Understanding The Manual Metal Lathe Drive System: Components & Benefits

Manual Metal Lathe Drive System

A manual metal lathe drive system is crucial for shaping metal. It transforms the machine’s power into motion. Without it, cutting and shaping become difficult. Did you know that the drive system can impact the lathe’s speed and precision? Understanding how it works helps users achieve better results. By exploring gears, belts, and pulleys, operators can enhance their crafting skills. This knowledge makes metalworking not just easier, but also more enjoyable.Advantages of Manual Metal Lathe Drive Systems

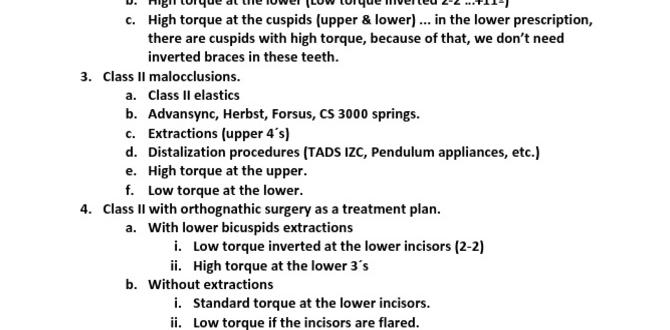

Benefits of precision control in machining. Costeffectiveness of manual lathes.Using a manual metal lathe drive system offers many benefits. First, precision control is key in machining. This means operators can create exact shapes and sizes. It’s great for making parts that fit perfectly. Second, manual lathes are cost-effective tools. They are usually cheaper than automatic machines. This helps shops save money and invest in other important tools.

What are the advantages of precision control and cost-effectiveness?

Precision control offers better accuracy. This makes a big difference in quality. Cost-effectiveness means less spending on machines. This helps small businesses thrive.

- Higher quality products

- Less waste of materials

- Lower costs for equipment

Common Components of Drive Systems

Description of motors used in manual metal lathes. Role of pulleys and belts in power transmission.Every manual metal lathe needs a motor to spin the workpiece. These motors come in different sizes and powers, helping the lathe do its job like a pro! The magic happens through pulleys and belts. They work together to transfer power from the motor to the lathe’s spindle, making things smooth and speedy! Without them, it would be like trying to drive a car with no wheels—no fun at all!

| Component | Description |

|---|---|

| Motor | Generates power to spin the lathe. |

| Pulleys | Helps change direction and speed of the motor power. |

| Belts | Transmits power between the motor and the spindle. |

Maintenance Tips for Manual Metal Lathe Drive Systems

Routine inspections and lubrication practices. Common issues and troubleshooting tips.Keeping your manual metal lathe working smoothly is like caring for a pet—routine checks are essential! Start by inspecting belts and gears for wear and tear. Don’t forget to oil those squeaky parts; they need love too! If your lathe makes odd noises, it might be time to investigate. Sometimes, dirt is the main culprit. Check the table for levelness; a wobble can turn the best projects into quirky art pieces! Here’s a handy table for quick fixes:

| Issue | Solution |

|---|---|

| Squeaking Sounds | Lubricate the drive system. |

| Inconsistent Speed | Check for worn belts and adjust. |

| Table Wobbling | Level the table and tighten bolts. |

Remember, a little maintenance goes a long way—no one wants a grumpy lathe! Stay sharp and keep those metal chips dancing.

Choosing the Right Manual Metal Lathe Drive System

Factors to consider when selecting a drive system. Recommendations for different types of machining tasks.When picking a manual metal lathe drive system, consider these important factors:

- Power requirements: Know how much power you need for your projects.

- Speed settings: Select a system with adjustable speeds for different tasks.

- Durability: Ensure the drive system can handle the workload.

- Maintenance: Look for systems that are easy to maintain.

For simple tasks, a basic drive system may work well. However, more complex projects might need advanced features. Always match the drive system to your specific machining goals.

What factors influence the choice of a manual metal lathe drive system?

Power, speed, durability, and maintenance are key factors.

Recommendations based on tasks:

- For small woodturning projects, a low-power system is ideal.

- For metalworking, choose a high-speed, robust drive.

