Have you ever watched a metal lathe at work? It’s like magic! A manual metal lathe bench is not just a tool; it’s an entire world of creativity and precision. Imagine shaping metal with your own hands. That’s what this amazing machine allows you to do.

Did you know that metal lathes have been around for centuries? They started in ancient Egypt and are still essential today. Picture yourself learning this age-old craft! With a manual metal lathe bench, you can transform simple metal rods into stunning creations.

Many people feel surprised when they see the complex shapes a lathe can produce. From beautiful bowls to intricate tools, the possibilities are endless. Why not learn how to use one yourself? You might discover a new passion or hobby along the way!

So, are you ready to dive into the world of metalworking? Let’s explore how a manual metal lathe bench can help unleash your creativity!

Manual Metal Lathe Bench: Essential Features And Benefits

Exploring the Manual Metal Lathe Bench

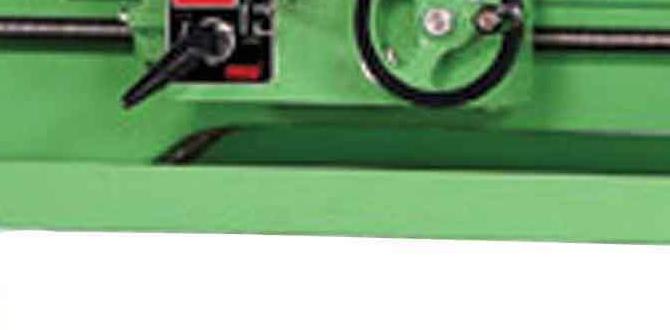

A manual metal lathe bench is an essential tool for many DIY enthusiasts and professionals. It helps shape and cut metal with precision. Imagine turning a simple metal rod into a beautiful chair leg! The lathe operates by rotating the metal, allowing users to create unique designs easily. Fun fact: Lathes have been around since ancient Egypt! Knowing how to use a manual metal lathe bench opens up a world of creative possibilities in metalworking.What is a Manual Metal Lathe Bench?

Definition and purpose of a manual metal lathe bench. Key components and features.A manual metal lathe bench is like a wizard’s table for metal work. It spins metal to shape it into amazing objects, like pots, gears, or perhaps a shiny sword for a costume party! Key parts include the lathe itself, which does the spinning, and the tool rest that holds cutters. Together, they help create precise designs. With a sturdy frame and smooth operation, it’s a favorite for hobbyists and pros alike!

| Component | Purpose |

|---|---|

| Lathe | Spins metal for shaping |

| Tool Rest | Holds cutting tools steady |

| Base | Supports everything and keeps it sturdy |

Benefits of Using a Manual Metal Lathe Bench

Precision and control in metalworking. Costeffectiveness compared to CNC lathes.Using a manual metal lathe bench gives you super precision and control. You can shape metal pieces exactly how you want them. It’s like having a magic wand for metal! Plus, it’s cheaper than fancy CNC lathes. While CNC machines are great, they can empty your wallet faster than a candy thief on Halloween. So, if you’re a budget-conscious maker, this is a win-win!

| Feature | Manual Metal Lathe | CNC Lathe |

|---|---|---|

| Cost | Lower | Higher |

| Control | High | Medium |

| Precision | Excellent | Very Good |

Choosing the Right Manual Metal Lathe Bench

Factors to consider: size, power requirements, and capabilities. Popular brands and models to look for.Choosing a manual metal lathe bench needs careful thought. Size matters; bigger lathes can handle larger projects. Think about power requirements; some need more energy than others. Lastly, consider capabilities; do you need it for basic tasks or advanced jobs? Popular brands like Grizzly, Jet, and Shop Fox offer reliable options. Check out models like the Grizzly G0602 or Jet JWL-1442 to find what suits you best.

What factors should I consider when buying a manual metal lathe bench?

Important factors include:

- Size: Make sure it fits your workspace.

- Power: Know how much energy is needed.

- Capabilities: Decide what tasks you will do.

