Have you ever wondered how objects are made with such precision? A manual metal lathe pulley plays a big role in that process. Imagine a workshop filled with machines whirring and spinning. Each piece of metal gets shaped just right, thanks to the pulley.

In many workshops, the manual metal lathe pulley is a hero. It helps connect parts of the lathe, making it possible to turn metal into incredible shapes. This simple yet powerful tool might not seem like much, but without it, machining would be much harder.

Did you know that before electric lathes, workers relied on muscle power? Using a manual metal lathe pulley, they turned pieces of metal using their own strength. It’s amazing how much has changed but how much remains the same.

Next time you see a metal object, think about the machine that helped create it. The manual metal lathe pulley is key to that process. Let’s dive deeper into how this simple tool makes a big difference in machining!

Manual Metal Lathe Pulley: Essential Components Explained

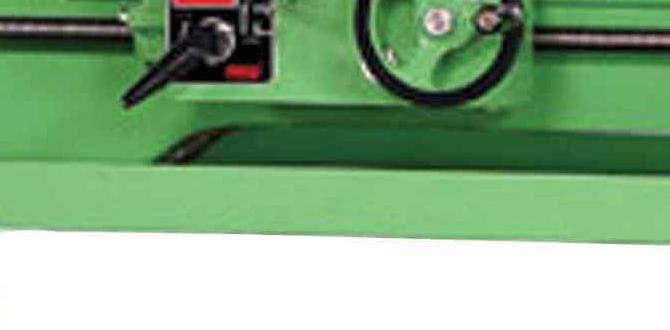

Manual Metal Lathe Pulley

A manual metal lathe pulley plays a crucial role in shaping metal. Have you ever wondered how metal gets shaped into useful tools? The pulley system helps control the lathe’s speed, making it easier for users to create precise parts. With various sizes and functions, these pulleys ensure smooth operation. Imagine creating your own metal masterpieces! Understanding manual metal lathe pulleys not only enhances your skills but also opens a world of creative possibilities.What is a Manual Metal Lathe Pulley?

Definition and purpose of lathe pulleys. Importance in the operation of manual metal lathes.A manual metal lathe pulley is a key part of a lathe machine. It helps manage the speed of the spinning metal. The pulley connects the motor to the spindle. This connection is vital for smooth operation and shaping metal parts. Pulleys allow for different cutting speeds. This is important for various projects. Proper use of a pulley can lead to better results and safer working conditions.

Why Are Pulleys Important?

Pulleys help control the movements of a lathe. This is crucial for precision work. A well-functioning pulley system ensures:

- Efficient power transfer

- Correct rotational speed

- Reduced wear and tear on parts

Types of Manual Metal Lathe Pulleys

Different designs and configurations. Comparison of fixed vs. variable speed pulleys.Manual metal lathe pulleys come in two main designs: fixed and variable speed. Each type serves different purposes. Fixed pulleys maintain a constant speed, while variable speed pulleys allow speed adjustments. This flexibility helps in precise machining tasks.

- Fixed Pulleys: Simple design, steady speed.

- Variable Speed Pulleys: Adjustable speed, more versatile.

Choosing the right one depends on whether you need speed control or a steady pace. For many tasks, variable speed offers more benefits, giving you control over your work.

What are the advantages of variable speed pulleys?

Variable speed pulleys allow for better precision and flexibility in machining. You can easily adjust the speed based on the material you’re working with, making it easier to achieve the desired results.

Benefits of Using Pulley Systems in Lathes

Enhanced control over spindle speed. Increased efficiency in machining processes.Using a pulley system with a lathe is like having a superpower! It gives you better control over spindle speed, which means you can perform tasks more precisely. Imagine being able to switch speeds faster than flipping a pancake! This increased control leads to higher efficiency in machining processes. You’ll finish projects quicker and with less waste. Just think of it as trading a tricycle for a sports car—getting from point A to point B has never been so much fun!

| Benefit | Description |

|---|---|

| Enhanced Control | Lets you change speeds easily for better precision. |

| Increased Efficiency | Speeds up work without sacrificing quality. |

Choosing the Right Pulley for Your Manual Metal Lathe

Key factors to consider (size, material, compatibility). Recommendations for different lathe models.Selecting a pulley for your manual metal lathe can feel like picking the right ice cream flavor—so many choices! Key factors include size, material, and if it’s compatible with your lathe model. For instance, a pulley that’s too big might make your lathe sound like a squirrel on a sugar rush. Check the size specs closely!

| Lathe Model | Recommended Pulley Size | Material |

|---|---|---|

| Model A | 4 inches | Cast Iron |

| Model B | 6 inches | Aluminum |

| Model C | 5 inches | Steel |

Your manual metal lathe is a workhorse. Treat it right! A well-chosen pulley will help it run smoothly and make your projects easier. Remember to consider these details and your lathe will thank you by making fewer weird noises.

