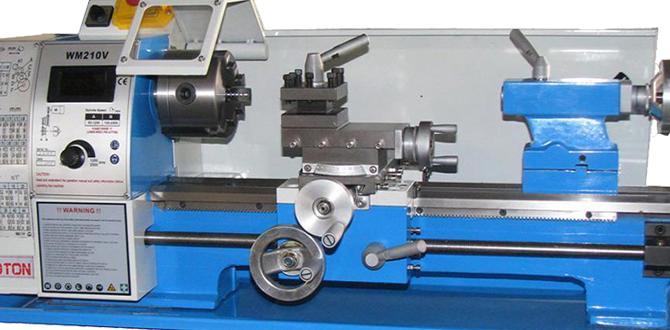

Have you ever seen a metal lathe in action? These machines create amazing shapes from metal. But just like any tool, they need proper care to work well. That’s where our maintenance guide for the metal lathe bench comes in.

Taking care of your metal lathe is not just for experts. Even beginners can learn how to keep their machines in great shape. Imagine your lathe breaking down just as you’re finishing a project. How frustrating would that be!

In this article, we will explore easy steps for cleaning and maintaining your metal lathe. We will share tips that can help you avoid problems and extend the life of your machine. Ready to dive in and learn more about the proper maintenance of your metal lathe bench? Let’s get started!

Essential Maintenance Guide For Metal Lathe Bench Operation

Maintenance Guide for Metal Lathe Bench

Keeping a metal lathe bench in top shape is essential for smooth operation. Regular cleaning and lubrication help prevent wear and tear. Did you know that just a few minutes of maintenance can extend the life of your lathe? Check belts and screws often to avoid costly repairs. Use the right tools and techniques for quick fixes. Following a solid maintenance guide ensures your projects run smoothly and safely. Ready to keep your lathe in perfect condition?Routine Maintenance Checks

Checklist for daily and weekly inspections. Signs of wear and tear to watch for.Regular checks are key to keeping your metal lathe in top shape. Make a checklist for daily and weekly inspections. Check for signs of wear, like strange noises or loose parts. Smaller problems can turn into big ones if ignored.

- Daily: Inspect the belts and lubrication points.

- Weekly: Look for rust and clean the machine.

- Watch for unusual vibrations or smells.

With these simple steps, your lathe will run smoothly. Consistent care keeps it safe and effective. Remember, a well-maintained machine helps you work better!

What should I check daily on my metal lathe?

You should check the belts, lubrication points, and look for any loose bolts or parts. Regular checks help catch problems early.

What are signs of wear and tear on a metal lathe?

Signs include strange noises, unusual vibrations, or loose parts. Staying aware can save you time and money in repairs.

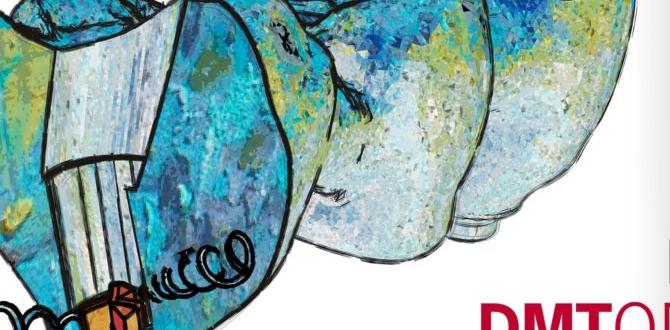

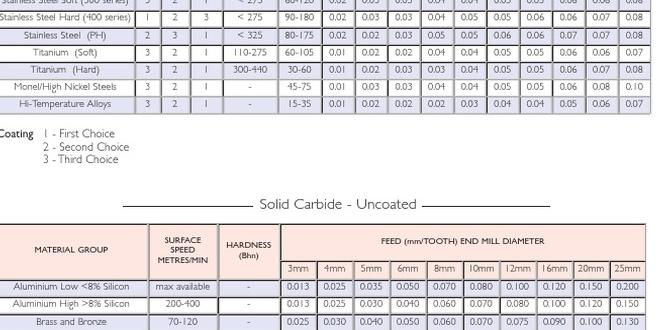

Cleansing and Lubrication Protocols

Best practices for cleaning metal lathe surfaces. Recommended lubricants and their application techniques.Keeping your metal lathe clean is like giving it a warm hug! Start with a soft brush to sweep away dust and filings. Follow that with a gentle wipe using a lint-free cloth—think of it as a spa day for your machine. Now, for lubrication, apply the right oils to keep everything running smoothly. Use light machine oil or way oil in tight spots where parts meet. Just a few drops will do, like adding seasoning to your favorite dish!

| Lubricant Type | Application Method |

|---|---|

| Light Machine Oil | Drop on moving parts |

| Way Oil | Apply generously on slideways |

| Sewing Machine Oil | Use sparingly for fine details |

Don’t forget, a happy lathe makes for happy projects! Treat it well, and it will reward you with precision and smooth operation.

Calibration and Alignment Techniques

Stepbystep guide to calibrating the lathe. Methods for ensuring precision and accuracy in alignment.To keep your lathe working well, follow these steps for calibration and alignment. First, check your machine’s level using a spirit level. Adjust as needed to ensure it sits straight. Next, use a dial gauge to measure the alignment between the chuck and tailstock. Lastly, make minor adjustments to get everything perfectly lined up. Precision is key for good work!

How important is calibration in a metal lathe?

Calibration is crucial for accuracy. It prevents mistakes and ensures your projects are precise. Even small errors can lead to big problems. So, always check and calibrate your lathe often!

