Have you ever dreamed of creating something amazing with your own hands? With a metal lathe machine, you can! Setting up a lathe workshop is not just for the experts. Even beginners can learn the ropes. Imagine transforming raw metal pieces into stunning objects, tools, or parts.

It all starts with the right lathe workshop setup. A well-organized space makes a big difference. You’ll need to think about safety, tools, and materials. Did you know that the first lathe dates back thousands of years? Ancient craftsmen used simple lathes to make everyday items.

Today, we have advanced machines that make this art easier and more precise. Are you ready to explore the world of metal turning? Let’s dive into the essentials of setting up your very own lathe workshop!

Essential Lathe Workshop Setup For Your Metal Lathe Machine

Lathe Workshop Setup: Metal Lathe Machine Essentials

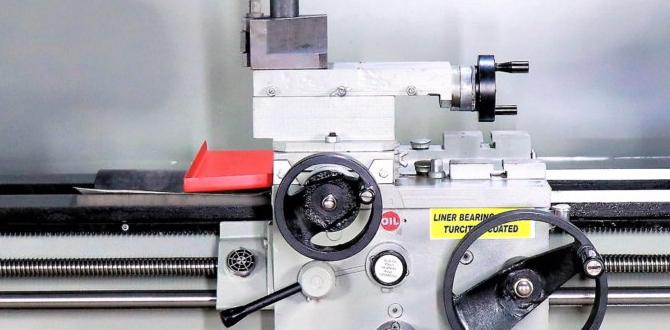

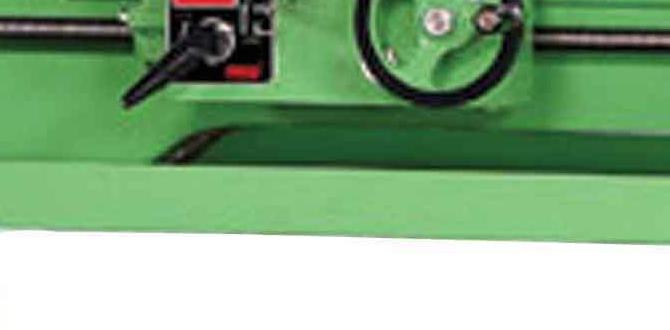

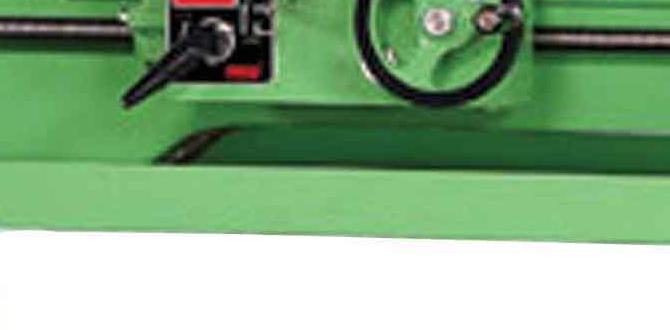

Setting up a lathe workshop can be exciting! A metal lathe machine is a key tool for shaping materials like metal or wood. Proper placement of the lathe is crucial. Ensure there’s enough space around it for safe operation. Arranging tools within reach saves time too. Did you know that adjusting the speed of the lathe can influence the finish of your project? Learning these basics can help both beginners and experienced users create amazing works.Choosing the Right Location for Your Lathe Workshop

Factors to consider (space, ventilation, access to power). Safety considerations and compliance with regulations.Picking the perfect spot for your lathe workshop is crucial. First, think about how much space you need to move around. A tight space can feel like a clown car! Next, make sure there’s good ventilation. You don’t want to breathe in the smoke or dust! Also, check nearby power outlets to run your machines. Safety should be your priority. Keep in mind local rules and guidelines to avoid surprises. A little planning now can save big headaches later!

| Factor | Importance |

|---|---|

| Space | Room to work safely |

| Ventilation | Fresh air = Happy worker |

| Power access | Keep machines running |

Essential Tools and Equipment for Lathe Workshops

List of primary tools needed (lathe, tool holders, cutting tools). Recommended additional equipment (toolbox, measuring tools, safety gear).Setting up a lathe workshop means having the right tools. Here’s what you need:

- Lathe: The main machine for shaping metal.

- Tool Holders: These hold the cutting tools in place.

- Cutting Tools: Essential for cutting and shaping materials.

It’s also smart to include extra equipment:

- Toolbox: Keep your tools organized.

- Measuring Tools: To ensure accuracy in your work.

- Safety Gear: Protect yourself with goggles and gloves.

With these tools, you can start your metalworking projects safely and efficiently!

What are the essential tools for a lathe workshop?

The essential tools for a lathe workshop include a lathe, tool holders, and cutting tools. Having these items ensures a successful setup.

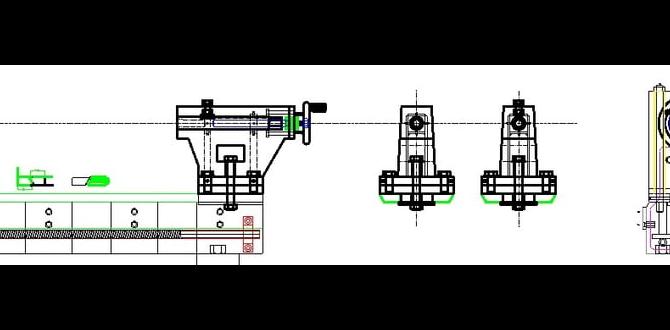

Preparing Your Workspace Layout

Best practices for organizing your workshop for efficiency. Importance of proper lighting and ergonomics.Organizing your workshop can make a big difference. A neat space helps you work smarter. Start by placing tools within arm’s reach. Keep your lathe machine clear for easy access. Good lighting is key. Proper lights help you see everything clearly. Also, think about where you stand and work. Make sure surfaces are the right height. This keeps you comfortable and less tired.

