Have you ever watched a craftsman skillfully shape metal? It’s like watching magic unfold. A manual metal lathe is a fascinating tool that can turn simple metal pieces into amazing shapes. But did you know that many people are now looking at how to make this process easier and faster? That’s where manual metal lathe automation comes into play.

Imagine a machine that can do the hard work for you. With automation, you can save time and effort. This means less sweating over the lathe and more time for creativity. Imagine not having to stand by the machine for hours. Instead, you could set it up and let it work while you tackle other projects.

Curious about how this automation can change the game for metalworking? Whether you’re a hobbyist or a pro, understanding manual metal lathe automation is key. It opens up new doors to making your work more efficient and exciting!

Manual Metal Lathe Automation: Revolutionizing Machining Techniques

Understanding Manual Metal Lathe Automation

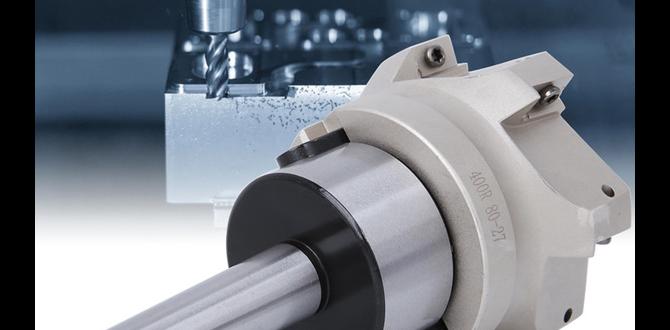

Automation enhances manual metal lathes, making them more efficient and precise. Have you ever wondered how machines can produce parts so accurately? With automation, these lathes can run longer without human help. They reduce errors and speed up production. This means better quality parts in less time. Imagine a factory where machines work tirelessly, while workers focus on bigger tasks. That’s the power of manual metal lathe automation!Understanding Manual Metal Lathes

Definition and basic components of manual metal lathes. Common applications and industries using manual lathes.A manual metal lathe is a machine used to shape metal pieces. It works by rotating the metal while cutting tools carve out the desired shape. The main parts of a manual lathe include the bed, headstock, tailstock, and carriage. They work together like a well-coordinated dance team!

Manual lathes are popular in many industries, from car repair shops to craft workshops. They help make everything from gears to sculptures. Did you know that manual lathes have been around for centuries? They’re like the grandpas of machining! The following table shows some common applications and industries that rely on manual lathes:

| Application | Industry |

|---|---|

| Gears and Axles | Automotive |

| Custom Parts | Manufacturing |

| Artistic Sculptures | Art and Craft |

So, next time you see a shiny metal part, remember that a manual lathe might have helped create it!

The Need for Automation in Metal Lathing

Challenges faced with manual operation. Benefits of integrating automation systems in machining.Working with manual metal lathes can be tough. Operators face challenges like slow speeds and high errors. Mistakes can waste materials and time. Automation helps solve these problems. With machines doing the work, processes become faster and more precise. Benefits include:

- Improved speed and efficiency

- Less waste of materials

- Higher accuracy in production

- Fewer chances of human error

Integrating automation systems into metal lathing can make work easier and safer. This is important for better results!

What are the key benefits of automation in metal lathing?

Automation means better efficiency and accuracy. Machines can work faster, reducing delays. They also cut down on mistakes, saving materials and costs.

Key Technologies Driving Automation in Manual Lathes

Sensors and IoT integration in manufacturing. Software solutions for monitoring and process control.In the world of manual lathes, exciting technologies are shaking things up! First up, sensors and IoT integration make machines smarter and safer. These sensors can detect problems before they turn into disasters. Imagine your lathe warning you, “Hey, something’s off!” Next, software solutions step in. They monitor every move, like a personal coach for your lathe! This process control software keeps everything running smoothly, ensuring quality without the confusing jargon. With these tools, automation becomes as easy as pie. Just don’t try to eat that pie near the lathe!

| Technology | Role |

|---|---|

| Sensors | Detect issues in real-time |

| IoT | Connects machines for better communication |

| Software Solutions | Monitors and controls processes |

Cost vs. Benefits: Evaluating Automation Investment

Initial investment costs associated with automation. Longterm savings and productivity improvements.Investing in automation can seem pricey at first. You may face initial costs for equipment and setup. But think about the long-term rewards. Automation often leads to big savings on labor and time. It also helps factories work faster and produce more. Here are some points to consider:

- Initial Costs: High at the start.

- Long-Term Savings: Less labor needed, lower costs over time.

- Productivity Improvements: More items made in less time.

In the end, many see that the benefits of automation greatly outweigh the costs.

