Have you ever dreamed of creating your own metal projects? Imagine crafting your own tools or parts right in your garage. A lathe workshop setup can make that dream a reality. One of the best tools for this is a mini metal lathe.

Mini metal lathes are perfect for beginners and experts alike. They can handle a variety of jobs. You can shape, cut, and polish metal with ease. Plus, setting up a workshop around one is fun and rewarding.

But where do you start? What tools do you need? The setup process might seem tricky, but it can be easy if you have a plan. Picture arranging your space so everything is within reach. Sounds good, right?

In this article, we will explore the essentials of a lathe workshop setup. Together, we’ll discover how to choose the right mini metal lathe for your needs. Get ready to turn metal into your next project!

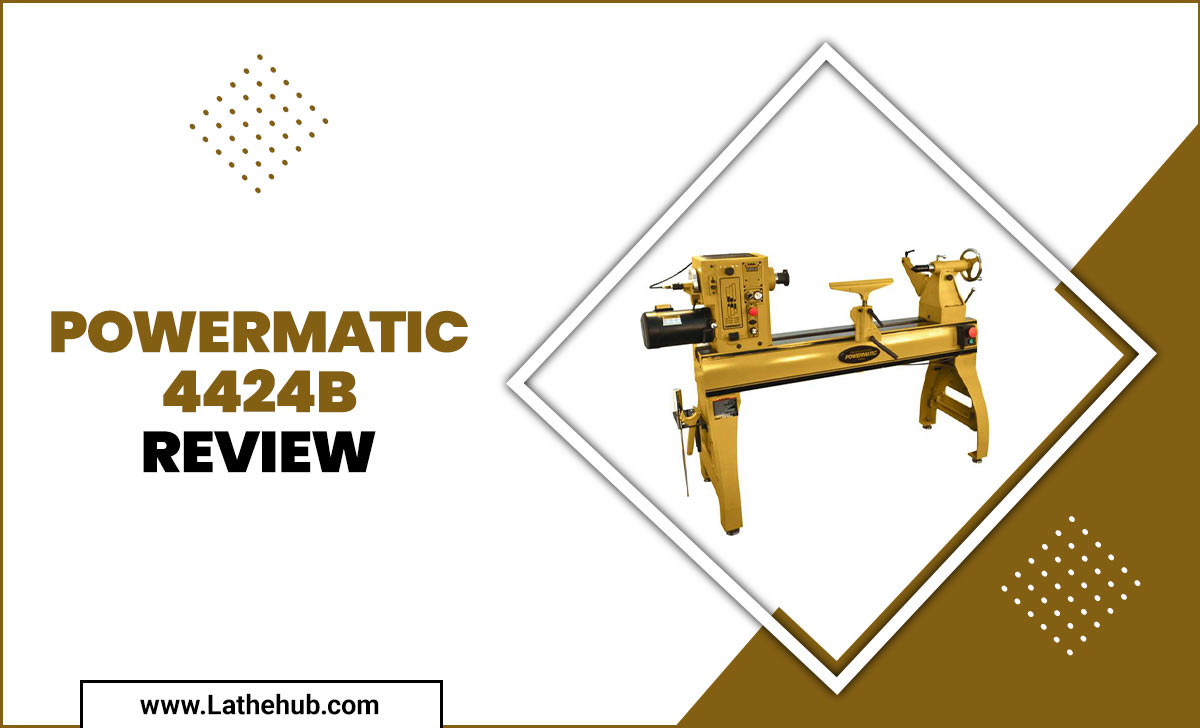

Essential Lathe Workshop Setup For Mini Metal Lathe

Lathe Workshop Setup for Mini Metal Lathes

Setting up a lathe workshop for mini metal lathes can be exciting. You learn about choosing the right tools, organizing your space, and safety measures. A well-designed setup boosts productivity and creativity. Did you know that even small lathes can handle intricate projects? By understanding how to maintain these machines, you ensure they last longer. Every step counts – from lighting to tool storage. Ready to transform your workshop into a maker’s paradise?Understanding Mini Metal Lathes

Definition and purpose of a mini metal lathe. Key features and functionalities.A mini metal lathe is a small, powerful machine. It shapes metal by spinning the material against a tool. This machine is used for making precise parts for various projects. Some key features include:

- Versatility: Capable of turning, drilling, and cutting.

- Size: Compact and easy to fit in small workspaces.

- Precision: Allows accurate measurements for detailed work.

These features make mini metal lathes popular among hobbyists and professionals alike!

What is the main use of a mini metal lathe?

The main use of a mini metal lathe is to create metal parts with great accuracy. This tool helps in various tasks, from crafting models to repairing machinery.

How does a mini metal lathe work?

A mini metal lathe works by holding the metal piece in place. As the piece spins, a cutting tool shapes it into the desired form.