Installation and Maintenance of Lathe Pulleys

Stepbystep installation guidelines. Regular maintenance practices to extend pulley lifespan.To install a lathe pulley, follow these simple steps:

- First, gather your tools. You will need a wrench and a screwdriver.

- Next, ensure the lathe is unplugged.

- Carefully remove the old pulley if there is one.

- Align the new pulley with the spindle.

- Tighten it securely with a wrench.

For regular maintenance, check the pulley for wear and tear:

- Lubricate it every few months.

- Inspect for any loose screws.

- Keep dust and debris away, as it can cause damage.

Doing this helps your pulley last longer and work better.

How can I maintain my lathe pulley effectively?

Regularly checking and cleaning your lathe pulley is key. Inspect it for signs of damage and ensure it’s properly lubricated. This will help keep it functioning smoothly for years.

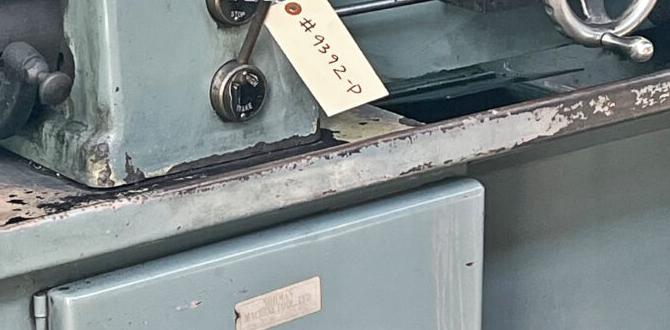

Common Issues with Manual Metal Lathe Pulleys

Troubleshooting common pulleyrelated problems. Tips for resolving performance issues.Manual metal lathe pulleys can face several common problems. These issues might slow down your work. It’s important to know how to troubleshoot them. Start by checking for wear and tear on the belts. Here’s a quick list of tips:

- Look for any cracks in the pulley.

- Ensure the belts are tight and not slipping.

- Keep the pulleys clean and free of dust.

- Lubricate moving parts regularly.

If you follow these tips, your lathe should run smoothly again!

What are typical problems with manual metal lathe pulleys?

The common problems include belt slippage, wear and tear, and misalignment. These can affect performance and cause delays. Regular checks help prevent issues.

Upgrading Your Lathe Pulley System

Signs that an upgrade is necessary. Popular pulley upgrades and their benefits.Sometimes, your lathe pulley system may need an upgrade. Look for signs like strange noises, slipping belts, or reduced performance. These issues can affect your projects. Popular upgrades include replacing old pulleys with high-quality materials and adjusting the size for better speed control. Benefits of these upgrades are:

- Increased efficiency

- Improved precision

- Longer machine life

Upgrading can make your work faster and more enjoyable!

What are signs to upgrade your pulley system?

Signs include unusual sounds, slipping, and slower speeds.

What types of upgrades are popular?

- Reinforced pulleys for durability.

- Variable-speed pulleys for better control.

- Lightweight materials to reduce strain.

Safety Precautions When Working with Lathes

Essential safety measures to follow. Use of protective equipment and proper handling techniques.Working with a lathe sounds cool, but safety comes first! Always wear safety goggles to protect your eyes from flying shavings. Don’t forget sturdy gloves to keep your fingers intact. Make sure your hair is tied back—no one wants a bad hair day turned lathe-style! Proper handling is key. Always check that your workpiece is secure before starting. Little habits like these can save you from big accidents.

| Safety Measure | Description |

|---|---|

| Safety Goggles | Protect your eyes from debris. |

| Gloves | Keep fingers safe from cuts. |

| Secure Hair | Avoid tangling in the machine. |

| Workpiece Check | Ensure everything is tightly fastened. |

Remember, safety first means you can keep on creating without any mishaps! A little caution goes a long way.

Resources for Further Learning

Recommended books, tutorials, and online forums. Community resources for metalworking enthusiasts.Learning more about metalworking can be a fun adventure! Check out some great books, online tutorials, and forums where fellow enthusiasts share tips. You’ll find everything you need to master that manual metal lathe pulley. Want to know how? Here are some resources:

| Resource Type | Name | Description |

|---|---|---|

| Book | Metalworking for Beginners | A friendly guide packed with hands-on projects. |

| Tutorial | Lathe 101 | Simple video series for new lathes users. |

| Forum | Metalworkzone | A community where you can ask questions and share stories. |

Join these communities and become a metal miracle maker! Who knew metal could bend our brains and our fun side?

