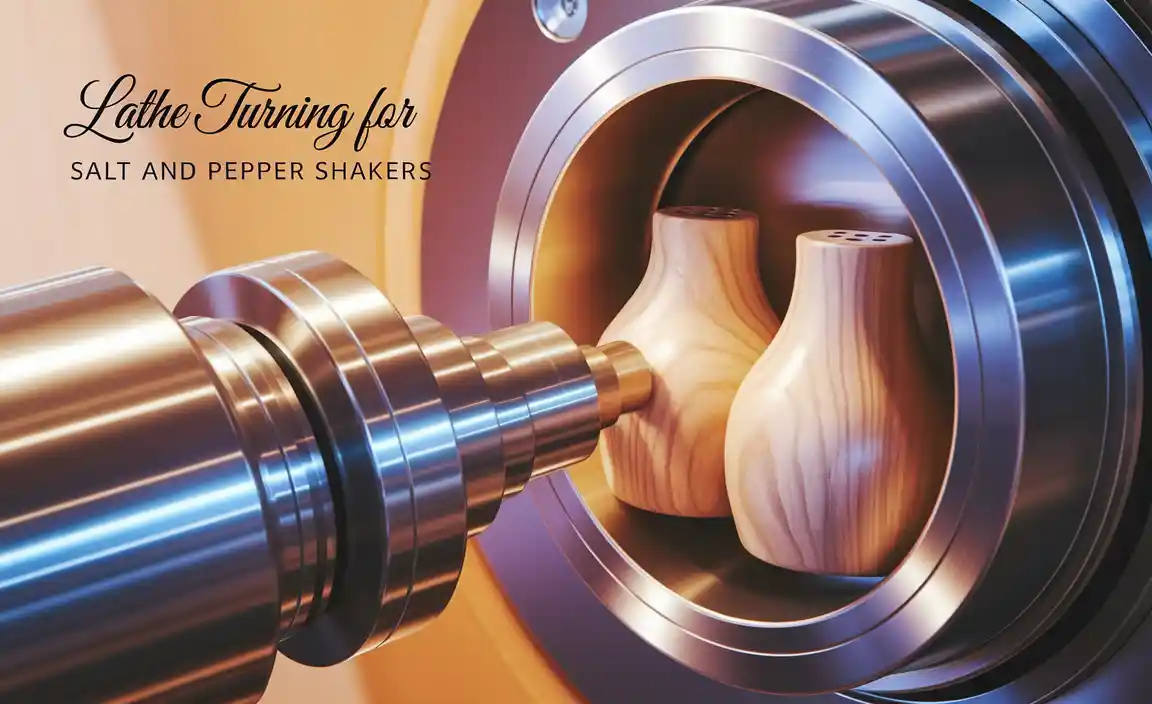

Imagine stepping into a workshop filled with buzzing machines and the smell of fresh metal shavings. A lathe workshop setup is where creativity meets engineering. Have you ever wondered how those metal pieces are shaped smoothly and precisely? The star of the show is often the metal lathe motor. It makes the magic happen!

Setting up a lathe workshop can seem tricky. But with a bit of planning, you can create your perfect space. Did you know that a well-placed motor can make your lathe run like a dream? It’s true! A few simple tips can transform your workshop into a haven for metalworking.

So, what should you consider when setting up your lathe workshop? Let’s explore the essentials you need to make your projects successful. Whether you are a beginner or an expert, understanding your motor and setup can help you create amazing things.

