Have you ever wanted to create something amazing with your own hands? A lathe workshop can help turn your ideas into reality. A metal lathe drive system is one of the most important parts of this workshop. It powers the machine and shapes the metal into various forms.

But setting up a lathe workshop can seem tricky at first. What tools will you need? How do you arrange everything? These questions might feel overwhelming. Yet, with a bit of guidance, anyone can manage it! Imagine watching a simple piece of metal transform into a beautiful vase.

Did you know that lathes have been around for thousands of years? They have helped many artisans craft unique items. Now, with a good understanding of how a metal lathe drive system works, you can join this creative tradition!

Let’s dive into the essential steps for setting up your lathe workshop. It’s time to unleash your creativity!

Lathe Workshop Setup: Optimizing Your Metal Lathe Drive System

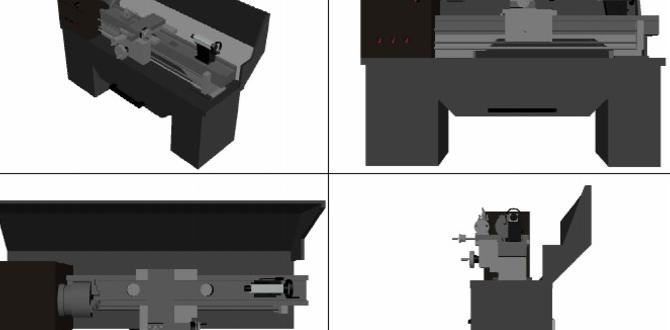

Lathe Workshop Setup: Metal Lathe Drive System

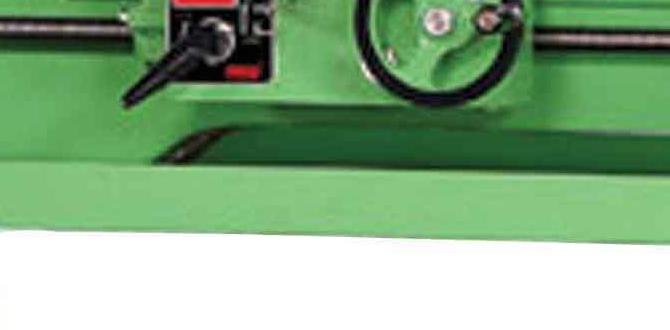

Setting up a metal lathe workshop can be a fun adventure! Imagine creating your own tools and parts. The drive system is key to making this possible. It connects the motor to the lathe, helping it spin at the right speed. Knowing how gears and belts work can make your lathe more efficient. Plus, understanding lubrication keeps it running smoothly. Want to turn metal into amazing creations? Master the drive system to enhance your workshop skills!Choosing the Right Location for Your Lathe Workshop

Factors to consider for optimal workspace layout. Importance of ventilation and safety protocols.Setting up your lathe workshop needs careful thought. Space is important for moving around. Think about these factors:

- Room size: Enough space is key.

- Ventilation: Fresh air keeps you safe from dust fumes.

- Safety: Keep tools within reach but stored safely.

Good ventilation helps reduce harmful air. Always wear safety gear, like goggles and masks. This keeps you safe while you work. Remember this: a well-planned space makes your work easier and more fun.

What are the key elements for lathe workshop safety?

Key elements include good ventilation, proper tool storage, and wearing safety gear.Ensure safety by:

- Checking equipment regularly.

- Keeping the area tidy.

Essential Tools and Equipment for Lathe Workshop Setup

List of necessary hand tools and measuring instruments. Recommendations for additional equipment to enhance functionality.To create a successful lathe workshop, you need the right tools. Essential hand tools include wrenches, screwdrivers, and hammers. Measuring instruments like calipers and tape measures are also important. These help ensure accurate work. For added functionality, consider tools like a band saw or a drill press.

- Wrenches

- Screwdrivers

- Hammers

- Calipers

- Tape Measures

- Band Saw

- Drill Press

What are the must-have tools for a lathe workshop?

The must-have tools include wrenches, hammers, screwdrivers, calipers, and a tape measure. It’s also helpful to have a band saw and a drill press to make your work easier.

How to Configure Your Lathe Drive System

Stepbystep guide on setting up belt and gear systems. Adjustments for ensuring precision and efficiency.Setting up your lathe drive system is crucial for smooth operation. Follow these simple steps to configure your belt and gear systems:

- Choose the right belt size for your lathe.

- Align the motor and spindle correctly.

- Check for tightness in belts and gears.

- Run a test to see if everything works smoothly.

Make adjustments carefully. Ensure parts fit snugly to avoid slipping. This will help achieve precision and efficiency in your tasks. A well-setup system can make your lathe work better and last longer.

What is the best way to maintain the drive system?

To maintain your drive system, regularly check belts for wear and tension. Clean gears and apply lubricant as needed. This keeps everything running smoothly and prevents breakdowns.

Maintenance and Troubleshooting of Drive Systems

Common issues faced with metal lathe drive systems. Preventative maintenance tips to prolong system life.Drive systems in metal lathes can face several common issues. These may include strange noises, poor speed control, or vibrations. Regular maintenance can help prevent these problems. Here are a few tips:

- Check the belts for wear and tear.

