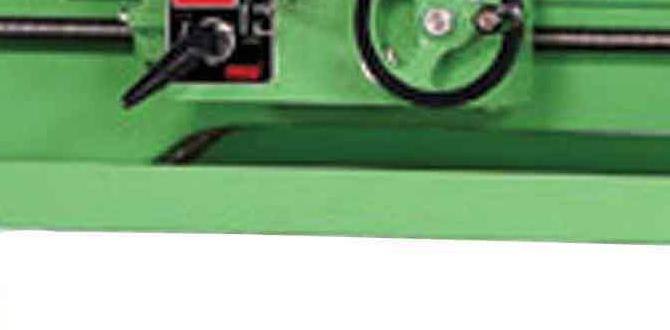

Picture this: you walk into a workshop filled with tools and machines. The air is buzzing with the sound of a metal lathe transforming a simple piece of metal into a beautiful, tapered shape. Isn’t that fascinating? Setting up a lathe workshop can be an exciting project, especially if you enjoy working with your hands.

Have you ever wondered how those perfect, angled pieces are made? Taper turning on a metal lathe is a key skill that opens a world of possibilities. Whether you want to create custom tools or cool decorations, mastering this technique is a great first step.

In this article, we’ll explore how to set up a lathe workshop that fits your needs. From choosing the right machines to organizing your tools, we’ve got you covered. Are you ready to dive into the world of taper turning? Let’s get started!

Setting Up A Lathe Workshop: Metal Lathe Taper Turning Techniques

Lathe Workshop Setup: Metal Lathe Taper Turning

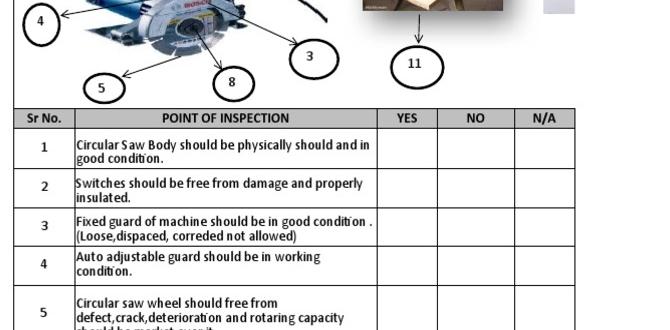

Setting up a metal lathe workshop can be exciting and rewarding. Understanding taper turning is key for many projects. Have you ever wondered how to create perfectly shaped objects? A metal lathe helps with that! First, make sure your lathe is well-placed and stable. Proper tools and safety gear are essential. Learn about the different attachments for your lathe, as they can make taper turning easier. With practice, you can create everything from simple pins to complex parts. Enjoy the satisfaction of shaping metal into useful items!Choosing the Right Metal Lathe for Taper Turning

Factors to consider in selecting a lathe. Comparison of different lathe models suitable for taper turning.Finding the right metal lathe for taper turning can feel like searching for a needle in a haystack. First, consider the size and power needed for your projects. Some lathes are tiny but mighty, while others can spin your dreams into reality. Compare features like variable speed, durability, and the ability to twist and shout—oops, I mean taper! Here’s a quick comparison of popular models:

| Lathe Model | Power (HP) | Speed Range (RPM) | Price ($) |

|---|---|---|---|

| Model A | 1.5 | 100-2000 | 500 |

| Model B | 2.0 | 200-3000 | 800 |

| Model C | 2.5 | 150-3500 | 1200 |

Pick a lathe that fits your needs and budget. Remember, every expert was once a beginner. Happy turning!

Workspace Layout and Organization

Ideal workspace dimensions for optimal functionality. Tips for organizing tools and materials effectively.Creating a great workspace is important. You need enough space for a metal lathe. A size of 12 by 16 feet works well. It gives you room to move and work safely. Organizing tools can make your work easier.

Here are some tips to keep your workshop tidy:

- Place tools on wall shelves.

- Use labeled boxes for small items.

- Keep frequently used tools nearby.

- Leave pathways clear for safety.

Good organization saves time and helps you work better.

What is the best way to organize my workshop?

Use storage bins, wall racks, and labels to keep everything in its place. This makes finding tools quick and easy.

Setting Up Your Lathe for Taper Turning

Stepbystep guide on setting up the lathe. Key adjustments necessary for precise taper turning.To set up your lathe for taper turning, follow these steps: First, ensure the lathe is on a stable surface. Next, mount the workpiece securely. Then, adjust the tailstock at the right angle. Finally, check your cutting tools for sharpness. Each adjustment is crucial for a smooth taper.

