Have you ever wondered how metal parts are made? A lathe workshop is where the magic happens. In this workshop, the metal lathe plays a key role. It’s a tool that spins metal to shape it. But what about the quill? This part helps control the tool’s depth. Together, they make creating precise shapes easy.

Imagine a craftsman working with a glowing piece of metal. The lathe spins fast as the craftsman skillfully feeds the metal. Each turn shapes the metal into something useful and beautiful. Isn’t that fascinating? Did you know that lathes have been used for thousands of years? They have come a long way since ancient times!

Setting up a lathe workshop is an exciting journey. You can learn how to use different tools and techniques. With the right setup, anyone can become a skilled metal worker. Are you ready to dive into the world of lathe workshop setups? Let’s explore together!

Essential Lathe Workshop Setup: Metal Lathe Quill Guide

Lathe Workshop Setup: Metal Lathe Quill

Setting up a metal lathe workshop can be exciting. One key focus is the lathe quill. The quill allows you to adjust cutting tools easily. Have you ever watched a craftsman seamlessly shape metal? The quill is a big part of that magic! To create accurate pieces, ensure the quill slides smoothly and aligns well. Proper setup can save time and improve precision. Remember, a well-organized workshop with a functional quill makes for better projects and more success!Importance of Quill in Metal Lathes

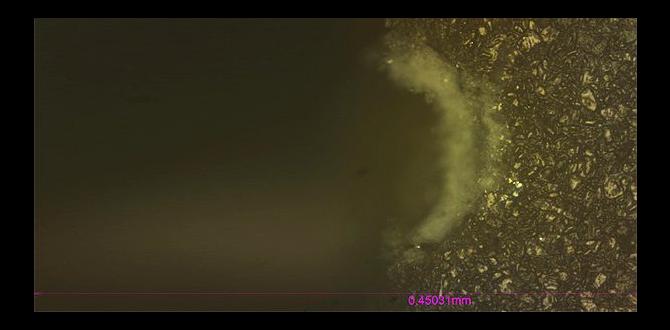

Function of the quill in the turning process. How quill design affects precision and performance.A quill in a metal lathe isn’t just a fancy pen! It plays a key role during the turning process. The quill holds the cutting tool, guiding it smoothly as it shaves off metal. A smart quill design can make all the difference. It boosts precision and performance. Imagine trying to slice a cake with a wobbly knife! Not easy, right? A steady quill lets you create tight, beautiful shapes without fuss.

| Quill Features | Impact on Performance |

|---|---|

| Precision | High accuracy in cuts |

| Stability | Less vibration equals better results |

| Material | Stronger material enhances durability |

So next time you hear “quill,” remember its hotshot role in making those lovely metal pieces! Without it, machining would be as messy as a paint fight! Keep it steady for great success!

Tools and Equipment Needed for Lathe Workshop Setup

List of essential tools required for setting up a metal lathe. Importance of additional equipment like safety gear and measuring tools.Setting up a lathe workshop requires some important tools. You’ll need the metal lathe itself and a sturdy workbench to hold it. Don’t forget a tool holder, cutting tools, and a chuck for holding parts. Additional items like safety gear and measuring tools are also very important. Safety goggles protect your eyes while measuring tools help you get the right size.

What tools do you need for a lathe workshop?

You need a metal lathe, workbench, tool holder, cutting tools, a chuck, safety goggles, and measuring tools.Essential Tools Checklist:

- Metal Lathe

- Workbench

- Tool Holder

- Cutting Tools

- Chuck

- Safety Goggles

- Measuring Tools

Step-by-Step Guide to Setting Up Your Lathe Workshop

Preparing your workspace: layout and organization tips. Installation process for the metal lathe and accessories, including the quill.To make your lathe workshop work better, start by planning your space. Think about where you want everything. Keep your tools close for easy access. Keep your workbench clear so you can think and create.

Next, settle on a spot for your metal lathe and accessories, like the quill. Follow these steps:

- Check the lathe’s manual for instructions.

- Make sure the surface is strong and stable.

- Secure the lathe with bolts to avoid movement.

- Attach the quill properly to ensure smooth operation.