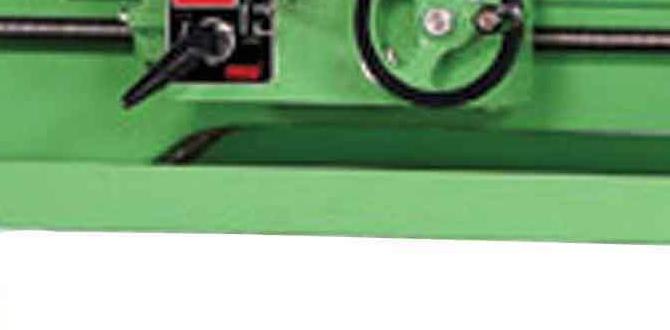

Setting Up Your Manual Metal Lathe Bench

Stepbystep guide to proper installation and configuration. Safety precautions to observe during setup.To set up your manual metal lathe bench, follow these steps carefully. Start by placing the lathe on a sturdy, level surface. Make sure it’s fixed securely to avoid movement. Then, connect the necessary electrical components. Check that all safety guards are in place. Always wear safety goggles and gloves during setup. Also, keep the area clean to avoid accidents. Following these steps helps ensure a safe workspace for your projects.

What are some safety precautions during setup?

Always wear protective gear, keep tools away from the lathe, and ensure proper ventilation.Key Safety Tips:

- Wear safety goggles

- Use gloves

- Keep the workspace tidy

- Ensure good lighting

- Secure loose clothing

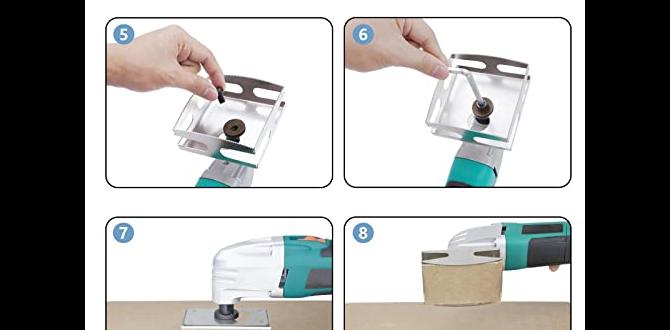

Common Techniques and Projects for Manual Metal Lathes

Examples of basic projects for beginners. Techniques for advanced metalworking.A manual metal lathe bench offers a great way to explore metalworking. Beginners can start with simple projects like making spindles, candle holders, or tool handles. These projects help build basic skills.

Advanced users can try more challenging techniques, such as:

- Creating complex gears

- Turning shafts

- Milling intricate designs

These projects improve precision and enhance creativity. Did you know that many expert metalworkers started with simple projects? They turned their hobbies into successful careers!

What kind of projects can beginners do with a manual metal lathe?

Beginners can make spindles, candle holders, and simple tools. These projects are simple and help build confidence!

What techniques should advanced metalworkers use?

Advanced metalworkers can focus on creating gears, turning shafts, and milling intricate patterns. These techniques require skill and practice!

Maintenance Tips for Long-Lasting Performance

Routine maintenance tasks to ensure optimal functioning. Signs of wear and when to seek repairs.Taking care of your manual metal lathe bench is very important. Regular maintenance keeps it working well. Here are some simple tasks to do:

- Clean the machine after use.

- Lubricate moving parts regularly.

- Check belts and blades for damage.

Look for signs of wear, like strange noises or parts that do not move smoothly. If you notice these signs, it’s time to seek repairs. This way, your lathe will last longer and stay in great shape!

What are the signs that your manual metal lathe bench needs repairs?

Watch for unusual sounds, vibrations, or difficulties in operation.

Frequently Asked Questions about Manual Metal Lathe Benches

Common queries and expert answers. Troubleshooting tips for users.People often have many questions about using a manual metal lathe bench. Here are some common queries with helpful answers:

How can I fix common problems?

Here are a few tips for troubleshooting:

- Check for loose parts. Tighten everything before starting.

- Ensure the blade is sharp. A dull blade can ruin your work.

- Inspect the power source. Confirm it’s connected properly.

