Have you ever wondered how metal parts are made? Or how machines turn big chunks of metal into beautiful shapes? A lathe workshop setup can do just that! It’s like magic. You start with a heavy piece of metal, and after some skillful work, you create something useful.

One cool part of this magic is the gear train. The gear train helps move the lathe and controls how it works. It’s the part that makes everything tick. Imagine spinning a toy top! The faster you spin, the more fun it gets. A lathe works the same way, thanks to its clever gear train setup.

If you dream of building your own metal projects, a lathe workshop is a great place to start. You can turn your ideas into real objects. Whether it’s gadgets or art, the possibilities are endless. So, why not dive into the world of metal lathes and discover how they work? You might find a new hobby or even a career!

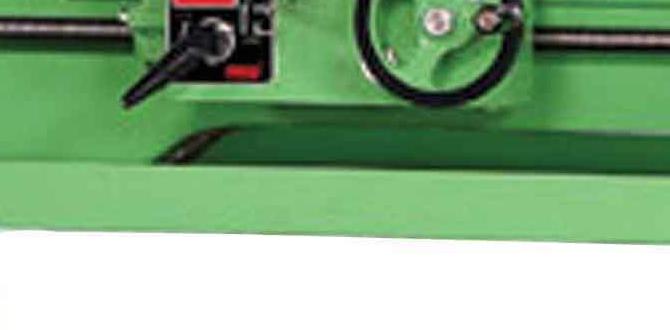

Essential Lathe Workshop Setup: Mastering Metal Lathe Gear Train — Setting Up A Lathe Workshop Efficiently Is Crucial For Any Metalworking Enthusiast Or Professional. One Of The Key Components Of This Setup Is Understanding The Metal Lathe Gear Train, Which Directly Impacts The Lathe’S Performance And Versatility. In This Article, We’Ll Explore The Essential Aspects Of Setting Up Your Lathe Workshop And How To Optimize Your Gear Train For Precise Machining. Understanding The Metal Lathe Gear Train The Gear Train In A Metal Lathe Consists Of Various Gears That Control The Speed And Torque Of The Spindle. Proper Configuration Of These Gears Allows Users To Cut Materials At Different Speeds, Accommodate Various Tool Types, And Create Complex Shapes. Key Components Of A Lathe Workshop Setup 1. **Lathe Machine**: The Centerpiece Of Your Workshop; Choose A Quality Metal Lathe Suitable For Your Projects. 2. **Work Benches**: Ensure You Have Sturdy, Dedicated Work Surfaces To Support Your Lathe And Other Tools. 3. **Tooling And Accessories**: Gather Necessary Tools Such As Cutting Tools, Chucks, And Tool Holders That Complement Your Lathe. 4. **Safety Equipment**: Invest In Personal Protective Gear Such As Goggles, Gloves, And Aprons To Ensure A Safe Working Environment. Setting Up Your Metal Lathe Gear Train 1. **Select The Right Gears**: Choose Gears That Match The Specifications Of Your Lathe. Consider Factors Like Ratio And Material For Durability. 2. **Adjust Gear Ratios**: Experiment With Different Gear Ratios To Find The Ideal Setup For Your Machining Needs. This Tweaking Can Help Optimize Cutting Speed And Efficiency. 3. **Regular Maintenance**: Keep Gears Well-Lubricated And Free From Debris To Prolong Their Lifespan. Regular Checks Can Prevent Any Surprises During Operation. 4. **Learning Through Practice**: Implement Theoretical Knowledge Into Practice. Use Scrap Metal To Practice And Understand How Gear Adjustments Influence Lathe Operations. Conclusion An Effective Lathe Workshop Setup Goes Beyond Just Having The Right Machine; It Involves Mastering The Metal Lathe Gear Train For Optimal Performance. By Understanding Each Component Of Your Lathe And Making Thoughtful Adjustments, You Can Enhance Your Metalworking Projects Significantly. Whether You’Re A Hobbyist Or A Seasoned Pro, Investing Time In Setting Up Your Workspace To Understand The Intricacies Of The Gear Train Will Lead To Greater Precision And Creativity In Your Work.

Lathe Workshop Setup: Metal Lathe Gear Train

Setting up a metal lathe workshop can be exciting and daunting. The gear train is central to the lathe’s operation. It helps control the speed and torque. Did you know that the right gear train can make your projects smoother and more accurate? Understanding the gears helps you adjust settings for different tasks. Careful setup means better results and safer operation. With the right knowledge, anyone can start making amazing things with a lathe.Essential Tools for Your Lathe Workshop

List of mandatory tools for maintenance and operation. Optional accessories that enhance productivity.Every lathe workshop needs the right tools to work well. Here are some essential tools:

- Tool Bits: Different shapes for cutting metal.

- Chucks: Hold the workpiece securely.

