Have you ever wondered what it takes to set up a workshop with a metal lathe? Imagine transforming raw metal into amazing shapes and tools. It all starts with a smart lathe workshop setup.

Setting up your metal lathe can feel overwhelming at first. But don’t worry! With some careful planning, you can create a space that inspires creativity and productivity. Did you know that a well-organized workshop can make your projects easier? That means more time making and less time searching!

In this article, we will explore the essential steps for a successful metal lathe setup. You’ll learn what tools you need and how to arrange them. So, get ready to dive into the exciting world of metalworking!

Lathe Workshop Setup: Essential Tips For Metal Lathe Setup

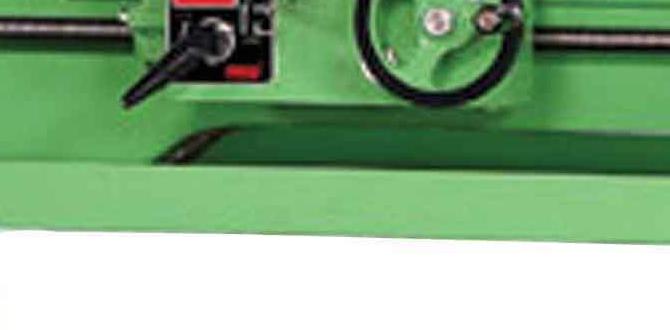

Lathe Workshop Setup: Metal Lathe Setup

Setting up a lathe workshop requires careful planning. First, choose a sturdy table to hold the lathe safely. Next, organize your tools for easy access. Safety gear, like goggles and gloves, is essential. Did you know that a well-set workshop can boost your creativity? You’ll also want good lighting to avoid accidents. With these tips, your metal lathe setup will be efficient and enjoyable. Ready to start crafting your ideas?Choosing the Right Lathe for Your Workshop

Factors to consider when selecting a metal lathe. Popular types of metal lathes available in the market.Picking the right lathe for your workshop is key. Several factors matter. Think about how big the lathe is and its power. Do you want a small one for easy jobs or a bigger one for complex work? Popular metal lathes include:

- Mini lathes: Great for beginners and small projects.

- Benchtop lathes: Mid-size and good for small shops.

- Industrial lathes: Best for heavy-duty tasks and professionals.

Choose wisely to make your workshop a success!

What should you consider when buying a lathe?

Consider size, power, and features like speed and control options. Each factor impacts how well you can work on projects.

Essential Tools and Equipment for Metal Lathe Setup

List of musthave tools for a complete setup. Additional accessories to enhance lathe functionality.Setting up a metal lathe requires some essential tools. These tools help make the work easier and safer. Here’s a list of must-have items for your lathe setup:

- Cutting tools

- Tool holders

- Workholding devices

- Measuring tools

- Safety gear

Some additional accessories can enhance your lathe’s functionality. Consider adding:

- Live centers

- Lathe chucks

- Faceplates

- Digital readout systems

Workspace Design and Layout for a Lathe Workshop

Best practices for organizing your lathe workspace. Safety considerations in workspace layout.Designing a lathe workshop is like setting up a puzzle, but without the missing pieces (we hope!). Start by placing your metal lathe in a spacious corner. A clean layout lets you work faster. Keep tools nearby but organized—think of it as a tools dance party, without the tripping! Safety should be your top priority; make sure everything is within arm’s reach but not in the way. That way, you avoid mishaps and keep your toes safe!

| Best Practices | Safety Tips |

|---|---|

| Keep tools organized | Wear safety goggles |

| Have enough lighting | Keep the area clean |

| Plan for movement | Use non-slip mats |

By following these tips, you’ll create a workspace that’s not only efficient but safe, leaving more time for your creative projects (and fewer trips to the band-aid aisle)! Remember, a well-designed workspace makes for a happy (and less clumsy) lathe user.

