Have you ever wondered how important it is to check the preload on your metal lathe bearings? It’s a bit like tuning a guitar. If the strings are too loose or too tight, the music just doesn’t sound right!

Metal lathes are powerful machines used to shape metal. They work best when everything is adjusted perfectly. One crucial part of this adjustment is checking the bearing preload.

A well-set bearing preload ensures the lathe runs smoothly and lasts longer. Imagine trying to ride a bike with loose wheels—they wobble and make steering tough. Similarly, lathes need proper tightening to avoid problems.

In this article, we will explore the steps to check your metal lathe bearing preload. You’ll discover the simple tricks that can help keep your lathe in top shape. Ready to learn how to avoid wobbly bearings? Let’s dive in!

Metal Lathe Bearing Preload Check: A Comprehensive Guide

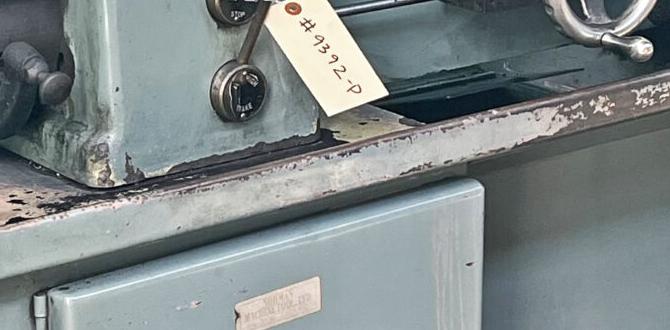

Metal Lathe Bearing Preload Check

Have you ever wondered how to keep your metal lathe running smoothly? Checking the bearing preload is crucial. Proper preload ensures that the bearings spin freely but aren’t too loose. If your lathe feels inconsistent, it might be time for a preload check. This simple task can improve accuracy and extend the lathe’s life. Regular checks can save you from costly repairs, too. Remember, a well-maintained lathe produces the best results!Understanding Bearing Preload

Definition of bearing preload and its significance in metal lathes. Types of preload: axial, radial, and combined.Bearing preload means putting pressure on the bearings in a metal lathe. It helps the machine work smoothly and lasts longer. Different types of preload exist:

- Axial preload: This type pushes along the axis, supporting end-to-end loads.

- Radial preload: This one supports side-to-side loads, keeping everything stable.

- Combined preload: This type uses both axial and radial force for better balance.

This balance is essential. It improves accuracy and reduces wear over time. Proper preload makes sure your lathe runs like a champ!

What is bearing preload?

Bearing preload is the force applied to bearings to keep them tight, helping machines run smoothly.Types of Bearing Preload:

- Axial Preload

- Radial Preload

- Combined Preload

Importance of Proper Preload in Metal Lathes

Impact of preload on machining accuracy and surface finish. Consequences of improper preload: wear, vibration, and operational failure.Proper preload in metal lathes is like giving your machine a comfy hug. It keeps everything tight and snug, which helps with machining accuracy and a smooth surface finish. If things get loose, watch out! You’ll see more wear and tear, annoying vibrations, and even operational failure. A happy lathe is a precise lathe!

| Consequence of Improper Preload | Effect |

|---|---|

| Wear | Increased maintenance costs |

| Vibration | Poor surface finish |

| Operational Failure | Downtime and productivity loss |

Remember, if you don’t check your preload, your lathe might start throwing a tantrum! Keeping it just right ensures smooth operations and happy machining.

Signs of Incorrect Bearing Preload

Symptoms indicating potential preload issues. Diagnostic tests to identify preload problems.Without the right preload, machine problems may show up. You might hear strange noises. The machine may vibrate more than usual. Parts might even wear out faster. Check these signs:

- Unusual sounds during operation.

- Excessive vibrations.

- Uneven wear on bearings.

- Frequent need for adjustments.

To find problems, conduct simple checks. Look for wear patterns or listen carefully while the lathe runs. Often, these signs help catch issues early. Make your machines last longer!

What are the signs of incorrect bearing preload?

Common signs include abnormal sounds and extra vibrations. Checking these symptoms can help find issues early. It is important to listen to your machine!

Step-by-Step Guide to Checking Bearing Preload

Detailed procedure for performing the preload check. Safety precautions to consider during the process.To check bearing preload, start by gathering tools like a torque wrench and feeler gauge. Make sure to turn off the machine and unplug it for safety. Then, follow these steps:

- Remove the bearing cover.

- Check the nut tension with a torque wrench.

- Use a feeler gauge to measure any gaps.

- Adjust preload according to the manufacturer’s guide.

- Recheck all measurements.

