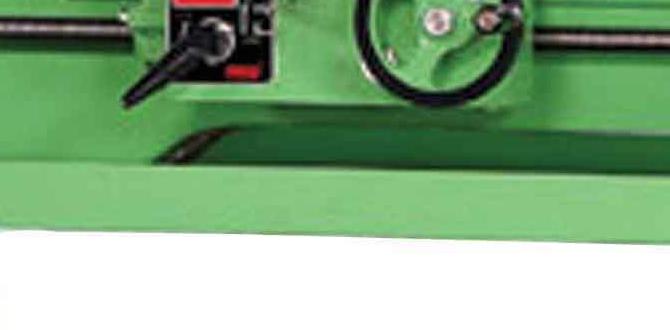

Have you ever wondered how metal objects are made? A lathe workshop is where that magic happens. Many people don’t know that a metal lathe can be a great tool for both hobbyists and professionals. Do you enjoy creating or fixing things? If so, setting up a lathe workshop could be exciting for you!

In this article, we will explore how to set up a metal lathe controller and why it is so important. Imagine shaping metal into the exact shape you want. It’s not just about making things; it’s about turning your ideas into reality.

Did you know that the first lathes were made thousands of years ago? They have come a long way since then! Today’s metal lathe controllers make work easier and more precise. Understanding how to set this up can help you become a better maker.

So, are you ready to dive into the world of metal lathes? Let’s discover how to create your very own workshop!

Lathe Workshop Setup: Metal Lathe Controller Essentials

Lathe Workshop Setup: Metal Lathe Controller

Setting up a lathe workshop can be an exciting adventure. A metal lathe controller is key to achieving precision. It allows for better control over the cutting speeds and feeds. Imagine creating perfectly shaped parts with ease! You learn to adjust settings for various materials, making your projects smoother. A solid setup not only enhances your skills but also boosts your confidence. Did you know that a well-organized workspace can spark creativity? Dive into the world of metal lathes and watch your ideas come to life!Essential Tools and Accessories for Your Lathe Workshop

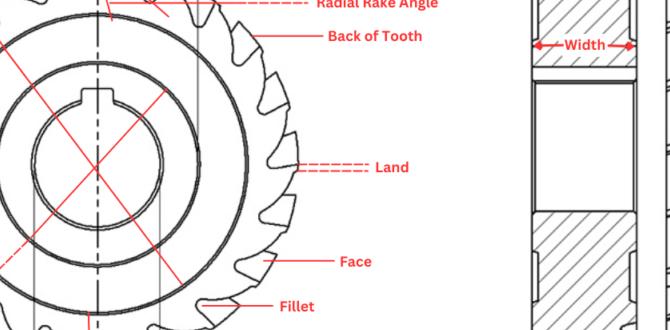

List of musthave tools for effective lathe operations. Recommended accessories to enhance functionality.Starting a lathe workshop is like preparing for a cooking contest. You need the right tools to whip up your best projects! Must-have tools include a sturdy metal lathe, sharp cutting tools, and essential safety gear like goggles. To enhance your workshop, consider adding a digital readout for precision and a sturdy workbench for support. Remember, the right accessories can turn a good project into a great one!

| Essential Tools | Recommended Accessories |

|---|---|

| Metal Lathe | Digital Readout |

| Cutting Tools | Workbench |

| Goggles | Tool Holders |

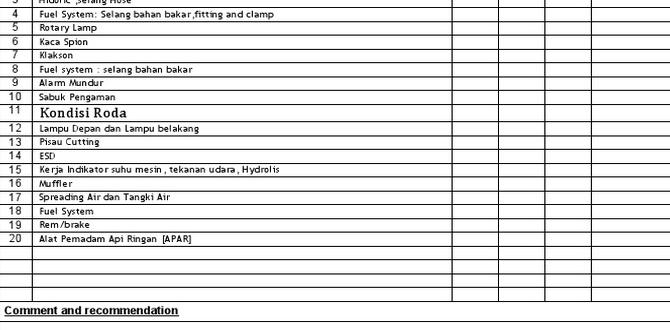

Setting Up Your Lathe Workspace

Key considerations for workshop layout and organization. Safety measures to implement in your lathe workshop.Start by arranging your workspace smartly. Leave space to move around the machine. Keep tools close but organized. Use shelves for storage. Remember these important safety tips:

- Always wear safety glasses.

- Keep floor clean and dry.

- Know where the emergency stop button is.

A safe and tidy area helps you work better!

What are the key aspects of setting up a lathe workshop?

