Imagine stepping into a room filled with the hum of machines and the smell of metal shavings. This is the magic of a lathe workshop. Here, creativity meets precision in an exciting world of metalwork.

Setting up a lathe workshop is like creating your very own adventure in craftsmanship. Have you ever wanted to turn a simple piece of metal into something amazing? With the right tools and setup, you can!

Let’s talk about metal lathe cutting tools. These tools transform dull metal into smooth shapes and beautiful designs. It’s fascinating to think how a small tool can make such a big difference.

In this article, we will explore how to set up your lathe workshop. You will learn about essential cutting tools and how to use them effectively. Prepare to start your journey into the exciting world of metal lathe work!

Lathe Workshop Setup: Essential Metal Lathe Cutting Tools

Lathe Workshop Setup: Metal Lathe Cutting Tools

Setting up a metal lathe workshop can be exciting! Key points include choosing the right lathe for your projects. Essential cutting tools like carbide inserts and high-speed steel bits make a big difference. Proper tool setup ensures accuracy and efficiency. Did you know that a well-maintained lathe can last decades? Planning your workspace layout is also crucial for safety and comfort. With the right tools, you can create amazing pieces of art or functional parts.Choosing the Right Space for Your Lathe Workshop

Considerations for floor space and layout. Importance of ventilation and lighting.Finding a spot for your lathe workshop is like choosing a cozy corner for a picnic. You want enough floor space for your metal lathe and tools without bumping into things like a clumsy squirrel. Make sure to plan your layout to keep everything within arm’s reach. Good ventilation is key, too. You don’t want to inhale dust all day; that’s as fun as eating a rock! Bright lighting helps you see what you’re doing and keeps your toes safe. Remember, a well-lit workshop is a happy workshop!

| Factor | Importance |

|---|---|

| Floor Space | Provides room for tools and movement |

| Layout | Keeps tools accessible and organized |

| Ventilation | Reduces dust inhalation |

| Lighting | Improves visibility and safety |

Metal Lathe Types and Their Applications

Explanation of different metal lathe types (e.g., bench lathes, floor lathes). Ideal uses and features of each lathe type.Different metal lathes serve unique purposes. Bench lathes are small and perfect for light work. They are often used for hobby projects and repairs. In contrast, floor lathes are larger and designed for heavy-duty tasks. They are great for making big parts in factories. Here’s a quick look:

- Bench Lathes: Ideal for small projects and home use.

- Floor Lathes: Best for industrial work and larger pieces.

Choosing the right lathe depends on your projects. Each type has features that fit specific needs.

What types of metal lathes are there?

There are mainly bench lathes and floor lathes. Bench lathes are smaller and suitable for light tasks, while floor lathes are larger and meant for heavy work.

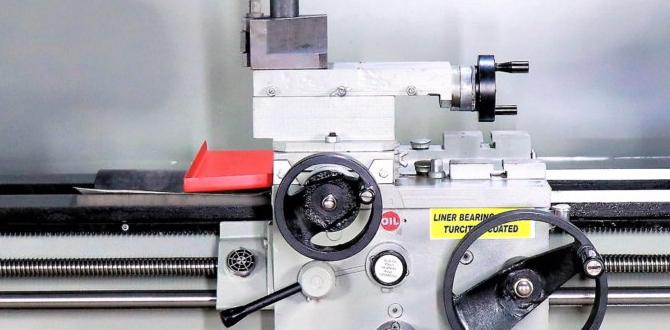

Setting Up Your Metal Lathe

Stepbystep guide for lathe installation and leveling. Wiring and safety precautions to consider.Follow these steps to set up your metal lathe safely. First, level the lathe with shims. This keeps it steady while you work. Next, connect the lathe to a power source. Use a proper outlet and check wires for damage. Always use safety gear, like goggles and gloves. Clear the area of clutter. Lastly, read the safety manual for more tips about metal lathe cutting tools.

What safety precautions should I consider?

Always unplug the lathe when not in use. Wear safety goggles and keep hands away from moving parts. Also, keep the workspace clean and dry to prevent slips.Maintenance and Care for Your Metal Lathe

Routine maintenance tasks to extend lathe lifespan. Troubleshooting common issues with metal lathes.Keeping your metal lathe in top shape is easy with some simple care. Regularly clean it and oil moving parts to prevent rust. This routine upkeep can make your lathe last longer—almost like giving it a spa day! If something goes wrong, check the belts and bearings first. They can be sneaky troublemakers. Remember, a happy lathe is a productive lathe! Here’s a handy table for common issues:

| Issue | Solution |

|---|---|

| Lathe won’t start | Check power supply and switches |

| Unusual noise | Inspect belts and bearings |

| Inaccurate cuts | Adjust tool settings |

Resources for Further Learning and Community Engagement

Recommended books and online courses for lathe enthusiasts. Forums and clubs for networking and sharing experiences.There are many resources to help you dive deeper into the world of lathes. Consider reading “Lathe Work” by Ian Bradley or “The Modern Machinist” by James N. O. Smith. Online courses like those on Udemy can teach you new skills quickly. To connect with others, join local clubs or online forums like Reddit’s r/Machinists. Sharing your experiences makes learning fun!

