Have you ever wondered how to keep your metal lathe running smoothly? A well-maintained lathe can make all the difference in your projects. It can help you create precise parts and save you time.

Using a quick change tool post is a great way to save time when working on your lathe. But did you know that proper maintenance is key for this tool? Without good care, your lathe could face problems that make it less effective.

Imagine working on an important project only to find that your tools aren’t working as they should. Frustrating, right? Regularly maintaining your metal lathe and its quick change tool post can prevent this type of trouble. It keeps everything in top shape and ready for action.

Join us as we explore the maintenance guide for your metal lathe. You’ll learn easy tips to keep your quick change tool post working efficiently. Let’s dive into the world of lathes and discover how simple maintenance can lead to great results!

Maintenance Guide: Metal Lathe Quick Change Tool Post

Maintenance Guide for Metal Lathe Quick Change Tool Post

Keeping your metal lathe quick change tool post in good shape is vital for smooth operation. Regular cleaning and lubrication can greatly extend its life. Did you know that improper care can lead to costly repairs? Check for wear and tear regularly. Adjustments might be necessary to ensure precise cuts. Using the right tools makes a big difference, too. With proper maintenance, you can enjoy your lathe for years to come!Understanding Quick Change Tool Posts

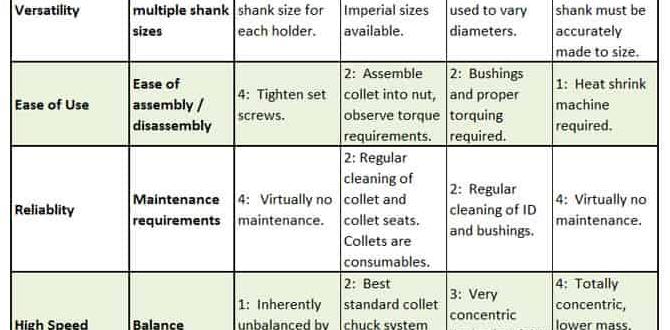

Definition and advantages of quick change tool posts. Common types of quick change tool posts used in metal lathes.Quick change tool posts make metal lathes easier to use. They allow quick tool swaps with minimal effort. This saves time and increases efficiency. A few advantages include:

- Speed — Changing tools is faster.

- Ease — Users can quickly adjust tools without hassle.

- Accuracy — Consistent tool alignment makes work precise.

There are several common types of quick change tool posts:

- Eeney-style: Simple and quick.

- Aloris-style: Offers great versatility.

- KO Lee: Known for durability.

These tools help make working with lathes fun and efficient!

What are the main benefits of quick change tool posts?

Quick change tool posts save time, increase efficiency, and enhance accuracy.

Key Features:

- Faster tool changes

- Easy adjustments

- Improved precision

Routine Maintenance Practices

Daily maintenance tasks to ensure smooth operation. Weekly and monthly maintenance recommendations.Taking care of your metal lathe is key for smooth work. Each day, clean the tool post and check for loose bolts. This ensures everything runs well. Weekly, look for wear and tear. Lubricate moving parts to keep them from rusting. Monthly, inspect safety features like the emergency stop.

- Daily: Clean and check bolts

- Weekly: Check for wear and lubricate

- Monthly: Inspect safety features

Why Maintenance Matters?

Regular maintenance prevents breakdowns and extends your metal lathe’s life. Just like caring for a pet, your tools need attention to stay happy and healthy! Did you know that machines last 20% longer with proper care?

Lubrication Techniques

Best lubricants for quick change tool posts. How and when to apply lubrication.Choosing the right lubricant is key for your quick change tool post. Use light machine oil for smooth movement. It keeps parts from wearing down. Apply it after every few uses, or whenever you notice stiffness. It’s easy! Here’s how:

- Clean the tool post with a cloth.

- Apply a few drops of oil to the moving parts.

- Wipe off any excess oil.

Regular lubrication helps your tool post last longer. Remember, a little maintenance goes a long way!

What are the best lubricants for quick change tool posts?

The best lubricants include light machine oil and silicone spray. Both keep your tools working smoothly and provide excellent protection.

Troubleshooting Common Issues

Identifying signs of wear and damage. Stepbystep troubleshooting process for common malfunctions.Every metal lathe needs a check-up now and then. Spotting wear or damage is like playing detective. Look for rust, broken parts, or leaks; they’re clues that something’s not right. Finding these issues early can save you time and money! Try this simple troubleshooting checklist:

| Issue | Solution |

|---|---|

| Strange noises | Check for loose screws or parts. |

| Inaccurate cuts | Inspect tool alignment and sharpness. |

| Tool post movement | Lubricate and tighten all fasteners. |

Following these steps can turn your lathe from moody to magnificent. Remember, a happy lathe means smoother projects!

Upgrading Your Quick Change Tool Post

Benefits of upgrading to a more advanced system. Recommended upgrades and modifications.Upgrading your tool post can boost your metal lathe’s magic. An advanced quick change tool post saves time and makes switching tools easier. Imagine changing tools faster than a magician pulls rabbits from hats! Recommended upgrades may include adding a locking mechanism for better stability and using high-quality tool holders for precision. Each enhancement can make your work smoother and more enjoyable.

| Upgrade | Benefit |

|---|---|

| Locking Mechanism | Improved stability |

| High-Quality Tool Holders | Better precision |

| Swivel Base | Easier angle adjustments |

With these upgrades, your lathe can go from good to *lathe-tastic*! Happy turning!

Maintenance Tools and Supplies

Essential tools for maintaining quick change tool posts. Additional supplies for effective maintenance.Keeping your quick change tool post in good shape requires some basic tools and supplies. Here are essential items for maintenance:

- Wrenches: Use these to tighten or loosen parts easily.

- Screwdrivers: Helpful for doing small fixes.