- Calipers: Measure sizes accurately.

- Cutting Fluids: Help cool and lubricate while cutting.

Optional accessories can boost your work:

- Digital Readouts: Show measurements clearly.

- Tool Holders: Keep tools organized and easy to access.

- Work Lights: Brighten your work area for better visibility.

What tools are needed for maintaining a lathe?

The main tools for lathe maintenance include cleaning brushes, lubricants, and wrenches. Keeping everything clean helps your lathe last longer!

Planning Your Lathe Workshop Layout

Factors to consider when designing the workspace for ease of use. Ergonomic setups to improve efficiency and safety.Setting up your lathe workshop is important for smooth work. First, think about space and accessibility. You need enough room to move around safely. A clear path helps you avoid accidents. Use ergonomic setups to make your work easier. This means your tools should be at the right height. A good layout saves time and energy. Here are some tips:

- Place your lathe in a central spot for easy access.

- Keep tools close by for quick use.

- Ensure good lighting to see clearly.

What is a good layout for a lathe workshop?

A good layout helps you work better. Keep your lathe in the center with tools around it. This makes everything easy to reach. An organized space leads to better results.

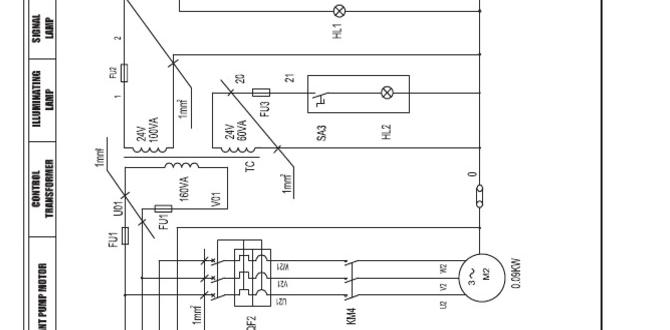

Setting Up the Metal Lathe Gear Train

Detailed explanation of gear train components and configurations. Stepbystep guide to assembling the gear train for optimal performance.Setting up a metal lathe gear train is like putting together a big puzzle—fun but tricky! A gear train usually includes gears, spacers, and a spindle. Each piece helps your lathe turn and spin with ease. To put it together, start with the gear layout. Match the sizes correctly to avoid any *gear-grinding horror stories*! Next, secure each component tightly. When all parts are snug, adjust the tension and spin! Your lathe should hum a happy tune.

| Component | Function |

|---|---|

| Gears | Transmit power and control speed |

| Spacers | Maintain *proper spacing* between gears |

| Spindle | Supports rotation of the workpiece |

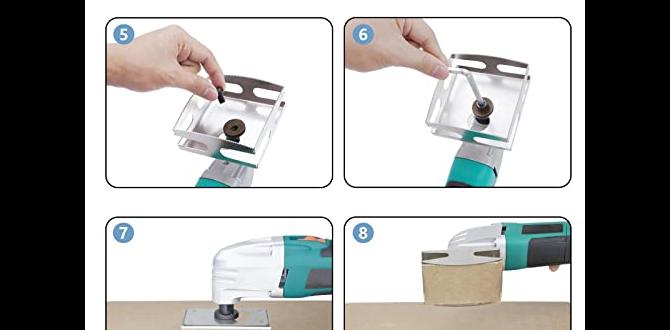

Common Metal Lathe Projects for Beginners

Suggested projects that help familiarize users with equipment. Tips on selecting materials and techniques for successful outcomes.Starting your metal lathe journey can be thrilling! Begin with simple projects like candle holders or small gears. These help you learn how to use the lathe and have fun. Always choose materials like aluminum or soft steel; they are easier to work with. Remember, practice makes perfect! A little laugh goes a long way: “Why did the lathe break up with the drill? It felt bored!”

| Project | Material | Skill Level |

|---|---|---|

| Candle Holder | Aluminum | Beginner |

| Small Gears | Soft Steel | Beginner |

| Pen Making | Wood | Intermediate |

These projects give you hands-on experience and help you get comfy with your lathe. Happy turning!

Maintenance Tips for Longevity of Your Lathe

Routine maintenance practices to ensure optimal functioning. Troubleshooting common issues with the gear train.Keeping your lathe in tip-top shape is a bit like taking care of a pet. It needs love and attention! Regularly clean it to keep those gears happy. Check for loose screws and tighten them up like giving your cat a little hug. If you hear strange noises, it might be a gear saying, “Help me!” Troubleshoot by looking for damaged parts. Here’s a quick table to help you keep everything in check:

| Maintenance Task | Frequency |

|---|---|

| Clean the Lathe | Every Use |

| Check for Loose Components | Weekly |

| Lubricate Gear Train | Monthly |

| Inspect for Wear and Tear | Every 3 Months |

By following these tips, you can keep your lathe running smoothly and make it last longer. Remember, a happy lathe means better projects! And who wouldn’t want that?