- Level the lathe carefully.

- Use a protractor for angle accuracy.

- Inspect tool height and alignment.

- Confirm the speed setting for materials.

What are the key adjustments for taper turning?

Key adjustments include ensuring correct tool height and selecting the right speed for the material. Small changes can make a big difference in your taper quality.

Remember, patience is key. Taking time to set up properly will help you create the best taper. Soon, you’ll be making perfect tapers with ease!

Techniques for Achieving Accurate Taper Turns

Recommended methods for measuring angles. Tips for maintaining consistent feed rates.To get perfect taper turns, measuring angles correctly is essential. Use a protractor or a digital angle gauge for accuracy. They help you check the angle as you work. Another tip is to keep a steady feed rate. It prevents mistakes when cutting. Here are some tips:

- Start slow and increase speed gradually.

- Use a consistent hand pressure on the lathe.

- Watch the cutting edge; don’t rush.

These methods will ensure clean and precise taper turns.

How do I measure the taper angle accurately?

Use a protractor or a digital gauge for precise measurements. These tools let you check the angles easily while working with your lathe.

Common Challenges and Solutions in Taper Turning

Identification of common taper turning problems. Troubleshooting strategies for each challenge.Taper turning isn’t always a smooth ride. Sometimes, you might face wobbling, uneven cuts, or even those pesky tool marks. No one likes a lopsided project! Here’s a fun table with some common challenges and how to fix them.

| Problem | Solution |

|---|---|

| Wobbling workpiece | Check the chuck tightness. A loose chuck is a lathe’s worst enemy! |

| Uneven taper | Aim for slow and steady. Quick cuts lead to accidents! |

| Tool marks | Use a sharp tool. Dull tools are just lazy sidekicks. |

With these insights in hand, you’ll be well on your way to mastering tapered turning and impressing everyone with your skills!

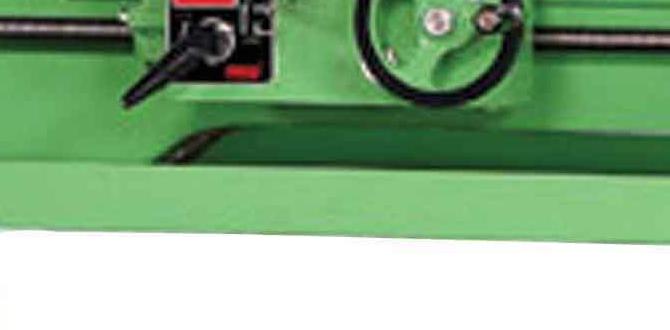

Maintenance Tips for Longevity of Your Lathe

Routine maintenance checklist for metal lathes. Tips for extending the life of your taper turning equipment.Keeping your lathe happy ensures it lasts longer and works better. A checklist for routine maintenance can be a lifesaver! Check for oil leaks, clean the bed regularly, and keep the tools sharp. Remember, clean machines are happy machines! A little brush now can save you a lot of time later. Don’t forget to tighten those bolts; they can get loose like my funny uncle at family dinners!

| Maintenance Task | Frequency |

|---|---|

| Check Oil Levels | Weekly |

| Clean the Bed | Every Session |

| Sharpen Cutting Tools | As Needed |

| Tighten Bolts | Monthly |

To make your taper turning equipment last, avoid pushing it too hard. Stay within limits, and give it a nice break after intense use. Even machines need a nap! Following these simple tips keeps your lathe purring like a kitten. And remember, regular TLC (that’s Tender Loving Care) means fewer repairs down the line!

Resources for Further Learning and Development

Recommended books and online courses. Workshops and community colleges offering handson training.Learning about metal lathes can be exciting! You can find great resources to help you. Here are some recommendations:

- Books: Look for books on metalworking. They often have pictures and step-by-step guides.

- Online Courses: Websites like Udemy and Coursera offer classes. You can learn at your own pace.

- Workshops: Check local community colleges. Many offer hands-on training for beginners.

These resources can build your skills and knowledge. Don’t hesitate to explore them!

What are some good resources for learning metal lathe skills?

Books and online courses are excellent for starting. Local workshops also provide hands-on experience.

Conclusion

In a lathe workshop setup, knowing how to use a metal lathe for taper turning is essential. We learned its importance for creating precise shapes. You can start by organizing your workspace and practicing safety measures. Try simple projects first to build your skills. For more tips and techniques, consider reading further about lathe operations to enhance your knowledge!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup For Taper Turning With A Metal Lathe:Sure! Here’s what you need to know about taper turning on a metal lathe. First, you must set up your lathe correctly. Make sure it’s steady and safe to use. Then, choose the right tools for taper turning. Finally, carefully measure angles to get the taper shape you want. Always remember to follow safety rules when working with machines!

