Have you ever wondered how metal parts are made with perfect threads? A lathe workshop setup is the answer. In this setup, you’ll find a metal lathe, a machine that spins metal to shape it. But what happens when you want to cut threads? This magical process allows you to create strong, precise features on metal pieces.

Imagine building your own bicycle or crafting a cool robot. Thread cutting on a lathe lets you join parts together securely. It’s like connecting puzzle pieces that fit perfectly! Isn’t it exciting to think about the projects you could create?

Did you know that even simple items use threads? Think of screws, bolts, or even your favorite toys! Each relies on thread cutting for strength. Setting up your lathe workshop means you can dive into a world of creativity. Are you ready to explore this fascinating craft?

Lathe Workshop Setup: Mastering Metal Lathe Thread Cutting

Lathe Workshop Setup: Metal Lathe Thread Cutting

Setting up a metal lathe workshop for thread cutting is an exciting journey! You’ll learn the essential tools and steps to create precise threads. First, choose the right lathe and gear for your project. Understanding the basics of measurement and speed is crucial. Have you ever wondered how to cut fine threads just right? With practice, you can master this skill. Remember, safety is key. Keep your workspace organized for smoother operations. Embrace the art of thread cutting!Understanding Lathe Components and Their Functions

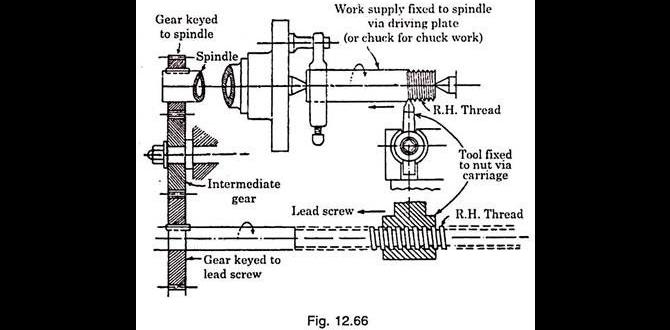

Detailed explanation of key lathe parts (headstock, tailstock, carriage). Role of each component in the thread cutting process.Understanding lathe parts is key for anyone using a metal lathe. Three main parts make up a lathe: the headstock, tailstock, and carriage. Each serves a special role, especially in thread cutting.

- Headstock: This is where the motor is found. It holds the spindle, rotating the workpiece.

- Tailstock: This part supports the other end of the workpiece. It can hold tools for drilling and cutting.

- Carriage: This moves along the bed. It controls tool movement over the workpiece during cutting.

When cutting threads, these parts work together. The headstock spins, while the carriage moves the cutting tool. The tailstock keeps everything steady. Knowing these parts makes lathe work smoother and more effective.

What are the key components of a lathe?

The key components of a lathe include the headstock, tailstock, and carriage. Each part contributes to the lathe’s ability to cut and shape metal effectively.

Workspace Organization for Optimal Efficiency

Tips for designing an efficient lathe workspace. Importance of safety measures in workspace setup.Keeping your lathe workspace neat is key for success. Start by arranging tools within arm’s reach. This saves time and makes work smoother. Use shelves and bins to organize parts. Don’t forget about safety! Wear goggles and keep the area clean. A clutter-free space helps prevent accidents. Here are some tips:

- Label drawers and containers.

- Maintain good lighting to see clearly.

- Store sharp tools safely.

Why is safety important in a lathe workshop?

Safety helps prevent injuries and accidents during metal lathe work. Proper setup and precautions create a safer environment for everyone. Always prioritize safety to enjoy your crafting!Setting Up Your Metal Lathe for Thread Cutting

Stepbystep guide on calibrating the lathe. Adjustments needed for different thread sizes and types.Calibrating your metal lathe for thread cutting may sound tricky, but it’s as easy as pie! First, check your machine’s alignment. Ensure it’s straight like a pencil. Next, set the threading dial according to your desired thread type. This dial works like magic but might just be a little finicky. For different threads, adjust the gears based on a handy guide like the one below:

| Thread Size | Gear Ratio |

|---|---|

| 1/4″ | 1:1 |

| 1/2″ | 2:1 |

| 3/4″ | 3:1 |

Remember, patience is key! Adjusting for thread sizes can feel like adapting your grandma’s famous cookie recipe. Too much flour? It crumbles! Not enough? It’s a gooey mess! Always refer to your lathe’s manual for best results, and don’t forget to wear safety goggles—your eyes are more precious than a shiny new lathe!

