Have you ever wondered how a metal lathe works? Imagine spinning a piece of metal smoothly and precisely. It all starts in a well-organized lathe workshop setup.

A metal lathe can be a magical tool for creating parts. One of its key elements is the pulley, which helps control the speed of the machine. But setting up a lathe workshop can seem tricky. Where do you begin?

Many people think that a lathe workshop requires a lot of space. The truth is, you can create a fantastic workspace even in a small area. You just need to know how to set it up right.

Starting with a metal lathe pulley is a smart move. Understanding how these pulleys work will help you use your lathe effectively. It’s like learning the secret to a good recipe before you start cooking!

In this article, we will explore the important steps for a successful lathe workshop setup. You’ll find tips, tricks, and maybe a few surprises along the way. Let’s dive in and unlock the world of metalworking together!

Lathe Workshop Setup: Essential Metal Lathe Pulley Guide

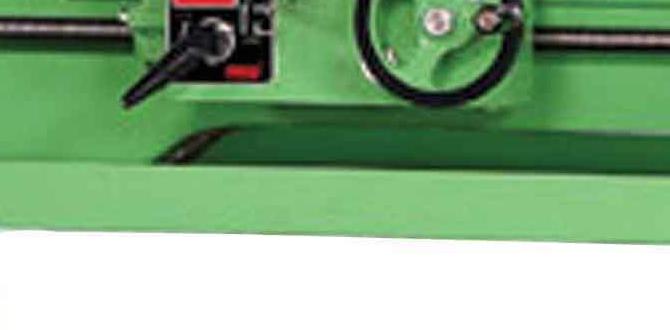

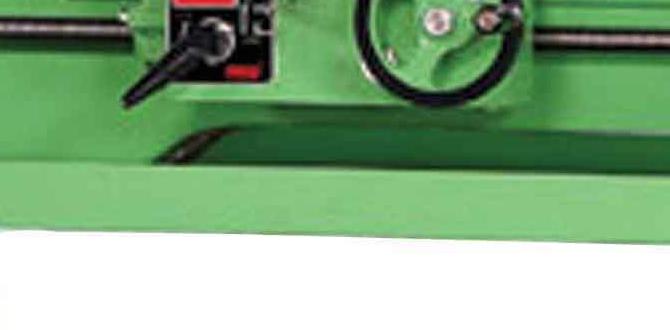

Lathe Workshop Setup: Metal Lathe Pulley

Setting up a metal lathe workshop can be exciting and rewarding. A properly arranged workshop helps improve efficiency and accuracy. Readers learn about the critical role of the lathe pulley in this setup. The right pulley can enhance the machine’s performance, making it easier to work on metal projects. Did you know that using an appropriate pulley size can greatly reduce wear and tear on your lathe? Choosing the right tools and layout makes projects more enjoyable and successful.Understanding Metal Lathes

Definition and key components of a metal lathe. Types of metal lathes available in the market.A metal lathe is like a wizard’s tool for shaping metal! It spins metal pieces while a sharp tool cuts away material. Key parts include the spindle, where the metal goes, and the tool post, where the cutting tool sits like it’s on a throne.

Various types exist, each with its magical powers. There are bench lathes for small projects and heavy-duty engine lathes for big jobs, like turning metal into something amazing. Here’s a quick table to help you pick!

| Type | Description |

|---|---|

| Bench Lathe | Small, perfect for hobbyists. |

| Engine Lathe | Heavy-duty, used in many workshops. |

| CNC Lathe | Computer-controlled for precision. |

With a metal lathe, you can create anything! Now that’s a tool worth its weight in gold — or metal!

Importance of Workshop Setup

Benefits of a wellorganized lathe workshop. Impact on productivity and safety standards.Setting up your lathe workshop properly is a game changer. A well-organized space helps you find what you need quickly. This boosts your productivity, making every minute count. Imagine searching for tools like a detective on a missing sock mission—it’s not fun! Also, neat setups keep safety in check. Avoiding clutter reduces accidents, so you can work without worry. Let’s face it, a tidy bench is way nicer than a pile of chaos!

| Benefits | Impact |

|---|---|

| Boosts Productivity | Less time searching |

| Improves Safety | Fewer accidents |

| Generates Focus | Better results |

Selecting the Right Pulley System

Different types of pulley systems for metal lathes. Factors to consider when choosing pulleys for your lathe.Choosing the right pulley system for your metal lathe is key. Think of it like picking a sidekick for your DIY adventures. There are several types, each with unique traits. Consider belt pulleys for smooth operations or gear pulleys for increased strength. Keep in mind factors like size, load capacity, and the lathe’s speed range. Here’s a handy table to simplify choice:

| Type | Pros | Cons |

|---|---|---|

| Belt Pulleys | Quiet, smooth | Less torque |

| Gear Pulleys | High torque | Can be noisy |

Remember, the right pulley could save you from turning your lathe into a rickety roller coaster!

