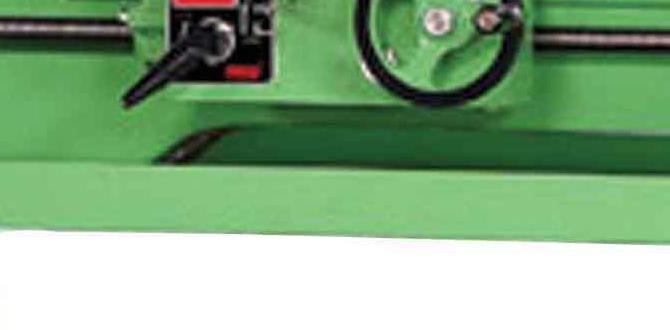

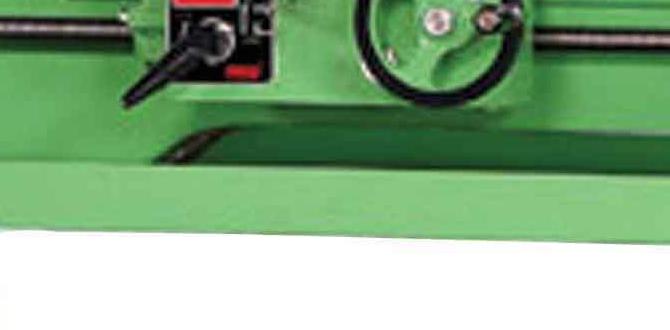

Imagine standing in a workshop filled with the sound of machines humming. The metal lathe gleams under the bright lights. Have you ever wondered how those precise threads are made? A lathe workshop setup is where creativity meets engineering. The threading dial on the lathe is a magical tool, allowing users to create beautiful patterns and forms.

Setting up a workshop to use a metal lathe can be exciting and rewarding. You can shape metal into whatever you imagine. It’s like turning your ideas into real objects! Did you know that the first lathes date back to ancient Egypt? They have come a long way since then.

In this article, we will explore how to set up a lathe workshop. We’ll dive into the details of the metal lathe and how to use the threading dial. Whether you’re a beginner or want to improve your skills, you’ll find something useful. Get ready to transform your workshop into a space of endless possibilities!

Lathe Workshop Setup: Essential Guide For Metal Lathe Threading Dial

Lathe Workshop Setup: Mastering Metal Lathe Threading Dial

Setting up a metal lathe can seem tricky, but it’s quite fun! A proper workshop setup is key for perfect threading. Having a good threading dial helps you measure threads accurately, which leads to better results. Did you know that a well-calibrated lathe can improve your workflow? Imagine creating precise parts for your projects! With the right tools and techniques, you can easily bring your metalworking dreams to life.Essential Tools and Accessories for Metal Lathe Setup

List of tools needed for a wellequipped lathe workshop. Importance of having a quality threading dial.A metal lathe workshop needs the right tools for success. Here’s a list of essential items:

- Metal lathe

- Threading dial

- Cutting tools

- Measuring tools

- Chucks and collets

- Workholding devices

- Safety gear

A quality threading dial is crucial for making precise threads. It helps you keep track of your measurements. With a good threading dial, your work will be more accurate and efficient. This leads to better results and a successful project.

What tools do I need for a lathe workshop?

You need a metal lathe, threading dial, measuring tools, and safety gear to set up a lathe workshop.

Preparing Your Workspace for Lathe Operations

Key considerations for optimizing workshop layout. Safety precautions to take in a lathe workshop.Arranging your lathe workshop well is important. A good layout helps you work better and stay safe. Keep tools within reach. Make sure to have enough space to move around. Good lighting is a must. It helps you see the details clearly.

- Keep the lathe away from walls.

- Provide a sturdy workbench nearby.

- Store materials and tools in organized bins.

Safety is key in a lathe workshop. Always wear protective gear like goggles and gloves. Keep the area tidy to avoid accidents. Make sure to unplug the lathe when not in use. Follow these tips to ensure a safe and efficient workspace.

What safety gear should I wear in the workshop?

Wear goggles, gloves, and ear protection to prevent injuries.

Steps to Set Up Your Metal Lathe

Detailed process of assembling and calibrating the lathe. Importance of level placement and securing the machine.Setting up your metal lathe is an exciting task! Follow these steps to assemble and calibrate it correctly. First, check the instructions in the manual. Next, ensure your lathe is placed on a flat surface. This is important because a level machine works better. Secure it tightly to prevent movement. After that, adjust the threading dial for accurate measurements. Make sure to test the lathe by running it at low speed before full use. This way, you’ll be ready to create amazing things!