Safety Practices in the Lathe Workshop

Critical safety measures to avoid accidents. Personal protective equipment (PPE) essentials for lathe users.Before you dive into the world of spinning metal, let’s chat about safety! First, it’s key to keep your workspace tidy. A clean area helps prevent silly accidents. Remember to wear your Personal Protective Equipment (PPE), like goggles and gloves. These protect you from flying bits of metal and other nasties. Seriously, no one wants a high-speed piece of metal in their eye!

| PPE Essentials | Purpose |

|---|---|

| Safety Goggles | Shield eyes from debris |

| Heavy-Duty Gloves | Protect hands from sharp edges |

| Steel-Toed Boots | Prevent foot injuries from heavy objects |

| Ear Protection | Reduce noise exposure |

Being cautious is like having a safety net. It keeps you from making a *lathe-ic* mistake. So gear up, stay alert, and enjoy your time in the workshop!

Conclusion

In setting up a lathe workshop, understanding the metal lathe gear train is key. It helps you control speed and torque effectively. Remember to choose the right gears for your project. Always prioritize safety while you work. For more tips and detailed guidance, we encourage you to explore further resources or practical tutorials. Happy machining!FAQs

What Are The Essential Components Of A Gear Train In A Metal Lathe, And How Do They Work Together To Achieve Different Spindle Speeds?A gear train in a metal lathe has several important parts. These include gears, a motor, and a spindle. The motor turns the gears, which then turn the spindle. By changing the gears, we can make the spindle go faster or slower. This helps us use the lathe for different kinds of work.

How Can I Determine The Proper Gear Ratios Needed For Specific Machining Tasks In A Lathe Workshop Setup?To find the right gear ratios for your lathe, you need to think about your task. First, see how fast you want the lathe to turn. Then, look at the size of the tool or part you are working with. You can use a gear ratio chart that shows the speed you need for different jobs. Finally, adjust the gears until the numbers match what you need.

What Are The Advantages Of A Gear Train System Over Other Speed Control Mechanisms In Metal Lathes?A gear train system helps metal lathes work better in a few ways. First, it gives you more precise control over speed. You can easily change speeds with different gears. This system also has fewer parts that can break, making it last longer. Overall, it’s simple and reliable for cutting metal.

How Do I Properly Maintain And Troubleshoot The Gear Train In A Metal Lathe To Ensure Optimal Performance?To keep the gear train in a metal lathe working well, you should check it often. Look for any dirt or old oil and clean it. You can use a cloth to wipe it down. If it makes strange noises, it might need oil. Also, make sure all the parts are tight but not too tight. If something seems broken, ask an adult for help.

What Safety Precautions Should Be Taken When Setting Up And Using The Gear Train System In A Metal Lathe?When using the gear train system in a metal lathe, we need to be careful. Always wear safety goggles to protect your eyes. Keep your hands away from moving parts. Make sure the machine is turned off before setting it up. Finally, check that all the parts are secure and in good condition before starting.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Of A Gear Train In A Metal Lathe, And How Do They Work Together To Achieve Different Spindle Speeds? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A gear train in a metal lathe has several important parts. These include gears, a motor, and a spindle. The motor turns the gears, which then turn the spindle. By changing the gears, we can make the spindle go faster or slower. This helps us use the lathe for different kinds of work.”}},{“@type”: “Question”,”name”: “How Can I Determine The Proper Gear Ratios Needed For Specific Machining Tasks In A Lathe Workshop Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right gear ratios for your lathe, you need to think about your task. First, see how fast you want the lathe to turn. Then, look at the size of the tool or part you are working with. You can use a gear ratio chart that shows the speed you need for different jobs. Finally, adjust the gears until the numbers match what you need.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of A Gear Train System Over Other Speed Control Mechanisms In Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A gear train system helps metal lathes work better in a few ways. First, it gives you more precise control over speed. You can easily change speeds with different gears. This system also has fewer parts that can break, making it last longer. Overall, it’s simple and reliable for cutting metal.”}},{“@type”: “Question”,”name”: “How Do I Properly Maintain And Troubleshoot The Gear Train In A Metal Lathe To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the gear train in a metal lathe working well, you should check it often. Look for any dirt or old oil and clean it. You can use a cloth to wipe it down. If it makes strange noises, it might need oil. Also, make sure all the parts are tight but not too tight. If something seems broken, ask an adult for help.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Setting Up And Using The Gear Train System In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the gear train system in a metal lathe, we need to be careful. Always wear safety goggles to protect your eyes. Keep your hands away from moving parts. Make sure the machine is turned off before setting it up. Finally, check that all the parts are secure and in good condition before starting.”}}]}