Essential Lathe Workshop Setup: Choosing The Right Metal Lathe Motor — Setting Up A Lathe Workshop Requires Careful Planning And Selection Of Equipment To Achieve The Best Results In Metalworking. One Of The Most Crucial Components Of This Setup Is The Metal Lathe Motor, Which Influences The Machine’S Performance And Efficiency. Here’S A Guide To Help You Navigate Through The Essentials Of A Lathe Workshop Setup, Focusing On The Metal Lathe Motor Selection. Understanding Your Requirements 1. **Identify The Type Of Projects**: Before Selecting A Metal Lathe Motor, Consider The Type Of Projects You Will Undertake. Will You Be Working On Heavy-Duty Components Or Lighter Materials? Your Choice Of Motor Will Vary Accordingly. 2. **Assess The Power Needs**: The Power Rating Of The Motor Is Vital. Typically Measured In Horsepower, Ensure The Motor Can Handle The Workload Of Your Lathe Without Strain. Choosing The Right Motor 1. **Motor Types**: There Are Brushed And Brushless Motors Available In The Market. Brushless Motors Often Require Less Maintenance And Offer Better Torque At Lower Speeds Than Brushed Motors. 2. **Rpm Range**: The Revolutions Per Minute (Rpm) Of The Motor Is Essential For Achieving Precise Machining. Look For A Motor That Offers A Suitable Rpm Range For Your Desired Applications. 3. **Voltage And Wiring**: Ensure That Your Workspace Can Support The Voltage Requirements Of The Motor. Additionally, Follow The Proper Wiring Guidelines For Safety. Lathe Workshop Layout 1. **Workspace Organization**: Design Your Lathe Workshop Layout To Maximize Efficiency. Keep Your Tools, Materials, And Lathe Easily Accessible To Minimize Movement During Workflow. 2. **Safety Considerations**: Install Proper Safety Equipment And Maintain A Clean Workspace To Prevent Accidents. Ensure That The Motor And Machinery Are Adequately Shielded And That Emergency Stops Are Within Reach. Maintenance Tips 1. **Regular Inspection**: Frequently Inspect The Metal Lathe Motor For Wear And Tear, Ensuring It Operates Smoothly. 2. **Lubrication**: Keep The Motor Well-Lubricated As Per The Manufacturer’S Guidelines To Enhance Longevity And Performance. Conclusion A Well-Planned Lathe Workshop Setup With The Right Metal Lathe Motor Can Significantly Enhance Your Metalworking Projects. By Understanding Your Power Requirements And Carefully Selecting The Appropriate Components, You Can Ensure That Your Workshop Is Equipped For Success. Whether You’Re A Seasoned Machinist Or Just Starting, Taking The Time To Set Up Your Lathe Workshop Properly Will Pay Dividends In The Quality Of Your Work.

Lathe Workshop Setup: Metal Lathe Motor

Setting up a metal lathe workshop is exciting. The motor is key to your lathe’s power. Choosing the right motor impacts speed and performance. Did you know an efficient motor can improve your work quality? When you consider space, ensure you have enough room for the lathe and motor. Use sturdy benches to support your projects. With the right setup, you can create anything from simple to complex metal designs. Start your workshop journey today!Understanding Your Metal Lathe

Types of metal lathes and their applications. Key components and their functions.Metal lathes come in different types. Each serves a unique purpose. For example, engine lathes are common in workshops. They are great for making parts and tools. CNC lathes use computers for precise work. They help in creating complex shapes easily. Basic parts of a metal lathe include:

- Bed: Holds everything together.

- Headstock: Contains the motor and controls.

- Tailstock: Provides support for longer pieces.

- Carriage: Moves the cutting tool.

Each part plays a key role in the lathe’s function. Understanding these can help you use a lathe better.

What are the different types of metal lathes?

There are two main types: engine lathes for general use and CNC lathes that allow for automated precision.

Key Components of Metal Lathes

- Bed: Base of the lathe.

- Headstock: Holds the motor and controls.

- Tailstock: Supports longer materials.

- Carriage: Moves tools for cutting.

Choosing the Right Space for Your Lathe Workshop

Necessary dimensions and workspace layout. Considerations for ventilation and lighting.Finding the perfect spot for your lathe workshop is like picking the best seat in a movie theater. You’ll want plenty of room! Ideally, aim for at least 10×12 feet for comfort and movement. Make sure your layout allows for easy access to tools and materials. Don’t forget about ventilation and lighting. Good airflow will keep you from feeling like a hot potato, and bright lights help you see every detail. So grab a measuring tape and a sandwich—you’ll need energy for this!

| Considerations | Why It Matters |

|---|---|

| Space Dimensions | Room to move and work safely. |

| Ventilation | Prevents stuffiness and keeps your brain clear. |

| Lighting | Helps avoid mistakes that can make you want to facepalm. |

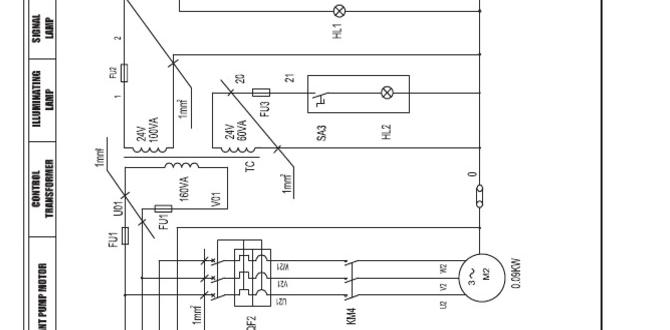

Setting Up Electrical Connections Safely

Guidelines for electrical installation in a workshop. Importance of circuit breakers and grounding.Creating electrical connections in your workshop is like connecting the dots, but with wires! Start by checking all your tools and equipment for any loose connections. Always use circuit breakers to prevent fire hazards and electrical shocks. They act like superheroes, stopping too much current before it causes trouble. Grounding is also super important; it keeps your equipment and you safe. Remember, no one wants a surprise shock while working!