Techniques for Accurate Thread Cutting

Discussion of various thread cutting methods (chasing, singlepoint cutting). Best practices for achieving precision in threaded components.Thread cutting can be a bit tricky, but it’s also exciting! There are two popular methods: chasing and single-point cutting. Chasing is like threading a needle but with metal. You move the tool along the workpiece to create the thread. Single-point cutting is more like sculpting; you slowly carve out the thread shape. To be precise, always check your measurements and go slow. Remember, in the world of metal, precision is key—nobody wants a wobbly screw!

| Technique | Description | Best For |

|---|---|---|

| Chasing | Move the tool along the surface. | Quick threads |

| Single-point Cutting | Carve out threads carefully. | High precision |

Common Challenges in Thread Cutting and Solutions

Identification of frequent issues faced during thread cutting. Practical solutions and tips for overcoming obstacles.Thread cutting can be tricky! Many people face common problems like poor quality threads, uneven cuts, and tool wear. Luckily, there are ways to solve these issues and improve your work.

- Checking the tool sharpness: A dull tool can cause bad cuts.

- Correct speed and feed rate: Too fast or slow can harm your project.

- Using the right cutting fluid: This helps keep things cool and smooth.

- Proper setup: Ensure everything is aligned correctly.

By following these tips, you’ll cut threads like a pro in no time!

What are some tips for better thread cutting?

Practice using a slow feed rate and check your tools often. Keep your lathe clean and well-maintained. Good habits lead to great results!

Maintenance Tips for Longevity of Your Metal Lathe

Routine maintenance practices to keep the lathe in top condition. Importance of cleanliness and lubrication in thread cutting.Taking good care of your metal lathe is key to keeping it running smoothly. A few simple practices can make a big difference. Regularly clean the machine to keep dust and shavings from becoming its worst enemy. Also, lubrication is crucial for keeping those parts moving without a hitch—not unlike how we all need oil in our joints! Think of it as giving your lathe a spa day. Here’s a quick look at some essential maintenance tips:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Cleaning | After each use | Remove chips and debris to avoid damage. |

| Lubricating | Weekly | Apply oil to moving parts for smooth operation. |

| Checking Belts | Monthly | Inspect for wear and replace if needed. |

Remember, a happy lathe makes for happy threading! Keeping it clean and well-oiled can save you from costly repairs down the line.

Resources for Further Learning and Community Support

Listing of books, videos, and online courses for enhancing lathe skills. Connecting with forums and groups for tips and troubleshooting advice.Enhancing your lathe skills can be fun and exciting! There are many great resources to help you along the way. Check out books like “The Lathe Book” for step-by-step advice. YouTube is full of entertaining videos that show lathe techniques in action. Online platforms offer courses that can turn you into a lathe champ!

Don’t forget about connecting with others! Join forums and groups to share tips and troubleshoot issues. Having a community makes learning enjoyable. Who knows? You might even meet someone who thinks your lathe projects are cooler than a cat wearing sunglasses!

| Resource Type | Examples |

|---|---|

| Books | The Lathe Book, Metalworking for the Blind |

| Videos | YouTube lathe channels, Skillshare |

| Online Courses | Udemy, Coursera |

| Forums and Groups | Reddit, Facebook Groups |

In fact, many beginners find valuable help from friendly pros willing to share what they know. Remember, even the best lathe masters started as curious newbies! So dive into learning and let your creativity spin!