Essential Tools and Equipment

List of necessary tools for mini lathe operation. Recommended safety equipment for beginners.Starting with a mini lathe is exciting! To work safely and effectively, you need the right tools. Here’s a list of essential tools for your lathe workshop setup mini metal lathe:

- Cutting tools

- Chucks

- Tool holders

- Measuring tape

- Calipers

Don’t forget about safety. Here are some recommended safety items:

- Safety goggles

- Dust mask

- Gloves

Using the right tools keeps you safe. It also makes your work easier and more fun!

What tools do you need for a mini lathe?

You need basic tools like cutting tools, chucks, and measuring devices. These help you create great projects!

Choosing the Right Location for Your Workshop

Factors to consider when selecting a workshop space. Importance of proper ventilation and lighting.Finding the perfect spot for your workshop can be a game-changer! Consider a space that is not too noisy or crowded. Noise can distract you from your masterpiece, and we don’t want to accidentally turn our sweet lathe into a drum kit! Good ventilation is a must; without it, you may feel woozy from all those metal shavings flying about. Lighting is crucial too; bright lights keep your eyes safe and help you see those tiny details. Remember, in the world of metal, it’s “shine bright or go home!”

| Factor | Importance |

|---|---|

| Location | Less noise and distraction |

| Ventilation | Prevents fume buildup and keeps air fresh |

| Lighting | Helps see details clearly |

Setting Up Your Mini Metal Lathe

Stepbystep guide to positioning and securing your lathe. Tips for optimizing workspace layout.First, choose a sturdy table or workbench. Your lathe will wobble like a dancer on a tightrope if it’s not secure! Next, make sure to leave enough room on all sides for easy movement. Then, level your lathe with a trusty bubble level. This keeps your workspace balanced, and nobody likes wonky crafts! Here’s a quick tip for optimizing your layout:

| Tip | Description |

|---|---|

| Keep it tidy! | Organize tools within reach. It saves time and keeps projects flowing smoothly. |

| Stay away from clutter! | A clean workspace is a happy workspace. No one wants to trip over a rogue wrench! |

Finally, add good lighting! No one wants to squint while crafting. Bright light makes everything easier, and you can even pretend to be a professional at work.

Power Supply and Electrical Considerations

Recommended electrical requirements for mini lathes. Safety measures for electrical setups.When setting up your mini lathe, choose the right power supply. Most mini lathes need between 110 to 220 volts for safe operation. It’s important to have dedicated circuits to prevent overloads. Always check the user manual for specific needs. Safety is key! Make sure your workspace has proper grounding. Use circuit breakers to protect from surges. Inspect cords for damage often. Lastly, do not use damaged plugs or extension cords to keep everyone safe.

What are the electrical requirements for mini lathes?

Mini lathes typically require 110 to 220 volts, depending on the model.Safety measures include:

- Using circuit breakers.

- Checking for ground connections.

- Inspecting cords regularly.

Maintenance and Care for Longevity

Routine maintenance tasks to keep your lathe in optimal condition. Troubleshooting common problems.Taking care of your lathe is important. Regular checks keep it running well. Here are some simple maintenance tasks:

- Clean the lathe after each use.

- Check oil levels and refill if needed.

- Tighten loose screws and bolts.

Sometimes, problems can happen. If the lathe makes strange noises, it might need oil. Poor cuts mean the tool needs sharpening. Fixing these issues early can save time and money.

What are some common problems with mini metal lathe?

Common problems include vibration issues, poor accuracy, and unusual sounds. Regular maintenance helps prevent these problems.

Resources for Further Learning

Online courses and tutorials for beginners. Recommended books and manuals for advanced techniques.Learning about mini metal lathes can be fun and exciting! There are many resources to help you grow your skills. Online courses can teach you the basics in a simple way. Look for videos or tutorials that focus on lathes. Books and manuals are great for advanced techniques. They can guide you through complex projects. Here are some helpful resources:

- Online Courses: Check platforms like Udemy or Coursera.

- YouTube Tutorials: Search for beginner-friendly videos on lathes.

- Books: “The Lathe Book” by Ernie Conover is recommended.

- Manuals: Look for guides specific to your lathe model.

What online resources can help with lathe techniques?

Online courses and YouTube videos can help you learn lathe techniques.These tools make learning easy and fun. Each resource offers something different. Use them to explore your interests in the lathe workshop setup.

Community and Support Networks

Benefits of joining lathe workshops or forums. Finding local maker spaces and groups for networking.Joining lathe workshops or forums can be a great way to learn and connect with others. You will discover new skills and improve your craft. Many workshops offer hands-on experience and tips from experts. Engaging with a community can boost your confidence and creativity. Local maker spaces are also helpful. You can find new friends who share your interests. Networking is fun and leads to exciting projects.

What are the benefits of joining lathe workshops?

Joining lathe workshops helps you learn, meet new people, and grow your skills.