Setting Up Your Metal Lathe: Step-by-Step Guide

Instructions for assembling and positioning your lathe. Calibration and leveling techniques for optimal performance.First, gather your metal lathe and tools like a kid ready for a big LEGO build! Start by assembling the lathe as per the manual. Follow each step carefully; no one wants a wobbly lathe! Position it on a sturdy bench where you have enough room to work. Once it’s in place, it’s calibration time! Use a level to ensure it’s straight. Check it with a spirit level—yes, like a tiny floor party for your lathe! Make tiny adjustments as needed. A well-calibrated lathe is a happy lathe.

| Steps | Details |

|---|---|

| Assembly | Follow the manual step-by-step. |

| Positioning | Place it on a stable, roomy bench. |

| Leveling | Use a spirit level for accuracy. |

Electrical and Power Supply Considerations

Determining power requirements for your metal lathe. Safe practices for electrical setup and wiring.Setting up your metal lathe requires careful attention to electrical needs. First, make sure you know how much power your lathe needs. Measure the voltage and wattage to avoid overloading circuits. Safety is key in any electrical setup. Use properly rated wires and circuit breakers to protect against shocks and fires.

- Check power requirements for your specific lathe model.

- Always follow safety guidelines for wiring.

- Consider using a surge protector.

How do you determine power needs for a metal lathe?

Check the manufacturer’s guidelines. This information will tell you voltage and wattage needs. Keeping your setup safe is essential for smooth operation.

Maintenance Tips for Longevity of Your Metal Lathe

Regular maintenance tasks to keep your lathe in good condition. Troubleshooting common issues with metal lathes.To keep your metal lathe working well, regular maintenance is key. It helps prevent problems and extends its life. Here are some simple tasks:

- Clean the lathe after each use.

- Check and lubricate moving parts.

- Adjust the tailstock and tool rest.

- Inspect for loose bolts or signs of wear.

If you face any issues, like strange noises or uneven cuts, troubleshoot quickly. Often, these problems are just minor adjustments away.

How do you troubleshoot common metal lathe issues?

Start by checking for loose parts or lack of oil. Tightening bolts or adding lubrication can fix many problems. If cuts aren’t straight, adjust the tool position. Regular checks can save time and repairs.

Creating a Safe Operating Environment

Importance of personal protective equipment (PPE). Implementing safety protocols in your workshop.Safety is a must in any workshop. Personal Protective Equipment (PPE) keeps you safe from sharp tools and flying metal. Always wear goggles, gloves, and steel-toed boots. This gear protects you and helps you feel secure.

Implementing safety rules also helps. Make sure everyone knows the rules. Here are some basic guidelines:

- Keep the area clean and free of clutter.

- Do not wear loose clothing that can get caught in machines.

- Always follow machine instructions carefully.

Following these steps makes your workshop a safer place to work.

Why is PPE important in a workshop?

PPE protects you from injuries, helps you feel safe, and boosts confidence while working.

Additional Resources for Learning Lathe Techniques

Recommended books, tutorials, and online courses. Community forums and groups for lathe enthusiasts.Learning new lathe techniques can be fun and exciting. There are many resources to help you. Recommended books provide detailed information on various methods. Video tutorials are great for visual learners and show step-by-step guides. Online courses offer structured lessons for deeper learning. Joining community forums lets you connect with fellow lathe enthusiasts. They share tips and answer questions. Here are some helpful resources:

- Books: Look for titles on lathe operation and safety.

- Tutorials: Websites like YouTube have many video lessons.

- Courses: Check platforms like Udemy or Coursera for courses on metalworking.

- Forums: Sites like Reddit and dedicated lathe forums are valuable for sharing experiences.

What is the best way to learn lathe techniques?

The best way to learn is by combining books, videos, and community advice. Use these resources to improve your skills steadily.

Conclusion

In conclusion, setting up a metal lathe workshop is important for effective metalworking. Choose a clean, organized space to work safely. Make sure you have the right tools and equipment. Always prioritize your safety with gear like goggles and gloves. Now that you know the basics, explore more about lathe techniques and improve your skills further!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Setup:Sure! Setting up a lathe workshop means you need a clean, safe space. You should have good lighting and your tools nearby. Make sure the lathe is sturdy and level. Always wear safety gear, like goggles. Lastly, check your machine before starting to work. It’s important to stay safe!

