Have you ever wondered how metal parts are made? A lathe workshop holds the answer. Setting up a lathe workshop is both fun and rewarding. You can create amazing projects with just a few metal lathe parts. Imagine crafting your own tools or custom pieces!

In this article, we will explore how to set up your very own lathe workshop. You will learn about the essential metal lathe parts that make everything possible. Do you dream of building something unique? A lathe can turn that dream into reality.

Did you know that lathes have been used for thousands of years? They started as simple tools, yet they’ve evolved into powerful machines. The excitement of this journey lies in the creation process, where you shape metal with precision. Join us as we uncover the steps to organize your workshop and get started on your next project!

Essential Metal Lathe Parts For Your Lathe Workshop Setup

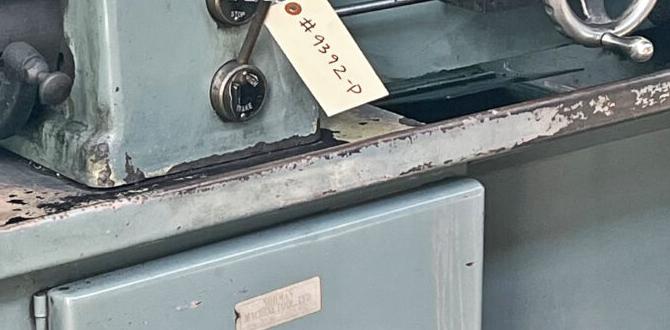

Lathe Workshop Setup: Metal Lathe Parts

Setting up a lathe workshop can be exciting and a bit puzzling. There are key parts to know about your metal lathe. Understanding components like the tailstock, headstock, and bed helps you work better. Did you know that proper setup can increase your safety and precision? Picture yourself creating perfect parts with ease! This guide shares simple tips to help you arrange your workspace and master your metal lathe. Get ready to turn your ideas into reality!Understanding the Basics of Metal Lathes

Definition and function of a metal lathe. Different types of metal lathes available in the market.A metal lathe is a tool that shapes metal. It holds metal pieces and spins them while cutting tools shape them into the desired form. This process helps create items like screws, rods, and more. There are different types of metal lathes, including:

- Bench Lathes

- Engine Lathes

- CNC Lathes

- Toolroom Lathes

Each type serves different needs. Understanding these basics can help anyone choose the right lathe.

What is the main function of a metal lathe?

The main function of a metal lathe is to cut and shape metal. It spins the metal piece and uses tools to create shapes like cylinders and grooves.

What are the common types of metal lathes?

- Bench Lathes: Small and great for beginners.

- Engine Lathes: Versatile for many projects.

- CNC Lathes: Computer-controlled for precise work.

- Toolroom Lathes: Used for intricate, detailed jobs.

Choosing the Right Lathe for Your Workshop

Factors to consider: size, power, material, and precision. Comparison between hobbyist and industrial lathes.Picking the right lathe for your workshop is crucial. Consider these factors:

- Size: Make sure it fits your space well.

- Power: Think about what you will create and choose accordingly.

- Material: Different lathes work better with specific materials.

- Precision: Higher precision means better results.

For hobbyists, smaller lathes work fine. They are easier to move and cost less. In contrast, industrial lathes are larger and more powerful. They handle heavy materials and produce high-quality items. Always choose based on your needs.

What is the difference between hobbyist and industrial lathes?

Hobbyist lathes are smaller and ideal for simple projects. Industrial lathes are larger, more powerful, and built for heavy-duty tasks.

Preparing Your Workshop for Lathe Operations

Recommended workspace layout for efficiency and safety. Essential safety equipment for operating a lathe.Setting up a workshop for lathe operations is important for safety and smooth work. First, arrange your workspace to keep tools and materials close. Make sure there’s enough room to move around safely. Don’t forget to keep the floor clean to avoid trips and falls.

Having the right safety equipment is key. Wear protective goggles and gloves while operating the lathe. Also, use ear protection if the machine is loud. Here are some essential items:

- Safety goggles

- Gloves

- Ear protection

- Dust mask

What should you consider for a lathe workspace?

Consider safety, efficiency, and space. A clean and organized area helps you work better.

Essential Tools and Accessories for Lathe Setup

Musthave tools: cutting tools, measuring tools, and clamps. Optional accessories for enhanced functionality: DRO systems, tool holders.Setting up a lathe workshop requires some important tools. First, you need cutting tools to shape the metal. Next, measuring tools help you get the right size. Clamps hold pieces firmly while you work. Optional accessories, like DRO systems and tool holders, can make your job easier and more precise.

- Cutting tools for shaping

- Measuring tools for accuracy

- Clamps for holding

With the right setup, your lathe work will be fun and successful!

What are the must-have tools for a lathe workshop?

Key tools include cutting tools, measuring tools, and clamps. These are essential for effective operation and accuracy in metalworking.

Step-by-Step Guide to Assembling Your Lathe

Detailed instructions for setting up each component. Common mistakes to avoid during the assembly process.To assemble your lathe, follow these steps carefully for each part. Start with the base. Ensure it is level. Next, attach the bed. Align it correctly. Install the tailstock and carriage. Make sure they slide smoothly. Connect the motor and check the wiring. Finally, adjust the tool rest and chuck. Remember to avoid these mistakes:

- Don’t rush the assembly.

- Check for loose screws.

- Ensure parts are compatible.

Taking time now will save trouble later!

What are common mistakes to avoid while assembling a lathe?

Common mistakes include rushing the process, overlooking loose screws, and using incompatible parts. Always double-check connections and alignments to ensure everything fits and operates smoothly.