Sure! Please provide the question you want me to answer.

What Are The Essential Tools And Accessories Needed For Setting Up A Metal Lathe For Taper Turning?To set up a metal lathe for taper turning, you’ll need a few important tools. First, get a taper attachment. This helps shape the metal at an angle. Next, use a cutting tool to trim the metal. You’ll also need a ruler or caliper to measure the angles. Don’t forget safety glasses to protect your eyes while you work!

How Do You Calculate The Taper Angle And Dimensions Required For A Specific Project When Using A Metal Lathe?To calculate the taper angle, you first need to measure the start and end diameters of your project. Then, you find the difference between these two sizes. Next, you can use a protractor to measure the angle between the two ends. Finally, you set your metal lathe to that angle and adjust the lengths to match your project. Make sure to double-check your measurements for accuracy!

What Is The Process For Aligning The Tailstock With The Headstock To Achieve Accurate Taper Turning Results?To align the tailstock with the headstock, first, check if they are both straight. You can use a long bar or rod. Place it between the two and see if it touches both ends evenly. If one side is higher, adjust the tailstock down or up until it matches. Then, test it again to make sure everything is straight and ready for taper turning.

What Are Some Common Techniques Used To Facilitate Taper Turning On A Metal Lathe, Such As Offset Tailstock Or Compound Slide Adjustments?To make a taper on a metal lathe, you can use a few simple ways. One method is to move the tailstock to one side. This helps create a slope on the metal. Another way is to adjust the slide that holds the cutting tool, called the compound slide. You can turn the compound slide at an angle to shape the metal as it spins.

How Can You Ensure The Safety Of Both The Operator And The Workspace During Taper Turning Operations On A Metal Lathe?To keep everyone safe during taper turning on a metal lathe, you should wear safety goggles to protect your eyes. Always keep your hands away from moving parts. Make sure the area is clean and free of tools or obstacles. Check that all guards are in place before you start. Lastly, never rush and always follow the machine’s safety rules.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workshop Setup For Taper Turning With A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s what you need to know about taper turning on a metal lathe. First, you must set up your lathe correctly. Make sure it’s steady and safe to use. Then, choose the right tools for taper turning. Finally, carefully measure angles to get the taper shape you want. Always remember to follow safety rules when working with machines!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Accessories Needed For Setting Up A Metal Lathe For Taper Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for taper turning, you’ll need a few important tools. First, get a taper attachment. This helps shape the metal at an angle. Next, use a cutting tool to trim the metal. You’ll also need a ruler or caliper to measure the angles. Don’t forget safety glasses to protect your eyes while you work!”}},{“@type”: “Question”,”name”: “How Do You Calculate The Taper Angle And Dimensions Required For A Specific Project When Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calculate the taper angle, you first need to measure the start and end diameters of your project. Then, you find the difference between these two sizes. Next, you can use a protractor to measure the angle between the two ends. Finally, you set your metal lathe to that angle and adjust the lengths to match your project. Make sure to double-check your measurements for accuracy!”}},{“@type”: “Question”,”name”: “What Is The Process For Aligning The Tailstock With The Headstock To Achieve Accurate Taper Turning Results?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock with the headstock, first, check if they are both straight. You can use a long bar or rod. Place it between the two and see if it touches both ends evenly. If one side is higher, adjust the tailstock down or up until it matches. Then, test it again to make sure everything is straight and ready for taper turning.”}},{“@type”: “Question”,”name”: “What Are Some Common Techniques Used To Facilitate Taper Turning On A Metal Lathe, Such As Offset Tailstock Or Compound Slide Adjustments?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a taper on a metal lathe, you can use a few simple ways. One method is to move the tailstock to one side. This helps create a slope on the metal. Another way is to adjust the slide that holds the cutting tool, called the compound slide. You can turn the compound slide at an angle to shape the metal as it spins.”}},{“@type”: “Question”,”name”: “How Can You Ensure The Safety Of Both The Operator And The Workspace During Taper Turning Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep everyone safe during taper turning on a metal lathe, you should wear safety goggles to protect your eyes. Always keep your hands away from moving parts. Make sure the area is clean and free of tools or obstacles. Check that all guards are in place before you start. Lastly, never rush and always follow the machine’s safety rules.”}}]}