Sure! I can help with that. Just ask me your question, and I’ll give you a simple answer.

What Are The Essential Tools And Equipment Needed For A Complete Metal Lathe Workshop Setup?To set up a metal lathe workshop, you need a few key tools. First, you need a metal lathe, which cuts and shapes metal. Next, you want safety gear, like goggles and gloves, to protect yourself. You also need measuring tools, like calipers and rulers, to check your work. Finally, have cutting tools and a strong workbench for better results.

How Should A Metal Lathe Be Positioned In A Workshop To Ensure Safety And Efficiency During Operation?You should place the metal lathe on a sturdy table. Make sure it has enough space around it. This helps you move safely without bumping into things. Keep tools and materials close, but not cluttered. Always keep the area clean to avoid accidents.

What Are The Best Practices For Organizing And Storing Tools And Materials In A Metal Lathe Workshop?To keep your metal lathe workshop tidy, start by grouping similar tools together. Use shelves or boxes to store the tools you use often. Label everything, so you know where to find stuff quickly. Always put tools back in their place after using them. Clean your workspace regularly to stay safe and focused while working.

How Do You Properly Maintain And Calibrate A Metal Lathe To Achieve Optimal Performance?To keep a metal lathe working well, you should clean it regularly. Check for any loose parts and tighten them. You can oil the moving parts to help them move smoothly. To calibrate, measure the tools and check that everything is set to the right size. This helps make sure your projects turn out great!

What Are The Common Electrical And Ventilation Requirements For A Metal Lathe Workshop Environment?In a metal lathe workshop, you need good electricity and air flow. Make sure you have enough power outlets for all machines. It’s also important to use machines that are safe and made for your workshop. Good ventilation helps remove dust and bad smells, so we can breathe easily. Using fans or opening windows keeps the air fresh.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup And Metal Lathe Setup:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Setting up a lathe workshop means you need a clean, safe space. You should have good lighting and your tools nearby. Make sure the lathe is sturdy and level. Always wear safety gear, like goggles. Lastly, check your machine before starting to work. It’s important to stay safe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can help with that. Just ask me your question, and I’ll give you a simple answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Equipment Needed For A Complete Metal Lathe Workshop Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe workshop, you need a few key tools. First, you need a metal lathe, which cuts and shapes metal. Next, you want safety gear, like goggles and gloves, to protect yourself. You also need measuring tools, like calipers and rulers, to check your work. Finally, have cutting tools and a strong workbench for better results.”}},{“@type”: “Question”,”name”: “How Should A Metal Lathe Be Positioned In A Workshop To Ensure Safety And Efficiency During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should place the metal lathe on a sturdy table. Make sure it has enough space around it. This helps you move safely without bumping into things. Keep tools and materials close, but not cluttered. Always keep the area clean to avoid accidents.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Organizing And Storing Tools And Materials In A Metal Lathe Workshop?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe workshop tidy, start by grouping similar tools together. Use shelves or boxes to store the tools you use often. Label everything, so you know where to find stuff quickly. Always put tools back in their place after using them. Clean your workspace regularly to stay safe and focused while working.”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Calibrate A Metal Lathe To Achieve Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, you should clean it regularly. Check for any loose parts and tighten them. You can oil the moving parts to help them move smoothly. To calibrate, measure the tools and check that everything is set to the right size. This helps make sure your projects turn out great!”}},{“@type”: “Question”,”name”: “What Are The Common Electrical And Ventilation Requirements For A Metal Lathe Workshop Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe workshop, you need good electricity and air flow. Make sure you have enough power outlets for all machines. It’s also important to use machines that are safe and made for your workshop. Good ventilation helps remove dust and bad smells, so we can breathe easily. Using fans or opening windows keeps the air fresh.”}}]}