Quick tips for alignment:

- Use a level to check flatness.

- Measure with a dial gauge for accuracy.

- Adjust until everything lines up well.

Common Issues and Troubleshooting

Identification of typical problems faced by metal lathe users. Troubleshooting methods and quick fixes for issues.Every metal lathe user faces challenges now and then. Common issues include slipping belts, uneven cuts, and noisy operations. If your lathe sounds like a grumpy old man, it might be time for a checkup! Quick fixes can often save the day. Ensure everything is tightened, adjust the feed rate, or simply clean the machine. To make troubleshooting easier, here’s a handy table:

| Problem | Quick Fix |

|---|---|

| Slipping belt | Tighten or replace the belt |

| Uneven cuts | Check alignment and adjust tools |

| Noisy operation | Lubricate moving parts |

Keep these tips in mind to keep your metal lathe happy and humming along!

Long-Term Care Tips

Strategies for extending the lifespan of your metal lathe. Importance of proper storage and environmental considerations.Taking care of your metal lathe is key for it to last longer. To keep it running smoothly, always clean it after use. Dust and chips can be its worst enemy! Store it in a dry place to prevent rust. A little oil goes a long way in keeping parts moving freely. Avoid leaving it in damp areas. Also, try to give it a cozy cover when not in use—like a blanket for your machine! It might not need warmth, but it sure likes a good shield from dust!

| Tip | Description |

|---|---|

| Regular Cleaning | Clean after each use to avoid buildup. |

| Dry Storage | Keep it in a dry area to prevent rust. |

| Lubrication | Use oil to keep moving parts functioning. |

| Protective Cover | A cover keeps dust and debris away. |

Use these simple strategies, and your lathe will be happy for years. Remember, a little care today means a lot less trouble tomorrow!

Upgrading and Modifying Your Metal Lathe

Potential upgrades to enhance performance. Considerations before modifying existing equipment.Upgrading your metal lathe can greatly improve its performance. Think about adding features like a digital readout or better cutting tools. These upgrades can make your work easier and more precise. But before making changes, consider the following:

- Will this upgrade fit my current lathe?

- Is it worth the cost?

- Do I have the skills to install it myself?

Making smart upgrades can lead to better results. Always weigh your options before modifying equipment. This way, you can enjoy a more efficient workspace!

What upgrades can I consider for my metal lathe?

Some upgrades include improved cutting tools, digital readouts, and better motors. These can enhance accuracy and ease of use.

Resources for Further Learning

Recommended books, videos, and forums for metal lathe enthusiasts. Information on professional maintenance services and training opportunities.If you want to get better at using metal lathes, there are many helpful resources available. Here are a few to check out:

- Books: Look for titles like “Lathe Work: A Complete Guide” or “The Metal Lathe” for practical tips.

- Videos: YouTube has many channels that show metal lathe techniques and repairs.

- Forums: Join online groups like the Metalworking Stack Exchange to share tips and ask questions.

- Professional Services: Sometimes, you may need expert help for maintenance. Look up local machinists.

- Training Opportunities: Consider taking a workshop at a community college or local makerspace.

Keep exploring, and you will become a skilled metal lathe enthusiast!

What are some good books about metal lathes?

Check out “Lathe Work: A Complete Guide” for great tips. Another good book is “The Metal Lathe.” They can help you learn a lot!

Conclusion

In summary, a maintenance guide for your metal lathe bench helps keep it in top shape. Regular checks can prevent bigger problems. Always clean and lubricate your lathe to ensure it runs smoothly. If you want to learn more, check out detailed manuals or videos online. Taking care of your equipment now will make your work easier and more enjoyable later!FAQs

What Are The Essential Cleaning Steps To Maintain A Metal Lathe Bench For Optimal Performance?To keep a metal lathe bench clean and working well, you should follow these steps. First, wipe off any dirt and oil with a cloth. Next, check for any chips or small pieces of metal and clean those up. You should also make sure that all tools are in their right places. Finally, inspect the lathe for any dust or rust and clean that too.

How Can Regular Inspection Of The Lathe Bench Components Prevent Wear And Tear?Regularly checking the lathe bench parts helps us find problems early. When we spot issues like loose screws or dirt, we can fix them before they cause bigger damage. This way, we keep everything running smoothly. It also saves us money on repairs later. Taking a few minutes to inspect can make our tools last much longer.

What Types Of Lubricants Are Recommended For Maintaining A Metal Lathe Bench?To keep a metal lathe bench working well, you can use a few different types of lubricants. One good choice is machine oil, which helps keep metal parts moving smoothly. You can also use grease for areas that need a thicker coating. Remember to apply these lubricants regularly to prevent rust and wear. Always follow the instructions on the lubricant’s container for the best results.

What Should Be Checked Regularly To Ensure The Alignment And Accuracy Of The Metal Lathe Bench?To keep your metal lathe bench working well, you should check a few things regularly. First, look at the level of the bench to make sure it’s even. Next, check the cutting tool alignment to ensure it’s straight. You should also inspect the belts and gears for any wear or damage. Finally, keep the area clean to avoid any problems while you work.

How Can I Identify And Address Common Issues That Arise With A Metal Lathe Bench Over Time?To spot common issues with a metal lathe bench, you should check for rust, loose parts, and strange noises. Look closely at all the pieces and tighten anything that feels wobbly. Clean the surfaces to remove any dirt or grease. If you hear odd sounds, stop using it and find out what’s wrong. Regular checks help keep your lathe working well!