Conclusion

In summary, setting up a metal lathe workshop for thread cutting is exciting and rewarding. You need proper tools, a clean workspace, and careful planning. Always prioritize safety and practice regularly. As you gain experience, try more complex projects. Explore tutorials and books to deepen your skills. Enjoy the journey of mastering your lathe!FAQs

What Are The Essential Tools And Equipment Needed For Setting Up A Metal Lathe Workshop For Thread Cutting?To set up a metal lathe workshop for thread cutting, you need a few important tools. First, you’ll need a metal lathe, which spins metal to shape it. Next, get cutting tools that can slice through metal easily. You’ll also need a ruler or caliper to measure things accurately. Finally, don’t forget safety gear like goggles and gloves to protect yourself while working.

How Do You Properly Align And Calibrate A Metal Lathe For Accurate Thread Cutting Operations?To align and calibrate a metal lathe, first, make sure it’s level. Use a straight edge to check the bed and adjust legs as needed. Next, check the spindle’s alignment with the bed; it should be straight and true. You can measure it with a dial indicator. Finally, set the cutting tool properly and test on scrap material to ensure it cuts threads accurately.

What Safety Precautions Should Be Taken When Working With A Metal Lathe During Thread Cutting Processes?When using a metal lathe to cut threads, you should always wear safety goggles to protect your eyes. Make sure your hair and clothes are tucked away so they don’t get caught in the machine. Keep your hands away from moving parts and only use your tools when needed. Lastly, never rush; take your time to do it safely.

How Do You Determine The Correct Thread Pitch And Depth Settings For Different Materials When Using A Metal Lathe?To choose the right thread pitch, you first think about the material you’re using. Hard materials need finer threads, while softer ones can have coarser threads. Next, you set the depth by testing how deep the threads go into the material. You can start with a small depth and adjust as needed. Remember to measure carefully to make sure everything fits right!

What Are The Common Mistakes To Avoid While Cutting Threads On A Metal Lathe, And How Can They Be Prevented?When cutting threads on a metal lathe, you might make a few common mistakes. First, don’t rush; going too fast can ruin your work. Always check the machine settings before starting. Make sure your tool is sharp and in good condition. Finally, measure often to ensure your cuts are accurate. These tips will help you avoid problems and make better threads!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Tools And Equipment Needed For Setting Up A Metal Lathe Workshop For Thread Cutting? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe workshop for thread cutting, you need a few important tools. First, you’ll need a metal lathe, which spins metal to shape it. Next, get cutting tools that can slice through metal easily. You’ll also need a ruler or caliper to measure things accurately. Finally, don’t forget safety gear like goggles and gloves to protect yourself while working.”}},{“@type”: “Question”,”name”: “How Do You Properly Align And Calibrate A Metal Lathe For Accurate Thread Cutting Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and calibrate a metal lathe, first, make sure it’s level. Use a straight edge to check the bed and adjust legs as needed. Next, check the spindle’s alignment with the bed; it should be straight and true. You can measure it with a dial indicator. Finally, set the cutting tool properly and test on scrap material to ensure it cuts threads accurately.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Working With A Metal Lathe During Thread Cutting Processes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe to cut threads, you should always wear safety goggles to protect your eyes. Make sure your hair and clothes are tucked away so they don’t get caught in the machine. Keep your hands away from moving parts and only use your tools when needed. Lastly, never rush; take your time to do it safely.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Thread Pitch And Depth Settings For Different Materials When Using A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right thread pitch, you first think about the material you’re using. Hard materials need finer threads, while softer ones can have coarser threads. Next, you set the depth by testing how deep the threads go into the material. You can start with a small depth and adjust as needed. Remember to measure carefully to make sure everything fits right!”}},{“@type”: “Question”,”name”: “What Are The Common Mistakes To Avoid While Cutting Threads On A Metal Lathe, And How Can They Be Prevented? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When cutting threads on a metal lathe, you might make a few common mistakes. First, don’t rush; going too fast can ruin your work. Always check the machine settings before starting. Make sure your tool is sharp and in good condition. Finally, measure often to ensure your cuts are accurate. These tips will help you avoid problems and make better threads!”}}]}