Have you ever dreamed of building your own parts? Turning a simple piece of metal into something special is exciting. A lathe workshop can make this dream come true. With a metal lathe, you can shape materials into amazing designs.

But what if your lathe could do even more? Imagine upgrading to a CNC setup. That’s like giving your lathe superpowers! You could create intricate parts with ease. A CNC retrofit takes your basic lathe and turns it into a high-tech machine.

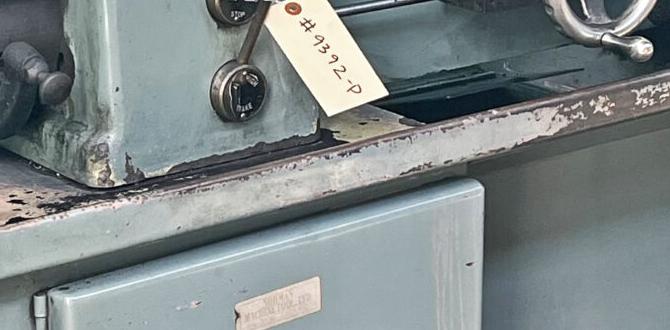

Many hobbyists start with old lathes. They are often cheap and easy to find. By adding a CNC retrofit, you can transform this old tool into a modern marvel. Does this sound interesting to you?

In this article, we will explore how to set up your lathe workshop. We will show you how to install a metal lathe CNC retrofit. You’ll be amazed at what you can achieve!

Lathe Workshop Setup: Metal Lathe Cnc Retrofit Guide

Lathe Workshop Setup: Metal Lathe CNC Retrofit

Setting up a lathe workshop can seem daunting. But with the right steps, it becomes manageable. Learn how to retrofit a metal lathe for CNC use, turning it into a powerful machine. This upgrade increases precision and efficiency, making your projects easier. Have you ever wondered how professionals achieve such fine details? Proper setup and tools make all the difference. Dive into the world of metalworking and explore the benefits of modern technology in your workshop.Understanding the Basics of Lathe Operations