- Cleaning Brushes: Keep the tool post clear of debris.

- Lubricants: Use oil to keep moving parts smooth.

With the right tools, maintenance becomes quick and easy. Regular check-ups will help your lathe last longer, saving you time and money.

What tools do I need for metal lathe maintenance?

You need wrenches, screwdrivers, cleaning brushes, and lubricants. These tools help keep your lathe running well.

Safety Considerations

Safety protocols during maintenance procedures. Importance of wearing protective gear.Always follow safety rules when working with a metal lathe. This helps prevent accidents. Wear protective gear like gloves, goggles, and earplugs. The right gear can keep you safe from flying debris and loud noises. Be careful when changing tools during maintenance, as sharp edges can hurt you. Keep your workspace clean to avoid slips and falls. It’s smart to double-check that your lathe is powered off before starting repairs.

What should I wear for safety during maintenance?

Wear protective gear such as:

- Safety goggles to protect your eyes.

- Gloves to shield your hands from cuts.

- Earplugs to guard against loud sounds.

FAQs About Quick Change Tool Post Maintenance

Commonly asked questions and expert answers. Tips for beginners and experienced lathe users.Wondering about how to keep your quick change tool post in top shape? You’re not alone! Here are some questions beginners and pros often ask:

| Question | Answer |

|---|---|

| How often should I clean it? | After every use, or it might start feeling grumpy! |

| What’s the best way to lubricate it? | A few drops of light oil work wonders! |

| Should I check for wear and tear? | Absolutely! Regular check-ups keep it feeling young! |

Staying on top of these simple tips can make your lathe life so much easier! Plus, a happy tool post means happy turning. Who knew maintenance could be so much fun?

Conclusion

In summary, a maintenance guide for your metal lathe’s quick change tool post helps keep everything running smoothly. Regular checks prevent problems and extend your tool’s life. You can clean, oil, and adjust parts easily. We encourage you to follow the guide for the best results. Explore more resources to improve your skills and enjoy your lathe even more!FAQs

What Are The Common Signs Of Wear Or Damage On A Quick Change Tool Post That Indicate It Needs Maintenance Or Replacement?You can spot problems on a quick change tool post by looking for a few signs. Check for cracks or breaks in the metal. If the tool post feels loose or wobbly, it may need fixing. You might also see rust or corrosion. If these signs are there, it’s time for maintenance or replacement.

How Can I Properly Clean And Lubricate The Components Of A Metal Lathe’S Quick Change Tool Post?To clean your metal lathe’s quick change tool post, first turn off the machine and unplug it. Use a soft brush or cloth to remove dirt and chips. Then, wipe the parts with a clean, dry cloth. For lubrication, apply a light oil to the moving parts. Be careful not to use too much oil; a little goes a long way!

What Tools And Supplies Are Necessary For Performing Routine Maintenance On A Quick Change Tool Post?To take care of a quick change tool post, we need a few important tools and supplies. You should have a wrench to tighten bolts. A screwdriver is also helpful for adjusting parts. Don’t forget some oil to keep everything running smoothly. A clean cloth will help wipe away dirt and dust.

How Do I Adjust The Alignment And Tension Of A Quick Change Tool Post To Ensure Optimal Performance?To adjust the alignment of a quick change tool post, first check if it’s sitting straight on the lathe. You can loosen the screws, then gently move it until it lines up correctly. For tension, tighten the locking screws just enough so the tool post doesn’t wobble. Make sure the tools stay secure while you work. Always test it by turning the lathe on and watching how it works!

What Are The Best Practices For Troubleshooting Issues With A Quick Change Tool Post, Such As Tool Slippage Or Difficulty In Tool Changes?To fix problems with a quick change tool post, first check the tool holder. Make sure it’s clean and tight. If the tool slips, tighten the screws better. You can also look for wear and tear on the parts. If you still have trouble, ask for help or watch a video for tips.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Damage On A Quick Change Tool Post That Indicate It Needs Maintenance Or Replacement? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot problems on a quick change tool post by looking for a few signs. Check for cracks or breaks in the metal. If the tool post feels loose or wobbly, it may need fixing. You might also see rust or corrosion. If these signs are there, it’s time for maintenance or replacement.”}},{“@type”: “Question”,”name”: “How Can I Properly Clean And Lubricate The Components Of A Metal Lathe’S Quick Change Tool Post? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean your metal lathe’s quick change tool post, first turn off the machine and unplug it. Use a soft brush or cloth to remove dirt and chips. Then, wipe the parts with a clean, dry cloth. For lubrication, apply a light oil to the moving parts. Be careful not to use too much oil; a little goes a long way!”}},{“@type”: “Question”,”name”: “What Tools And Supplies Are Necessary For Performing Routine Maintenance On A Quick Change Tool Post? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of a quick change tool post, we need a few important tools and supplies. You should have a wrench to tighten bolts. A screwdriver is also helpful for adjusting parts. Don’t forget some oil to keep everything running smoothly. A clean cloth will help wipe away dirt and dust.”}},{“@type”: “Question”,”name”: “How Do I Adjust The Alignment And Tension Of A Quick Change Tool Post To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the alignment of a quick change tool post, first check if it’s sitting straight on the lathe. You can loosen the screws, then gently move it until it lines up correctly. For tension, tighten the locking screws just enough so the tool post doesn’t wobble. Make sure the tools stay secure while you work. Always test it by turning the lathe on and watching how it works!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Troubleshooting Issues With A Quick Change Tool Post, Such As Tool Slippage Or Difficulty In Tool Changes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with a quick change tool post, first check the tool holder. Make sure it’s clean and tight. If the tool slips, tighten the screws better. You can also look for wear and tear on the parts. If you still have trouble, ask for help or watch a video for tips.”}}]}