Have you ever faced problems with accuracy while using a metal lathe? Many hobbyists and professionals encounter this issue. It’s often due to something called backlash. Backlash can make your work less precise, leading to frustration.

But don’t worry! There’s a simple metal lathe backlash elimination trick that can help. Imagine crafting a perfect part without all that annoying play in the gears. How great would that be?

In this article, we will explore this clever trick. You will learn how to keep your lathe working smoothly. Say goodbye to those pesky mistakes! Get ready to improve your metalworking game.

Metal Lathe Backlash Elimination Trick: A Simple Guide

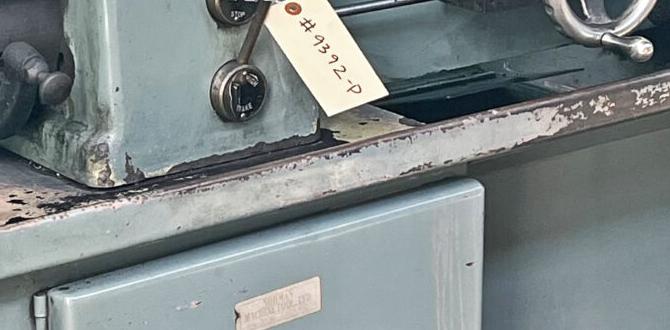

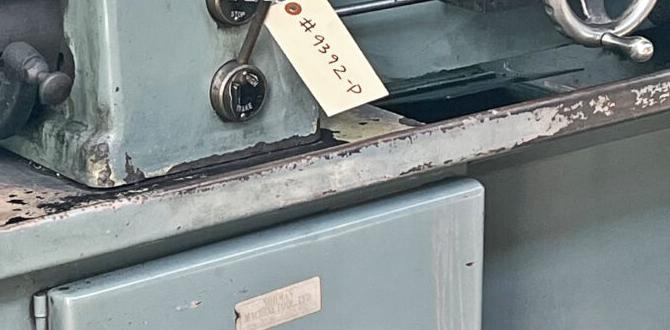

Metal Lathe Backlash Elimination Trick

Did you know that even a tiny wobble in your metal lathe can ruin precision? Backlash can be a real headache! This clever trick helps eliminate that pesky play. By adjusting your lathe properly, you can improve accuracy and create perfect pieces. Just think about the difference it makes when your tools work smoothly! Want to craft with confidence? Master this simple technique to keep your projects on track. Say goodbye to frustrating errors!Understanding Backlash in Metal Lathes

Definition and causes of backlash in metal lathes. Importance of minimizing backlash for precision machining.Backlash is a common issue in metal lathes. It happens when there is a gap between parts that move. This gap can cause machines to be less precise. What causes backlash? Several factors contribute:

- Worn-out parts

- Loose screws

- Poorly aligned components

Minimizing backlash is crucial. Less backlash means better accuracy. This can lead to smoother cuts and improved quality in your projects. It helps in getting the right measurements every time!

What is the impact of backlash on machining?

Backlash can lead to errors and rough edges. It affects the final product, making it look less professional. To produce quality work, managing backlash is vital.

Common Symptoms of Backlash

How to identify backlash in your metal lathe. Impact of backlash on machining accuracy and surface finish.Backlash can be a sneaky little gremlin in your metal lathe. You might notice it when your machine seems to skip a beat or produce uneven edges on your workpiece. This can happen when you suddenly change the direction of the cut. The tool may not move exactly where you expect, leading to poor accuracy and a rough surface. It’s like trying to catch a slippery fish—tricky and frustrating!

How can you tell if backlash is the culprit? Pay attention to these signs:

| Symptom | Description |

|---|---|

| Play in the Handle | Feel some wiggle before the tool moves? That’s a red flag! |

| Surface Marks | Does your part have strange lines or grooves? Backlash might be the reason! |

| Inconsistent Measurements | Measurements not adding up? Check for that backlash gremlin! |

Understanding these symptoms can save you time and materials. Plus, you’ll be less likely to throw your tools out of frustration. Instead, you can tackle that backlash like a pro!

Tools and Equipment Needed for Backlash Elimination

Essential tools for diagnosing and fixing backlash. Recommended products and brands for effective results.To tackle backlash in metal lathes, you need the right tools. Here are some essential items:

- Caliper: Measure spacing with accuracy.