What if it vibrates too much?

Balance the lathe better. Sometimes, adding weight helps it run smoother.

How can I avoid mistakes?

Always measure twice. This helps catch errors before cutting.

Conclusion

In conclusion, a manual metal lathe bench is an essential tool for precision work. It helps you shape metal accurately and is great for DIY projects. You can create useful items and improve your skills. We encourage you to explore tutorials online or visit a workshop. Try using a lathe to gain hands-on experience and unleash your creativity!FAQs

What Are The Essential Features And Components Of A Manual Metal Lathe Bench Setup?A manual metal lathe bench setup has a few important parts. First, you need the lathe itself. It helps shape metal into different forms. You also need a sturdy bench to put it on. Other tools you might use include cutting tools and a chuck, which holds the metal in place. Don’t forget safety gear, like goggles, to protect your eyes!

How Do You Properly Maintain And Lubricate A Manual Metal Lathe To Ensure Optimal Performance?To take care of a manual metal lathe, you should clean it regularly. Use a soft cloth to wipe off dust and chips. Check the oil levels often and add new oil to moving parts. Lubricate the gears and ways with the right oil to help it run smoothly. Finally, always follow the instruction manual for the best tips!

What Safety Precautions Should Be Taken When Using A Manual Metal Lathe Bench?When using a manual metal lathe bench, always wear safety glasses to protect your eyes. Keep your hair tied back and wear snug clothes to avoid getting caught in the machine. Make sure your hands are clear of the moving parts. Never distract someone while they are using the lathe. Finally, check that all tools are in good shape and that the area is clean and organized.

What Types Of Materials Can Be Effectively Machined Using A Manual Metal Lathe?You can use a manual metal lathe to machine different materials. Some good examples are metals like aluminum, brass, and steel. You can also work with softer materials, like plastic and wood. These materials can be shaped and cut easily with the lathe. It helps create parts and tools for many projects.

How Does The Setup And Operation Of A Manual Metal Lathe Compare To That Of A Cnc Lathe?A manual metal lathe is like a simple machine that you control by hand. You move the tools and workpieces yourself. A CNC lathe, which stands for Computer Numerical Control lathe, uses a computer to do the work for you. You just set it up and press a button. This makes CNC lathes faster and more precise, while manual lathes let you feel the work more closely.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Features And Components Of A Manual Metal Lathe Bench Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A manual metal lathe bench setup has a few important parts. First, you need the lathe itself. It helps shape metal into different forms. You also need a sturdy bench to put it on. Other tools you might use include cutting tools and a chuck, which holds the metal in place. Don’t forget safety gear, like goggles, to protect your eyes!”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Lubricate A Manual Metal Lathe To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of a manual metal lathe, you should clean it regularly. Use a soft cloth to wipe off dust and chips. Check the oil levels often and add new oil to moving parts. Lubricate the gears and ways with the right oil to help it run smoothly. Finally, always follow the instruction manual for the best tips!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Manual Metal Lathe Bench? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a manual metal lathe bench, always wear safety glasses to protect your eyes. Keep your hair tied back and wear snug clothes to avoid getting caught in the machine. Make sure your hands are clear of the moving parts. Never distract someone while they are using the lathe. Finally, check that all tools are in good shape and that the area is clean and organized.”}},{“@type”: “Question”,”name”: “What Types Of Materials Can Be Effectively Machined Using A Manual Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a manual metal lathe to machine different materials. Some good examples are metals like aluminum, brass, and steel. You can also work with softer materials, like plastic and wood. These materials can be shaped and cut easily with the lathe. It helps create parts and tools for many projects.”}},{“@type”: “Question”,”name”: “How Does The Setup And Operation Of A Manual Metal Lathe Compare To That Of A Cnc Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A manual metal lathe is like a simple machine that you control by hand. You move the tools and workpieces yourself. A CNC lathe, which stands for Computer Numerical Control lathe, uses a computer to do the work for you. You just set it up and press a button. This makes CNC lathes faster and more precise, while manual lathes let you feel the work more closely.”}}]}