Imagine this: you have a metal lathe, and it’s your favorite tool. One day, you notice something wrong with the bed ways. They look worn out, and you can’t make parts like you used to. Have you ever faced that problem? It’s common with metal lathes, and fixing the bed ways can seem like a puzzle.

Repairing your metal lathe bed ways can save you money and extend the life of your tool. Did you know that even a small scratch on the bed ways can affect your work? It can lead to bigger problems down the line. But don’t worry! With a few tips and tricks, you can tackle this repair with confidence.

In this article, we will explore basic methods for repairing metal lathe bed ways. You will learn what tools you need, how to assess the damage, and the steps to fix it. Let’s get started! Your metal lathe deserves the best care.

Metal Lathe Bed Ways Repair: Essential Guide And Tips

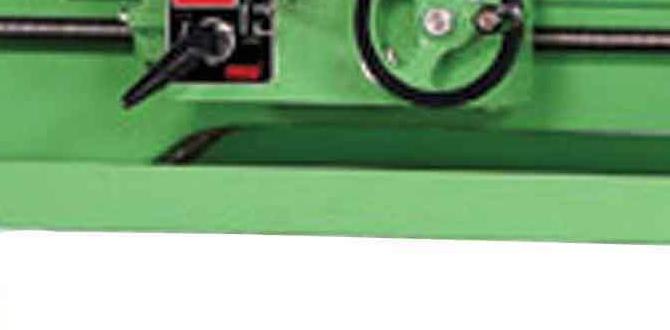

Metal Lathe Bed Ways Repair

Repairing the bed ways of a metal lathe can significantly improve its performance. You first need to assess the wear and damage on the surface. This could involve scraping and resurfacing methods. Did you know that even small imperfections can lead to larger issues? Regular maintenance can help prevent major repairs. Using proper techniques and tools is essential for a smooth finish. With care, a well-maintained lathe can last for decades. Are you ready to keep your equipment in top shape?Understanding Metal Lathe Bed Ways and Their Importance

Description of metal lathe bed ways. Importance in maintaining precision in metalworking.Think of metal lathe bed ways as the unsung heroes of the metalworking world! These trusty tracks help the lathe’s parts move in a straight line, making sure everything stays perfectly aligned. Without a smooth and level bed, your metal parts might end up as crooked as a dog’s hind leg! Precision is key in metalworking, and bed ways play a huge role in keeping the machines running smoothly. As they say, “A straight bed keeps the lathe ahead!”

The table below gives a snapshot of how metal lathe bed ways contribute to precision in metalwork:

| Feature | Importance |

|---|---|

| Smoothness | Makes movements easy and precise |

| Alignment | Keeps parts in the right place |

| Durability | Ensures long-term accuracy |

So, next time you’re in the workshop, remember: Treat your bed ways with care, and they’ll keep your metalwork square!

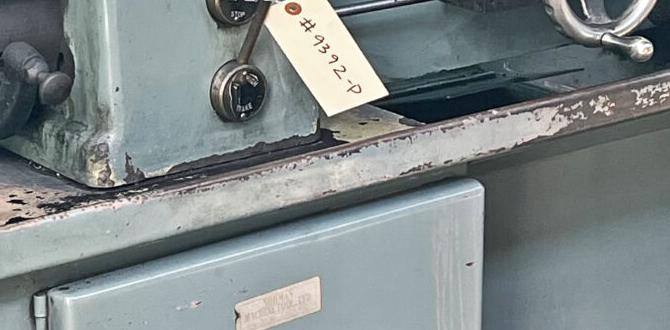

Common Issues with Lathe Bed Ways

Identifying typical wear and misalignment problems. Factors contributing to wear and damage.Lathe bed ways often face common issues due to regular use. Wear and misalignment are typical problems. Metal chips and dirt can speed up wear. Uneven loads or incorrect setup can also cause issues. Check often for signs like grooves or shifts. Fixing them early helps keep your tools working well.

What are signs of wear on lathe bed ways?

Signs of wear on lathe bed ways include visible grooves, uneven surfaces, or movement during operation. Regular inspection helps catch these issues early.

Inspection and Diagnosis Procedures

Tools and equipment needed for inspection. Methodologies for assessing damage and wear. Importance of detailed measurement and documentation.Let’s roll up our sleeves and dive into the nuts and bolts of inspecting metal lathe bed ways. First, you’ll need the right gadgets. Tools like calipers, micrometers, and dial indicators are your best pals. They help you measure without getting cross-eyed. Once you have your arsenal, it’s time to assess damage. Now, was that a scratch or a canyon? Document every discovery; it’s practically detective work with metal. A detailed report keeps surprises away. Remember: A picture’s worth a thousand words, but accurate numbers never lie.

| Tool | Purpose |

|---|---|

| Calipers | Measure thickness and gaps |

| Micrometers | Precision measurement of wear |

| Dial Indicators | Detect deviations and unevenness |

Handy hint: “Measure twice, cut once” isn’t just for woodworkers; it’s your mantra now. Consistent documentation ensures you’re on track. After all, identifying problems early can save time and extend the life of the machine. So, knock your socks off and become a true metal detective!

