Have you ever wondered how craftsmen make amazing metal designs? A metal lathe is a key tool in their workshops. Setting up a lathe workshop can be exciting and fun!

Imagine creating unique items with your own hands. With the right lathe workshop setup, you can turn simple metal pieces into works of art. What if you could design these products using CAD software? This adds a whole new level to your projects.

Did you know that a lathe workshop is where many DIY projects start? From small parts to large creations, you can make anything once you understand the basics. So, are you ready to learn how to set up your own workshop? Let’s dive in and explore the world of metal lathe CAD design together!

Lathe Workshop Setup: Metal Lathe Cad Design Essentials

Lathe Workshop Setup: Metal Lathe CAD Design

Setting up a lathe workshop is exciting! You learn how to select the right metal lathe and plan your workspace carefully. Using CAD design tools, you can visualize your layout and improve efficiency. Did you know that an organized space can make you more productive? A well-thought-out setup allows for safer operation and better quality work. Discover tips for choosing equipment and arranging your workspace effectively for the best results. Let’s get started on bringing your ideas to life!Planning Your Lathe Workshop Layout

Factors to consider when designing your workshop space. Optimal layout examples for efficiency and safety.Creating a great workshop is important. Think about where you will put your tools, materials, and machines. Safety and workflow are key factors. Make sure there’s enough space to move around. Here are some tips:

- Plan for easy access to tools.

- Keep safety gear nearby.

- Use bright lights for good visibility.

- Set up a workbench with storage.

Good layout examples include having the lathe at a comfortable height and keeping enough room for other equipment. This helps you work better and stay safe!

What should I consider when planning my lathe workshop?

Focus on space, safety, and organization. Make sure to have enough room for movement and tools. Efficient layouts help you work faster and safer.

Essential Tools and Equipment for a Lathe Workshop

Musthave tools and equipment aside from the lathe machine. Importance of proper tool selection for specific projects.To build a great lathe workshop, you need tools beyond the lathe machine. Each tool plays a key role in making your projects successful. Proper tool choice is vital. Using the right tools can make your tasks easier and improve your work quality.

- Calipers: Measure materials precisely.

- Tool holders: Secure cutting tools safely.

- Chucks: Hold workpieces firmly.

- Cutting tools: Essential for shaping metal.

- Workstations: Organized space enhances productivity.

What tools are needed for a lathe workshop?

Essential tools include calipers, tool holders, chucks, cutting tools, and a proper workstation.

Choosing the right tools boosts accuracy. They help prevent mistakes and save time. Remember, a well-set workshop brings out the best in your lathe projects!

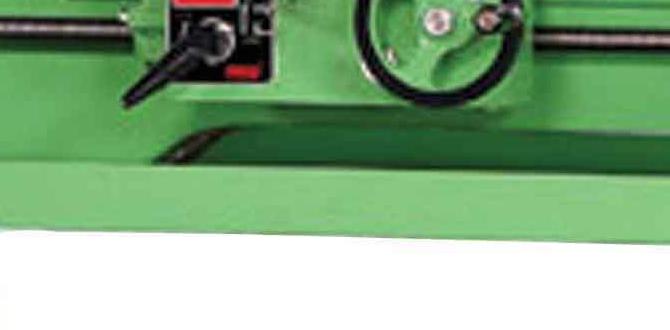

Setting Up Your Metal Lathe

Stepbystep guide to installing and leveling your lathe. Tips for securing your lathe and ensuring precision.To set up your metal lathe, follow these easy steps:

- Choose a strong, flat surface.

- Use a level to check the ground.

- Adjust the feet of the lathe for balance.

Next, secure your lathe firmly to prevent movement. This helps ensure precision while working. Double-check all connections and use bolts if needed. Remember, a well-set lathe leads to better projects!

How do I secure my lathe for precision?

To ensure more accuracy, tighten all bolts and check the level frequently. Using rubber pads can also help reduce vibrations while you work.

Safety Protocols in the Lathe Workshop

Comprehensive safety measures to follow while operating a lathe. Recommended personal protective equipment (PPE) for lathe users.Working in a lathe workshop can be exciting, but safety must come first. Always follow these important measures to stay safe:

- Keep the workspace tidy.

- Check machines before use.

- Watch out for loose clothing or hair.

- Use proper lighting.

- Have a first-aid kit ready.

Personal protective equipment (PPE) is also vital for safety:

- Wear goggles to protect your eyes.

- Use gloves to guard your hands.

- Put on a mask for dust protection.

Remember, safety is key for a smooth and fun experience in the lathe workshop!

What PPE should I wear while using a lathe?

Wear goggles, gloves, and a mask to protect yourself. These will keep your eyes, hands, and lungs safe while you work.

Common Troubleshooting Tips for Lathe Operations

Identifying and resolving common issues encountered in lathe work. Maintenance tips to prevent operational problems.Lathe work can sometimes be tricky. It’s important to recognize the most common issues that can pop up. Regular maintenance can help avoid many of these problems. Here are some tips:

- Check and tighten all bolts before starting.

