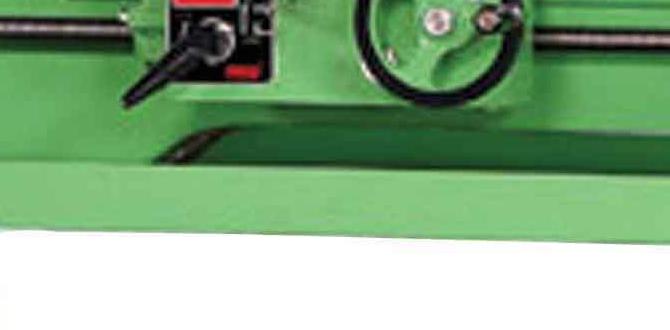

Imagine stepping into a workshop filled with the hum of machinery and the smell of metal shavings. That’s the dream of many budding engineers and hobbyists. A lathe workshop setup offers endless possibilities if you’re drawn to making things from metal. Have you ever wondered how a simple block of metal transforms into intricate parts? It all starts with the metal lathe carriage.

The metal lathe carriage is the heart of this creative process. It moves the cutting tool smoothly, shaping the metal into your desired form. Whether you want to make a new toy or a part for a model car, understanding how to set up your lathe workshop correctly is key. Setting up your workshop can be a fun adventure where you learn and create.

In this article, we will explore how to set up your lathe workshop for success. We will dive into the essential parts, tips for safety, and tricks to maximize your space. Let’s embark on this journey together and unlock the potential in your metal lathe!

Lathe Workshop Setup: Optimizing Metal Lathe Carriage Efficiency

Setting Up a Metal Lathe Workshop

Creating a metal lathe workshop can be both exciting and rewarding. You learn important aspects like choosing the right space and tools. The carriage of the lathe plays a crucial role in ensuring accuracy. Did you know that a well-set lathe can help produce intricate designs with ease? Proper setup helps in achieving high-quality work. Engaging with the workshop’s layout can boost your creativity and efficiency. Why not dive into the world of metalworking? It’s a journey filled with possibilities!Planning Your Lathe Workshop Space

Determining the ideal location and layout for your metal lathe.. Considerations for safety, accessibility, and workflow efficiency..Setting up your lathe workshop needs careful thought. Choose a spot that is quiet and spacious. Your metal lathe should be easy to reach and have enough light. Think about where tools and materials will go. This helps keep things safe and tidy. A good layout lets you work faster.

- Keep pathways clear.

- Ensure proper lighting.

- Place heavy tools close to the ground.

Amazing fact: Organizing your workshop can increase your productivity by 30%!

What is crucial for safety in a lathe workshop?

Safety gear and proper machine setup are crucial. Be mindful of your surroundings and always wear protective equipment. This keeps you safe while you work!

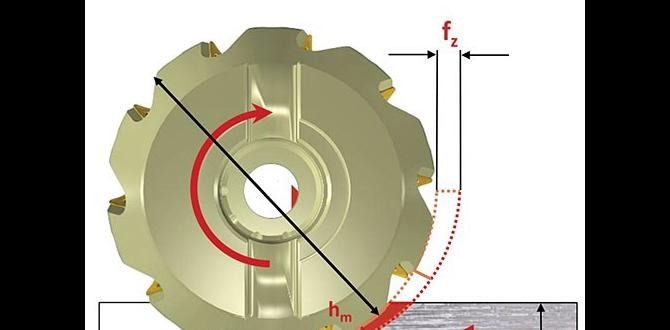

Essential Tools and Accessories for Metal Lathe Carriage

List of musthave tools for operating the metal lathe.. Additional accessories that enhance functionality and precision of the carriage..To run a metal lathe carriage smoothly, you’ll need some trusty tools. Here’s a sneak peek of the essentials: first up, you can’t go wrong with a tool post, which helps hold your cutting tools in place. Next on the list is a reliable tailstock to support your workpieces. Add a few calipers for accurate measurements, and you’re golden! Accessories like a steady rest and chucks make the process even snappier. Check out the table below for a simple overview:

| Tool | Purpose |

|---|---|

| Tool Post | Holds cutting tools |

| Tailstock | Supports workpieces |

| Calipers | Measure accurately |

| Steady Rest | Adds stability |

| Chucks | Grips workpieces |

With this toolbox, you’ll be ready to turn your metal projects into masterpieces—or at least avoid turning your fingers into scrap!