Best Practices for Quill Adjustment and Maintenance

How to properly adjust the quill for optimal performance. Maintenance tips to ensure longevity and reliability of the quill.Adjusting your quill correctly is important for smooth operation. Start by ensuring the quill moves freely without sticking. Check the tension; it should not be too tight. A well-adjusted quill improves accuracy and safety.

For maintenance, here are some tips:

- Clean the quill regularly to remove dust and debris.

- Lubricate moving parts to prevent wear.

- Inspect for wear and tear often.

- Tighten loose screws to maintain stability.

By following these steps, you can keep your quill in top shape and increase its lifespan.

How can I adjust the quill for better performance?

Adjust the quill by checking its movement and ensuring it operates smoothly. Make sure it has the right tension, allowing for easy adjustments.

What maintenance tips ensure quill reliability?

Regular cleaning, lubrication, and inspection of parts help maintain the quill’s reliability and performance.

Common Issues with Quill Setup and Troubleshooting Tips

Identification of common problems faced during quill setup. Effective troubleshooting techniques and solutions.Setting up a quill? Sounds easy, right? But wait! Sometimes things go haywire. You might find the quill isn’t aligned or moves too stiffly. Others may hear a strange noise, like a cat stuck in a tree. Don’t panic! Start by checking the alignment and lubrication. A good oiling can be magic! Here’s a quick table to guide you through some common issues:

| Problem | Solution |

|---|---|

| Quill misalignment | Adjust the mounting screws carefully. |

| Stiff movement | Lubricate with the right oil. |

| Unusual sounds | Check for loose parts and tighten them. |

Follow these tips, and your quill will be smoother than a buttered biscuit! Happy lathing!

Enhancing Your Metal Lathe Experience

Recommended upgrades and modifications for better quill performance. Suggestions for workshops and resources for ongoing learning.Upgrading your metal lathe can make a big difference. There are several simple modifications for better quill performance. Here are some helpful suggestions and resources:

- Install a quick-release quill lock for faster adjustments.

- Add a digital readout for precise measurements.

- Consider a better feed system for smoother operation.

Workshops offer hands-on learning opportunities. Look for local classes or online videos. Books on metalworking are great too. Keep learning and practicing to enhance your skills.

What are effective upgrades for a metal lathe?

Useful upgrades include a better quill lock, digital readouts, and upgraded feed systems. These changes can improve accuracy and efficiency.

Conclusion

In setting up your lathe workshop, focus on the metal lathe quill. It helps with precision and control in your projects. Make sure to arrange tools for easy access and safety. Check out beginner guides and videos to learn more. With practice, you can master your lathe skills and create amazing pieces. Let’s get started!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Workshop Setup And The Use Of A Metal Lathe Quill:1. **What is a lathe?** A lathe is a machine that spins metal to shape it. You can use it to make round things, like table legs. 2. **How do you set up a lathe workshop?** First, choose a safe space with good lighting. Then, gather your tools and materials. Keep everything organized so you can find what you need easily. 3. **What does the quill on a metal lathe do?** The quill helps to hold and adjust tools. We can move it up and down for different shapes and cuts. 4. **Why is safety important in a workshop?** Safety keeps you from getting hurt. Always wear goggles and gloves. Also, keep your workspace tidy to avoid accidents. 5. **What tools do you need in a lathe workshop?** You need basic tools like chisels, measuring tapes, and safety gear. It helps to have a good chair and strong workbench too!

Sure! Please share the question you’d like me to answer.

What Are The Essential Tools And Equipment Needed For Setting Up A Metal Lathe Workshop, Specifically For Quill Operations?To set up a metal lathe workshop for quill operations, you need a few important tools. First, get a metal lathe. This machine helps you shape metal pieces. Next, you’ll need cutting tools to cut and smooth the metal. A set of measuring tools like calipers helps you check sizes. Lastly, don’t forget safety gear, like goggles and gloves, to keep you safe while you work!

