | Adjacent to the lathe for convenience |

| Storage | Along the walls for more space |

This setup allows you to work like a pro and keeps things handy. Remember, a well-planned layout is key for smooth sailing in any project!

Safety Precautions for Lathe Workshop Operations

Common hazards associated with metal lathes. Best practices for maintaining a safe work environment.Working in a lathe workshop can be exciting, but safety is super important! Metal lathes can be tricky, and there are some common hazards. Pieces of metal can fly off, and loose clothing can get caught. Make sure to wear tight clothes and safety goggles. That way, you won’t look like a human target! Keep your workspace clean to avoid slips and falls. Here’s a quick table for safety tips:

| Hazard | Best Practice |

|---|---|

| Flying Debris | Wear goggles and a face shield. |

| Loose Clothing | Dress snugly. Leave the baggy stuff at home! |

| Cluttered Workspace | Keep your area tidy. No one likes a messy ninja! |

By following these tips, you’ll stay safe and sound while turning metal into magic!

Regular Maintenance and Upkeep for Longevity

Importance of routine maintenance checks. Tips for troubleshooting common lathe issues.Keeping your lathe in top shape is key for lasting performance. Regular maintenance checks help prevent problems. A well-maintained lathe cuts better and lasts longer. Look out for common issues like unusual noises or vibrations. If you spot something off, check the alignment and lubrication. Here are some tips:

- Inspect belts for wear.

- Clean the machine regularly.

- Ensure proper lubrication of parts.

- Keep all tools organized and sharpened.

Doing these things can save you time and money. Remember, a little upkeep goes a long way!

How often should I check my lathe?

Check your lathe every month for best results. This helps catch small issues before they become big problems.

Maximizing Productivity through Workflow Optimization

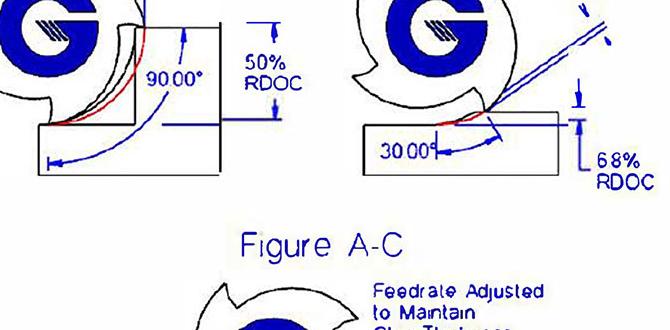

Techniques for streamlining lathe operations. Measuring and analyzing productivity metrics.To improve lathe operations, think about how to make everything smoother. Start by organizing tools and materials. This saves time and cuts out extra steps. Next, pay attention to how long tasks take. Measuring time lets you see where to improve. Also, try using simple automation for regular tasks. It can make things faster and easier.

- Keep tools within reach.

- Use checklists for tasks.

- Track time for each job.

- Set goals for better speed.

How can I measure productivity in a lathe workshop?

You can measure productivity by tracking the time spent on each task. Keeping records helps you see where to improve. Regular analysis of this data shows trends and areas for faster work.

Case Studies: Successful Lathe Workshop Automation

Realworld examples of automated lathe setups. Lessons learned and key takeaways from each case study.Many businesses have seen great success by automating their lathe workshops. For example, one metal shop increased its output by 40% after switching to automated systems. Another company reduced its errors by 35% with automated inspections. Here are some lessons learned:

- Efficiency: Automation speeds up production.

- Accuracy: Fewer mistakes lead to higher quality products.

- Cost Savings: Less waste saves money over time.

These examples show how automation can transform a lathe workshop. It’s not just about machines; it’s about smarter work!

What are some benefits of automating a lathe workshop?

Automation often leads to increased efficiency, better accuracy, and lower costs. By using machines to take over repetitive tasks, workers can focus on more important jobs.

Conclusion

In conclusion, setting up a metal lathe workshop with automation can boost your efficiency and precision. Start by organizing tools for easy access. Invest in quality equipment to improve your work. You can explore resources online to learn more about automation techniques. Take the next step and transform your workshop today for better results in your projects!FAQs

Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Automation:Sure! In a lathe workshop, we set up machines to shape metal and wood. We can use tools like lathes, which spin materials fast. Sometimes, we add automation to help machines run themselves. This makes work faster and safer. It’s fun to watch what we create!

Sure! I can help with that. Please provide me with the question you want answered.

What Are The Key Factors To Consider When Setting Up A Metal Lathe Workshop For Optimal Efficiency And Safety?To set up a metal lathe workshop, think about space first. You need enough room to move safely around the lathe. Next, make sure your tools are organized and easy to reach. Safety gear, like goggles and gloves, is important too. Finally, keep the area clean to prevent accidents.

How Can Automation Be Integrated Into A Traditional Metal Lathe Setup To Improve Production Rates And Reduce Operator Fatigue?You can add a special robot arm to help with heavy lifting on the metal lathe. This robot can load and unload parts quickly. You can also use a computer to control the lathe and make it run faster. This way, you don’t have to stand and watch all the time. It makes work easier and lets you finish more pieces in less time!

What Types Of Software Are Best Suited For Programming Automated Metal Lathe Operations, And How Do They Enhance The Machining Process?The best software for programming metal lathes includes Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM). CAD helps you design parts on a computer, and CAM turns those designs into commands for the lathe. These programs make it easier to create precise and complex shapes. They save time and reduce mistakes, making the machining process smoother and faster.

What Are The Benefits And Challenges Of Converting A Manual Lathe To A Cnc Lathe In An Automated Workshop Environment?Converting a manual lathe to a CNC (Computer Numerical Control) lathe has many benefits. First, it makes work faster and more precise. You can create complex shapes easily. However, there are challenges too. The new machine can be expensive, and you must learn how to use it properly.

How Can Sensors And Iot Technology Be Utilized To Monitor And Control Metal Lathe Operations In A Fully Automated Workshop?We can use sensors and IoT technology to watch metal lathes in a workshop. Sensors can check if machines are working well. They can tell us if something is wrong, like getting too hot. We can also control the machines from our phones or computers. This way, we keep everything running safely and smoothly!