Step-by-Step Setup of the Metal Lathe Carriage

Detailed instructions for installing and aligning the carriage.. Common challenges during setup and how to troubleshoot them..Setting up your metal lathe carriage can be as tricky as untangling a ball of yarn. First, gather your tools and read the manual. Measure twice and align the carriage carefully on the bed. Here’s a little secret: use shims if needed, especially if your carriage is feeling a bit snug!

Common troubles include misalignment or stubborn screws. If the carriage doesn’t glide smoothly, double-check the screws and re-level the base. You might even discover your toolbox needs a therapy session too!

| Common Challenges | How to Fix |

|---|---|

| Misalignment | Re-measure and adjust the carriage. |

| Stuck screws | Use a bit of oil or grab a bigger wrench! |

Remember, patience is key. With some practice, you’ll handle that lathe like a pro!

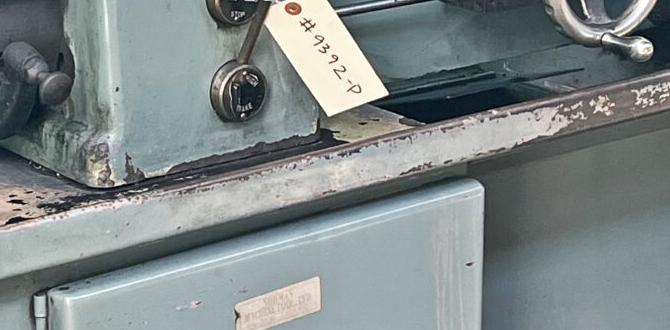

Maintenance Tips for Longevity of Your Metal Lathe Carriage

Best practices for routine maintenance and cleaning.. Signs of wear and how to address them before they escalate..Keeping your metal lathe carriage in shape is like giving it a day at the spa—some cleaning and care can go a long way! Regularly wipe it down to remove grime and grease. A clean lathe is a happy lathe. Look for signs of wear, like unusual noises or rough movements. Address these issues quickly, or your lathe might end up in a cranky mood!

| Maintenance Tips | Signs of Wear | Actions to Take |

|---|---|---|

| Clean regularly | Strange noises | Check bearings |

| Inspect belts | Rough movements | Lubricate parts |

| Oil moving parts | Slow response time | Adjust settings |

By following these tips, your lathe will operate smoothly and last longer, saving you from unexpected repairs!

Common Projects and Applications for the Metal Lathe Carriage

Examples of typical projects that can be accomplished with a metal lathe.. Exploration of industries and fields that benefit from using metal lathes..A metal lathe carriage is useful in many projects. You can create items like gears, shafts, and pulleys. Students often use lathes in school workshops to design fun projects. Industries like automotive and aerospace frequently rely on metal lathes for precise parts. Here are some typical uses:

- Building custom tools

- Making machine parts

- Creating artwork or sculptures

These examples show how important metal lathes are in different fields. They help make things faster and more accurate.

What are some common applications for metal lathes?

Common applications include producing parts for machines, tools, and prototypes across various industries.

Safety Precautions and Best Practices in the Lathe Workshop

Key safety measures to employ when working with a metal lathe.. Best practices for ensuring a safe working environment in the workshop..Safety is key in a lathe workshop. Always wear protective goggles and gloves. Keep long hair tied back to avoid accidents. Make sure your work area is clean and uncluttered. Here are some best practices:

- Check all tools before use.

- Never leave the lathe running unattended.

- Use the right speed for each material.

- Stay focused and avoid distractions.

Following these rules helps you stay safe and make great work pieces!

What should I wear in a lathe workshop?

In a lathe workshop, you should wear goggles, gloves, and tight-fitting clothes to protect yourself from flying debris.

How do I keep my workspace safe?

Keep your workspace clean, organized, and free of clutter. This prevents accidents and makes working easier.