How Do You Properly Calibrate And Align The Quill On A Metal Lathe To Ensure Accurate Machining?To calibrate and align the quill on a metal lathe, first, make sure the machine is off. Check that the quill is clean and free of dust. You can use a dial indicator to measure any gaps. Adjust the quill until it sits straight and doesn’t wobble. Finally, tighten everything back up and test it with a small piece of metal to check accuracy.

What Safety Precautions Should Be Taken When Operating A Metal Lathe, Particularly Regarding The Use Of The Quill?When using a metal lathe, always wear safety glasses to protect your eyes. Keep your hands away from the moving parts, especially the quill, which holds the tool. Make sure your hair and clothes are tied back and not loose. Never reach into the lathe when it’s running. Lastly, always follow instructions and ask an adult for help if you’re unsure.

How Can One Troubleshoot Common Issues That Arise While Using The Quill In Metal Lathe Operations?To troubleshoot problems with the quill in a metal lathe, first check if it’s stuck. You can do this by moving the quill up and down. If it’s hard to move, clean any dirt or chips around it. Next, make sure the quill is properly locked when using it. If the cutting isn’t smooth, adjust the speed and pressure. These steps can help fix many common issues!

What Are The Differences In Quill Design And Functionality Between Various Models Of Metal Lathes, And How Do These Differences Affect Machining Processes?Different metal lathes have different quill designs. A quill is a part that holds the cutting tool. Some quills can move up and down easily, while others are more fixed. If a quill moves more, you can make more shapes. If it’s sturdy, it helps with strong cuts. These differences change how we machine or shape the metal.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Workshop Setup And The Use Of A Metal Lathe Quill:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “1. **What is a lathe?** A lathe is a machine that spins metal to shape it. You can use it to make round things, like table legs. 2. **How do you set up a lathe workshop?** First, choose a safe space with good lighting. Then, gather your tools and materials. Keep everything organized so you can find what you need easily. 3. **What does the quill on a metal lathe do?** The quill helps to hold and adjust tools. We can move it up and down for different shapes and cuts. 4. **Why is safety important in a workshop?** Safety keeps you from getting hurt. Always wear goggles and gloves. Also, keep your workspace tidy to avoid accidents. 5. **What tools do you need in a lathe workshop?** You need basic tools like chisels, measuring tapes, and safety gear. It helps to have a good chair and strong workbench too!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Equipment Needed For Setting Up A Metal Lathe Workshop, Specifically For Quill Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe workshop for quill operations, you need a few important tools. First, get a metal lathe. This machine helps you shape metal pieces. Next, you’ll need cutting tools to cut and smooth the metal. A set of measuring tools like calipers helps you check sizes. Lastly, don’t forget safety gear, like goggles and gloves, to keep you safe while you work!”}},{“@type”: “Question”,”name”: “How Do You Properly Calibrate And Align The Quill On A Metal Lathe To Ensure Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate and align the quill on a metal lathe, first, make sure the machine is off. Check that the quill is clean and free of dust. You can use a dial indicator to measure any gaps. Adjust the quill until it sits straight and doesn’t wobble. Finally, tighten everything back up and test it with a small piece of metal to check accuracy.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe, Particularly Regarding The Use Of The Quill?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety glasses to protect your eyes. Keep your hands away from the moving parts, especially the quill, which holds the tool. Make sure your hair and clothes are tied back and not loose. Never reach into the lathe when it’s running. Lastly, always follow instructions and ask an adult for help if you’re unsure.”}},{“@type”: “Question”,”name”: “How Can One Troubleshoot Common Issues That Arise While Using The Quill In Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot problems with the quill in a metal lathe, first check if it’s stuck. You can do this by moving the quill up and down. If it’s hard to move, clean any dirt or chips around it. Next, make sure the quill is properly locked when using it. If the cutting isn’t smooth, adjust the speed and pressure. These steps can help fix many common issues!”}},{“@type”: “Question”,”name”: “What Are The Differences In Quill Design And Functionality Between Various Models Of Metal Lathes, And How Do These Differences Affect Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different metal lathes have different quill designs. A quill is a part that holds the cutting tool. Some quills can move up and down easily, while others are more fixed. If a quill moves more, you can make more shapes. If it’s sturdy, it helps with strong cuts. These differences change how we machine or shape the metal.”}}]}