Impact of Drive System Design on Lathe Performance

How drive system design affects machining accuracy. Influence of drive system on material handling and productivity.The design of a drive system plays a key role in how well a lathe works. Good design helps improve machining accuracy. This means parts are made to fit better. It also affects how materials are handled. A strong drive system boosts productivity, making the work faster and easier. Here are important effects:

- Better precision makes parts fit correctly.

- Efficient material movement saves time.

- Less downtime means more work gets done.

How does the drive system improve lathe work?

The drive system can enhance lathe performance. It helps in making precise cuts and handling materials swiftly. Some designs can increase output by up to 30%, making lathes more efficient and useful.

Future Trends in Manual Metal Lathe Drive Systems

Emerging technologies in drive systems. Predictions for automation and control in manual lathes.The future looks bright for manual metal lathe drive systems. New technologies are emerging to improve them. We can expect more automation and better control methods. These changes will make lathes easier to use and more efficient. Here are some trends to watch:

- Smart sensors for real-time feedback

- Enhanced user interfaces for better control

- Integration with advanced manufacturing systems

Experts predict that these advancements could lead to a significant boost in productivity, making tasks simpler for workers. In the end, this means more precision and less waste.

What is the impact of automation on manual lathes?

Automation will increase efficiency and accuracy in manual lathes, allowing operators to produce high-quality parts with less effort.

Conclusion

In summary, a manual metal lathe drive system is essential for shaping metal parts. You should understand how these systems work for better projects. They use belts and gears for power, giving you control over speed and precision. To improve your skills, explore hands-on practice or tutorials online. Happy machining, and keep learning about this exciting field!FAQs

Sure! Here Are Five Related Questions On The Topic Of Manual Metal Lathe Drive Systems:Sure! Here are five related questions on manual metal lathe drive systems: 1. What is a manual metal lathe? A manual metal lathe is a machine that shapes metal. You can spin the metal and cut it to make different shapes. 2. How does the drive system work? The drive system makes the lathe turn. It uses a motor and belts to move the metal piece quickly. 3. Why do we use a lathe? We use a lathe to create parts for machines. It helps us make things like wheels or rods that need to be precise. 4. What is the difference between manual and automatic lathes? Manual lathes need a person to control them, while automatic lathes can run on their own with less help. 5. How can you stay safe while using a lathe? You should always wear safety goggles and keep your hands away from moving parts. Be careful and ask for help if needed!

Sure! Just ask me your question and I’ll be happy to help.

What Are The Different Types Of Drive Systems Commonly Used In Manual Metal Lathes, And How Do They Differ In Operation?Manual metal lathes have a few types of drive systems. One type is belt drive, where a belt turns the machine. It’s smooth and easy to use. Another type is gear drive, which uses gears to make the machine turn. Gear drives can provide more power but may make more noise. Each type works differently, but they all help the lathe shape metal.

How Does The Power Transmission System Of A Manual Lathe Affect Its Cutting Performance And Precision?The power transmission system of a manual lathe sends energy from the motor to the cutting tool. If it works well, the lathe cuts smoothly and accurately. If it has problems, the cutting can be rough or imprecise. This means you need a good power system to make sure your work looks nice and is just right.

What Maintenance Practices Are Essential For Ensuring The Longevity And Efficiency Of A Manual Metal Lathe Drive System?To keep a manual metal lathe running well, you should do regular checks. First, clean it often to remove dust and metal shavings. Next, oil the moving parts to keep everything smooth. You should also check the belts and change them if they’re worn out. Finally, always tighten loose screws to avoid any surprises!

How Can The Speed And Torque Of A Manual Lathe Be Adjusted, And What Impact Does This Have On The Machining Process?You can adjust the speed of a manual lathe using knobs or levers. Changing the speed helps make the cut smoother or faster. Torque helps in cutting harder materials. If you have more torque, it can handle tougher jobs better. Adjusting these settings helps you make better shapes and sizes from your materials.

What Role Do V-Belts And Pulleys Play In The Drive System Of A Manual Lathe, And How Can They Affect Vibration And Noise Levels During Operation?V-belts and pulleys help turn the machine parts of a manual lathe. They connect the motor to the lathe, making it work. If the V-belts are worn out or loose, they can shake and make noise. This can cause the lathe to vibrate more, which isn’t good for the work you’re doing. Keeping them in good shape helps the lathe run smoothly and quietly.