What is the main advantage of automating a manual metal lathe?

The main advantage is increased productivity. Automating a manual metal lathe allows for faster and more precise work. This means you make more products in less time, which can lead to higher profits.

Case Studies: Successful Automation Implementations

Example of a small business benefiting from lathe automation. Largescale production facility automating their metal lathe processes.Imagine a small business that uses a manual metal lathe. This shop automated its processes to save time and money. They saw a huge jump in productivity. Now, they complete tasks faster and with less waste. This change helped them grow and hire more workers.

In a large production facility, automation made a big difference too. They improved efficiency with new technology. Here are some results:

- 20% more production

- 15% less material waste

- Average project time cut in half

Automation brought these companies success and gave them a brighter future.

How does automation help businesses?

Automation helps businesses save time and costs, allowing them to produce more items faster and with better quality.

Common Challenges and Solutions in Automating Manual Lathes

Technical difficulties in retrofitting manual machines. Workforce training and skill development for automation.Automating manual lathes can be tricky. Many face technical difficulties when adding new gadgets to old machines. It often feels like fitting a puzzle piece that doesn’t quite match. Also, workers need proper training to handle new tools. Without this, mistakes can happen, which makes the process frustrating. Companies should invest time in training programs to ensure everyone feels confident and capable.

What are common challenges in automating manual lathes?

Some challenges include compatibility of machines and the need for worker training. Fitting old machines with new tech can be tough, and workers might not know how to use it.

Here are a few key challenges:

- Technical issues with retrofitting machines.

- Need for skilled training programs.

- High initial costs for automation tools.

Statistics show that about 70% of companies face problems with automation due to lack of skill development. Addressing these challenges can lead to a smoother transition and better results.

The Future of Manual Metal Lathe Automation

Trends in smart machining and Industry 4.0. Predictions for the evolution of manual lathes in automated environments.Smart machining is changing how we use manual lathes. With trends like Industry 4.0, machines will connect more with each other. This will help them work smarter and faster. Soon, we might see lathes that adjust on their own. They will learn from mistakes and improve each time they work. What can we expect in the future? Here are some thoughts:

- More automated features for less manual work

- Higher efficiency due to real-time data

- Safer work environments with reduced human error

This shift to automation will make metal lathes even more important in factories.

How will manual lathes evolve?

Experts believe that in the next few years, manual lathes will become more automated. They will use smart technology to improve production. Automation can help save time and reduce errors.

Conclusion

In summary, manual metal lathe automation improves efficiency and precision in machining. You can save time and reduce errors with these tools. We’ve learned that combining technology with traditional methods brings better results. Explore more about lathe automation to enhance your projects. Don’t hesitate to dive deeper into this exciting field! Your creations can become even better with automation tools.FAQs

What Are The Key Components Of A Manual Metal Lathe That Can Be Automated To Improve Efficiency And Precision In Machining Processes?You can make a manual metal lathe better by automating a few key parts. First, you can use a machine to move the tool automatically. This helps make cuts faster and more even. Next, a digital display shows you exactly how much to move, so it’s more accurate. Finally, adding a tool changer saves time when you need different tools for different jobs.

How Can The Integration Of Cnc Technology Enhance The Capabilities Of A Manual Metal Lathe While Maintaining The Option For Manual Operation?Integrating CNC technology into a manual metal lathe means we get the best of both worlds. You can use the computer to help make precise cuts and shapes. This saves time and makes your work easier. Yet, you still have the choice to operate the lathe manually. This way, you can enjoy the fun of hands-on work when you want to!

What Are The Cost Implications And Potential Return On Investment When Automating A Manual Metal Lathe For Small-Scale Production?Automating a manual metal lathe can cost a lot at first. You might need to buy new machines and tools. However, once it’s set up, it can help you make items faster and with fewer mistakes. This means you can sell more products and earn more money over time. So, even if it costs a lot at the start, you could make that money back and even more later on.

What Safety Considerations Should Be Taken Into Account When Implementing Automation On Manual Lathes?When using automation on manual lathes, we must think about safety first. Always wear safety glasses to protect your eyes. Keep hands and clothes away from moving parts to avoid getting caught. Make sure the area is clear of people when the machine is running. Finally, check for proper shut-off switches in case something goes wrong.

How Can Sensors And Feedback Systems Be Utilized To Monitor The Performance And Maintenance Needs Of An Automated Manual Metal Lathe?You can use sensors on the metal lathe to check its movements and temperature. These sensors send information to a computer. The computer tells you if something is wrong or if the machine needs fixing. This helps you keep the lathe working well and safe for everyone. Regular reminders from the system can help you remember to check or clean the machine, too.