Why is level placement important?

Level placement helps the lathe work smoothly. If it’s uneven, parts may wear down faster, and you could make mistakes. An unsteady lathe can also cause safety issues. Always take a moment to check!

Key Steps to Remember:

- Read the manual carefully.

- Place the lathe on a flat, stable surface.

- Secure the machine tightly.

- Adjust the threading dial for accuracy.

- Test the lathe at low speed before full use.

Threading Dial: Its Role and Importance in Lathe Work

Explanation of what a threading dial is and its primary functions. Best practices for using the threading dial for accuracy.A threading dial is like a little helper in your lathe workshop. It makes sure your threading is neat and tidy. This dial shows you where to start and stop cutting the threads. For accurate results, always line up the dial correctly with the marks on your lathe. It’s like playing a game of hide and seek — you want to find the right spot quickly! Remember, practice makes perfect, and having fun helps too!

| Best Practices | Description |

|---|---|

| Alignment | Ensure the threading dial is perfectly aligned with the lathe markings. |

| Steady Hands | Keep your hands steady for a smoother experience. |

| Patience | Take your time to get it right. Good things come to those who wait! |

Common Metal Lathe Projects for Beginners

Ideas for simple projects to practice with the lathe. Recommended materials for firsttime users.Starting with a metal lathe can be exciting! Begin with simple projects like wooden dowels or small knobs. These are easy and fun. Plus, they help you get a feel for the machine. For materials, choose soft woods or aluminum. They’re forgiving and won’t break the bank. Remember, even a pencil holder can become a masterpiece with a twist (and maybe a few giggles). Get creative; your lathe could be the next wizard behind your coolest crafts!

| Project Idea | Recommended Material |

|---|---|

| Wooden Dowel | Soft Wood |

| Knobs | Aluminum |

| Pencil Holder | Wood or Plastic |

Maintenance Tips for Longevity of Your Lathe

Routine maintenance tasks to keep your lathe in top shape. Signs that indicate when a lathe needs servicing.To keep your lathe running like a pro, stick to a simple maintenance routine. Check the oil levels often; a well-oiled lathe is a happy lathe! Look out for squeaks or strange noises; they might signal trouble ahead. If your lathe starts vibrating like it wants to dance, it’s time for a check-up. Remember, a little TLC goes a long way in stretching your lathe’s lifespan.

| Routine Checks | Signs of Trouble |

|---|---|

| Check oil levels | Squeaking sounds |

| Clean the components | Excessive vibration |

| Inspect belts and gears | Slower performance |

Resources for Advanced Lathe Techniques and Learning

Recommended books, videos, and online courses for further learning. Forums and communities where lathe enthusiasts share knowledge.If you want to improve your lathe skills, there are great resources to help you. Books and videos can show you advanced techniques. Try online courses for hands-on learning. You can also join forums where enthusiasts share tips and experiences. This builds your knowledge and connects you with others. Here are some recommendations:

- Books: “Metalworking for Beginners,” “Lathe Fundamentals”

- Videos: YouTube channels like “Machinist Workshop”

- Online Courses: Websites like Udemy and Coursera

- Forums: LatheTech Forums, Reddit’s r/Machinists

What are the best platforms for learning lathe techniques?

Some top platforms are YouTube for videos, Udemy for courses, and books for in-depth reading. These resources make learning fun and easy!

Frequently Asked Questions about Lathe Setup and Operation

Common queries beginners may have regarding lathe use. Troubleshooting tips for typical issues faced in metal lathing.Many new users have questions about using a lathe. Here are answers to common queries:

What are the basic steps to set up a lathe?

Start by leveling the lathe. Attach the power supply and check the alignment of the tailstock and headstock. Secure your workpiece in the chuck. Adjust the cutting tools as needed.

How can I fix problems while lathing?

Here are a few simple tips:

- If the lathe makes strange noises, check for loose parts.

- If the cutting tool is not sharp, sharpen or replace it.

- If the piece is vibrating, ensure it’s balanced properly.

Being aware of these solutions can save time and frustration. Remember, practice makes perfect! Happy lathing!