Conclusion

Setting up a metal lathe carriage in your workshop is essential for smooth operations. Make sure your lathe is level and secure. Keep your tools organized for easy access. Regular maintenance will keep your lathe in top shape. We encourage you to explore more resources for tips and techniques. Happy machining, and enjoy creating amazing projects!FAQs

Sure! Here Are Five Questions Related To Setting Up A Metal Lathe Carriage In A Workshop:Sure! Here are some questions to think about when setting up your metal lathe carriage: 1. What tools do we need to set up the lathe? 2. How do we measure the lathe’s position correctly? 3. Where should we place the lathe in our workshop? 4. How do we secure the carriage to avoid movement? 5. What safety gear do we need when using the lathe? These questions help us get our metal lathe ready to work safely and effectively!

Sure! Just let me know what question you want me to answer.

What Are The Key Components Of A Metal Lathe Carriage And How Do They Function Together?A metal lathe carriage has a few important parts. First, there’s the saddle, which moves back and forth. Then, we have the cross slide, which can move side to side. The compound rest lets you tilt the cutting tool for different angles. Together, these parts help us shape metal by moving the tool in various directions.

How Do You Properly Align And Level The Carriage On A Metal Lathe To Ensure Precision Machining?To align and level the carriage on a metal lathe, first use a bubble level. Place it on the lathe bed. Adjust the feet until the bubble is centered. Next, check that the carriage moves smoothly along the bed. If it sticks or binds, make small adjustments until it moves freely. This helps your lathe make precise cuts!

What Are The Best Practices For Maintaining The Metal Lathe Carriage To Prevent Wear And Ensure Accurate Operation?To keep your metal lathe carriage working well, clean it often. Use a soft cloth to wipe off dirt and oil. Check for rust and remove it quickly with sandpaper. You should also apply oil to the moving parts to help them slide smoothly. Make sure to check the screws and parts regularly to keep everything tight and secure.

How Should You Adjust The Carriage For Different Types Of Machining Operations, Such As Turning Or Facing?To adjust the carriage for turning, you need to set it so the tool can move in a straight line. For facing, you adjust it to move side to side across the piece. Make sure to tighten the adjustments well. This helps keep everything in place while you work. Always double-check your settings before starting!

What Safety Precautions Should Be Taken When Setting Up And Operating The Carriage Of A Metal Lathe?When using a metal lathe, always wear safety goggles to protect your eyes. Make sure your hair and clothes are tucked in so they don’t get caught. Check that all tools are in good shape and don’t have any damage. Keep your hands away from moving parts, and don’t rush while working. Lastly, always follow the machine’s instructions carefully to stay safe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Setting Up A Metal Lathe Carriage In A Workshop:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions to think about when setting up your metal lathe carriage: 1. What tools do we need to set up the lathe? 2. How do we measure the lathe’s position correctly? 3. Where should we place the lathe in our workshop? 4. How do we secure the carriage to avoid movement? 5. What safety gear do we need when using the lathe? These questions help us get our metal lathe ready to work safely and effectively!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Carriage And How Do They Function Together?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe carriage has a few important parts. First, there’s the saddle, which moves back and forth. Then, we have the cross slide, which can move side to side. The compound rest lets you tilt the cutting tool for different angles. Together, these parts help us shape metal by moving the tool in various directions.”}},{“@type”: “Question”,”name”: “How Do You Properly Align And Level The Carriage On A Metal Lathe To Ensure Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and level the carriage on a metal lathe, first use a bubble level. Place it on the lathe bed. Adjust the feet until the bubble is centered. Next, check that the carriage moves smoothly along the bed. If it sticks or binds, make small adjustments until it moves freely. This helps your lathe make precise cuts!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining The Metal Lathe Carriage To Prevent Wear And Ensure Accurate Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe carriage working well, clean it often. Use a soft cloth to wipe off dirt and oil. Check for rust and remove it quickly with sandpaper. You should also apply oil to the moving parts to help them slide smoothly. Make sure to check the screws and parts regularly to keep everything tight and secure.”}},{“@type”: “Question”,”name”: “How Should You Adjust The Carriage For Different Types Of Machining Operations, Such As Turning Or Facing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the carriage for turning, you need to set it so the tool can move in a straight line. For facing, you adjust it to move side to side across the piece. Make sure to tighten the adjustments well. This helps keep everything in place while you work. Always double-check your settings before starting!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Setting Up And Operating The Carriage Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Make sure your hair and clothes are tucked in so they don’t get caught. Check that all tools are in good shape and don’t have any damage. Keep your hands away from moving parts, and don’t rush while working. Lastly, always follow the machine’s instructions carefully to stay safe.”}}]}