What are some good resources for learning about lathes?

Books and online courses can help you understand lathes better. Also, joining forums and clubs lets you connect with others who share your interests.

Some recommended resources:

- Books: “Lathe Work” by Ian Bradley.

- Online Courses: Udemy’s lathe courses.

- Forums: Reddit’s r/Machinists.

- Clubs: Local makerspaces or hobby clubs.

Conclusion

In summary, setting up a lathe workshop with metal lathe cutting tools is essential for precision work. Choose quality tools for better results. Organize your space for safety and efficiency. Always practice good techniques to improve your skills. Start with simple projects, and don’t hesitate to explore more resources to advance your knowledge. Let’s get crafting!FAQs

Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Cutting Tools:Sure! A lathe is a special tool used to shape metal. In a lathe workshop, you need space, good lighting, and safety gear. Metal lathe cutting tools help us cut and shape metal pieces. Always wear goggles to protect your eyes while working. Keep your tools organized so you can find them easily when you need them.

Sure! Please share the question you would like me to answer.

What Essential Components Should Be Included In A Lathe Workshop Setup For Optimal Performance And Safety?In a lathe workshop, you need a few important things. First, have a good-quality lathe machine for spinning materials. Second, make sure you have safety gear, like goggles and gloves. Third, keep tools and parts organized and close by to use easily. Finally, ensure good lighting so you can see what you’re doing clearly.

How Do You Select The Appropriate Cutting Tools For Different Types Of Metalworking Projects On A Lathe?To pick the right cutting tools for a lathe, you first think about the metal you’re using. Different metals need different tools. Soft metals like aluminum need sharp tools, while harder metals like steel need stronger tools. You also check the shape of the tool to match the job. Finally, you can ask an expert or look online for tips if you’re unsure.

What Maintenance Practices Should Be Implemented To Ensure The Longevity And Accuracy Of Metal Lathe Cutting Tools?To keep metal lathe cutting tools working well, you should clean them after each use. Make sure to remove any leftover metal shavings. You also need to check for any damage, like chips or cracks. Sharpen the tools regularly to keep them cutting smoothly. Finally, store them in a dry and safe place to avoid rust.

How Can You Determine The Correct Speeds And Feeds For Various Materials When Using A Lathe?To find the right speeds and feeds for a lathe, you can start by looking at charts. These charts show the best settings for different materials, like metal or wood. You can also ask your teacher or an expert for help. Always remember to start slow, then adjust as needed. This way, you keep everything safe and work better!

What Are The Differences Between High-Speed Steel (Hss) And Carbide Cutting Tools, And When Should Each Be Used In A Lathe Workshop?High-speed steel (HSS) tools are softer and easier to sharpen. They work well for simple tasks and small jobs. Carbide tools are harder and last much longer. They are best for cutting tough materials or doing heavy work. Use HSS for light jobs and carbide for more difficult ones.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Cutting Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a special tool used to shape metal. In a lathe workshop, you need space, good lighting, and safety gear. Metal lathe cutting tools help us cut and shape metal pieces. Always wear goggles to protect your eyes while working. Keep your tools organized so you can find them easily when you need them.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Essential Components Should Be Included In A Lathe Workshop Setup For Optimal Performance And Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a lathe workshop, you need a few important things. First, have a good-quality lathe machine for spinning materials. Second, make sure you have safety gear, like goggles and gloves. Third, keep tools and parts organized and close by to use easily. Finally, ensure good lighting so you can see what you’re doing clearly.”}},{“@type”: “Question”,”name”: “How Do You Select The Appropriate Cutting Tools For Different Types Of Metalworking Projects On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To pick the right cutting tools for a lathe, you first think about the metal you’re using. Different metals need different tools. Soft metals like aluminum need sharp tools, while harder metals like steel need stronger tools. You also check the shape of the tool to match the job. Finally, you can ask an expert or look online for tips if you’re unsure.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Implemented To Ensure The Longevity And Accuracy Of Metal Lathe Cutting Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep metal lathe cutting tools working well, you should clean them after each use. Make sure to remove any leftover metal shavings. You also need to check for any damage, like chips or cracks. Sharpen the tools regularly to keep them cutting smoothly. Finally, store them in a dry and safe place to avoid rust.”}},{“@type”: “Question”,”name”: “How Can You Determine The Correct Speeds And Feeds For Various Materials When Using A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right speeds and feeds for a lathe, you can start by looking at charts. These charts show the best settings for different materials, like metal or wood. You can also ask your teacher or an expert for help. Always remember to start slow, then adjust as needed. This way, you keep everything safe and work better!”}},{“@type”: “Question”,”name”: “What Are The Differences Between High-Speed Steel (Hss) And Carbide Cutting Tools, And When Should Each Be Used In A Lathe Workshop?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “High-speed steel (HSS) tools are softer and easier to sharpen. They work well for simple tasks and small jobs. Carbide tools are harder and last much longer. They are best for cutting tough materials or doing heavy work. Use HSS for light jobs and carbide for more difficult ones.”}}]}