Repair Techniques for Metal Lathe Bed Ways

Explanation of scraping and regrinding methods. When to opt for replacement vs. repair. Retrofitting techniques for advanced wear.Repairing metal lathe bed ways needs careful choices. Scraping is one method. It smooths out uneven surfaces to help the lathe work better. Regrinding is another method. This sharpens worn-out areas. Sometimes, repairs are better than replacements. Ask yourself: is the damage minor or major? If damage is advanced, retrofitting can save the day. This adds strong parts for extra support and life. Choosing the right repair can keep your lathe running for years.

When do I replace or repair metal lathe bed ways?

Deciding whether to repair or replace the lathe ways is crucial. **If the damage is minor, repairing is often cheaper and faster.** **For major wear, replacement might be necessary for safety and function.** Always consider the cost and how much use the lathe will get.

Repair Techniques

- Scraping smooths out uneven surfaces.

- Regrinding sharpens worn parts.

- Retrofitting adds new, strong components.

Detailed Steps for Scraping and Resurfacing

Guide to essential tools for scraping. Stepbystep process for accurately scraping bed ways. Tips for ensuring perfect alignment.Before diving into scraping, gather the right tools. You’ll need a scraper, a straight edge, and some grit for sanding. Think of it like picking your colors for art class—choosing the right ones is key!

| Essential Tools | Purpose |

|---|---|

| Scraper | For removing old material |

| Straight Edge | To check alignment |

| Sanding Blocks | For smoothing surfaces |

Next, follow these steps for accurate scraping: start from one end of the bed, apply even pressure, and scrape towards the other end. Don’t press too hard; you’re not trying to squash a bug!

Lastly, ensure perfect alignment by frequently checking with the straight edge. Remember, a well-aligned lathe is a happy lathe. If it’s off, adjust like you’re fixing a crooked picture on your wall—just a nudge to make it right!

Preventive Maintenance to Extend Lathe Bed Life

Routine maintenance practices to prevent rapid wear. Cleaning and lubrication recommendations. Regular inspection schedules and checklists.To keep your lathe bed in shape, regular care is important. Simple habits can make a big difference. Here’s what you can do:

- Clean the bed regularly to remove dust and debris.

- Use good oil for lubrication. This helps reduce friction.

- Check the bed for signs of wear every month.

- Make a checklist for inspections.

Doing these things can help extend the lathe bed life and keep it running smoothly.

How often should I inspect my lathe bed?

You should inspect your lathe bed every month. Regular checks help catch problems early and save you time and money.

Case Studies and Examples of Successful Repairs

Realworld examples of lathe bed way repairs. Insights and lessons learned from specific cases.Real-world cases of lathe bed way repairs show how handy skills can save the day. For example, one shop encountered deep scratches, which were a real pain! They used precision grinding and filled the gaps, turning their old lathe into a smooth operator again. Another shop faced a twist in their bed ways caused by a heavy load. They learned that proper support is key to avoid future mishaps. These stories remind us that a little care can go a long way!

| Case Study | Repair Method | Key Insight |

|---|---|---|

| Shop A | Precision Grinding | Fill gaps for smooth operation |

| Shop B | Reinforcement | Support avoids twists |

In repairs, sharing knowledge helps everyone improve. Remember, a good laugh and a solid plan can keep your lathe running smoothly!

Choosing the Right Professional for Complex Repairs

Criteria for selecting a repair professional or service. Cost considerations and budget planning.Choosing a skilled repair professional is crucial. Look for experience, good reviews, and proper certifications. Here are some guidelines:

- Check their experience with metal lathe bed ways.

- Read customer feedback for quality.

- Ensure they have relevant licenses.

Cost matters too. Set a budget and compare prices. Ask for quotes upfront to avoid surprises later. A higher price doesn’t always mean better work. Aim for value, not just cost.

What should I consider when hiring a repair expert?

Experience, customer reviews, and cost are key factors. Choose a professional who can meet your budget while providing quality work.

Tools and Resources for DIY Enthusiasts

Recommended tools and kits for DIY repairs. Community resources and support forums.DIY enthusiasts need the right tools for quick repairs. A few must-have tools include:

- Wrenches – For tightening and loosening nuts and bolts.

- Screwdrivers – Essential for assembling and disassembling parts.

- Measuring tape – To ensure everything fits perfectly.

