Imagine standing in your very own lathe workshop. Tools are arranged neatly, and the air buzzes with creativity. Do you feel excited yet? Setting up a lathe workshop can be a fun adventure.

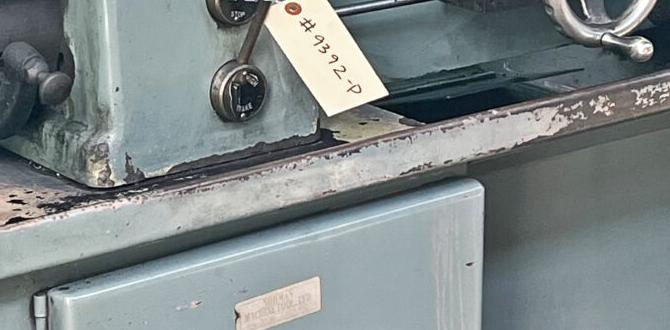

Many enthusiasts start with a metal lathe saddle. This piece is essential for operating your lathe smoothly. Have you ever wondered how a simple setup can turn raw metal into amazing projects?

It’s not just about having the right tools. It’s also about creating a space that inspires you. A well-organized workshop can make all the difference. Picture your lathe running smoothly, guiding each project with ease.

In this article, we will explore the steps to set up your lathe workshop. We’ll discuss where to place your lathe, how to choose the right tools, and tips for keeping everything tidy. By the end, you’ll be ready to start your metalworking journey!

Essential Lathe Workshop Setup: Optimizing Metal Lathe Saddle

Lathe Workshop Setup: Metal Lathe Saddle

Setting up a metal lathe workshop is exciting and rewarding. A well-structured lathe saddle is vital for precision work. Properly aligning the saddle enhances accuracy and efficiency. Have you ever thought about how a tiny adjustment can change your entire project? This setup helps in creating smooth cuts and perfect finishes. Fun fact: even the smallest change in the saddle position can make a big difference! Make sure to pay attention to your lathe setup, as it impacts your entire crafting experience.Key Components of a Metal Lathe

Description of the main parts of a metal lathe and their functions.. Importance of the lathe saddle and its impact on precision..A metal lathe has essential parts that work together. The main components are:

- Lathe Bed: This is the base that supports the whole machine.

- Saddle: The saddle holds tools and moves along the bed. It is key for shaping materials.

- Headstock: This part holds the motor and spindle, spinning the workpiece.

- Tailstock: It supports the other end of the piece and holds tools for drilling.

- Carriage: This moves the tool holder back and forth for cutting.

The lathe saddle is very important. It helps ensure accurate cuts, which affects the quality of the work. A well-set saddle can make a big difference in precision.

What are the main parts of a metal lathe?

The main parts are the lathe bed, saddle, headstock, tailstock, and carriage. Each part has its own unique function that helps create precise shapes from metal.

Understanding these components gives you a better idea of how a lathe works. This knowledge is vital for anyone wanting to use one in a workshop.

Choosing the Right Location for Your Lathe Workshop

Factors to consider when selecting a workshop space (size, ventilation, safety).. Importance of electrical and plumbing considerations..Finding the perfect spot for your workshop is like picking the right candy. It needs to be just right! Size is key; make sure there’s space for your lathe and you. Next, think about ventilation. You don’t want to breathe in sawdust like it’s a new cologne! Safety is a must—keep things organized to avoid accidents. Don’t forget about electrical and plumbing needs; you don’t want to trip over wires or flood your tools. A good setup lets you work happily and safely!

| Factor | Considerations |

|---|---|

| Size | Space for equipment and movement. |

| Ventilation | Keep air fresh, not dusty! |

| Safety | Organized tools help prevent accidents. |

| Electrical | Power tools need power! |

| Plumbing | Avoid water disasters. |

Essential Tools and Equipment for Setup

List of musthave tools to accompany the metal lathe.. Recommendations for safety equipment to ensure a safe working environment..Having the right tools makes a lathe workshop run smoothly. Here are the essential items you need:

- Measuring Tools: A caliper and ruler help you take accurate measurements.

- Cutting Tools: High-speed steel or carbide tools are best for cutting metal.

- Chucks: These hold the workpiece in place securely.

- Tool Holders: They allow easy changes of cutting tools.

- Deburring Tools: These clean sharp edges after cutting.

- Files: Use them to smooth out rough surfaces.

Safety is important too. Equip your workshop with:

- Safety Glasses: Protect your eyes from flying debris.

- Hearing Protection: This guards your ears against loud noises.

- Gloves: Keep your hands safe while working.