Always wear protective gear such as gloves and goggles. This helps keep you safe from any flying debris or sharp parts. Double-check that everything is secure before turning the machine back on. This ensures a smooth and safe operation.

What should I do if preload is incorrect?

If preload is incorrect, readjust the nut until it meets the specified torque. Make sure to follow guidelines to avoid damaging the machine.

Adjusting Bearing Preload

Methods for adjusting preload in metal lathe bearings. Best practices for ensuring optimal adjustment.Adjusting bearing preload is vital for smooth metal lathe operation. One method includes turning the adjusting nuts until they fit snugly against the bearings. Ensure you check the feel often; it should not be too tight or too loose.

- Use a feeler gauge to measure clearance accurately.

- Regularly inspect bearings for wear and proper fit.

- Keep the lathe clean and well-lubricated.

Following these best practices leads to better performance and longer bearing life.

Why is preload important in lathes?

Preload helps reduce vibrations and improves accuracy. Proper adjustment keeps parts aligned correctly, making your work easier and more precise.

Maintaining Optimal Bearing Preload

Routine maintenance tips to preserve bearing preload settings. Recommended schedules for regular checks and adjustments.Regular checks keep your metal lathe humming smoothly. For the best performance, inspect your bearing preload at least every month or before big projects. It’s like giving your lathe a check-up; it helps avoid surprises and breakdowns. Don’t forget to tighten those screws; they’re like the lathe’s friends, keeping everything together. If you notice any weird noises, give it a look!

| Maintenance Routine | Frequency |

|---|---|

| Preload Inspection | Monthly |

| Screw Tightening | Monthly |

| Noise Check | Before Major Use |

Tightening up the preload not only helps with performance but also makes your machine last longer. Remember, keeping an eye on those bearings is like checking your lunchbox before school—you never know what surprises might pop up!

Common Mistakes to Avoid

List of frequent errors made during preload checks and adjustments. How to prevent these mistakes for effective maintenance.Many people make common errors during bearing preload checks. These mistakes can cost time and money. To improve your maintenance, be aware of these points:

- Incorrect measurement of preload.

- Skipping the lubrication step.

- Forgetting to consult the manual.

- An uneven load distribution.

Learn from these errors. Always double-check your work. Follow guidelines closely for better results. Regular practice leads to fewer mistakes, ensuring your metal lathe runs well.

What should I know about bearing preload checks?

Regular checks improve performance. Always ensure proper preload settings for your lathe to avoid damage.

Conclusion

In summary, checking the preload of your metal lathe bearings is crucial for smooth operation. It prevents wear and tear, improving accuracy. To ensure the best performance, regularly inspect and adjust the preload. Remember, a little maintenance goes a long way. For more tips on lathe care, consider reading guides or watching tutorial videos. Your lathe will thank you!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Metal Lathe Bearing Preload Check:Sure! Checking the preload on metal lathe bearings is important. It makes sure the parts fit together just right. If they are too tight or too loose, the lathe won’t work well. You can check preload by turning the spindle and feeling how smooth it is. If it feels hard to turn, it might need adjustment.

Of course! Please share the question you’d like me to answer.

What Is The Purpose Of Checking Bearing Preload On A Metal Lathe?Checking bearing preload on a metal lathe helps keep the parts tight and steady. It makes sure the lathe spins smoothly. If the preload is too low or too high, the lathe can have problems. By checking it, we can fix issues and make our work better. This helps us create neat and accurate shapes from metal.

How Can Improper Bearing Preload Affect The Performance And Longevity Of A Lathe?Improper bearing preload can hurt a lathe’s performance. If the preload is too tight, it can make the lathe hard to move. This can cause parts to wear out faster. If it’s too loose, the lathe might shake and make mistakes. Both problems can shorten the lathe’s life and you won’t get good results.

What Tools Or Techniques Are Commonly Used To Measure Bearing Preload In A Metal Lathe?To measure bearing preload in a metal lathe, we often use a few simple tools. A dial indicator helps us see small changes in distance. A torque wrench can check the tightness of parts. We can also feel if the bearings are tight by hand. These tools help us make sure everything works smoothly!

What Are The Signs That Indicate A Bearing May Be Improperly Preloaded?If a bearing is not set correctly, you might notice some signs. It could get too hot when it runs. You might hear strange noises, like grinding or rattling. The machine could shake or vibrate more than usual. Finally, it may wear out faster than normal.

How Often Should Bearing Preload Checks Be Performed On A Metal Lathe To Ensure Optimal Performance?You should check the bearing preload on a metal lathe every few months. This keeps the machine running smoothly. If you use it a lot, check it more often. Regular checks help catch any problems before they get worse. Always follow the machine’s manual for the best advice.