Designing Your Workshop Layout

Optimal workspace configuration for lathe operations. Tips for managing workflow and minimizing clutter.Creating a good layout for your workshop is like setting the stage for a great play! You’ll want everything in its perfect spot. Place your metal lathe where you have plenty of room to move. You don’t want to trip over your toolbox while making something awesome. Keep the area clean; clutter is like a sneaky gremlin that steals your focus! Here’s a tiny table to help you think:

| Tip | Details |

|---|---|

| Clear Pathways | Make sure there’s enough space to walk around safely. |

| Tool Storage | Keep tools close by but stored neatly. No one wants a runaway wrench! |

| Lighting | Brighten up your space. The better you can see, the less chance of turning your project into a modern art piece! |

A good layout saves time and keeps things running smoothly. Remember, every inch counts! The right setup means fewer headaches and more fun with your lathe.

Safety Protocols in a Lathe Workshop

Essential safety gear for lathe operation. Common hazards and how to mitigate them.Working in a lathe workshop can be exciting, but safety is key. Always wear essential safety gear like goggles, gloves, and ear protection. Hazards include flying debris and loud noises. Here are ways to stay safe:

- Keep tools clean and well-maintained.

- Check that guards are in place.

- Be aware of your surroundings.

- Don’t wear loose clothing or jewelry.

Following these rules helps keep everyone safe and healthy while working with machines.

What is the essential gear for lathe operation?

Essential gear includes safety goggles, gloves, and ear protection. This gear protects you from debris, sharp edges, and loud sounds in the workshop.

Maintenance of Metal Lathes and Pulleys

Regular maintenance schedules and best practices. Troubleshooting common issues with metal lathes and pulley systems.Regular care is key for metal lathes and pulleys. Create a simple schedule to check and clean your machines. This helps them work better and last longer.

Common Maintenance Tasks:

- Check belts for wear.

- Lubricate moving parts.

- Clean debris from the work area.

- Tighten loose screws and bolts.

Sometimes, machines can have problems. If you hear unusual noises or notice vibrations, check the following:

- Are the belts aligned correctly?

- Is the lubrication sufficient?

- Are there any blockages in the system?

Taking care of your lathe and pulley can save time and money. Remember, regular checks lead to smooth operation!

How often should I maintain my metal lathe?

It is best to check your metal lathe weekly for general wear and dirt. A deep clean and detailed inspection should happen monthly. This keeps everything running well!

Projects to Try in Your Lathe Workshop

Beginner to advanced project ideas using a metal lathe. Resources for project plans and tutorials.Many fun projects await you in your lathe workshop! Here are some ideas ranging from beginner to advanced. You can create simple items like candle holders or move to complex pieces such as custom knobs. Resources are abundant online. Websites and YouTube channels offer detailed plans and tutorials for every skill level. Get inspired and start turning metal today!

- Beginner: Candle holders, coasters

- Intermediate: Tool handles, picture frames

- Advanced: Engine parts, decorative vases

What resources can I use for lathe projects?

You can find great guides online! Websites like Instructables and YouTube have videos and plans to help you. Many forums also share tips and tricks from other lathe enthusiasts.

Conclusion

In summary, setting up a lathe workshop with a metal lathe and pulley system is essential for smooth operations. You’ll need the right tools and space to work effectively. Consider organizing your workspace for safety and efficiency. Explore more about lathe setups and practice using your lathe to enhance your skills. Start your workshop today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup Focusing On Metal Lathe Pulleys:Sure! Here are five questions about metal lathe pulleys and setting up a workshop. 1. What is a lathe pulley used for? A lathe pulley helps turn the lathe machine. It makes sure the cutting tool spins correctly. 2. How do you choose the right pulley size? You need to check the lathe’s manual. It will tell you what size works best. 3. Can you install a pulley by yourself? Yes! You can follow the steps in the manual. Just be careful and ask for help if needed. 4. Why do pulleys need to be well-maintained? Keeping pulleys clean helps them work better. It also makes the lathe last longer. 5. What tools do you need for pulley setup? You will need basic tools like wrenches and screwdrivers. Check the lathe manual for more detail.