- Protective Clothing: Wear clothes that won’t get caught in machines.

What tools do I need for a metal lathe?

You will need measuring tools, cutting tools, and chucks. These are essential for making precise cuts and measurements.

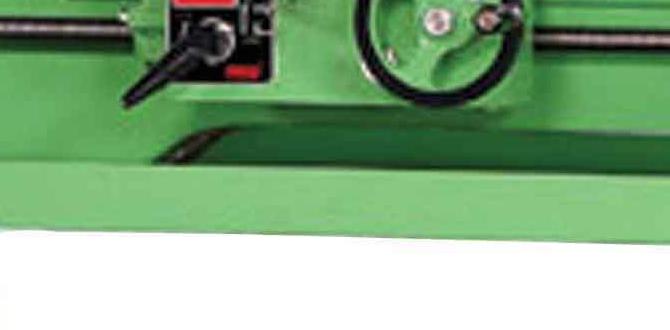

Setting Up Your Metal Lathe: Step-by-Step Guide

Detailed steps to position, level, and secure your metal lathe.. Importance of aligning the lathe saddle for optimal performance..To set up your metal lathe, follow these simple steps. First, choose a sturdy surface. Place the lathe on this surface. Use a level to make sure it is even. Then, secure it tightly with bolts. Make sure the lathe saddle is aligned. If it’s not, the lathe won’t work well. A well-aligned saddle helps create smooth cuts. Remember, the better you set it up, the better it performs!

Why is aligning the lathe saddle important?

Aligning the lathe saddle ensures proper and accurate cuts. It reduces wear and tear on your machine. A well-aligned lathe can help you finish projects faster. This means better results and more fun in your workshop!

Maintenance Tips for Your Metal Lathe and Saddle

Routine maintenance practices to ensure longevity and functionality.. Common issues related to the lathe saddle and how to address them..Keeping your metal lathe and saddle in tip-top shape is like taking care of a pet; they need love and regular check-ups! Start with routine maintenance. Clean off chips and oil often. This helps your lathe stay happy. If the saddle wiggles or sticks, it might need a little oil or cleaning. Don’t let it sulk in dirt!

| Tip | Action |

|---|---|

| Clean regularly | Wipe down surfaces and remove chips. |

| Oil parts | Apply lubricant to moving parts. |

| Check for damage | Inspect the saddle for cracks or wear. |

Remember, a little love goes a long way! Regular care can save you headaches later. Don’t ignore those squeaks; they might be the lathe’s way of asking for help!

Optimal Techniques for Operating the Lathe with a Focus on the Saddle

Best practices for operating the metal lathe to achieve precise results.. Tips for adjusting the saddle for different types of projects..Using a metal lathe can be exciting and rewarding. Here are some tips for best practices to get precise results:

- Always check the saddle alignment before starting. This helps in making accurate cuts.

- Adjust the saddle properly based on your project’s size and shape. This ensures smooth movements.

- Use the right speed for different materials. Slower speeds are better for harder metals.

- Keep the lathe clean and well-lubricated. This helps it run smoothly and last longer.

These practices will help you achieve amazing results while working on your projects!

How can you adjust the saddle for different projects?

To adjust the saddle, check the size of your material first. Then, move the saddle closer or farther away based on your needs. This helps achieve the best cutting range. Always make sure it’s secure before starting.

Resources for Further Learning and Improvement

Recommended books, websites, and courses to enhance lathe skills.. Community forums and groups for networking and advice on lathe workshop setup..If you’re eager to master your metal lathe skills, looking for engaging resources is a great start! Books like “The Fundamentals of Metalworking” provide clear instructions and tips. Websites such as YouTube offer endless tutorials. For those preferring structured learning, check out online courses on platforms like Udemy. You can also join community forums like Reddit’s metalworking group to connect with fellow hobbyists. They might even share some secrets to avoid turning your project into a spaghetti mess!

| Resource Type | Recommended Sources |

|---|---|

| Books | The Fundamentals of Metalworking |

| Websites | YouTube, Metalworking News |

| Online Courses | Udemy, Coursera |

| Community Forums | Reddit’s Metalworking Group |

Each of these resources can help you improve your lathe workshop setup and connect with other enthusiastic makers. Remember, learning can be fun, and a little humor goes a long way. After all, who knew metal chips could be this exciting?

Conclusion

In summary, setting up a lathe workshop with a metal lathe saddle is important for precision work. You should choose a sturdy foundation and ensure safety measures. Keep tools organized and maintain your lathe regularly. By following these tips, you can improve your projects. So, gather your materials and dive into your new workshop! Happy crafting!FAQs

Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe Saddle In A Workshop:To set up a metal lathe saddle, first, find a flat, sturdy table. Make sure you have enough space around it. Then, attach the saddle to the lathe carefully. You need to check that it moves smoothly. Lastly, adjust the settings so it works well for your projects.