Benefits of Joining Workshops:

- Learn from experts

- Share ideas and projects

- Gain valuable experience

- Build friendships

- Access new tools

Conclusion

In summary, setting up a mini metal lathe workshop is exciting and rewarding. You’ll need essential tools and a safe space. Keep your area organized and plan your projects carefully. Don’t forget to practice good safety habits. Now that you know the basics, dive into more resources or start your first project. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Setting Up A Mini Metal Lathe Workshop:Sure! Here are some questions about setting up a mini metal lathe workshop: 1. What do we need to start a mini metal lathe workshop? 2. How do you choose the right metal lathe? 3. What safety gear should you wear when using a lathe? 4. How do we organize our tools in the workshop? 5. What materials can we work with on a mini metal lathe?

Sure! Please provide the question you want me to answer.

What Are The Essential Tools And Equipment Needed For Setting Up A Mini Metal Lathe Workshop?To set up a mini metal lathe workshop, you need a few important tools. First, you need a mini metal lathe itself. Next, grab some cutting tools to help shape the metal. You’ll also need a drill, a measuring tape, and a caliper for accuracy. Don’t forget safety gear, like goggles and gloves, to protect yourself while working!

How Do You Select An Appropriate Workspace For A Mini Metal Lathe, Considering Factors Like Ventilation And Power Supply?To pick a good spot for a mini metal lathe, first, find a well-ventilated area. This means there should be good airflow to keep things safe. Next, make sure you have enough power outlets nearby for the lathe to work. Finally, choose a sturdy table that can hold the lathe steady while you use it.

What Safety Measures Should Be Implemented When Preparing A Workshop For Mini Metal Lathe Operations?When you prepare for mini metal lathe work, safety is very important. First, wear safety goggles to protect your eyes. Second, keep your hair tied back and wear tight clothes to avoid getting caught in the machine. We should also keep the area clean and tidy. Finally, make sure to know how to use the lathe properly before starting.

How Can You Effectively Organize And Store Lathe Accessories, Tools, And Materials In A Small Workshop Space?To organize your lathe accessories and tools, use shelves and bins. You can label each bin so you know what’s inside. Hang tools on the wall using hooks or pegboards. Keep your workspace tidy by putting things back after you use them. This way, everything is easy to find and use!

What Are Some Common Troubleshooting Tips For Setting Up And Maintaining A Mini Metal Lathe?To set up your mini metal lathe, first, make sure it’s on a sturdy table. Check that all parts are tight and secure. If it makes strange noises, look for loose parts or debris. Always keep it clean; wipe away metal shavings after each use. If something isn’t working right, refer to the manual to find solutions.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Setting Up A Mini Metal Lathe Workshop:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about setting up a mini metal lathe workshop: 1. What do we need to start a mini metal lathe workshop? 2. How do you choose the right metal lathe? 3. What safety gear should you wear when using a lathe? 4. How do we organize our tools in the workshop? 5. What materials can we work with on a mini metal lathe?”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Equipment Needed For Setting Up A Mini Metal Lathe Workshop?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a mini metal lathe workshop, you need a few important tools. First, you need a mini metal lathe itself. Next, grab some cutting tools to help shape the metal. You’ll also need a drill, a measuring tape, and a caliper for accuracy. Don’t forget safety gear, like goggles and gloves, to protect yourself while working!”}},{“@type”: “Question”,”name”: “How Do You Select An Appropriate Workspace For A Mini Metal Lathe, Considering Factors Like Ventilation And Power Supply?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To pick a good spot for a mini metal lathe, first, find a well-ventilated area. This means there should be good airflow to keep things safe. Next, make sure you have enough power outlets nearby for the lathe to work. Finally, choose a sturdy table that can hold the lathe steady while you use it.”}},{“@type”: “Question”,”name”: “What Safety Measures Should Be Implemented When Preparing A Workshop For Mini Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you prepare for mini metal lathe work, safety is very important. First, wear safety goggles to protect your eyes. Second, keep your hair tied back and wear tight clothes to avoid getting caught in the machine. We should also keep the area clean and tidy. Finally, make sure to know how to use the lathe properly before starting.”}},{“@type”: “Question”,”name”: “How Can You Effectively Organize And Store Lathe Accessories, Tools, And Materials In A Small Workshop Space?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To organize your lathe accessories and tools, use shelves and bins. You can label each bin so you know what’s inside. Hang tools on the wall using hooks or pegboards. Keep your workspace tidy by putting things back after you use them. This way, everything is easy to find and use!”}},{“@type”: “Question”,”name”: “What Are Some Common Troubleshooting Tips For Setting Up And Maintaining A Mini Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up your mini metal lathe, first, make sure it’s on a sturdy table. Check that all parts are tight and secure. If it makes strange noises, look for loose parts or debris. Always keep it clean; wipe away metal shavings after each use. If something isn’t working right, refer to the manual to find solutions.”}}]}