Sure! Please give me the question you’d like me to answer.

What Are The Key Considerations For Selecting The Right Pulley System For A Metal Lathe?When choosing a pulley system for a metal lathe, think about size, weight, and strength. You want a system that fits your lathe and can handle the weight of the lathe parts. The pulley should be strong enough to last a long time. You also need to consider how much speed you need. Find a pulley system that helps you work better and faster.

How Do You Calculate The Proper Pulley Ratios To Achieve The Desired Spindle Speed On A Metal Lathe?To calculate the right pulley ratios for your lathe, start by knowing the desired spindle speed. Spindle speed is how fast the lathe spins the part. Next, check the motor speed. You can find it on the motor label, usually in RPM, which means revolutions per minute. Finally, divide the motor speed by the desired speed. This will give you the pulley ratio you need to use.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Efficiency Of Lathe Pulleys?To keep lathe pulleys working well for a long time, we need to take care of them. First, always clean the pulleys to remove dust and dirt. Next, check for any damage or wear. If something looks broken, fix it quickly. Lastly, make sure to oil the moving parts often so they run smoothly.

How Can You Troubleshoot Common Issues Related To Belt Slippage Or Noise In A Metal Lathe Pulley System?To fix belt slippage or noise in a lathe, check if the belt is tight enough. If it’s too loose, you need to adjust it. Look for dirt or dust on the belt and pulleys; clean them if needed. Listen for any strange sounds; if you hear them, the bearings might be worn out. It’s important to check everything regularly to keep your lathe working well.

What Materials Are Typically Used For Manufacturing Lathe Pulleys, And How Do They Impact The Performance Of The Lathe?Lathe pulleys are usually made from materials like iron, steel, or plastic. Iron and steel are strong and help the lathe last a long time. Plastic is lighter and can make the machine run smoother. The material affects how well the lathe works, making it faster or slower depending on what you choose.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup Focusing On Metal Lathe Pulleys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about metal lathe pulleys and setting up a workshop. 1. What is a lathe pulley used for? A lathe pulley helps turn the lathe machine. It makes sure the cutting tool spins correctly. 2. How do you choose the right pulley size? You need to check the lathe’s manual. It will tell you what size works best. 3. Can you install a pulley by yourself? Yes! You can follow the steps in the manual. Just be careful and ask for help if needed. 4. Why do pulleys need to be well-maintained? Keeping pulleys clean helps them work better. It also makes the lathe last longer. 5. What tools do you need for pulley setup? You will need basic tools like wrenches and screwdrivers. Check the lathe manual for more detail. “}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Considerations For Selecting The Right Pulley System For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a pulley system for a metal lathe, think about size, weight, and strength. You want a system that fits your lathe and can handle the weight of the lathe parts. The pulley should be strong enough to last a long time. You also need to consider how much speed you need. Find a pulley system that helps you work better and faster.”}},{“@type”: “Question”,”name”: “How Do You Calculate The Proper Pulley Ratios To Achieve The Desired Spindle Speed On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calculate the right pulley ratios for your lathe, start by knowing the desired spindle speed. Spindle speed is how fast the lathe spins the part. Next, check the motor speed. You can find it on the motor label, usually in RPM, which means revolutions per minute. Finally, divide the motor speed by the desired speed. This will give you the pulley ratio you need to use.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Efficiency Of Lathe Pulleys?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep lathe pulleys working well for a long time, we need to take care of them. First, always clean the pulleys to remove dust and dirt. Next, check for any damage or wear. If something looks broken, fix it quickly. Lastly, make sure to oil the moving parts often so they run smoothly.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues Related To Belt Slippage Or Noise In A Metal Lathe Pulley System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix belt slippage or noise in a lathe, check if the belt is tight enough. If it’s too loose, you need to adjust it. Look for dirt or dust on the belt and pulleys; clean them if needed. Listen for any strange sounds; if you hear them, the bearings might be worn out. It’s important to check everything regularly to keep your lathe working well.”}},{“@type”: “Question”,”name”: “What Materials Are Typically Used For Manufacturing Lathe Pulleys, And How Do They Impact The Performance Of The Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe pulleys are usually made from materials like iron, steel, or plastic. Iron and steel are strong and help the lathe last a long time. Plastic is lighter and can make the machine run smoother. The material affects how well the lathe works, making it faster or slower depending on what you choose.”}}]}