Key aspects include smart workspace layout, organization, and safety measures.

Understanding Metal Lathe Controllers

Explanation of different types of lathe controllers. How to choose the right controller for your metal lathe.Lathe controllers help machines cut and shape metal accurately. There are different types, like manual, CNC, and digital controllers. CNC controllers use computers for precision work. Manual ones are good for hands-on experience. When picking a controller, think about:

- Skill Level: Are you a beginner or advanced?

- Project Needs: What type of work will you do?

- Budget: How much can you spend?

Selecting the right controller helps ensure success in your metal lathe projects.

What types of lathe controllers are available?

There are manual, CNC, and digital lathe controllers. Each has unique features. Manual controllers require hands-on skill. CNC controllers automate processes, allowing complex designs. Digital controllers offer easy adjustments and presets.

How to choose the right controller for your lathe?

- Consider your skill level.

- Think about the types of projects you will do.

- Set a budget before shopping.

Installation Process for a Metal Lathe Controller

Stepbystep guide to installing the controller. Troubleshooting common installation issues.Installing a metal lathe controller is simple if you follow these steps. First, clear your workspace. Next, connect the wires from the controller to the lathe. Ensure the connections fit snugly. Then, secure the controller with screws. Finally, plug in the power and turn on the machine. Problems may happen, but don’t worry! If the system doesn’t start, check the wiring again. Look for loose connections. If needed, consult the manual for more help.

What are common problems during installation?

Common issues include loose wires, wrong settings, or power problems.

Tips to Fix Issues:

- Double-check all connections.

- Make sure the power source works.

- Reset the controller settings if necessary.

Programming Your Metal Lathe Controller

Basics of programming and controlling lathe operations. Tips for optimizing lathe performance through programming.Programming your metal lathe controller is about making the machine do what you want. Start by learning the basics. Understand how to set speed, feed rate, and depth. Each part matters! Here are some tips to help you optimize your lathe performance:

- Use the right tools for each job.

- Check your settings before starting.

- Practice safe programming techniques.

By following these steps, you’ll produce better work and keep your lathe running smoothly.

How can I program my metal lathe controller?

To program your metal lathe controller, it’s important to understand the control panel. You set parameters like speed and cut depth, then test your setup. Adjust based on the results for the best outcomes.

Maintenance Tips for Your Metal Lathe and Controller

Regular maintenance tasks to keep your lathe in top shape. Best practices for maintaining your lathe controller.Keeping your metal lathe and controller in good shape is important. Regular care can help them work better and last longer. Here are some helpful tasks to do:

- Clean the lathe after every use.

- Check oil levels often.

- Inspect belts and gears for wear.

- Calibrate the controller regularly.

These simple steps can save time and money. Remember, a well-maintained machine gives better results!

What are best practices for maintaining your lathe controller?

Keep it free from dust and debris. Make sure connections are tight. Every few months, update the software. This prevents bugs and errors. A clean and updated controller helps your lathe run smoothly.

Common Issues and Solutions in Lathe Workshop Operations

Identifying frequent problems encountered in lathe work. Effective solutions to troubleshoot and resolve issues.Working in a lathe workshop can be rewarding, but it comes with challenges. Many face issues like improper cuts, noise, or tool wear. Knowing these problems can help you find quick solutions. Here are some common ones:

- Improper cuts: Check your settings and ensure the tool is sharp.

- Excessive noise: Lubricate moving parts regularly to reduce noise.

- Fast tool wear: Use the right materials, and replace tools when needed.

By identifying these common issues, you can keep your lathe running smoothly and efficiently.

What to do if the lathe is making a lot of noise?

Lubricate all moving parts and ensure they are adjusted correctly to minimize noise.

How can you improve cutting precision on a lathe?

Ensure the tool is sharp and check the machine’s alignment for better cuts.

Resources for Further Learning and Support

Recommended books, websites, and courses on lathe operation. Online communities and forums for lathe enthusiasts.For those eager to learn more about operating a lathe, many resources are available. Consider exploring these books and websites for great tips:

- “The Lathe Primer” by William M. C. G. Lehmann. This book is perfect for beginners.

- “Lathework: A Home Workshop Guide” by the late Paul E. Duffy. It covers all the basics.

- Online courses. Websites like Udemy offer many affordable options.

Joining online communities can help you connect with other lathe enthusiasts. Websites like Reddit and forums dedicated to woodworking and metalworking can be fantastic. You can ask questions and share your projects. Happy learning!

What are some popular online communities for lathe enthusiasts?