- Keep the drive system clean and free from debris.

- Lubricate moving parts regularly.

- Inspect electrical connections often.

A little care goes a long way. Fixing small issues early can save big problems later.

What are common issues with metal lathe drive systems?

Some common issues include overheating, misalignment, or excessive wear. It’s essential to monitor these conditions to ensure a smooth operation.

Enhancing Your Lathe Workshop for Advanced Projects

Upgrades and attachments to improve your lathe capabilities. Ideas for integrating CNC technology into your metal lathe setup.Upgrading your lathe workshop can turn your regular projects into amazing creations. Fancy attachments can boost your lathe’s skills—think of adding a ball screw for smooth movement or a steady rest for better support. Want to feel like a robot wizard? Consider integrating CNC technology! It allows precise control, making your lathe a mechanical genius. Plus, it means you can sip coffee while it works its magic. Here’s a look at some handy upgrades:

| Upgrades | Benefits |

|---|---|

| Ball Screw | Smoother operation |

| Steady Rest | Greater support |

| CNC Controller | Precision cuts |

| Tool Post | Quick tool changes |

Safety Measures in the Lathe Workshop

Recommended personal protective equipment (PPE). Essential safety practices when using a metal lathe.Staying safe in a lathe workshop makes you a hero! Always wear personal protective equipment (PPE) like goggles, gloves, and ear protection. These items protect you from flying chips and loud noises. Remember, safety glasses are the real superheroes for your eyes!

Following essential safety practices is a must. Keep your hands away from moving parts and ensure the workspace is clean. A cluttered area can lead to accidents faster than you can say “lathe!”

| Safety Gear | Purpose |

|---|---|

| Safety Goggles | Protect eyes from shavings |

| Gloves | Shield hands from sharp edges |

| Ear Protection | Guard against loud noise |

A little protection goes a long way. Stay safe, stay smart, and remember: “A lathe’s best friend is its operator – if that operator is wearing PPE!”

Estimating Costs for Lathe Workshop Setup

Breakdown of initial investment for tools and equipment. Ongoing costs to maintain your lathe workshop effectively.Setting up a lathe workshop can be exciting. First, think about the costs. You need to buy tools and equipment. Some essential items include:

- Lathe machine

- Cutting tools

- Safety gear

- Workbench

This initial investment can range from a few hundred to several thousand dollars. After that, remember ongoing costs like:

- Electricity

- Maintenance

- Supplies

Staying on top of these helps keep your workshop running smoothly.

What are the initial costs for a lathe workshop?

The initial costs can include various tools and machines. Buying a lathe machine, tools, and safety gear can total between $500 and $5,000. It all depends on the quality and brand you choose.

Conclusion

Setting up a lathe workshop with a metal lathe drive system is exciting and rewarding. You learn how to choose the right tools and organize your space. Understanding the drive system helps you operate the lathe safely and efficiently. We encourage you to explore more resources or practice in a hands-on workshop. Keep learning and enjoy creating!FAQs

What Are The Essential Components Of A Metal Lathe Drive System, And How Do They Interact To Provide Effective Power Transmission?A metal lathe drive system has a few important parts. First, there is a motor that gives power. Next, a belt connects the motor to the spindle, which spins the metal. Gears also help control the speed and direction of the spin. All these parts work together to move the lathe smoothly and help you shape metal.

How Does The Choice Of Motor Type (Ac, Dc, Or Stepper) Impact The Performance And Efficiency Of A Metal Lathe Drive System?The type of motor you choose for a metal lathe really matters. AC motors run smoothly and are good for big jobs. DC motors give you more control and can change speed easily. Stepper motors are great for precise movements. Each type helps the lathe work better or faster, depending on what you need.

What Factors Should Be Considered When Selecting The Appropriate Belt Or Gear System For The Drive Mechanism Of A Metal Lathe?When picking a belt or gear system for a metal lathe, you should think about a few things. First, consider how much power the lathe needs to work well. Next, think about how fast you want it to spin. You also need to check the space where you will put it. Finally, look at how easy it is to find and replace parts if they break.

How Can The Speed And Torque Of A Metal Lathe Drive System Be Effectively Controlled For Different Machining Operations?You can control the speed and torque of a metal lathe by using different settings. First, choose a proper speed based on what you’re making. Faster speeds work for softer materials, while slower speeds are better for harder ones. You can also adjust the torque, which helps how much strength the lathe uses. By changing these settings, you can make smooth and accurate parts!

What Safety Measures Should Be Implemented In A Lathe Workshop Setup To Ensure The Safe Operation Of The Metal Lathe Drive System?To stay safe in a lathe workshop, we should follow some important rules. First, always wear safety goggles to protect your eyes. Next, keep your hair tied back and wear tight clothing to avoid getting caught in the lathe. Make sure the area is clean and free of clutter, so you don’t trip. Lastly, never leave the lathe running when you are not using it.