- Toolkits – A complete set can save time and effort.

Community support is also vital. Online forums and local groups share tips and advice. Connecting with others can make repairs easier and more fun.

What are some important tools for DIY repairs?

Essential tools for DIY repairs include wrenches, screwdrivers, measuring tapes, and complete toolkits. These tools help make tasks faster and simpler.

Where can I find support for DIY projects?

Look for online forums, local workshops, and community groups. They offer great advice and inspiration for your projects.

Conclusion

In summary, repairing metal lathe bed ways can improve your lathe’s performance. You should regularly check for wear and damage. Using the right tools and techniques can make the job easier. Don’t hesitate to seek help if needed. For more tips, consider reading articles or watching videos about lathe maintenance. You can keep your lathe in great shape!FAQs

What Are The Common Signs That Indicate Wear Or Damage To The Ways Of A Metal Lathe Bed?You can tell if a metal lathe bed is worn or damaged in a few ways. First, look for visible scratches or grooves on the surface. Second, check if the tool moves unevenly or feels rough when you use it. You might also notice that the pieces you make don’t fit together well. Finally, listen for strange noises while it’s working; that might mean something is wrong.

What Are The Best Methods For Measuring And Assessing The Condition Of Lathe Bed Ways Before Proceeding With Repairs?To check a lathe bed’s condition, we can use a few easy methods. First, we should look for any visible cuts or bumps on the metal. Next, we can use a straightedge, which is a long, flat tool, to see if the bed is straight. Finally, a dial indicator can help us find small changes in height. After checking, we will know what repairs are needed to make the lathe work better.

What Materials And Techniques Are Recommended For Resurfacing Worn Lathe Bed Ways?To fix worn lathe bed ways, you can use a few materials and techniques. Start with a straightedge to check for flatness. If the surface is rough, you can use a grinding machine or scrape it down carefully. You’ll need abrasive materials, like sandpaper, to smooth the surface. After that, you can apply a special oil to keep it working nicely.

How Can One Effectively Align And Reassemble Lathe Bed Components After Completing A Repair On The Ways?To align and reassemble lathe bed parts, first, clean everything well. Next, lay the parts in the right order. You can use small blocks to help hold them straight. Then, gently tighten screws until everything feels snug. Finally, check that all parts move smoothly before using the lathe again.

What Preventative Maintenance Practices Should Be Employed To Prolong The Life Of Lathe Bed Ways After Repair?To take care of lathe bed ways after they are fixed, you should keep them clean and dry. Use a cloth to wipe off dirt and oil. You can also apply a light coat of oil to protect the metal. Make sure to check and adjust the tightness of screws regularly. Always store the lathe in a dry place to avoid rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate Wear Or Damage To The Ways Of A Metal Lathe Bed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell if a metal lathe bed is worn or damaged in a few ways. First, look for visible scratches or grooves on the surface. Second, check if the tool moves unevenly or feels rough when you use it. You might also notice that the pieces you make don’t fit together well. Finally, listen for strange noises while it’s working; that might mean something is wrong.”}},{“@type”: “Question”,”name”: “What Are The Best Methods For Measuring And Assessing The Condition Of Lathe Bed Ways Before Proceeding With Repairs? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check a lathe bed’s condition, we can use a few easy methods. First, we should look for any visible cuts or bumps on the metal. Next, we can use a straightedge, which is a long, flat tool, to see if the bed is straight. Finally, a dial indicator can help us find small changes in height. After checking, we will know what repairs are needed to make the lathe work better.”}},{“@type”: “Question”,”name”: “What Materials And Techniques Are Recommended For Resurfacing Worn Lathe Bed Ways? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix worn lathe bed ways, you can use a few materials and techniques. Start with a straightedge to check for flatness. If the surface is rough, you can use a grinding machine or scrape it down carefully. You’ll need abrasive materials, like sandpaper, to smooth the surface. After that, you can apply a special oil to keep it working nicely.”}},{“@type”: “Question”,”name”: “How Can One Effectively Align And Reassemble Lathe Bed Components After Completing A Repair On The Ways? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and reassemble lathe bed parts, first, clean everything well. Next, lay the parts in the right order. You can use small blocks to help hold them straight. Then, gently tighten screws until everything feels snug. Finally, check that all parts move smoothly before using the lathe again.”}},{“@type”: “Question”,”name”: “What Preventative Maintenance Practices Should Be Employed To Prolong The Life Of Lathe Bed Ways After Repair?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of lathe bed ways after they are fixed, you should keep them clean and dry. Use a cloth to wipe off dirt and oil. You can also apply a light coat of oil to protect the metal. Make sure to check and adjust the tightness of screws regularly. Always store the lathe in a dry place to avoid rust.”}}]}