| Guideline | Description |

|---|---|

| Use Circuit Breakers | Prevents overloads and protects against electrical fires. |

| Grounding | Ensures safety from electrical shocks and keeps the circuit stable. |

| Check Connections | Always make sure all connections are tight and secure. |

Following these rules makes your workshop safer and lets you focus on the fun stuff, like creating cool projects! Remember, safety first, thrills second!

Essential Tools and Equipment for a Lathe Workshop

Musthave tools for metalworking. Additional accessories to enhance lathe functionality.Setting up a lathe workshop requires some important tools. First up is the metal lathe itself. This machine is like the superhero of your workshop. You’ll also need cutting tools, which are perfect for shaping metal. Don’t forget the measuring tools! They help ensure everything fits just right, like a well-tailored suit.

| Must-Have Tools | Additional Accessories |

|---|---|

| Metal Lathe | Tool Holders |

| Cutting Tools | Chucks |

| Measuring Tools | Tool Rest |

Some accessories can take your lathe game to a whole new level. Tool holders make switching tools a breeze. Chucks help grip your workpieces tightly, so they won’t fly off like a rogue frisbee. Remember, a well-equipped workshop is a happy workshop!

Safety Measures and Best Practices in the Workshop

Personal protective equipment (PPE) requirements. Safe operating procedures for lathe work.Working safely in a lathe workshop is super important! Personal protective equipment (PPE) helps keep you safe. Always wear safety goggles to shield those peepers, and don’t skip gloves to protect your hands. Also, keep long hair tied back—don’t let it mingle with the lathe; it won’t end well!

| PPE Items | Purpose |

|---|---|

| Safety goggles | Protects eyes from flying debris |

| Gloves | Protects hands from sharp edges |

| Ear protection | Reduces noise exposure |

Follow safe operating procedures like keeping your workspace clean and organized. Do a quick check of the lathe before starting. If you hear a strange noise, *don’t* ignore it! It might lead to an unexpected adventure—like becoming an old rusty tool yourself!

Maintenance of Your Lathe Workshop and Equipment

Regular checkups and servicing tips. Troubleshooting common issues with lathe motors.Keeping your lathe workshop clean and well-maintained is important. Regular checkups help catch problems early. Clean metal lathe motors and check belts for wear. Inspect wiring for any damage. This can prolong their life.

If you face issues, here are some common troubleshooting tips:

- If the motor won’t start, check the power source.

- If it makes weird noises, listen for loose parts.

- If it shakes while running, make sure everything is balanced.

Remember, a well-cared lathe is a happy lathe!

What should I check regularly on my lathe?

Check the belts, bearings, and power supply. Lubricate moving parts to keep everything running smoothly.

Tips for cleaning your lathe:

- Wipe down surfaces after use.

- Remove shavings and chips.

Advanced Setup Options for Experienced Users

Upgrading motors and adding automation. Custom setups for specialized projects.For those with a bit more experience, upgrading your lathe motor can make a huge difference. A stronger motor speeds up work and improves results. Adding automation is like giving your lathe a personality. It can do tasks while you take a snack break. It’s even possible to create custom setups for special projects. Imagine turning your lathe into a robot sidekick! Here’s a quick look:

| Upgrade Options | Benefits |

|---|---|

| High-Torque Motors | Faster speeds, more power! |

| Automated Controls | Less manual work, more free time! |

| Custom Attachments | Perfect for unique tasks! |

These changes can turn your workshop into a creativity hotspot. So, why not take that leap and watch your projects soar?

Resources for Learning and Improvement

Recommended books and online courses. Community forums and support networks for metal lathe enthusiasts.Need some help with your metal lathe skills? Dive into great books and online courses that make learning fun! There are plenty of resources to explore. Check the table below for some top picks:

| Resource Type | Name | Link |

|---|---|---|

| Book | Metalworking: Sink or Swim | Read Here |

| Online Course | Intro to Metal Lathe | Sign Up |

| Forum | Lathe Enthusiasts Unite! | Join Now |

Plus, joining community forums is like having a team of metal magicians at your side! You can ask questions, share tips, and maybe even tell a bad lathe joke or two. After all, every great craftsman started somewhere!