- Use bright lights to avoid shadows.

- Arrange tools for quick access.

- Ensure work surfaces are at the right height.

How do you improve a workshop’s efficiency?

Use proper lighting, organize tools neatly, and set up your workspace for comfort.Setting Up Your Metal Lathe Machine

Stepbystep setup process for beginners. Calibration and testing for optimal performance.Setting up your metal lathe machine is exciting yet can feel like building a spaceship without an instruction manual. First, gather all tools. Make sure your lathe is on a solid surface; it shouldn’t wobble like a jelly! Next, connect the power and check for any loose wires. Now, it’s calibration time! Adjust the settings by turning the knobs, making sure everything is tight. If it sounds like a rock concert, you might want to loosen it up a bit!

Finally, perform a test run with a scrap piece of metal. This will help you tweak any settings to ensure optimal performance. Think of it like a warm-up before the main event. Remember, a well-set lathe is happier, quieter, and less likely to throw a tantrum!

| Step | Action |

|---|---|

| 1 | Gather tools and surface setup |

| 2 | Connect power safely |

| 3 | Calibrate the settings |

| 4 | Run a test with scrap metal |

Safety Practices in a Lathe Workshop

Key safety equipment and protocols to follow. Common hazards and how to avoid them.Safety in a lathe workshop is very important. Everyone should wear safety gear to stay protected. Key tools include goggles for eye protection, ear plugs for noise, and gloves to avoid cuts. Follow these safety rules:

- Always check the machine before use.

- Keep hands away from moving parts.

- Don’t wear loose clothing or jewelry.

- Use tools, not fingers, to hold materials.

Common hazards include flying debris and sharp edges. Always stay alert and follow these tips to stay safe.

What are some key safety equipment for a lathe workshop?

Key safety equipment includes goggles, gloves, and ear protection. These items help prevent injuries while working with a metal lathe machine.

Maintenance Tips for Longevity of Your Lathe Machine

Routine maintenance tasks (cleaning, lubrication). Troubleshooting common issues.To keep your lathe machine in good shape, regular care is key. Cleaning removes dust and chips that can harm moving parts. Lubricating with the right oil helps everything run smoothly. Check your machine often for signs of damage or wear. If you notice strange sounds or vibrations, it’s time to investigate.

What are routine maintenance tasks for a lathe machine?

Routine tasks include cleaning and lubrication. Cleaning helps prevent rust and buildup, while lubrication reduces friction. Both are crucial for smooth operation.

Common maintenance tasks:

- Clean the machine regularly.

- Oil the moving parts.

- Check for loose screws and belts.

Staying on top of these tasks keeps your lathe running well for many years.

Resources for Continued Learning and Improvement

Recommended books, online courses, and forums. Community resources for metalworking enthusiasts.Learning about metalworking doesn’t stop when you leave the workshop! Plenty of resources are out there to sharpen your skills and keep you entertained. Check out some awesome books that read like adventures with gears and metals. You can also sign up for online courses that feel like magic school, teaching you tricks to make your lathe sing. Don’t forget about forums—think of them as the watercooler chats of metalworking, where you can swap stories and tips with fellow enthusiasts.

| Resource Type | Examples |

|---|---|

| Books | The Metalworking Handbook, Basics of Metalworking |

| Online Courses | Udacity, Skillshare |

| Forums | Metalworking.com, Reddit’s r/metalworking |

Keep exploring these resources and watch your skills grow. After all, learning is like a lathe: the more you spin it, the smoother you get!

Conclusion

In conclusion, setting up a lathe workshop with a metal lathe machine can be exciting. You need space, tools, and safety gear to start. Organize your workspace for efficiency and comfort. Practice regularly to improve your skills. Explore online guides or videos for more tips. With these steps, you’ll become confident in your lathe projects and create amazing things!FAQs

What Are The Essential Tools And Accessories Needed For Setting Up A Metal Lathe Workshop?To set up a metal lathe workshop, you need a few important tools and accessories. First, you need the metal lathe itself, which helps shape metal parts. Next, get cutting tools like blades to cut the metal. You also need a ruler or caliper to measure things accurately. Don’t forget safety gear, like goggles and gloves, to keep you safe while you work!

How Do You Properly Align And Level A Metal Lathe To Ensure Accurate Machining?To align and level a metal lathe, first find a flat surface. Use a level tool to check if the lathe is straight. Adjust the feet of the lathe to make it even. Tighten all the screws after you’re sure it’s level. This helps you make better and more accurate parts!

What Safety Precautions Should Be Taken When Operating A Metal Lathe In A Workshop Setting?When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and remove loose clothing. Keep your hands away from moving parts. Make sure tools are in good condition and follow all instructions. Lastly, keep the area clean to avoid accidents.

How Can You Optimize Workspace Layout Around A Metal Lathe For Efficiency And Safety?To make your workspace safe and efficient around a metal lathe, keep tools close by. Place the lathe in an area with enough room to move around. Always have good lighting so you can see clearly. Make sure to store materials and equipment neatly to avoid tripping. Lastly, wear safety gear like goggles to protect yourself while working.

What Maintenance Practices Should Be Implemented To Keep A Metal Lathe In Good Working Condition?To keep a metal lathe working well, we should clean it often. You can use a soft cloth to wipe off dust and oil. Check the oil levels and add more if it’s low. Make sure all parts are tight and working right. Lastly, we should cover it when not in use to keep it safe.