Conclusion

In summary, a manual metal lathe pulley helps machines run smoothly by transferring power. Understanding how it works can improve your skills in metalworking. You can explore different pulley types and their uses to enhance your projects. Don’t hesitate to try new techniques and learn more about lathes. Keep experimenting, and you’ll become a metalworking pro!FAQs

Sure! Here Are Five Related Questions On The Topic Of Manual Metal Lathe Pulleys:Manual metal lathe pulleys help move parts for cutting metal. They connect the motor to the lathe, turning it on and off. You can change the pulley size to make the lathe go faster or slower. This helps us make different shapes and sizes of metal pieces. Using pulleys makes working with lathes easier and more fun!

Sure! Please provide the question you want me to answer.

What Is The Function Of Pulleys In A Manual Metal Lathe, And How Do They Affect The Machine’S Performance?Pulleys in a manual metal lathe help move and control the machine’s parts. They change the speed and direction of how things spin. This allows us to work faster or slower, depending on what we need. When pulleys work well, the lathe runs smoothly and makes better pieces. You can do your projects more easily and with great results!

How Do You Determine The Appropriate Pulley Ratio For A Specific Application On A Manual Metal Lathe?To find the right pulley ratio for your manual metal lathe, you first check the speed you need. Different jobs need different speeds. You can adjust the pulleys to change how fast the lathe spins. If you want it to spin faster, use smaller pulleys. If you need it to spin slower, use bigger pulleys. Always look at the job and choose the best fit!

What Are Some Common Issues That Can Arise With Pulleys On A Manual Metal Lathe, And How Can They Be Resolved?Pulleys on a manual metal lathe can have some problems. Sometimes, they can slip and not turn properly. You can fix this by tightening the belt around the pulleys. Other times, pulleys may get dirty or rusty. You can clean them and apply some oil to help them work better. Regular checks can keep everything running smoothly!

How Does The Material And Design Of The Pulley Impact The Overall Durability And Precision Of A Manual Metal Lathe?The pulley on a manual metal lathe helps it work smoothly. If you use strong materials, the pulley lasts longer. A well-designed pulley keeps everything in place, so the lathe cuts more accurately. If the pulley is weak or poorly made, it can cause problems, like wrong cuts or even breaks. So, good materials and design help make your lathe tough and precise!

What Maintenance Practices Should Be Followed To Ensure The Longevity And Efficiency Of The Pulleys In A Manual Metal Lathe?To keep the pulleys in a manual metal lathe working well, you should clean them regularly. Dust and grease can build up and cause problems. You also need to check for wear and tear. If something looks broken, fix it right away. Finally, make sure to oil the pulleys to keep them moving smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Manual Metal Lathe Pulleys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manual metal lathe pulleys help move parts for cutting metal. They connect the motor to the lathe, turning it on and off. You can change the pulley size to make the lathe go faster or slower. This helps us make different shapes and sizes of metal pieces. Using pulleys makes working with lathes easier and more fun!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Is The Function Of Pulleys In A Manual Metal Lathe, And How Do They Affect The Machine’S Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Pulleys in a manual metal lathe help move and control the machine’s parts. They change the speed and direction of how things spin. This allows us to work faster or slower, depending on what we need. When pulleys work well, the lathe runs smoothly and makes better pieces. You can do your projects more easily and with great results!”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Pulley Ratio For A Specific Application On A Manual Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right pulley ratio for your manual metal lathe, you first check the speed you need. Different jobs need different speeds. You can adjust the pulleys to change how fast the lathe spins. If you want it to spin faster, use smaller pulleys. If you need it to spin slower, use bigger pulleys. Always look at the job and choose the best fit!”}},{“@type”: “Question”,”name”: “What Are Some Common Issues That Can Arise With Pulleys On A Manual Metal Lathe, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Pulleys on a manual metal lathe can have some problems. Sometimes, they can slip and not turn properly. You can fix this by tightening the belt around the pulleys. Other times, pulleys may get dirty or rusty. You can clean them and apply some oil to help them work better. Regular checks can keep everything running smoothly!”}},{“@type”: “Question”,”name”: “How Does The Material And Design Of The Pulley Impact The Overall Durability And Precision Of A Manual Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The pulley on a manual metal lathe helps it work smoothly. If you use strong materials, the pulley lasts longer. A well-designed pulley keeps everything in place, so the lathe cuts more accurately. If the pulley is weak or poorly made, it can cause problems, like wrong cuts or even breaks. So, good materials and design help make your lathe tough and precise!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Efficiency Of The Pulleys In A Manual Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the pulleys in a manual metal lathe working well, you should clean them regularly. Dust and grease can build up and cause problems. You also need to check for wear and tear. If something looks broken, fix it right away. Finally, make sure to oil the pulleys to keep them moving smoothly.”}}]}