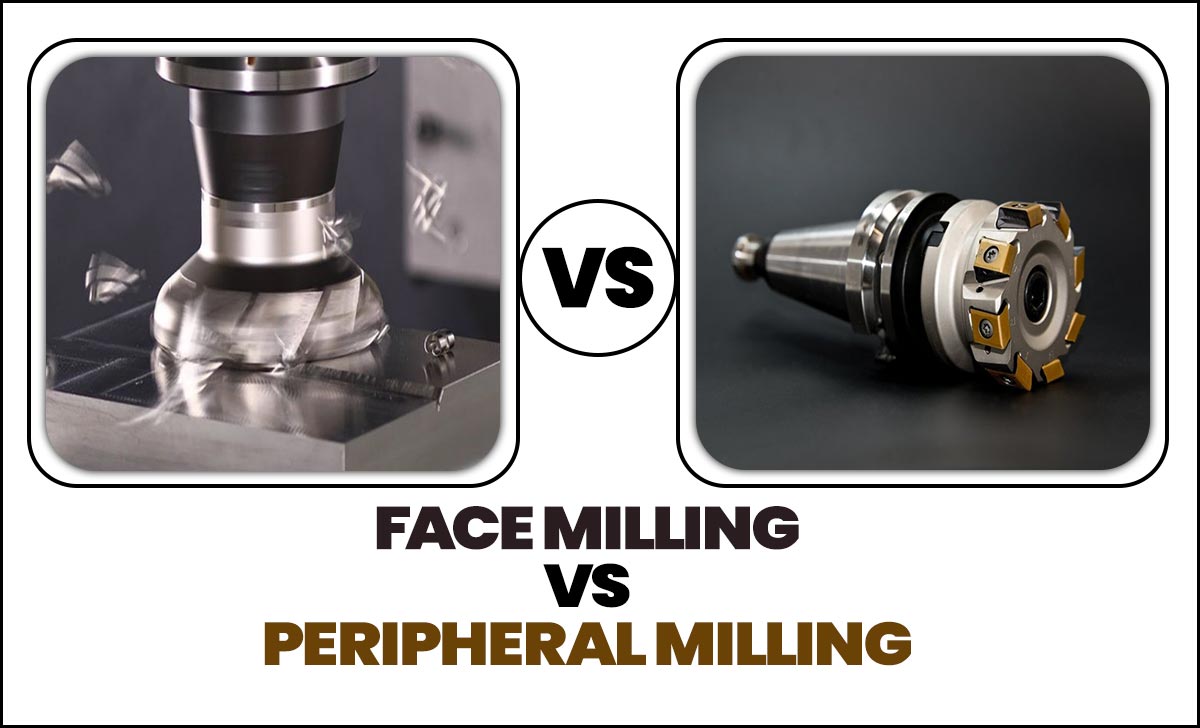

Explanation of lathe functions and types. Importance of precision in metalworking.A lathe is a special tool that helps shape metal or wood. It spins the material while cutting tools remove unwanted parts. There are different types of lathes, like manual and CNC (Computer Numerical Control). CNC lathes are more precise because a computer controls them.

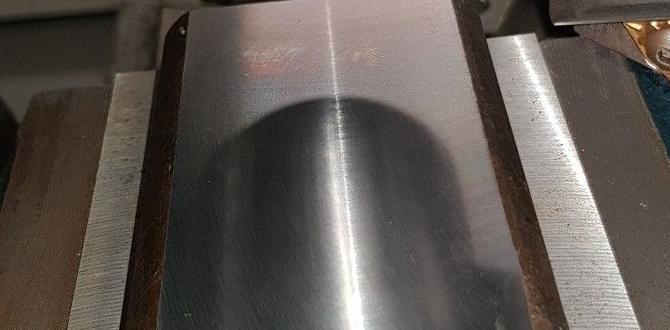

Precision is important in metalworking. It ensures that pieces fit together perfectly, making machines and tools work better. Even a small mistake can cause big problems. Always aim for accuracy when using a lathe!

What are the main functions of a lathe?

The main functions of a lathe are:

- Shaping materials: Cutting exact shapes from metal or wood.

- Drilling: Making holes in various materials.

- Sanding: Smoothing surfaces for a finished touch.

Why is precision important in metalworking?

Precision ensures that parts fit together well, making machines run smoothly. This is key in creating reliable tools and devices. Accurate work helps in reducing waste and saves money, too!

Choosing the Right Space for Your Lathe Workshop

Key considerations for workshop layout and accessibility. Safety measures and regulations to keep in mind.Setting up your lathe workshop requires smart choices about space. First, think about layout. Give your machines enough room to breathe and avoid playing tag with your tools. Don’t forget about accessibility. You want to reach everything easily—like that last cookie in the jar! Safety is also key. Make sure to follow rules like clear walkways and proper ventilation. And always wear safety goggles—you want to keep those peepers around! Here’s a quick table to help you remember:

| Consideration | Tip |

|---|---|

| Layout | Space for machines and movement |

| Accessibility | Easy reach for tools and materials |

| Safety | Follow guidelines; wear goggles! |

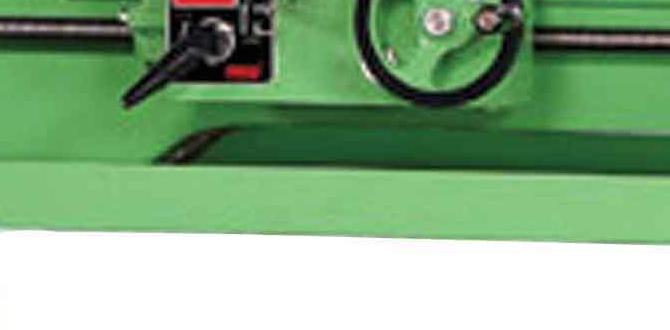

Selecting the Best Metal Lathe for Your Needs

Comparison of different types of metal lathes available. Factors to consider: size, power, and features.Choosing the right metal lathe can feel like picking the best ice cream flavor—too many options! You have a few types to consider. Bench lathes are great for small projects, while industrial lathes pack power for big jobs. Don’t forget to think about size! A huge lathe might fit like a sumo wrestler in a small car. Also, check the features. Some lathes come with fancy add-ons like digital readouts. Here’s a simple table to help you compare:

| Type | Size | Power | Features |

|---|---|---|---|

| Bench Lathe | Small | Low | Basic |

| Mid-Sized Lathe | Medium | Moderate | Intermediate |

| Industrial Lathe | Large | High | Advanced |

Remember, pick a lathe that fits your projects and your workshop space—unless you really want a wrestling match with your tools!