- Feeler gauge: Check gaps between parts.

- Wrench set: Tighten loose components.

- Adjustment tools: Modify settings easily.

Popular brands include Mitutoyo for precision measures and Craftsman for durable wrenches. Using quality tools results in better fixes.

What tools help in fixing backlash?

Calipers and feeler gauges are key tools for measuring and adjusting parts effectively.

Adjustment Techniques for Backlash Elimination

Stepbystep methods for adjusting screw nuts and gears. Detailed explanation of the “adjust and test” approach.Adjusting screw nuts and gears can feel a bit like solving a puzzle. First, check for any loose screws. Tighten them but don’t go overboard; you don’t want to strip anything! Next, loosen the nuts just a tad to allow for movement. Now the fun part—test it out! If you have too much play, tweak the adjustments until things fit snugly together. Repeat this step until it runs smoothly. As they say, “Patience is a virtue, especially when playing with machinery!”

| Step | Description |

|---|---|

| 1 | Check and tighten all screws. |

| 2 | Loosen nuts slightly for wiggle room. |

| 3 | Test the movement and adjust as needed. |

Remember, it’s all about adjusting and testing repeatedly. Think of it like tuning a guitar; sometimes you have to strum a little before it sounds just right!

Preventive Measures to Reduce Backlash

Best practices for routine maintenance to prevent backlash. Tips on selecting highquality components to reduce backlash.Keeping your metal lathe in top shape can help you avoid backlash. Regular maintenance is key. Here are some easy tips:

- Lubricate moving parts regularly.

- Check for loose bolts and tighten them.

- Clean the machine to remove dust and grime.

- Inspect belts for wear and replace if needed.

Choosing high-quality parts also matters. They stand the test of time and help reduce backlash. Quality gears and bearings work better. They hold their shape and fit well with other parts. Investing in good components will pay off in the long run.

How can I maintain my metal lathe to reduce backlash?

To maintain your metal lathe, focus on cleaning, lubricating, and checking that everything is tight. Regular care keeps your machine running smoothly and helps prevent backlash.

What components should I choose for my lathe?

For your lathe, choose high-quality gears and bearings. They fit better and last longer, which can greatly reduce backlash.

Advanced Backlash Compensation Techniques

Software solutions for electronic backlash compensation. How to modify CNC lathe parameters to minimize backlash.Finding new ways to beat backlash can make your CNC lathe sing like a canary! Many use software solutions that help with electronic backlash compensation. This nifty tech adjusts movements so you get smooth cuts every time. Even small tweaks to CNC lathe parameters can dramatically reduce backlash. For example, you can fine-tune settings like acceleration and deceleration. It’s like getting a coffee before work—suddenly, everything runs smoother! Here’s a quick look:

| Parameter | Effect on Backlash |

|---|---|

| Acceleration | Lower values can reduce skip or jerk. |

| Deceleration | Smoother stops can prevent wobble. |

| Step Pulse Width | Adjusting can improve response time. |

With these tips, your lathe might even pull off a few dance moves! More control means better results, which is the dream for any machinist. So get those tricks in place and watch your projects shine!

Case Studies: Successful Backlash Elimination

Examples of lathe operators who effectively eliminated backlash. Lessons learned and tips from experienced machinists.Many lathe operators have shared their successful experiences in eliminating backlash. For instance, one machinist fixed his lathe with simple adjustments. He tightened the screws and used lubrication. This made a big difference in his work. Others have learned to regularly check their machines.

- Use a dial indicator to find backlash.

- Make small adjustments to improve accuracy.

- Keep parts clean and well-oiled.

By sharing tips, these machinists help new operators avoid common mistakes. Learning from others’ experiences can lead to higher precision and better results.

What is a good method for reducing backlash?

Regular adjustments and lubrication can significantly reduce backlash.

Frequently Asked Questions about Backlash in Metal Lathes

Common queries and expert responses about backlash. Clarifications on myths and misconceptions related to lathe backlash.Backlash questions are common among users of metal lathes. Many people worry about this issue. Here are some key points and answers:

- What is backlash? Backlash is the slight movement in the lathe that can affect precision.

- Is backlash only a problem in old lathes? No, backlash can occur in any lathe, new or old.

- Can backlash be fixed? Yes, it can be reduced or eliminated with proper adjustment and techniques.