- Keep the lathe clean to avoid dust build-up.

- Lubricate moving parts often for smooth operation.

- Monitor the tool alignment for accurate cuts.

- Inspect belts and gears for wear and tear.

Fixing small issues early can save time and improve your work. Regular upkeep means your lathe works better, which is what everyone wants!

How can you fix common lathe problems?

After identifying issues, you can tighten loose parts, adjust the alignment, or replace worn tools. This helps keep your lathe running smoothly.

What are some preventive maintenance tips?

- Clean the machine frequently.

- Lubricate weekly.

- Inspect tools regularly for damage.

Sticking to these tips will help you have fewer problems during operations.

Conclusion

In summary, setting up a lathe workshop involves careful planning of space and tools. A metal lathe is essential for precision work. Using CAD design helps visualize your projects before you start. You can improve your skills by practicing and exploring tutorials online. Dive into more resources to enhance your lathe workshop and create amazing projects!FAQs

What Are The Essential Components Needed For Setting Up A Metal Lathe Workshop, And How Do They Influence The Overall Efficiency Of The Workspace?To set up a metal lathe workshop, you need a metal lathe, tools, storage space, and safety gear. The lathe helps us shape metal pieces. Tools make our work easier and faster. Storage keeps everything organized, so we don’t waste time looking for things. Safety gear, like goggles and gloves, keeps us safe while we work.

How Can Cad Software Be Utilized To Design A Layout For A Metal Lathe Workshop That Maximizes Workflow And Minimizes Safety Hazards?You can use CAD software, which stands for Computer-Aided Design, to make a map of your metal lathe workshop. First, sketch where each machine goes. Place tools and workstations close together to help you move quickly. Make sure aisles are wide, so you can walk safely. Finally, check that there are no dangerous spots where you might trip or bump into things.

What Specific Considerations Should Be Taken Into Account When Designing Custom Fixtures Or Tooling For A Metal Lathe Using Cad?When designing custom fixtures or tools for a metal lathe, you should think about several things. First, make sure the size fits your project. Second, check that it is strong enough for the metal you’re working with. Third, consider how easy it is to attach and remove the fixture. Lastly, think about how well it helps you reach all parts of the metal piece.

How Can Different Lathe Setups Be Modeled In Cad To Determine The Best Approach For Specific Machining Tasks Or Projects?We can use Computer-Aided Design (CAD) software to create models of different lathe setups. This helps us see how each setup works. We can try different designs without making anything yet. By comparing these models, we can find the best option for our project. This way, we save time and make better choices!

What Are Some Common Design Mistakes To Avoid When Creating A Cad Model For A Metal Lathe Workshop Layout?When making a CAD model for a metal lathe workshop, avoid making things too cramped. Leave enough space for people to move around easily. Don’t forget about safety areas, like fire exits and tool storage. Make sure the machines are easy to reach and use. Lastly, plan for good lighting so you can see what you’re doing.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Needed For Setting Up A Metal Lathe Workshop, And How Do They Influence The Overall Efficiency Of The Workspace? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe workshop, you need a metal lathe, tools, storage space, and safety gear. The lathe helps us shape metal pieces. Tools make our work easier and faster. Storage keeps everything organized, so we don’t waste time looking for things. Safety gear, like goggles and gloves, keeps us safe while we work.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Design A Layout For A Metal Lathe Workshop That Maximizes Workflow And Minimizes Safety Hazards? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software, which stands for Computer-Aided Design, to make a map of your metal lathe workshop. First, sketch where each machine goes. Place tools and workstations close together to help you move quickly. Make sure aisles are wide, so you can walk safely. Finally, check that there are no dangerous spots where you might trip or bump into things.”}},{“@type”: “Question”,”name”: “What Specific Considerations Should Be Taken Into Account When Designing Custom Fixtures Or Tooling For A Metal Lathe Using Cad? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing custom fixtures or tools for a metal lathe, you should think about several things. First, make sure the size fits your project. Second, check that it is strong enough for the metal you’re working with. Third, consider how easy it is to attach and remove the fixture. Lastly, think about how well it helps you reach all parts of the metal piece.”}},{“@type”: “Question”,”name”: “How Can Different Lathe Setups Be Modeled In Cad To Determine The Best Approach For Specific Machining Tasks Or Projects? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use Computer-Aided Design (CAD) software to create models of different lathe setups. This helps us see how each setup works. We can try different designs without making anything yet. By comparing these models, we can find the best option for our project. This way, we save time and make better choices!”}},{“@type”: “Question”,”name”: “What Are Some Common Design Mistakes To Avoid When Creating A Cad Model For A Metal Lathe Workshop Layout? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making a CAD model for a metal lathe workshop, avoid making things too cramped. Leave enough space for people to move around easily. Don’t forget about safety areas, like fire exits and tool storage. Make sure the machines are easy to reach and use. Lastly, plan for good lighting so you can see what you’re doing.”}}]}