CNC Retrofit: Upgrading Your Metal Lathe

Benefits of retrofitting a traditional lathe with CNC technology. Stepbystep guide to CNC retrofitting process. “`htmlUpgrading a traditional lathe to CNC brings cool benefits. First, you get precise cuts every time, like a robot chef in the kitchen. You also save time! A CNC lathe can work while you’re off munching on pizza. Want to try it? Here’s a quick step-by-step guide:

| Step | Description |

|---|---|

| 1 | Assess your lathe’s structure. |

| 2 | Choose the right CNC kit. |

| 3 | Install hardware components. |

| 4 | Connect electronics and software. |

| 5 | Test the setup before use. |

So, give your metal lathe a fancy upgrade! It’s like turning your trusty bicycle into a speedy motorcycle. Happy retrofitting!

“`Setting Up Power Supply and Electrical Requirements

Guidelines for safe electrical installation for lathe machinery. Importance of ensuring compatibility with CNC systems.Before starting the lathe, it’s important to set up the power supply correctly. Safe electrical installation protects both the machine and the user. Always use a dedicated circuit for your lathe. This helps avoid power problems that can affect performance. Make sure the electrical system is compatible with CNC controls. Using the wrong system can cause errors. Here are some tips to keep in mind:

- Check the voltage requirements.

- Use proper fuses and circuit breakers.

- Ensure good grounding of the machine.

Why is electrical compatibility important for CNC systems?

Electrical compatibility ensures that the machinery operates smoothly. Incompatible systems can lead to malfunction and damage. Always match your lathe’s power supply with the CNC’s specifications for safe and efficient operation.

Calibration and Maintenance of Your Lathe

Best practices for regularly calibrating your lathe. Common maintenance tasks to prolong the lifespan of your equipment.Regularly taking care of your lathe is key to keeping it in good shape. Proper calibration helps ensure precision. Check the settings often to avoid mistakes. Cleaning the lathe also plays a big role. Here are best practices for calibration and maintenance:

- Check alignment every month.

- Clean dust and debris weekly.

- Oil moving parts regularly.

- Inspect belts and gears every few months.

Doing these tasks will help your lathe last longer and work better. Always remember, a well-maintained lathe is a happy lathe!

How often should I calibrate my lathe?

You should calibrate your lathe at least once a month. Frequent checks help ensure accuracy and avoid mistakes during work.

What are common maintenance tasks?

- Cleaning and lubricating moving parts.

- Checking for wear and tear on belts.

- Tightening loose screws and bolts.

Troubleshooting Common Lathe Issues

List of frequent problems faced by lathe operators. Solutions and preventive measures to consider.Lathes can be tricky! Many operators face common issues that can cause headaches—like vibration problems or blade misalignment. Luckily, solutions exist! Regularly check your tools, maintain proper speed, and ensure everything is secured. If your lathe starts dancing like a rock star, try tightening the bolts. Or, if the finish looks rough, a gentle sanding might help. Remember, a happy lathe means a happy operator!

| Problem | Solution |

|---|---|

| Vibration | Tighten bolts and balance the setup |

| Blade Misalignment | Re-align the cutting tool |

| Rough Finish | Sand and polish |

Resources for Further Learning and Support

Recommended books and online courses on lathe operation. Exploring community forums and expert advice for troubleshooting.Learning about lathe operation can be exciting! Here are some great resources to help you. For books, look for “The Complete Guide to CNC Machining” and “Lathe Fundamentals”. Online courses are also helpful. Websites like Udemy and Coursera offer many options. Community forums are great for support too. They let you connect with other learners and get expert advice. Join these forums to troubleshoot problems and share tips!

- Books:

- The Complete Guide to CNC Machining

- Lathe Fundamentals

What are the best places to learn about lathe operations?

Some top places to learn include books, online courses, and community forums. These allow you to connect, ask questions, and find solutions.