Maintenance and Care for Your Metal Lathe

Regular maintenance tasks to ensure longevity. Troubleshooting common problems with metal lathes.Taking care of your metal lathe is like giving it a cozy blanket. Regular check-ups help it last longer and work better. You should clean the machine regularly to keep shavings away from moving parts. Don’t forget to oil it occasionally; two drops of oil can save your lathe from a sad day! If you notice noise or wobbling, it might be time to check the belts. Here’s a quick guide for you:

| Maintenance Task | Frequency |

|---|---|

| Clean lathe bed | Weekly |

| Lubricate moving parts | Monthly |

| Inspect belts and bearings | Every 3 months |

Remember, a happy lathe makes a happy workshop! Fixing common issues is often easy. So, keep that snazzy machine running smooth. After all, your future projects depend on it!

Advanced Techniques for Experienced Lathe Operators

Tips for customization and upgrades. Exploring creative applications and project ideas for metal lathes.Experienced lathe operators can take their skills to new heights with some fun upgrades and creative projects. Have you ever thought about customizing your lathe? Adding features like a digital readout can save you time and make your work easier. Imagine creating cool items like unique candle holders or toy parts. These projects can spark your creativity and make your workshop more exciting!

| Upgrade/Customization | Benefit |

|---|---|

| Digital Readout | Improved accuracy and easy measurements |

| Quick Change Tool Post | Faster tool changes for different cuts |

| Variable Speed Drive | More control over your lathe speed |

So, grab your tools and let your imagination run wild. Who knows? You might just create the next best thing in the lathe world!

Conclusion

In summary, setting up a metal lathe workshop is exciting and rewarding. You need essential parts like the lathe itself, tools, and safety gear. Keep your workspace organized for better results. Remember to follow safety rules while you work. For more tips, explore beginner guides or videos. Dive into your projects and enjoy creating!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Parts:Sure! A lathe workshop is where we use a machine called a lathe to shape metal. The main parts of a lathe include the bed, headstock, and tailstock. You will also find tools that help cut or shape the metal. It’s important to keep the workshop clean and organized. This way, you can find everything easily and work safely.

Sure! Please provide me with the question you want answered, and I’ll be happy to help!

What Are The Essential Components To Include In A Metal Lathe Workshop Setup For Optimal Performance?To set up a great metal lathe workshop, you need a sturdy workbench. You should have good lighting so you can see clearly. Keep tools like wrenches and measuring tapes close by. Safety gear, like goggles and gloves, is also important. Finally, a clean space helps you work better and stay safe.

How Do You Properly Maintain And Lubricate The Various Parts Of A Metal Lathe To Ensure Longevity And Efficiency?To take care of a metal lathe, you should clean it regularly. Wipe off any dust or chips after use. Use the right oil on moving parts to keep them running smoothly. Check the owner’s manual for where to put the oil. Always keep the lathe dry and free from rust to help it last longer.

What Safety Precautions Should Be Taken When Operating A Metal Lathe In A Workshop Environment?When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing so nothing gets caught. Make sure you don’t have loose tools or materials nearby. Always follow the machine’s instructions and keep your hands away from moving parts. Finally, ask a teacher or adult for help if you’re unsure about something.

How Can Different Lathe Accessories, Such As Chucks And Tooling Systems, Enhance The Functionality Of A Metal Lathe?Different lathe accessories, like chucks and tools, help you do more with a metal lathe. A chuck holds the metal piece securely so it doesn’t move while you work. Tooling systems give you the right tools to shape or cut the metal the way you want. With these accessories, you can make more shapes and sizes, plus finish things faster. This way, you can create better projects!

What Factors Should Be Considered When Choosing The Size And Type Of Metal Lathe For A Specific Workshop Setup?When choosing a metal lathe, think about how much space you have. You should also consider the projects you want to make. Smaller lathes are good for simple tasks, while bigger lathes can handle larger pieces. Don’t forget to check how heavy the machine is, because it needs a strong base. Finally, make sure it fits your budget and skill level.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Parts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe workshop is where we use a machine called a lathe to shape metal. The main parts of a lathe include the bed, headstock, and tailstock. You will also find tools that help cut or shape the metal. It’s important to keep the workshop clean and organized. This way, you can find everything easily and work safely.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you want answered, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Essential Components To Include In A Metal Lathe Workshop Setup For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a great metal lathe workshop, you need a sturdy workbench. You should have good lighting so you can see clearly. Keep tools like wrenches and measuring tapes close by. Safety gear, like goggles and gloves, is also important. Finally, a clean space helps you work better and stay safe.”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Lubricate The Various Parts Of A Metal Lathe To Ensure Longevity And Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of a metal lathe, you should clean it regularly. Wipe off any dust or chips after use. Use the right oil on moving parts to keep them running smoothly. Check the owner’s manual for where to put the oil. Always keep the lathe dry and free from rust to help it last longer.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe In A Workshop Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing so nothing gets caught. Make sure you don’t have loose tools or materials nearby. Always follow the machine’s instructions and keep your hands away from moving parts. Finally, ask a teacher or adult for help if you’re unsure about something.”}},{“@type”: “Question”,”name”: “How Can Different Lathe Accessories, Such As Chucks And Tooling Systems, Enhance The Functionality Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different lathe accessories, like chucks and tools, help you do more with a metal lathe. A chuck holds the metal piece securely so it doesn’t move while you work. Tooling systems give you the right tools to shape or cut the metal the way you want. With these accessories, you can make more shapes and sizes, plus finish things faster. This way, you can create better projects!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Choosing The Size And Type Of Metal Lathe For A Specific Workshop Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe, think about how much space you have. You should also consider the projects you want to make. Smaller lathes are good for simple tasks, while bigger lathes can handle larger pieces. Don’t forget to check how heavy the machine is, because it needs a strong base. Finally, make sure it fits your budget and skill level.”}}]}