- Do all lathes have backlash? Most lathes will have some degree of backlash.

Understanding these points can ease concerns about backlash. Knowing how to manage it leads to better results!

Conclusion

In summary, using a metal lathe backlash elimination trick helps improve accuracy and precision in your work. Understanding and adjusting your machine can make a big difference. Remember to check your settings regularly. If you’re eager to learn more, explore tutorials or guides online. These steps will make your metalworking projects easier and more enjoyable!FAQs

What Are The Common Causes Of Backlash In A Metal Lathe, And How Can They Be Identified?Backlash on a metal lathe happens when parts are loose. It can be caused by wear, poor adjustments, or dirt. You can spot it by moving the tool and seeing if it wiggles before cutting. If the tool doesn’t stay steady, that’s a sign of backlash. Regular checks and cleanings can help fix and prevent this issue.

What Techniques Can Be Used To Adjust The Gibs And Bearings On A Lathe To Reduce Backlash?To reduce backlash on a lathe, we can adjust the gibs and bearings. First, we can tighten the gibs, which hold parts together. Next, we can check the bearings to make sure they are not too loose. Sometimes, we need to replace old bearings if they are worn out. Lastly, we can keep everything clean and well-lubricated to help it work smoothly.

How Can The Use Of Anti-Backlash Nuts Or Devices Improve Precision In Metal Lathe Operations?Using anti-backlash nuts or devices helps keep the machine parts snug and tight. This means there is less wobble when you cut metal. With less movement, you can make smoother and more accurate shapes. It helps us create better pieces without mistakes. So, our work becomes cleaner and looks nicer too!

What Is The Significance Of Regular Maintenance In Minimizing Backlash On A Metal Lathe?Regular maintenance is super important for a metal lathe. It helps us keep the machine parts working smoothly. When we check and fix things, the lathe doesn’t move around too much, which is called backlash. Less backlash means our work turns out better and is more accurate. So, by taking care of our machine, we make sure it works well every time we use it!

Are There Specific Settings Or Adjustments That Can Be Made On Digital Readouts To Compensate For Backlash When Machining?Yes, you can adjust the digital readouts to help with backlash. Backlash is when there’s a small gap that makes your machine not move exactly where you want. You can set a backlash compensation option in the machine’s settings. This helps keep the readings accurate, so your cuts are better. Just remember to follow the machine’s manual for the right steps.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Causes Of Backlash In A Metal Lathe, And How Can They Be Identified? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Backlash on a metal lathe happens when parts are loose. It can be caused by wear, poor adjustments, or dirt. You can spot it by moving the tool and seeing if it wiggles before cutting. If the tool doesn’t stay steady, that’s a sign of backlash. Regular checks and cleanings can help fix and prevent this issue.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Adjust The Gibs And Bearings On A Lathe To Reduce Backlash? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce backlash on a lathe, we can adjust the gibs and bearings. First, we can tighten the gibs, which hold parts together. Next, we can check the bearings to make sure they are not too loose. Sometimes, we need to replace old bearings if they are worn out. Lastly, we can keep everything clean and well-lubricated to help it work smoothly.”}},{“@type”: “Question”,”name”: “How Can The Use Of Anti-Backlash Nuts Or Devices Improve Precision In Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using anti-backlash nuts or devices helps keep the machine parts snug and tight. This means there is less wobble when you cut metal. With less movement, you can make smoother and more accurate shapes. It helps us create better pieces without mistakes. So, our work becomes cleaner and looks nicer too!”}},{“@type”: “Question”,”name”: “What Is The Significance Of Regular Maintenance In Minimizing Backlash On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular maintenance is super important for a metal lathe. It helps us keep the machine parts working smoothly. When we check and fix things, the lathe doesn’t move around too much, which is called backlash. Less backlash means our work turns out better and is more accurate. So, by taking care of our machine, we make sure it works well every time we use it!”}},{“@type”: “Question”,”name”: “Are There Specific Settings Or Adjustments That Can Be Made On Digital Readouts To Compensate For Backlash When Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can adjust the digital readouts to help with backlash. Backlash is when there’s a small gap that makes your machine not move exactly where you want. You can set a backlash compensation option in the machine’s settings. This helps keep the readings accurate, so your cuts are better. Just remember to follow the machine’s manual for the right steps.”}}]}