Conclusion

Setting up a lathe workshop with a CNC retrofit can boost your metalworking skills. You can create precise parts and improve your projects. Remember to choose quality equipment and plan your space wisely. Start by researching more about CNC systems and tools. With practice, you’ll become proficient and enjoy the creative possibilities! Happy machining!FAQs

What Are The Essential Tools And Components Needed For A Successful Cnc Retrofit Of A Metal Lathe?To retrofit a metal lathe with CNC (Computer Numerical Control), you need some important tools and parts. First, you’ll need a CNC controller to tell the machine what to do. Next, get stepper motors or servos to move the lathe parts. You will also need proper wiring and connectors to hook everything up. Finally, you might want a computer with software to plan the tasks you want the lathe to do.

How Do You Determine The Appropriate Stepper Motors Or Servo Motors To Use In A Cnc Retrofit For A Metal Lathe?To choose the right stepper motors or servo motors for your CNC retrofit, we need to think about a few things. First, we check how much weight the motors will need to move. Next, we look at how fast and accurate we want the lathe to work. Then, we make sure the motors fit in our machine without any problems. Lastly, we read reviews and ask for advice to find the best motors for our project.

What Software Options Are Available For Controlling A Retrofitted Cnc Metal Lathe, And How Do They Compare In Terms Of Functionality And User-Friendliness?There are several software options for controlling a retrofitted CNC metal lathe. Some popular ones are Mach3, LinuxCNC, and Fusion 360. Mach3 is user-friendly and great for beginners. LinuxCNC is powerful but requires more setup knowledge. Fusion 360 offers design tools too, but it can be a bit tricky at first.

What Are Some Common Challenges Faced During A Cnc Retrofit Of A Metal Lathe, And How Can They Be Overcome?When you retrofit a metal lathe to CNC, you might face some problems. One challenge is fitting the new parts on the old machine. To fix this, you can carefully measure everything first. Another challenge is getting the software to work with the new setup. We can overcome this by using good instructions and asking for help if needed.

How Can You Ensure The Safety And Accuracy Of A Metal Lathe After Completing A Cnc Retrofit?To ensure safety and accuracy after retrofitting a metal lathe with CNC (Computer Numerical Control), check the machine carefully. First, make sure all parts are tight and working well. Then, test it with simple shapes to see if it cuts correctly. Always wear safety gear like goggles when you use it. Finally, keep the area clean and organized to avoid accidents.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Tools And Components Needed For A Successful Cnc Retrofit Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To retrofit a metal lathe with CNC (Computer Numerical Control), you need some important tools and parts. First, you’ll need a CNC controller to tell the machine what to do. Next, get stepper motors or servos to move the lathe parts. You will also need proper wiring and connectors to hook everything up. Finally, you might want a computer with software to plan the tasks you want the lathe to do.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Stepper Motors Or Servo Motors To Use In A Cnc Retrofit For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right stepper motors or servo motors for your CNC retrofit, we need to think about a few things. First, we check how much weight the motors will need to move. Next, we look at how fast and accurate we want the lathe to work. Then, we make sure the motors fit in our machine without any problems. Lastly, we read reviews and ask for advice to find the best motors for our project.”}},{“@type”: “Question”,”name”: “What Software Options Are Available For Controlling A Retrofitted Cnc Metal Lathe, And How Do They Compare In Terms Of Functionality And User-Friendliness? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are several software options for controlling a retrofitted CNC metal lathe. Some popular ones are Mach3, LinuxCNC, and Fusion 360. Mach3 is user-friendly and great for beginners. LinuxCNC is powerful but requires more setup knowledge. Fusion 360 offers design tools too, but it can be a bit tricky at first.”}},{“@type”: “Question”,”name”: “What Are Some Common Challenges Faced During A Cnc Retrofit Of A Metal Lathe, And How Can They Be Overcome? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you retrofit a metal lathe to CNC, you might face some problems. One challenge is fitting the new parts on the old machine. To fix this, you can carefully measure everything first. Another challenge is getting the software to work with the new setup. We can overcome this by using good instructions and asking for help if needed.”}},{“@type”: “Question”,”name”: “How Can You Ensure The Safety And Accuracy Of A Metal Lathe After Completing A Cnc Retrofit? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To ensure safety and accuracy after retrofitting a metal lathe with CNC (Computer Numerical Control), check the machine carefully. First, make sure all parts are tight and working well. Then, test it with simple shapes to see if it cuts correctly. Always wear safety gear like goggles when you use it. Finally, keep the area clean and organized to avoid accidents.”}}]}