Two excellent online communities are Reddit and Practical Machinist Forum. These platforms allow users to share ideas, seek advice, and discuss projects.

Conclusion

In summary, setting up a lathe workshop with a metal lathe controller is crucial for efficiency. You should choose the right tools and organize your workspace for safety. Always follow guidelines for operating your lathe. We encourage you to explore more about lathe projects and tutorials to enhance your skills. Start small and practice regularly to improve!FAQs

Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Controllers:Sure! A lathe workshop is where we use a machine called a lathe to shape metal or wood. To set it up, we need a clear space for the lathe and tools nearby. It’s important to keep everything organized so we can work safely. A metal lathe controller helps us program and control the lathe for precise cuts. This makes our work easier and more accurate!

Sure! Please give me the question you want me to answer.

What Are The Essential Components Needed For Setting Up A Metal Lathe Workshop, And How Do They Interact With The Lathe Controller?To set up a metal lathe workshop, you need a metal lathe, tools, and safety gear. The metal lathe helps us shape metal pieces. The lathe controller makes sure the machine runs smoothly and accurately. We also need a good workbench and proper lighting to see well. Safety gear, like goggles and gloves, keeps us safe while we work.

How Does The Choice Of A Digital Vs. Analog Controller Impact The Performance And Capabilities Of A Metal Lathe?A digital controller helps you program the metal lathe easily. It can remember settings and adjust them quickly. An analog controller has simple knobs but is not as precise. With a digital controller, you can make more complicated shapes. This means you can do more cool projects with a digital lathe!

What Factors Should Be Considered When Selecting A Lathe Controller For Precision Machining Tasks?When picking a lathe controller, think about what you need it to do. Check its accuracy, so it can make precise cuts. Consider how easy it is to use, so you don’t get confused. Look for features that help you work faster and better. Finally, see if it works well with your lathe machine.

How Can Advanced Features In Modern Lathe Controllers Improve Machining Accuracy And Efficiency In A Workshop Environment?Modern lathe controllers help us make better and faster parts. They can keep track of how the machine is working. This means we can catch mistakes before they happen. They also let us change settings quickly, so we can work on different projects easily. All this makes our work more accurate and saves us time!

What Are Common Troubleshooting Tips For Issues That May Arise With Metal Lathe Controllers During Operation?If your metal lathe stops working, check the power first. Make sure it’s plugged in and the switch is on. If it moves slowly, look at the speed settings. You might need to adjust them. Also, check the tools for any damage. If something looks broken, replace it to keep cutting smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Controllers:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe workshop is where we use a machine called a lathe to shape metal or wood. To set it up, we need a clear space for the lathe and tools nearby. It’s important to keep everything organized so we can work safely. A metal lathe controller helps us program and control the lathe for precise cuts. This makes our work easier and more accurate!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Needed For Setting Up A Metal Lathe Workshop, And How Do They Interact With The Lathe Controller?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe workshop, you need a metal lathe, tools, and safety gear. The metal lathe helps us shape metal pieces. The lathe controller makes sure the machine runs smoothly and accurately. We also need a good workbench and proper lighting to see well. Safety gear, like goggles and gloves, keeps us safe while we work.”}},{“@type”: “Question”,”name”: “How Does The Choice Of A Digital Vs. Analog Controller Impact The Performance And Capabilities Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital controller helps you program the metal lathe easily. It can remember settings and adjust them quickly. An analog controller has simple knobs but is not as precise. With a digital controller, you can make more complicated shapes. This means you can do more cool projects with a digital lathe!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Lathe Controller For Precision Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a lathe controller, think about what you need it to do. Check its accuracy, so it can make precise cuts. Consider how easy it is to use, so you don’t get confused. Look for features that help you work faster and better. Finally, see if it works well with your lathe machine.”}},{“@type”: “Question”,”name”: “How Can Advanced Features In Modern Lathe Controllers Improve Machining Accuracy And Efficiency In A Workshop Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Modern lathe controllers help us make better and faster parts. They can keep track of how the machine is working. This means we can catch mistakes before they happen. They also let us change settings quickly, so we can work on different projects easily. All this makes our work more accurate and saves us time!”}},{“@type”: “Question”,”name”: “What Are Common Troubleshooting Tips For Issues That May Arise With Metal Lathe Controllers During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe stops working, check the power first. Make sure it’s plugged in and the switch is on. If it moves slowly, look at the speed settings. You might need to adjust them. Also, check the tools for any damage. If something looks broken, replace it to keep cutting smoothly.”}}]}