Conclusion

In conclusion, setting up a lathe workshop requires careful planning. Choose a reliable metal lathe and a suitable motor for power. Organize your tools for easy access. Remember to prioritize safety measures. Now that you know the basics, start gathering your equipment. Explore more resources or guides to enhance your skills and make your workshop a success!FAQs

What Are The Essential Features To Consider When Selecting A Motor For A Metal Lathe In A Workshop Setup?When you choose a motor for a metal lathe, think about a few key things. First, look at the motor’s power, usually measured in horsepower (HP). More power helps you cut metal faster and easier. Next, check the motor’s speed. Different tasks need different speeds, so find a motor that can change speeds easily. Finally, make sure the motor fits your lathe’s size and can handle the work you plan to do.

How Can I Effectively Determine The Appropriate Horsepower And Torque Requirements For My Lathe Motor Based On The Materials I Plan To Work With?To find the right horsepower and torque for your lathe motor, start by knowing the materials you will use. Different materials need different strengths. For soft materials like wood, you need less power than for hard metals. Check guides online or ask experts about the specific needs for each material. This will help you choose the right motor for your projects.

What Are The Recommended Steps For Installing A Motor On A Metal Lathe To Ensure Safety And Optimal Performance?To install a motor on a metal lathe safely, first, make sure the lathe is unplugged. Then, read the motor’s instructions carefully. Next, attach the motor securely using screws and brackets. After that, connect the wires, making sure they match the colors. Finally, double-check everything, plug in the lathe, and test it gently to see if it works well.

How Do Different Types Of Lathe Motors (E.G., Ac Vs. Dc) Impact The Operation And Capabilities Of A Metal Lathe?AC motors use alternating current and are good for steady power. They are strong and last a long time. DC motors use direct current and can speed up or slow down easily. If you’re using a metal lathe, a DC motor gives you better control for detailed work. Each type helps the lathe do different jobs well.

What Safety Measures Should Be Implemented During The Setup And Operation Of A Lathe Motor In A Metalworking Workshop?When setting up and using a lathe motor, we need to be very careful. First, always wear safety goggles to protect your eyes. Make sure your hair and loose clothes are tied back so they don’t get caught. Check that the motor is off before you work on it. Finally, keep hands away from moving parts to avoid getting hurt.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Features To Consider When Selecting A Motor For A Metal Lathe In A Workshop Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you choose a motor for a metal lathe, think about a few key things. First, look at the motor’s power, usually measured in horsepower (HP). More power helps you cut metal faster and easier. Next, check the motor’s speed. Different tasks need different speeds, so find a motor that can change speeds easily. Finally, make sure the motor fits your lathe’s size and can handle the work you plan to do.”}},{“@type”: “Question”,”name”: “How Can I Effectively Determine The Appropriate Horsepower And Torque Requirements For My Lathe Motor Based On The Materials I Plan To Work With? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right horsepower and torque for your lathe motor, start by knowing the materials you will use. Different materials need different strengths. For soft materials like wood, you need less power than for hard metals. Check guides online or ask experts about the specific needs for each material. This will help you choose the right motor for your projects.”}},{“@type”: “Question”,”name”: “What Are The Recommended Steps For Installing A Motor On A Metal Lathe To Ensure Safety And Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a motor on a metal lathe safely, first, make sure the lathe is unplugged. Then, read the motor’s instructions carefully. Next, attach the motor securely using screws and brackets. After that, connect the wires, making sure they match the colors. Finally, double-check everything, plug in the lathe, and test it gently to see if it works well.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Lathe Motors (E.G., Ac Vs. Dc) Impact The Operation And Capabilities Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “AC motors use alternating current and are good for steady power. They are strong and last a long time. DC motors use direct current and can speed up or slow down easily. If you’re using a metal lathe, a DC motor gives you better control for detailed work. Each type helps the lathe do different jobs well.”}},{“@type”: “Question”,”name”: “What Safety Measures Should Be Implemented During The Setup And Operation Of A Lathe Motor In A Metalworking Workshop? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up and using a lathe motor, we need to be very careful. First, always wear safety goggles to protect your eyes. Make sure your hair and loose clothes are tied back so they don’t get caught. Check that the motor is off before you work on it. Finally, keep hands away from moving parts to avoid getting hurt.”}}]}