Sure, I can do that! Just give me the question you want help with, and I’ll provide a simple answer.

What Are The Key Components Of A Metal Lathe Saddle, And How Do They Function Together During Machining?A metal lathe saddle has a few important parts. First, there’s the base, which holds everything steady. Then there’s the carriage, which moves the tool. The tool holder keeps the cutting tool in place. These parts work together to shape metal pieces as they spin. When you turn the handle, the carriage moves, and the tool cuts the metal smoothly.

How Should The Metal Lathe Saddle Be Aligned With The Lathe Bed For Optimal Accuracy And Performance?To align the metal lathe saddle with the lathe bed, first, check for any dirt or debris. Clean the surfaces to make sure they’re smooth. Then, you should place the saddle evenly on the bed. Use a level to make sure it sits straight. Adjust it until it fits snugly and won’t move around. This helps your lathe cut straight and true!

What Maintenance Practices Should Be Followed To Ensure The Longevity And Precision Of The Lathe Saddle?To keep the lathe saddle working well, always clean it after you use it. Use a soft cloth to wipe off dust and oil. Check for any loose screws or parts and tighten them if needed. You should also apply lubricant to moving parts regularly to help them slide smoothly. Lastly, store the lathe in a dry place to avoid rust.

How Do Factors Like Saddle Weight And Material Affect The Stability And Machining Capabilities Of The Lathe?The saddle is a part of the lathe that holds the tool. If the saddle is heavy, it helps the lathe stay steady. A stable lathe doesn’t shake, so it cuts better. The material also matters; stronger materials are better for making precise cuts. So, a heavy and strong saddle helps the lathe work well.

What Adjustments Can Be Made To A Metal Lathe Saddle To Accommodate Different Workpiece Sizes Or Types Of Machining Operations?To adjust a metal lathe saddle, you can change the position of the clamps that hold your workpiece. You might need to move the saddle closer or farther away from the machine’s center. Also, you can change the height of the workpiece by adjusting the bed. These changes help you use different sizes of materials and do different types of cutting. Adjusting helps make sure everything fits and works well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe Saddle In A Workshop:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe saddle, first, find a flat, sturdy table. Make sure you have enough space around it. Then, attach the saddle to the lathe carefully. You need to check that it moves smoothly. Lastly, adjust the settings so it works well for your projects.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure, I can do that! Just give me the question you want help with, and I’ll provide a simple answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Saddle, And How Do They Function Together During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe saddle has a few important parts. First, there’s the base, which holds everything steady. Then there’s the carriage, which moves the tool. The tool holder keeps the cutting tool in place. These parts work together to shape metal pieces as they spin. When you turn the handle, the carriage moves, and the tool cuts the metal smoothly.”}},{“@type”: “Question”,”name”: “How Should The Metal Lathe Saddle Be Aligned With The Lathe Bed For Optimal Accuracy And Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the metal lathe saddle with the lathe bed, first, check for any dirt or debris. Clean the surfaces to make sure they’re smooth. Then, you should place the saddle evenly on the bed. Use a level to make sure it sits straight. Adjust it until it fits snugly and won’t move around. This helps your lathe cut straight and true!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Precision Of The Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lathe saddle working well, always clean it after you use it. Use a soft cloth to wipe off dust and oil. Check for any loose screws or parts and tighten them if needed. You should also apply lubricant to moving parts regularly to help them slide smoothly. Lastly, store the lathe in a dry place to avoid rust.”}},{“@type”: “Question”,”name”: “How Do Factors Like Saddle Weight And Material Affect The Stability And Machining Capabilities Of The Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The saddle is a part of the lathe that holds the tool. If the saddle is heavy, it helps the lathe stay steady. A stable lathe doesn’t shake, so it cuts better. The material also matters; stronger materials are better for making precise cuts. So, a heavy and strong saddle helps the lathe work well.”}},{“@type”: “Question”,”name”: “What Adjustments Can Be Made To A Metal Lathe Saddle To Accommodate Different Workpiece Sizes Or Types Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust a metal lathe saddle, you can change the position of the clamps that hold your workpiece. You might need to move the saddle closer or farther away from the machine’s center. Also, you can change the height of the workpiece by adjusting the bed. These changes help you use different sizes of materials and do different types of cutting. Adjusting helps make sure everything fits and works well.”}}]}