Conclusion

In summary, setting up a metal lathe workshop is exciting. A threading dial helps you make precise cuts. Remember to keep your tools organized and safe. You can start with small projects to practice your skills. Explore more resources and tutorials to deepen your knowledge. Let’s create something amazing together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Setting Up A Lathe Workshop With A Focus On A Metal Lathe’S Threading Dial:Sure! Setting up a lathe workshop is exciting. First, choose a good spot for your metal lathe. Make sure it’s on a strong table. The threading dial helps you create threads on metal. It shows you how far to move the tool when making those threads.

Sure! Just tell me the question you’d like me to answer, and I’ll be happy to help!

What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Assist In The Threading Process?A threading dial on a metal lathe helps you cut threads on a piece of metal. It shows you where to start and stop when you are making threads. This makes sure the threads are even and fit properly. Using the dial helps you line up everything perfectly for nice, clean threads. It makes the whole threading process easier and more accurate.

How Can You Properly Calibrate The Threading Dial On A Metal Lathe To Ensure Accurate Thread Dimensions?To calibrate the threading dial on a metal lathe, you first need to set the machine to a known position. Turn the lathe until the tool touches the starting point of the thread. Next, check the threading dial and make sure it reads zero. If it doesn’t, adjust it carefully until it does. Now, your threading dial is ready for precise work!

What Steps Should Be Taken To Set Up A Metal Lathe For Threading Operations, Including The Alignment Of The Threading Dial?To set up a metal lathe for threading, first, make sure the machine is clean and safe. Next, pick the right tool for the thread you want to make. Then, set the lathe’s speed to a low number. Now, to align the threading dial, turn the spindle by hand until the marker lines up with zero on the dial. Finally, you’re ready to start your threading work!

What Are The Common Mistakes To Avoid When Using The Threading Dial On A Metal Lathe During Thread Cutting?When using the threading dial on a metal lathe, you should avoid a few mistakes. First, don’t forget to stop the lathe before moving the tool. This helps prevent accidents. Second, always check the threading dial before you start cutting. Make sure it’s set to the right number. Lastly, don’t rush; take your time to ensure everything is lined up correctly.

How Does The Threading Dial Interact With The Lead Screw, And What Adjustments Can Be Made For Different Thread Pitches?The threading dial helps you cut threads on your project. It works with the lead screw, which moves the tool. When you turn the dial to a number, it tells the machine where to start. For different thread pitches, you can change the setting on the dial to match the size of the threads you want. This way, you get the right type of threads every time!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Setting Up A Lathe Workshop With A Focus On A Metal Lathe’S Threading Dial:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Setting up a lathe workshop is exciting. First, choose a good spot for your metal lathe. Make sure it’s on a strong table. The threading dial helps you create threads on metal. It shows you how far to move the tool when making those threads.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just tell me the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Assist In The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial on a metal lathe helps you cut threads on a piece of metal. It shows you where to start and stop when you are making threads. This makes sure the threads are even and fit properly. Using the dial helps you line up everything perfectly for nice, clean threads. It makes the whole threading process easier and more accurate.”}},{“@type”: “Question”,”name”: “How Can You Properly Calibrate The Threading Dial On A Metal Lathe To Ensure Accurate Thread Dimensions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the threading dial on a metal lathe, you first need to set the machine to a known position. Turn the lathe until the tool touches the starting point of the thread. Next, check the threading dial and make sure it reads zero. If it doesn’t, adjust it carefully until it does. Now, your threading dial is ready for precise work!”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Set Up A Metal Lathe For Threading Operations, Including The Alignment Of The Threading Dial?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for threading, first, make sure the machine is clean and safe. Next, pick the right tool for the thread you want to make. Then, set the lathe’s speed to a low number. Now, to align the threading dial, turn the spindle by hand until the marker lines up with zero on the dial. Finally, you’re ready to start your threading work!”}},{“@type”: “Question”,”name”: “What Are The Common Mistakes To Avoid When Using The Threading Dial On A Metal Lathe During Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the threading dial on a metal lathe, you should avoid a few mistakes. First, don’t forget to stop the lathe before moving the tool. This helps prevent accidents. Second, always check the threading dial before you start cutting. Make sure it’s set to the right number. Lastly, don’t rush; take your time to ensure everything is lined up correctly.”}},{“@type”: “Question”,”name”: “How Does The Threading Dial Interact With The Lead Screw, And What Adjustments Can Be Made For Different Thread Pitches?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you cut threads on your project. It works with the lead screw, which moves the tool. When you turn the dial to a number, it tells the machine where to start. For different thread pitches, you can change the setting on the dial to match the size of the threads you want. This way, you get the right type of threads every time!”}}]}